Heavy metal chelating agent

A technology of heavy metal scavenger and raw material, which is applied in the fields of adsorption water/sewage treatment, water pollutants, water/sewage treatment, etc. It can solve the problems of inability to remove metal ions and the removal of metal ions is not thorough enough, and achieve fast solid-liquid separation and good storage. Effects of stability and operational safety, good capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

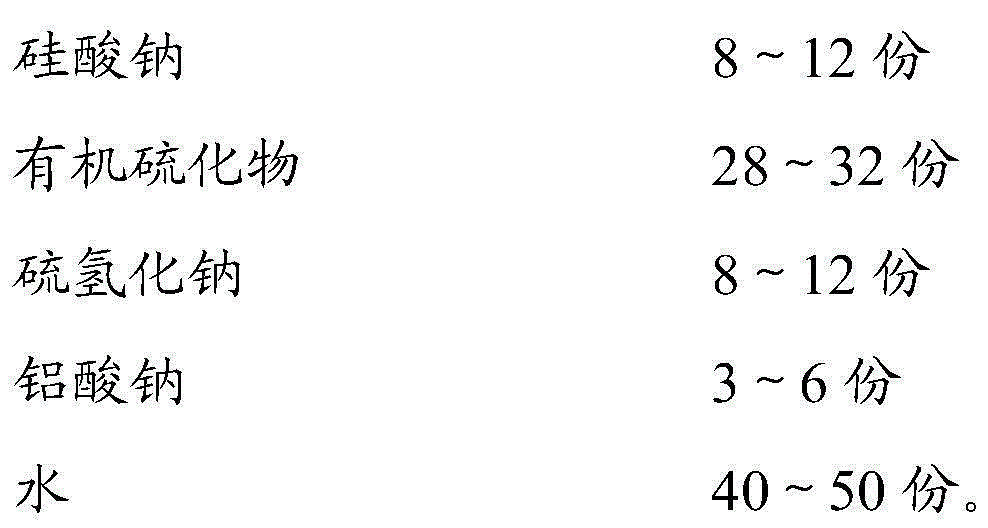

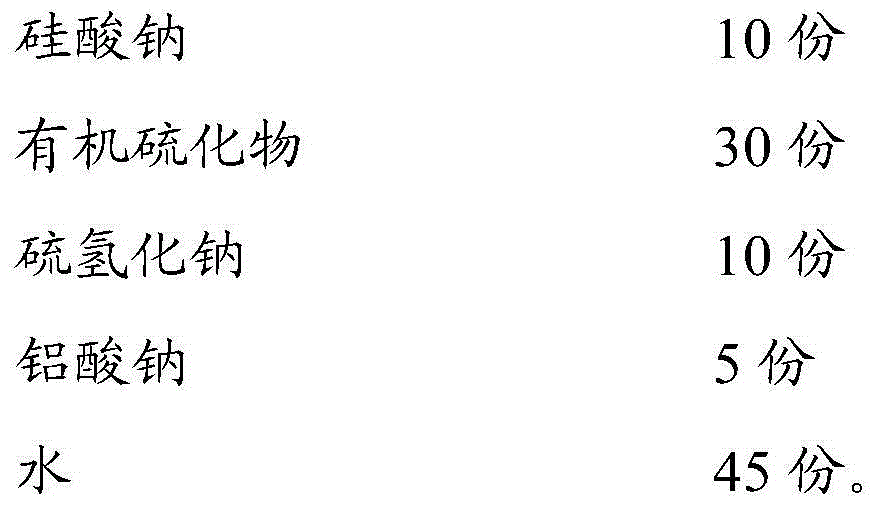

[0021] A heavy metal scavenger comprises 10 kg of sodium silicate, 30 kg of organic sulfide, 10 kg of sodium hydrosulfide, 5 kg of sodium aluminate and 45 kg of water.

[0022] The preparation method is that the above-mentioned amount of sodium silicate, organic sulfide, sodium hydrosulfide, sodium aluminate and water are mixed, stirred evenly at 45°C, and packaged. When used, the dosage is 30ppm.

Embodiment 2

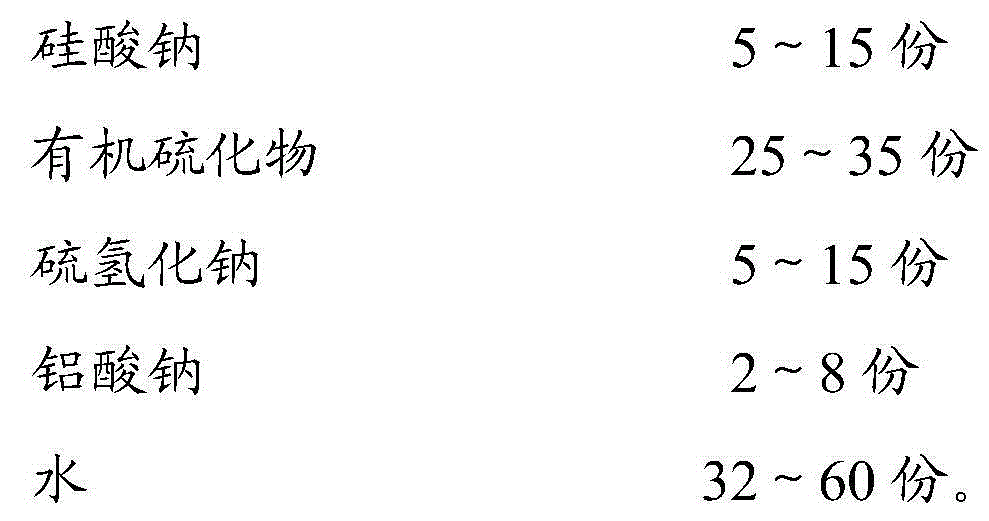

[0024] A heavy metal scavenger comprises 15 kg of sodium silicate, 35 kg of organic sulfide, 15 kg of sodium hydrosulfide, 8 kg of sodium aluminate and 37 kg of water.

[0025] The preparation method is that the above-mentioned amount of sodium silicate, organic sulfide, sodium hydrosulfide, sodium aluminate and water are mixed, stirred evenly at 40°C, and packaged. When used, the dosage is 20ppm.

Embodiment 3

[0027] A heavy metal scavenger comprises 15 kilograms of sodium silicate, 25 kilograms of organic sulfide, 5 kilograms of sodium hydrosulfide, 2 kilograms of sodium aluminate and 53 kilograms of water.

[0028] The preparation method is that the above-mentioned amount of sodium silicate, organic sulfide, sodium hydrosulfide, sodium aluminate and water are mixed, stirred evenly at 50°C, and packaged. When used, the dosage is 50ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com