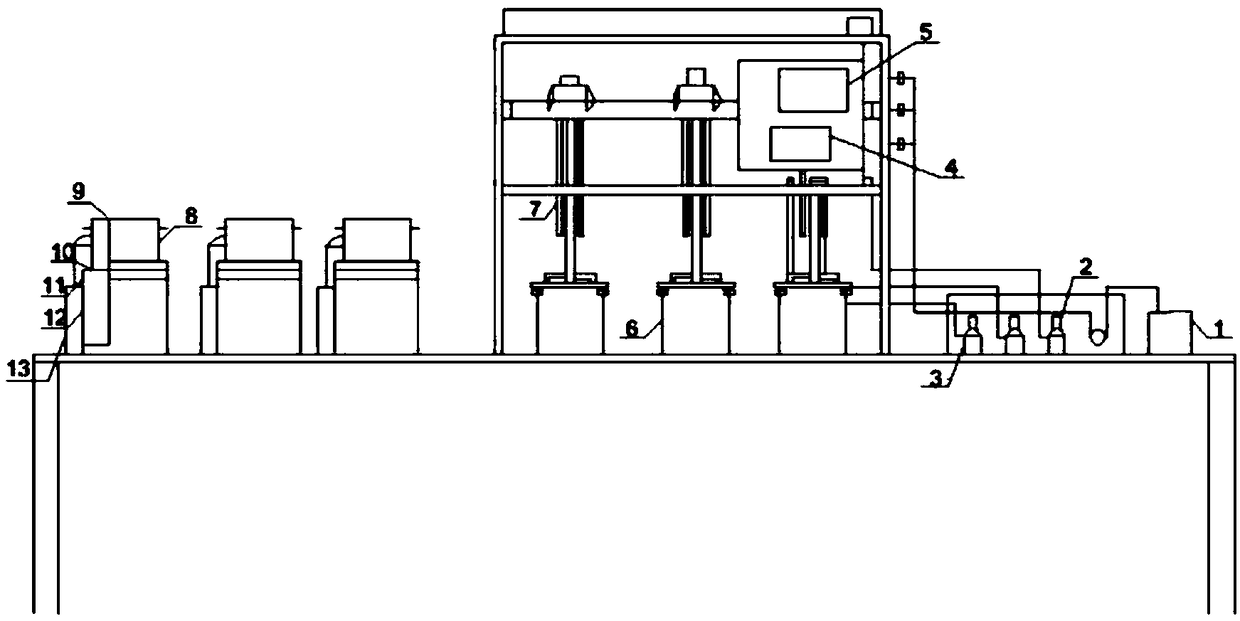

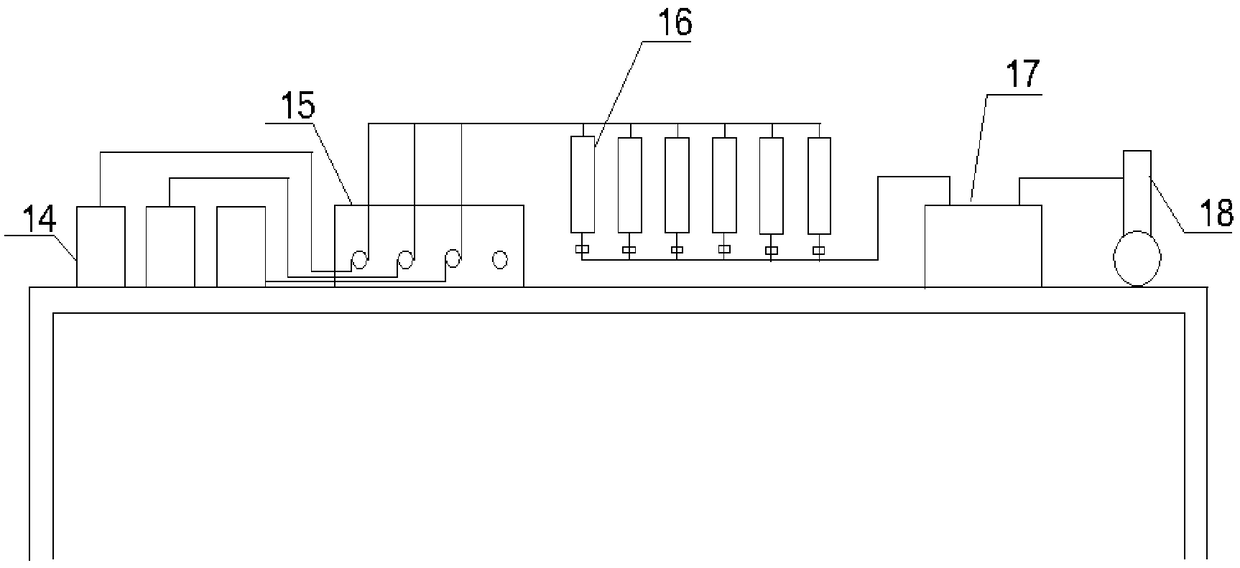

Remediation device for contaminated soil

A technology of polluted soil and dosing pump, which is applied in the field of contaminated soil remediation, can solve the problems of limited selection of pollutants and excessive waste liquid produced by remediation, so as to prevent secondary pollution, improve work efficiency, and highly efficient waste liquid collection process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Utilizing the soil oxidation treatment equipment provided by the present invention to oxidize the polluted soil collected from the polluted site, the amount of water and medicine can be flexibly dosed according to the actual situation of polluted soil, and different oxidants can be added according to different polluted soils. The basic physical and chemical properties of the soil are as follows: pH is 8.19, moisture content is 21.6%, and soil density is 2.04g cm -3 , the void ratio is 0.62, and the plasticity index is 12.0. The site soil is polluted by chlorophenol compounds such as 2,4-dichlorophenol (2,4-DCP) and 2,4,6-trichlorophenol (2,4,6-TCP). In this embodiment, two Treatment: 1) Activation of Na 2 S 2 o 8 Treatment: apply Na 2 S 2 o 8 +CaO(1:1), the dosing order is CaO→Na 2 S 2 o 8 ;2) Fenton treatment area: apply H 2 o 2 +FeSO 4 ·7H 2 O+CA(1:1:1), first apply 30% H 2o 2 , and then apply part of CA, FeSO 4 ·7H 2 O solid, remaining CA, FeSO 4 ·7...

Embodiment 2

[0043] Using the soil oxidation treatment equipment and leaching treatment equipment provided by the present invention, the contaminated soil collected in the polluted site can be oxidized and leached respectively, and the polluted soil is affected by phenolic compounds and heavy metals arsenic (As), lead (Pb), cadmium ( Cd) Contamination. Oxidation remediation is carried out on the contaminated soil first, followed by leaching remediation. Oxidation treatment uses activated Na 2 S 2 o 8 For processing, the leaching solvent is selected from three kinds of hydrochloric acid, EDTA and citric acid. After oxidation repair, the removal rate of phenolic compounds in the soil is as high as 97%. After repeated leaching repairs, the elution efficiency of arsenic in contaminated soil can reach more than 60%, among which EDTA has the highest leaching efficiency of As (about 64%); citric acid has the most stable removal efficiency of As; During the leaching process, hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com