High-quality chemical raw material hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of insufficient synergy effect, and achieve performance improvement, low price and good synergy effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

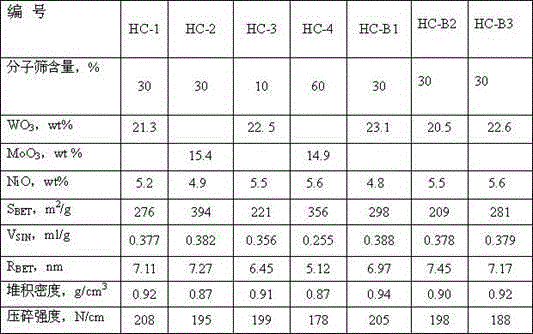

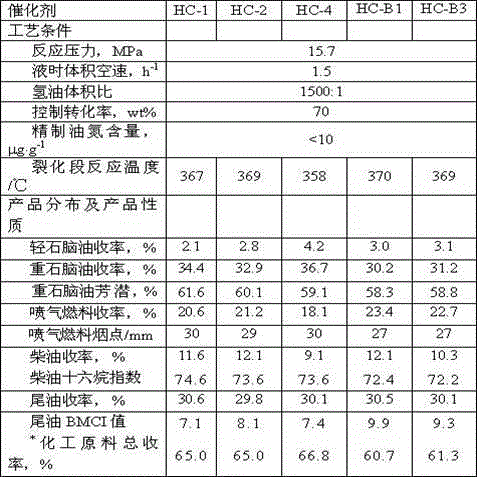

Embodiment 1

[0033] Based on the weight of the final hydrocracking catalyst, it contains 30% Y molecular sieve, 5.0% nickel oxide, 22.0% tungsten oxide, and the balance is alumina. The raw materials for preparing the aforementioned catalyst are selected: modified Y molecular sieve and aluminum hydroxide dry rubber powder.

[0034] The catalyst preparation process is as follows: Put the modified Y molecular sieve and aluminum hydroxide dry rubber powder into a 5% glycerol aqueous solution with a weight content of 80℃ and a stirring speed of 900 revolutions / min, stir for 3 hours, and centrifuge Filter, separate solid and liquid, and dry at 120°C for 4 hours. Mix the dry filter cake with the squeezing aid and sesame powder into a roller compactor and add 4gHNO 3 / 100mL of dilute nitric acid solution was peptized and extruded into a cylindrical shape with a diameter of 1.5mm. The wet bar was dried at 120°C for 4 hours and calcined at 550°C for 3 hours to prepare a catalyst carrier. Then the W-Ni...

Embodiment 2

[0037] Based on the weight of the final hydrocracking catalyst, it contains 30% Y molecular sieve, 5.0% nickel oxide, 15.0% molybdenum oxide, and the balance is alumina. The raw materials for preparing the aforementioned catalyst are selected: modified Y molecular sieve and aluminum hydroxide dry rubber powder.

[0038] The preparation method is the same as that in Example 1, except that the raw material is placed in an aqueous solution at a temperature of 80° C. and a stirring speed of 800 revolutions / min. The obtained catalyst number is HC-2.

[0039]

Embodiment 3

[0041] Based on the weight of the final hydrocracking catalyst, it contains 10% modified Y molecular sieve, 50% amorphous silicon aluminum, 5.0% nickel oxide, 22.0% tungsten oxide, and the balance is alumina. The raw materials for the preparation of the aforementioned catalyst were selected: modified Y molecular sieve, amorphous silicon aluminum and aluminum hydroxide dry rubber powder.

[0042] The preparation method is the same as that of Example 1, except that the raw materials are placed in a 10% acrylate aqueous solution with a weight content of 70° C. and a stirring speed of 800 revolutions / min. The obtained catalyst number is HC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com