Preparation and application of magnetic separation technique-based amphoteric carboxymethyl chitosan-based microspheres

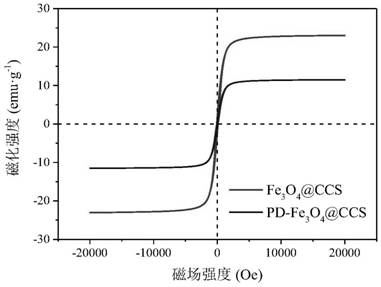

A technology of carboxymethyl chitosan and carboxymethyl chitosan, which is applied in the field of preparation of amphoteric carboxymethyl chitosan microspheres, can solve the difficulties of separation and recovery, limited amino group content, and negative heavy metal ion removal effect Unsatisfactory problems, etc., to achieve the effect of increasing adsorption capacity, efficient separation and recovery, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] One, the preparation method of the amphoteric carboxymethyl chitosan based microsphere based on magnetic separation technology, comprises the steps:

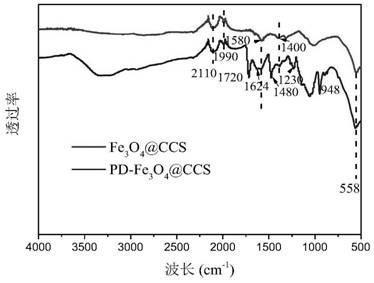

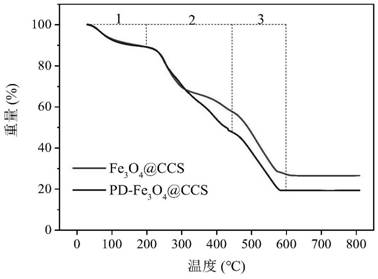

[0025] 1) Magnetic carboxymethyl chitosan microspheres (Fe 3 o 4 Preparation of @CCS)

[0026] 0.8g carboxymethyl chitosan (CCS) powder was dissolved in 20mL ultrapure water to make carboxymethyl chitosan suspension and then weighed 0.6g Fe 3 o 4 Nanoparticles were dispersed in 5 mL ultrapure water, and after ultrasonic treatment for 20 min, they were further mixed with carboxymethyl chitosan suspension to form carboxymethyl chitosan-Fe 3 o 4 The solution was mixed and stirred for 4h.

[0027] After mixing 125mL cyclohexane and 2mL Span 80 in a three-necked flask and stirring until the mixture became a paste, the carboxymethyl chitosan-Fe 3 o 4 The mixed solution was dropped dropwise into the three-neck flask under vigorous stirring, and after stirring for 40 min, the temperature was raised to 50°C, and 1.3 mL of g...

Embodiment 2

[0050] 1. Preparation of amphoteric carboxymethyl chitosan-based microspheres based on magnetic separation technology:

[0051] The difference between the preparation method of the amphoteric carboxymethyl chitosan-based microspheres based on magnetic separation technology and Example 1 in this embodiment is that the initiator in step 2) is ammonium persulfate of 0.033g / mL, and the addition amount is 8mL , the addition of methacryloyloxyethyltrimethylammonium chloride was 5mL, and other conditions were the same as in Example 1.

[0052] 2. Application of amphoteric carboxymethyl chitosan-based microspheres in binary hybrid system based on magnetic separation technology

[0053] This experiment is to explore the practical application of adsorbents on the adsorption of metal ions. It is divided into two groups, numbered A and B. Among them, group A uses laboratory tap water to prepare metal ion solutions, and group B uses water from Minzhu Lake of Chongqing University to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com