Patents

Literature

72results about How to "Applicable preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

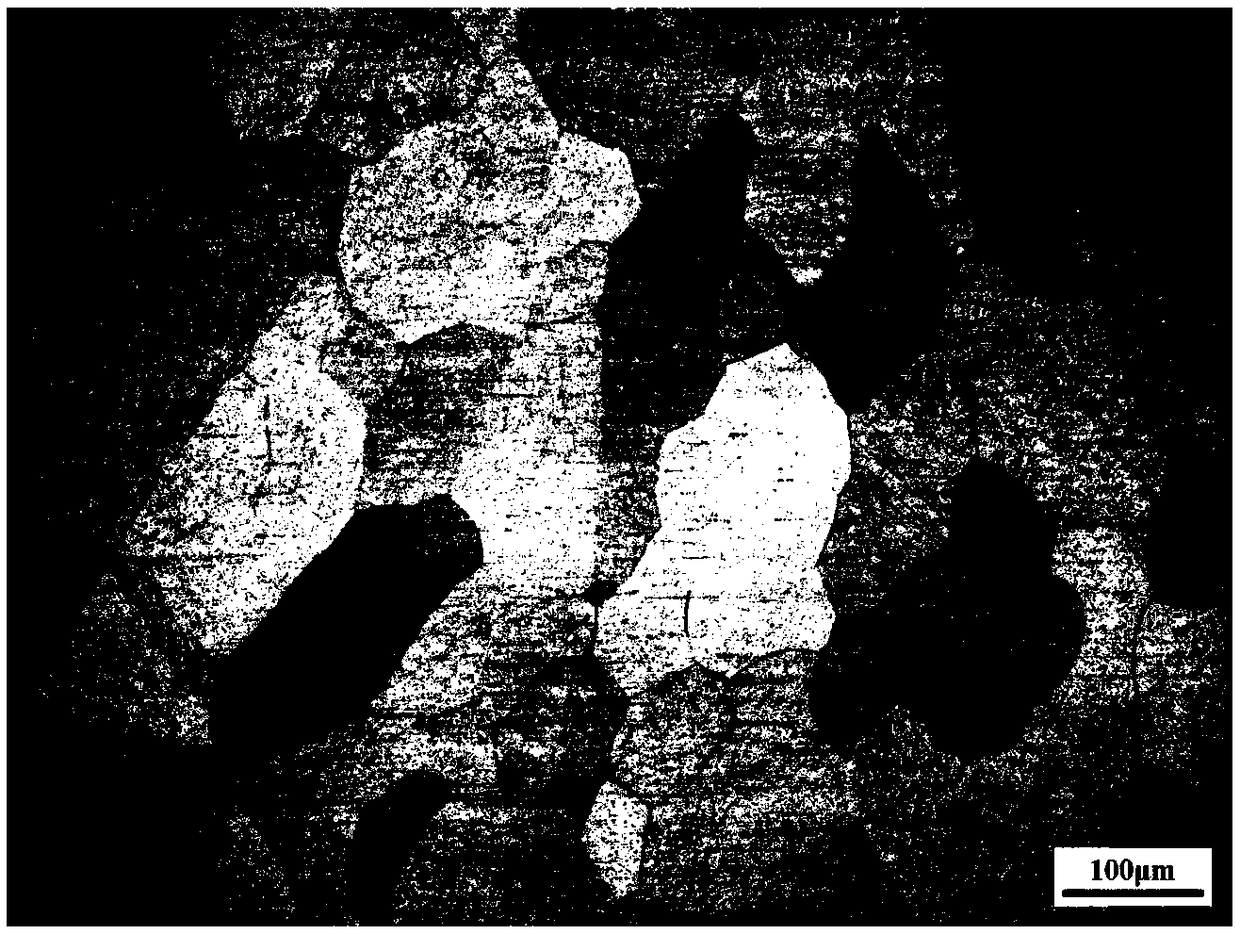

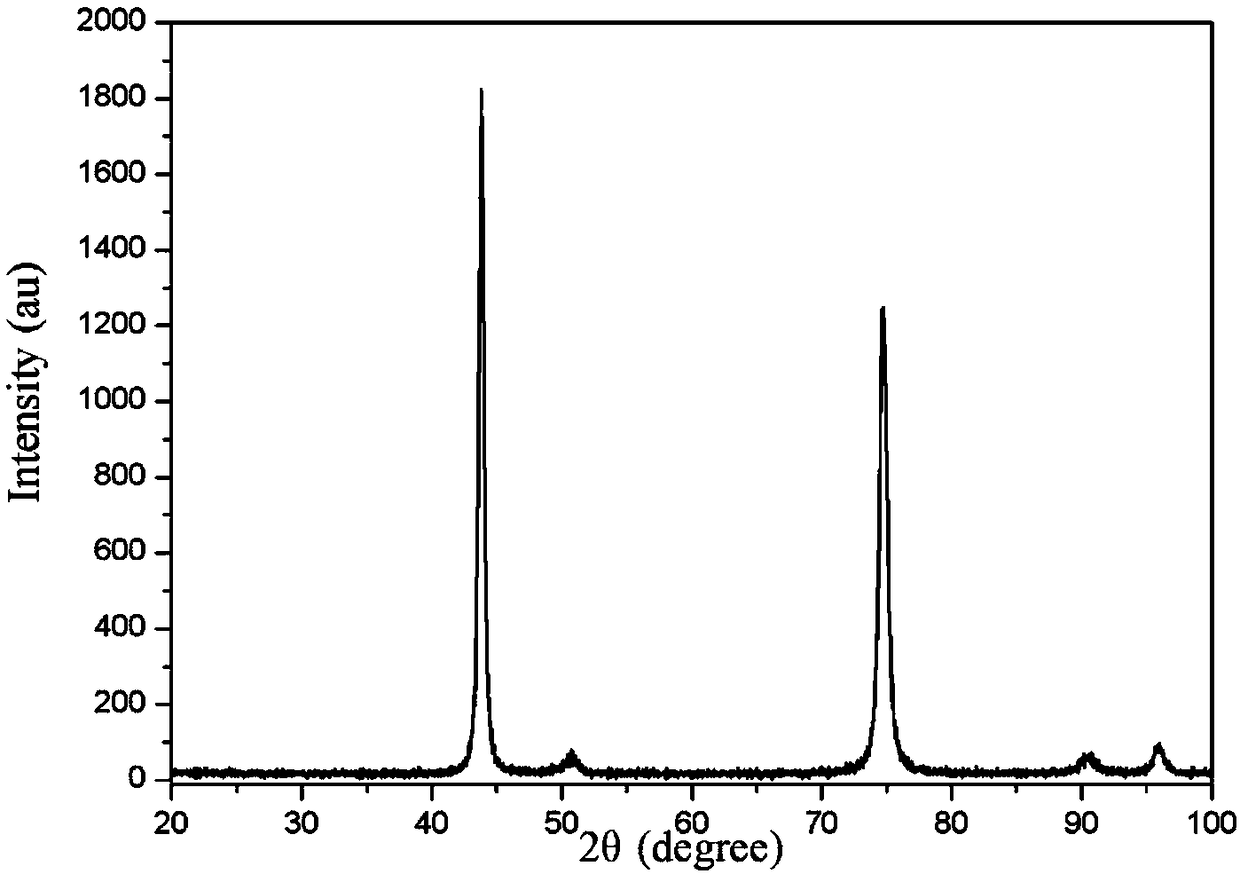

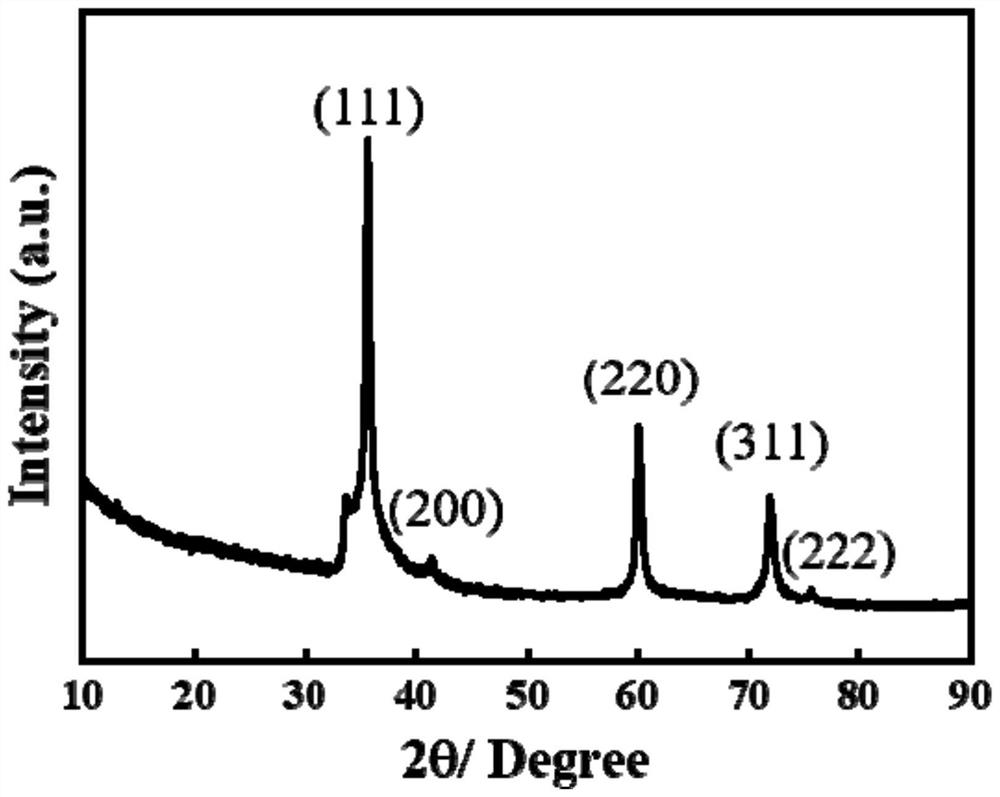

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

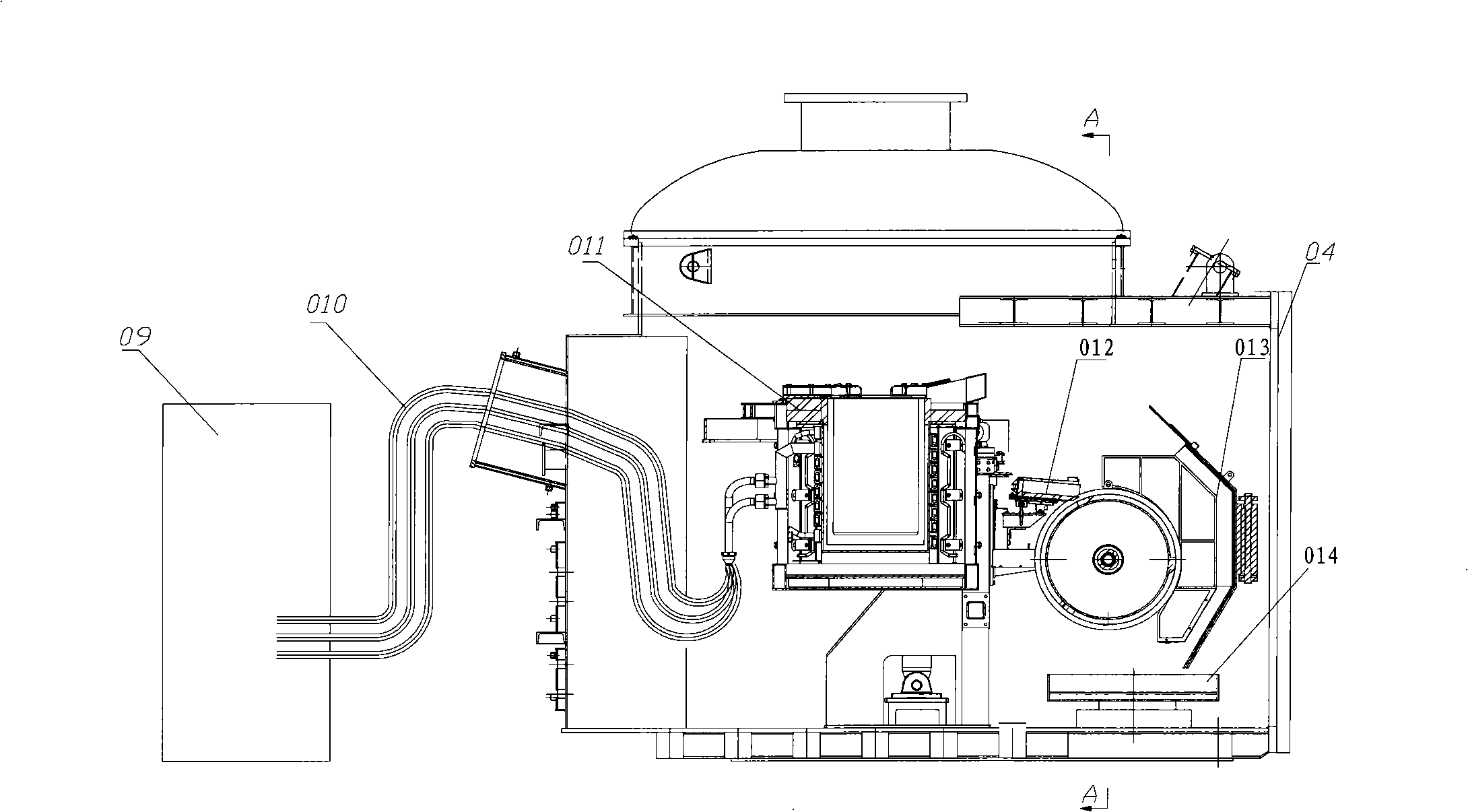

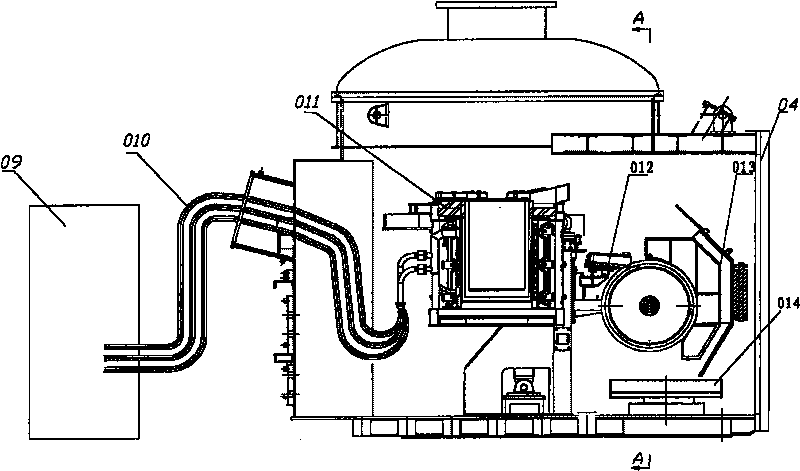

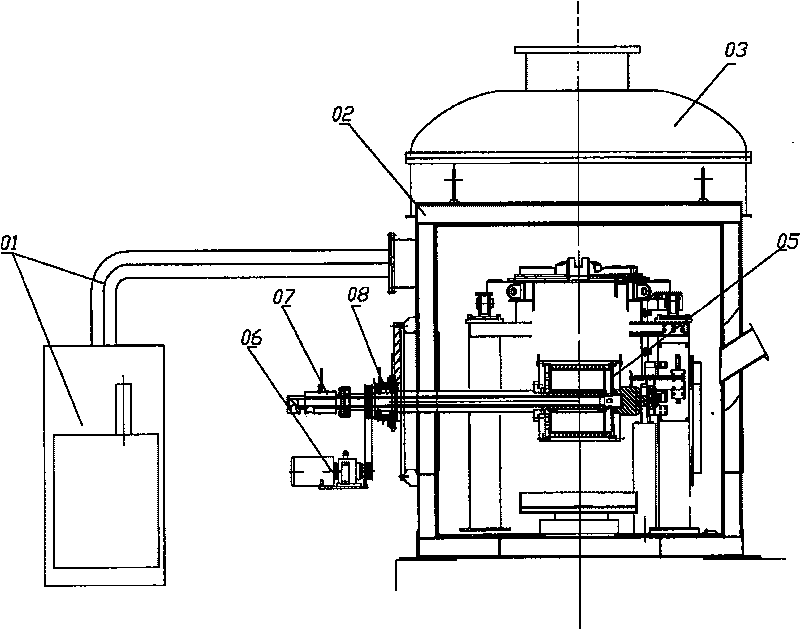

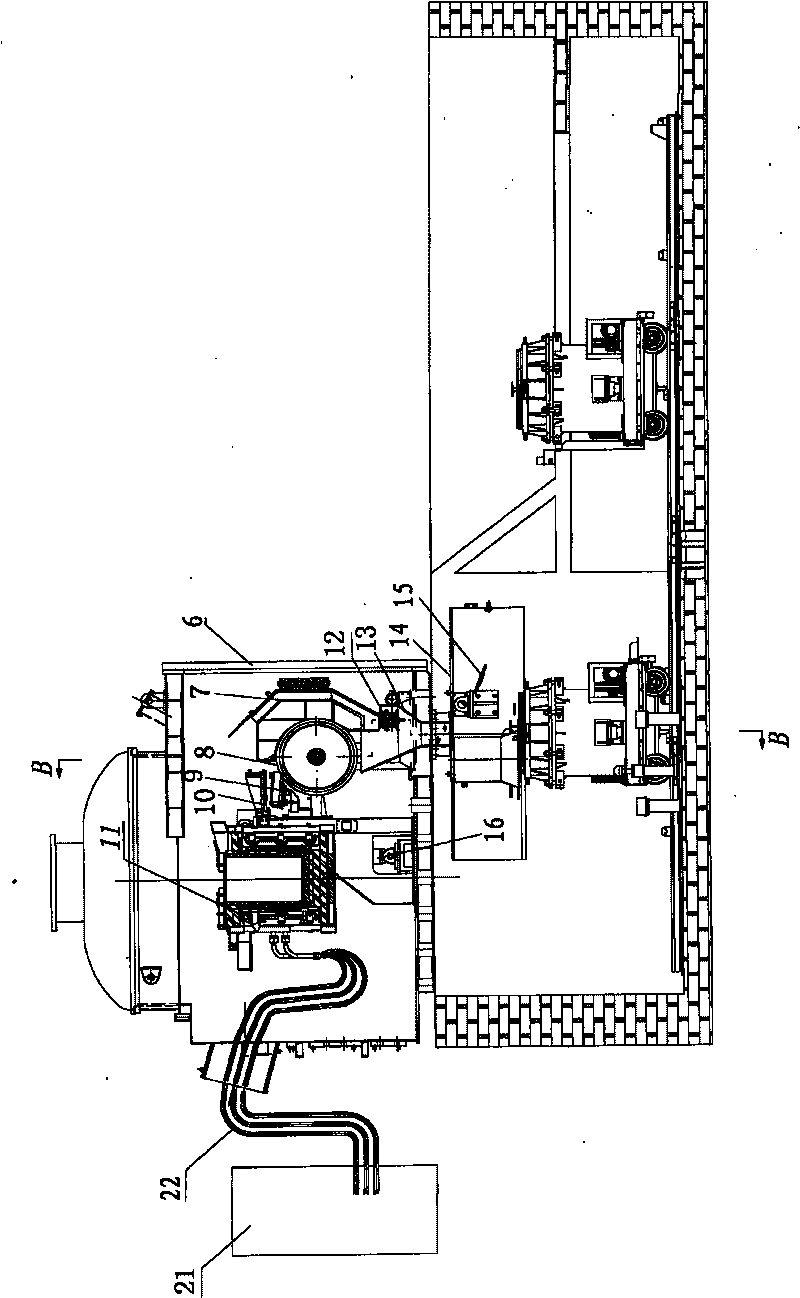

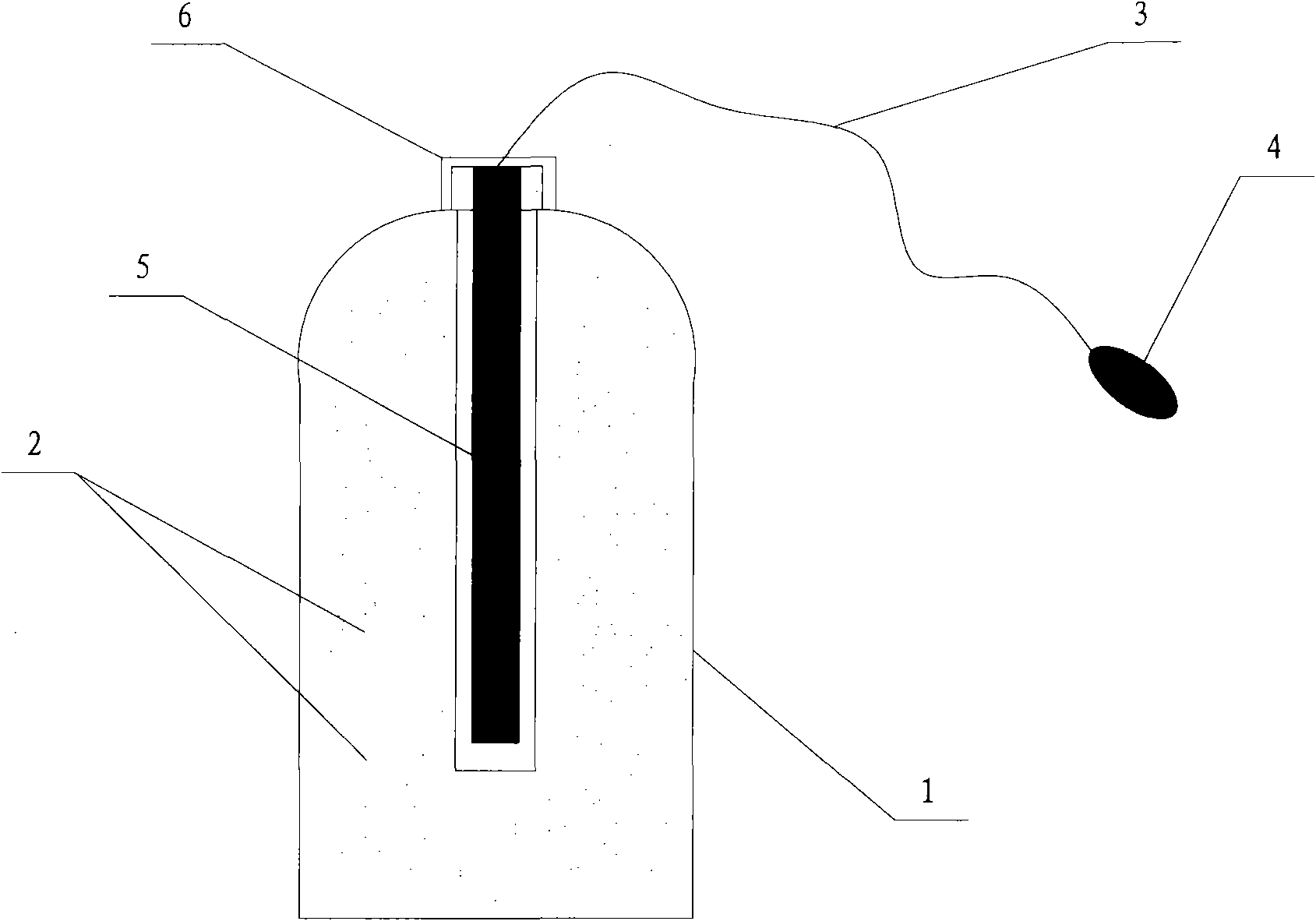

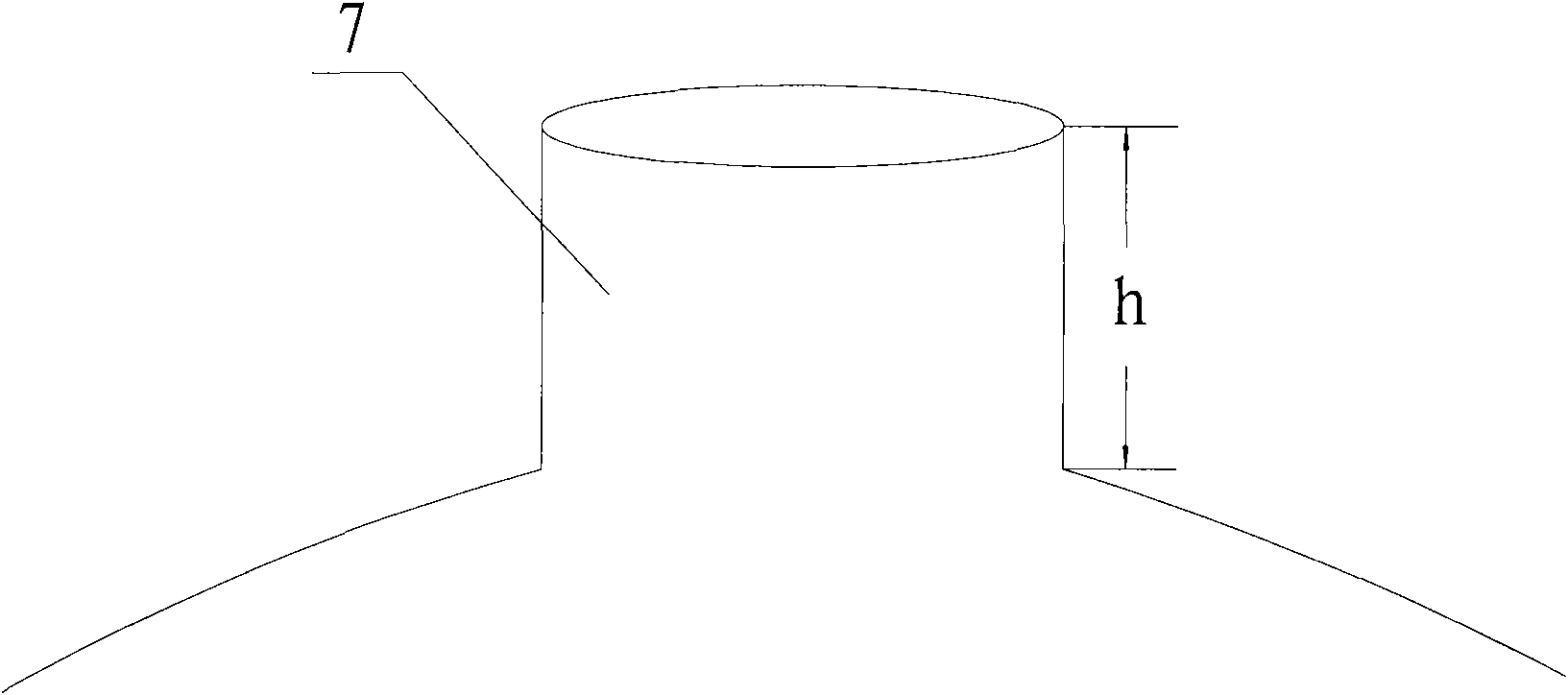

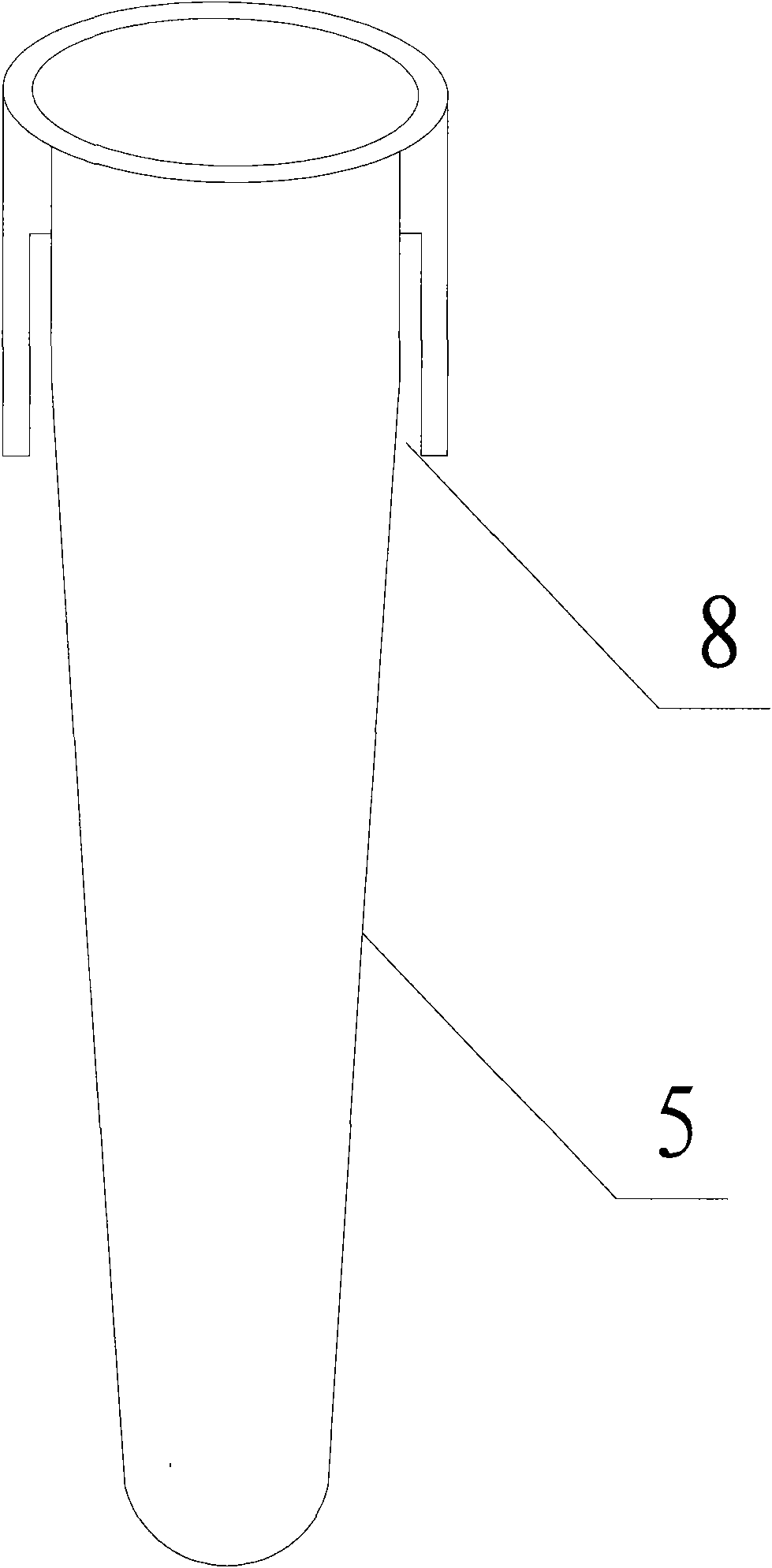

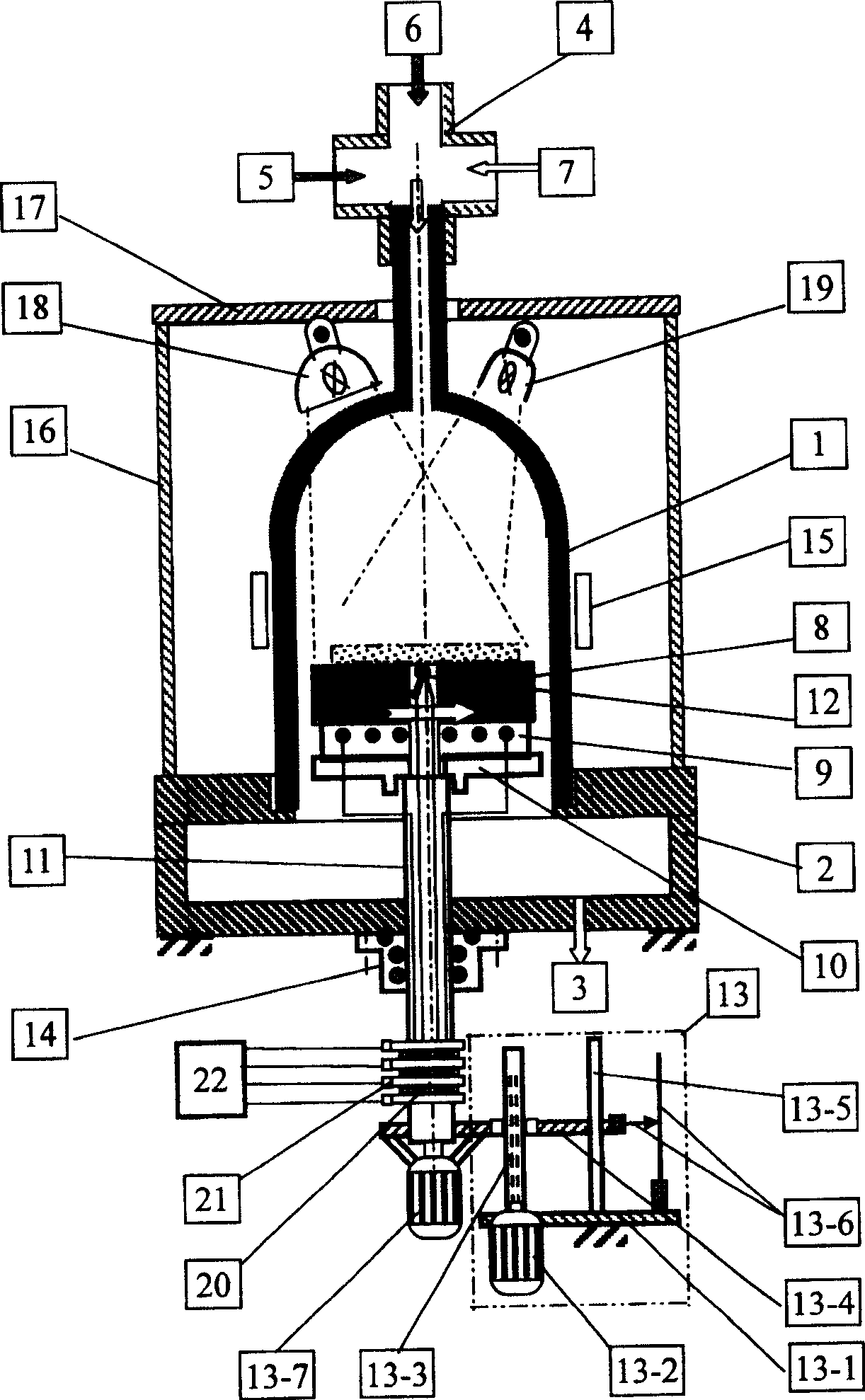

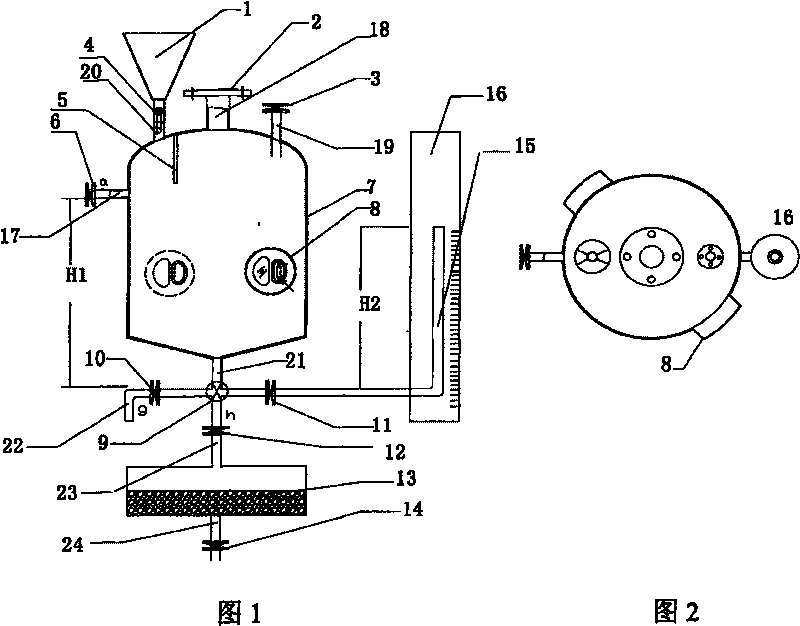

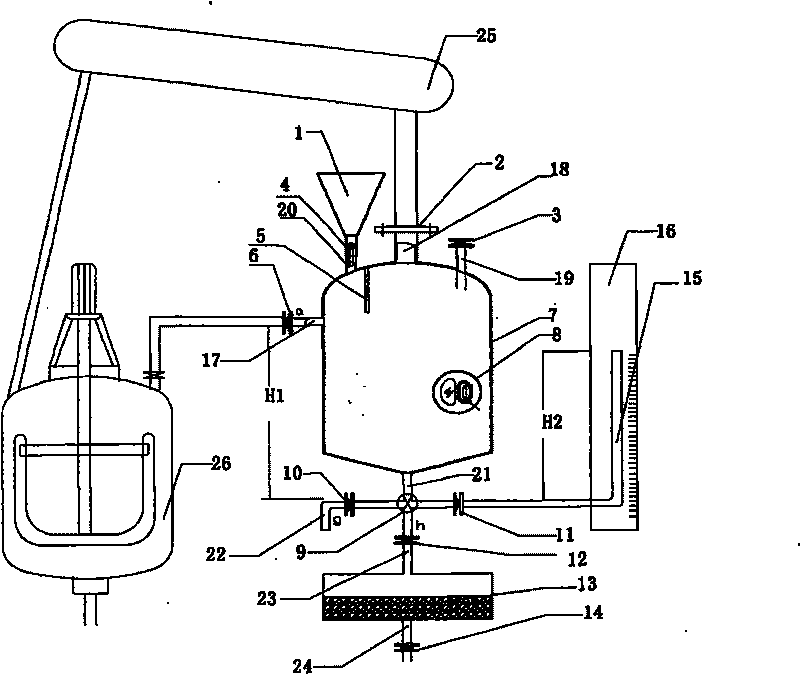

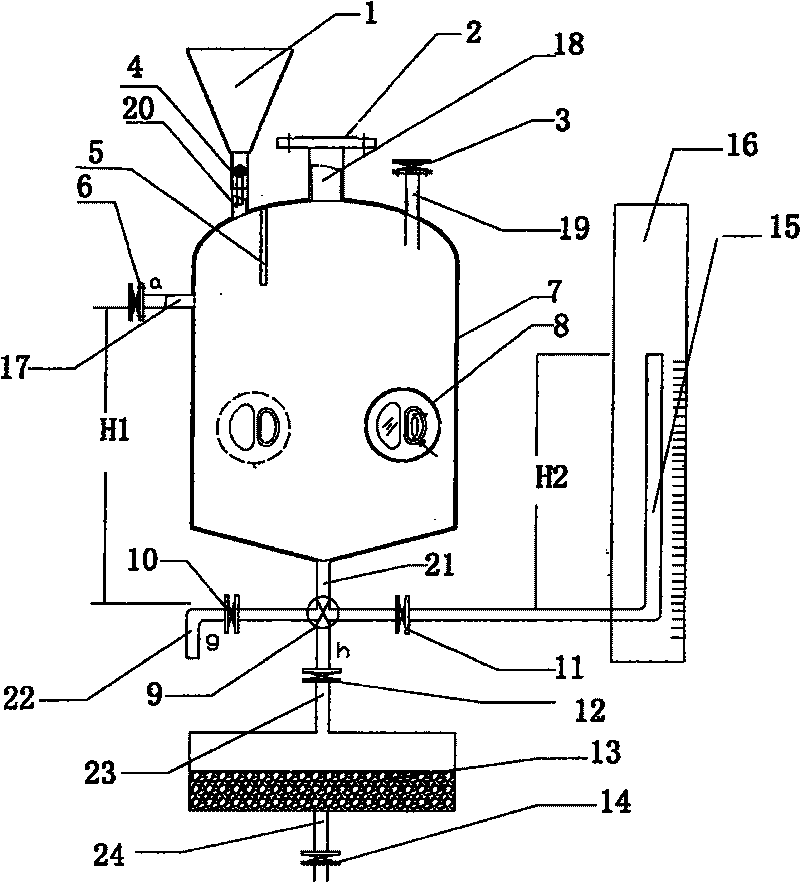

Vacuum induction smelting furnance

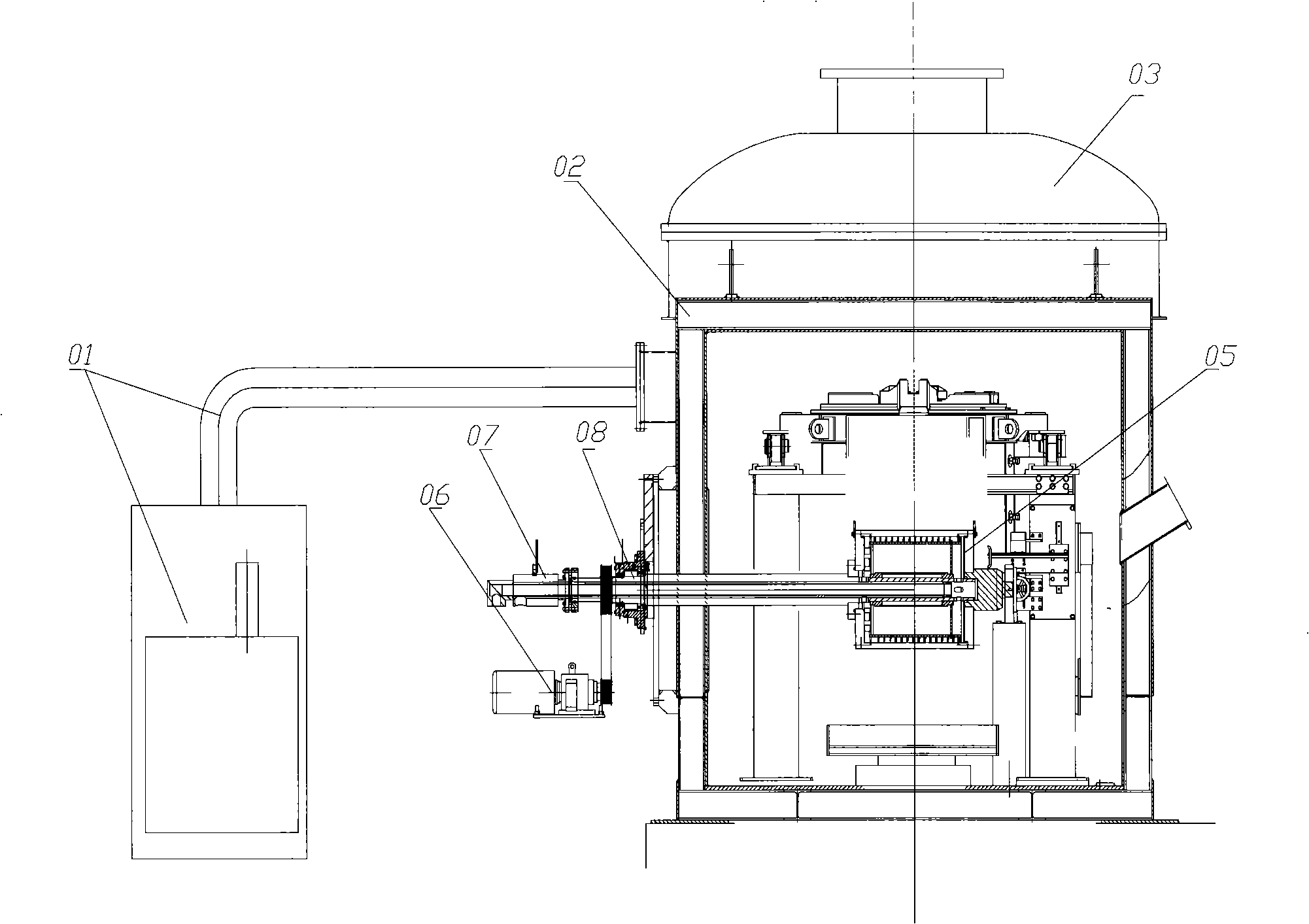

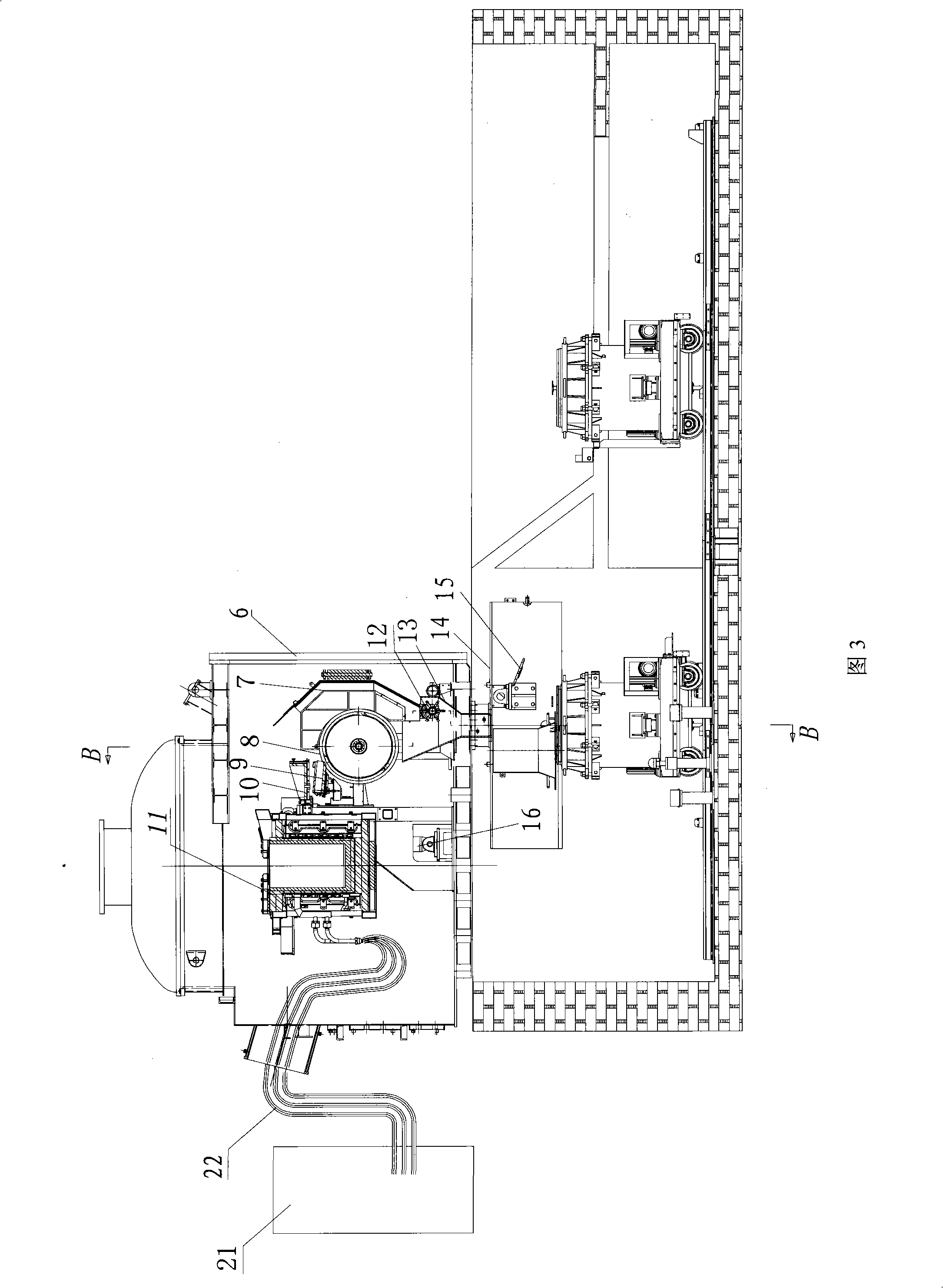

ActiveCN101347836AUniform thicknessUniform cooling effectCasting plantsCharge manipulationCooling effectFlap valve

The invention discloses a vacuum induction melting furnace, which relates to a crucible furnace that is suitable for charging treatment in vacuum or special atmosphere. The invention provides an improved vacuum induction melting furnace with better casting cooling effect and good productivity, which comprises a vacuum melting chamber, a medium frequency coil furnace, a set of vacuum pump and a corresponding vacuum pipeline system, a electric control system, a medium frequency power supply system, a hydraulic cylinder control system, a cooling system, and a pit discharging system. The cooling system is provided with a tundish feed divider, a belt wheel cooling mechanism, a baffle cooling mechanism and a turning wheel cooling mechanism. The pit discharging system comprises a medial chamber box, an inner container, an outer container, a walking car, a hydraulic lifting cylinder, a pit track, a flap valve and a guide shell. The guide shell and the flap valve are arranged in the medial chamber box, the outer container is fixedly arranged on the walking car, and the inner container is sheathed at the inner wall of the outer container.

Owner:厦门嘉鹭金属工业有限公司

Preparation method of high-quality glycerin monostearate

ActiveCN102964245AFully purifiedControl acid valueOrganic compound preparationCarboxylic acid esters preparationHydrogenated Palm OilDistillation

The invention discloses a preparation method of high-quality glycerin monostearate. The method comprises the steps of reacting hydrogenated palm oil and glycerol under strong base catalysis to generate ester, and carrying out four-stage distillation to obtain high-quality glycerin monostearate. The acid value of the product is reduced to below 0.4, the freezing point is raised to 64-66 DEG C, the quality of the product is improved, and the difficulty of the prior art is overcome. Besides, the problems in the prior art that the pipeline is blocked by slag produced in the distillation process, the production efficiency is lowered, the product quality is reduced, the production is discontinuous and the processing efficiency is low resulting from scaling of an evaporating surface and a condensing surface are solved. Glycerol and hydrogenated palm oil can be recycled, so that the cost is low, the yield is high, the product quality is improved, and the whole processing controllability is high. The high-quality glycerin monostearate is suitable for industrial production.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

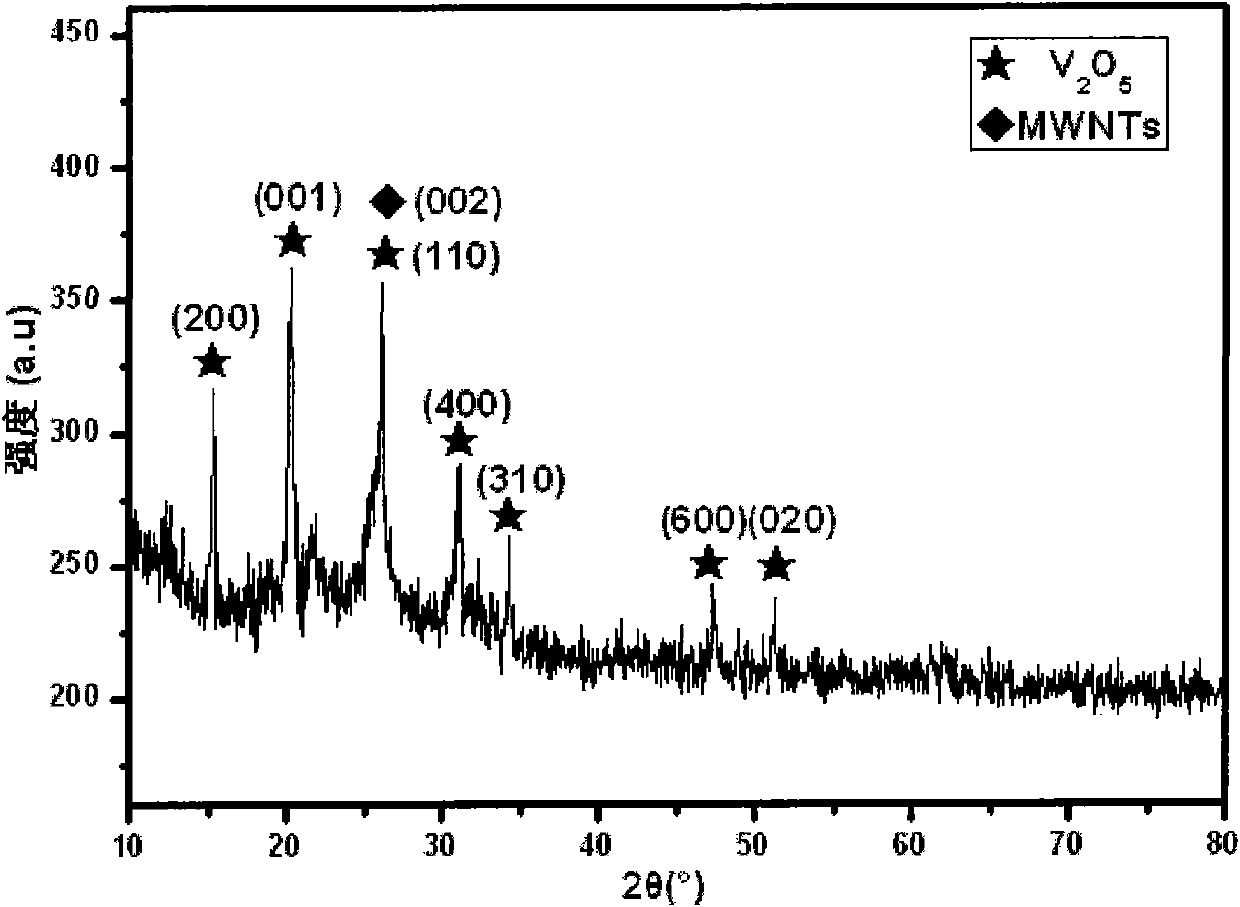

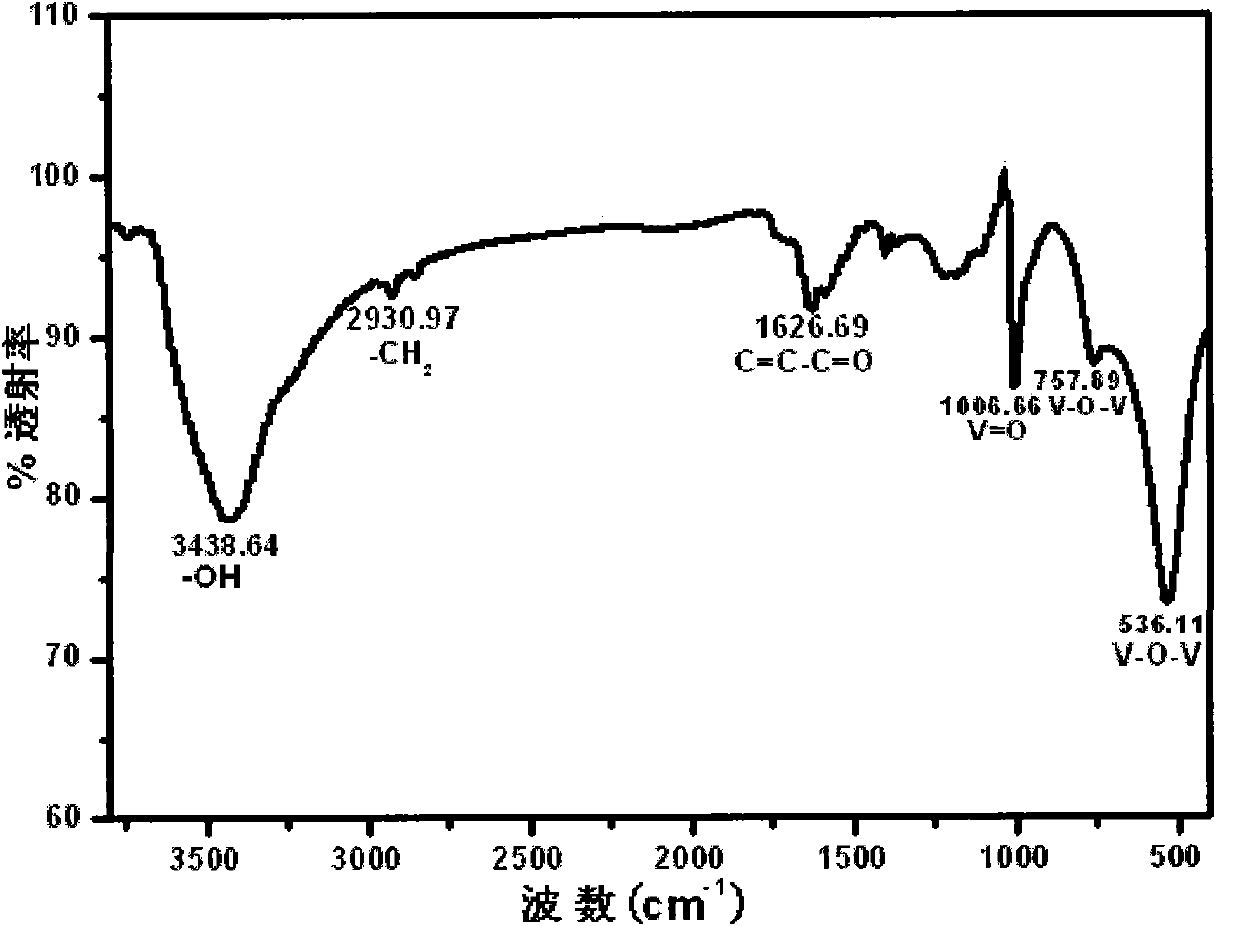

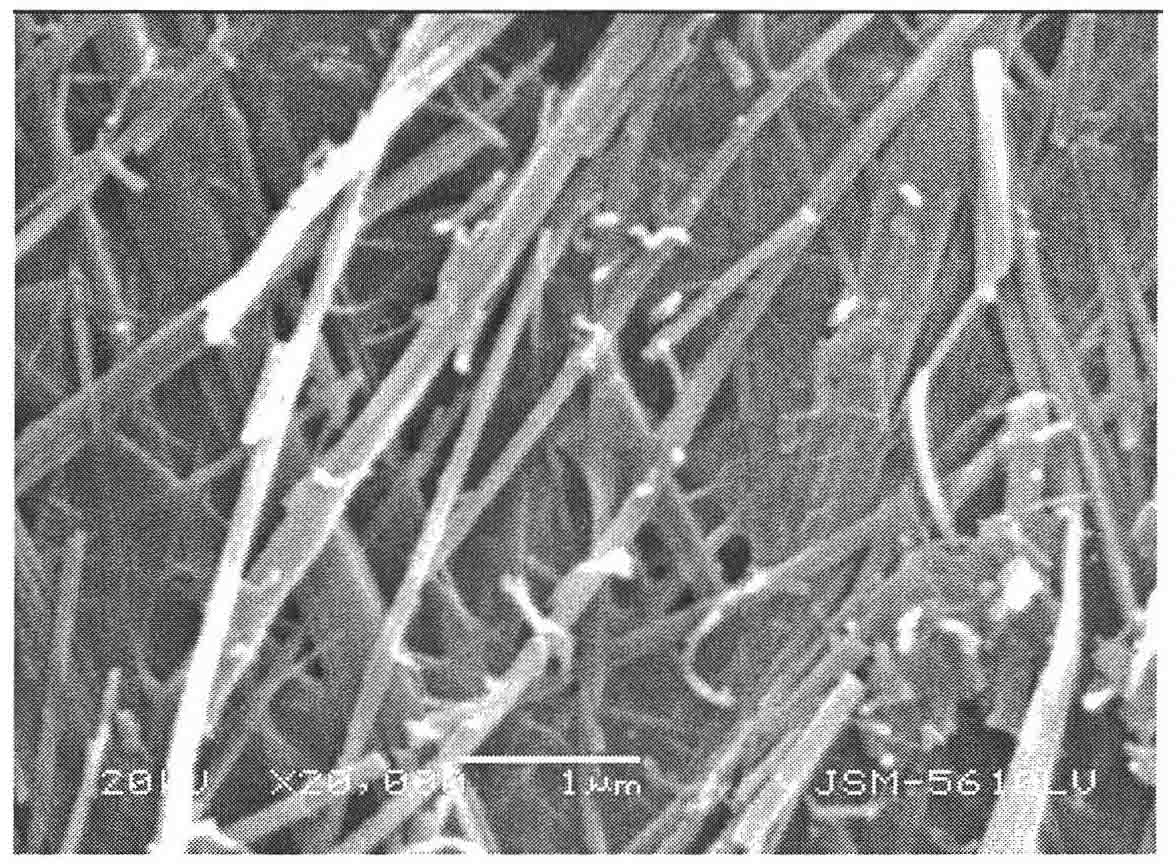

Preparation method of vanadium oxide/carbon nanometer tube composite materials with interpenetrating network structures

ActiveCN101767771AReduce usageEasy to prepareNanostructure manufactureCarbon nanotubeVanadium(III) oxide

The invention provides a preparation method of vanadium oxide / carbon nanometer tube composite materials with interpenetrating network structures. The carbon nanometer tubes with good conductivity are adopted for self assembly with single-dimensional vanadium oxide nanometer materials on the nanometer scale, so the carbon nanometer tubes have the effects of conductive bridges between all interwoven single-dimensional vanadium oxide nanometer materials for building interpenetrating network structures under the microcosmic dimensions, and the composite material with the structure can be used as a lithium ion injection material with high capacity and high stability. The method comprises the following preparation processes: using V2O5 collosol prepared by a quenching method as a vanadium source; using the carbon nanometer tubes dressed by sulphuric acid and nitric acid as assembly initiation sources; mixing and stirring the V2O5 collosol and the carbon nanometer tubes for more than 1 hour;then taking the reaction for 1 to 7 days through the water heating technology at 150 to 190 DEG C; washing and filtering obtained materials by deionized water for 2 to 5 times; and baking materials at 60 to 100 DEG C for obtaining the vanadium oxide / carbon nanometer tube composite materials with the interpenetrating network structures. The composite material has wide application when being used as the lithium ion injection material in the fields such as secondary lithium ion batteries, electrochromic devices, photoelectric switches, catalysis and sensors and the like.

Owner:WUHAN UNIV OF TECH

Vacuum induction smelting furnance

ActiveCN101347836BUniform thicknessUniform cooling effectCasting plantsCharge manipulationCooling effectFlap valve

The invention discloses a vacuum induction melting furnace, which relates to a crucible furnace that is suitable for charging treatment in vacuum or special atmosphere. The invention provides an improved vacuum induction melting furnace with better casting cooling effect and good productivity, which comprises a vacuum melting chamber, a medium frequency coil furnace, a set of vacuum pump and a corresponding vacuum pipeline system, a electric control system, a medium frequency power supply system, a hydraulic cylinder control system, a cooling system, and a pit discharging system. The cooling system is provided with a tundish feed divider, a belt wheel cooling mechanism, a baffle cooling mechanism and a turning wheel cooling mechanism. The pit discharging system comprises a medial chamber box, an inner container, an outer container, a walking car, a hydraulic lifting cylinder, a pit track, a flap valve and a guide shell. The guide shell and the flap valve are arranged in the medial chamber box, the outer container is fixedly arranged on the walking car, and the inner container is sheathed at the inner wall of the outer container.

Owner:厦门嘉鹭金属工业有限公司

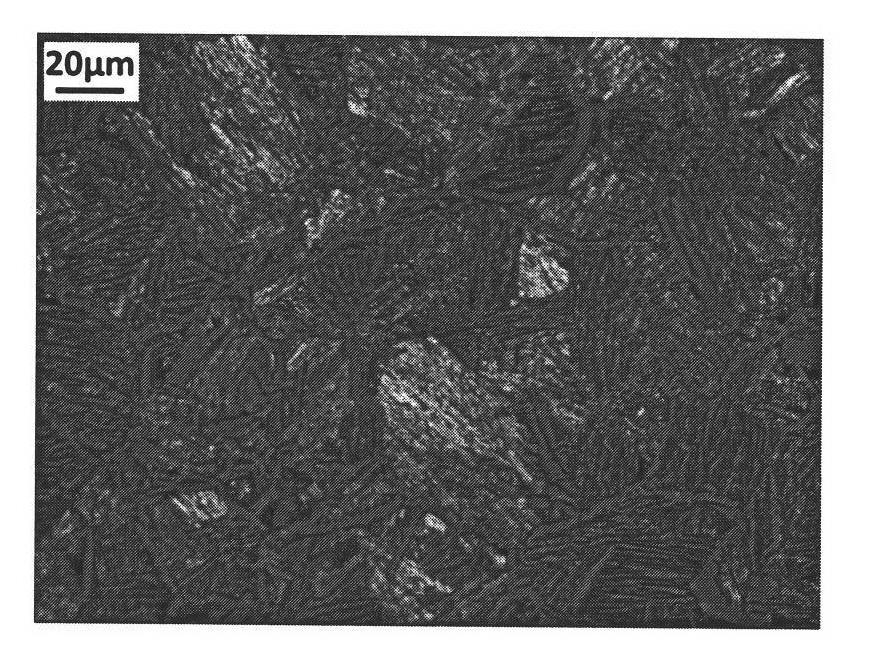

Method for preparing titanium alloy through high-speed pressing formation

InactiveCN102586639APerformance deteriorationHigh densityTitanium matrix compositesFlexural strength

The invention discloses a method for preparing a titanium alloy through high-speed pressing formation. The method comprises the following steps of: mixing titanium-containing metal powder, lubricating a die wall, preparing a pressed shape through high-speed pressing formation, and performing vacuum sintering. The high-compactness titanium alloy is prepared through high-speed pressing formation and vacuum sintering; the process is simple; and the short-flow and low-cost preparation of the high-performance titanium alloy is realized. The compactness of the prepared titanium alloy is more than or equal to 98.08 percent; the Vickers hardness (HV) is 374 to 394; and the bending strength is 1,439 to 2,170MPa. The method is also applicable to the preparation of other titanium alloys and titanium-based composite materials in which titanium is taken as a matrix.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

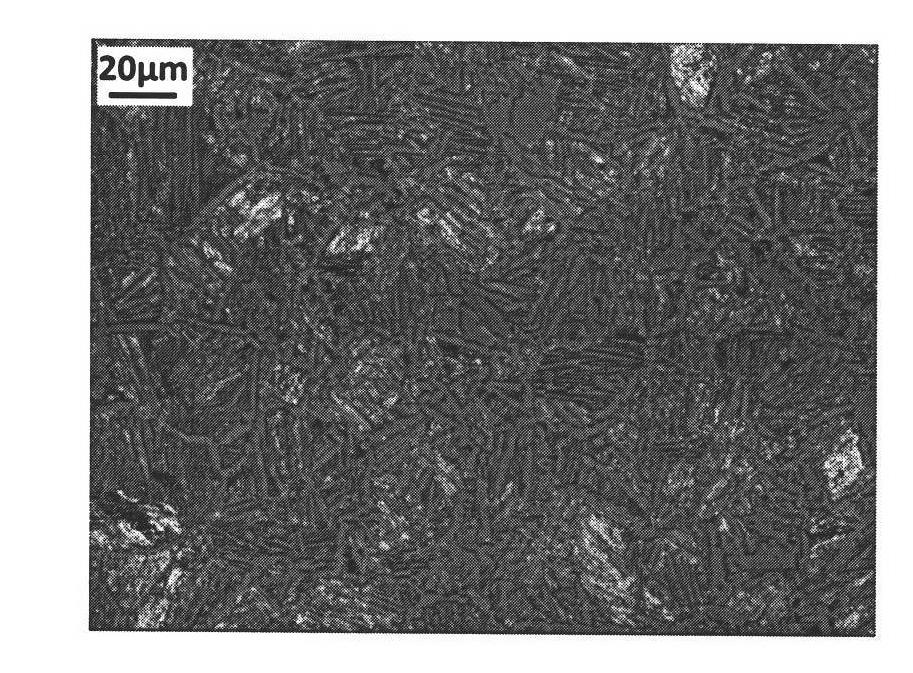

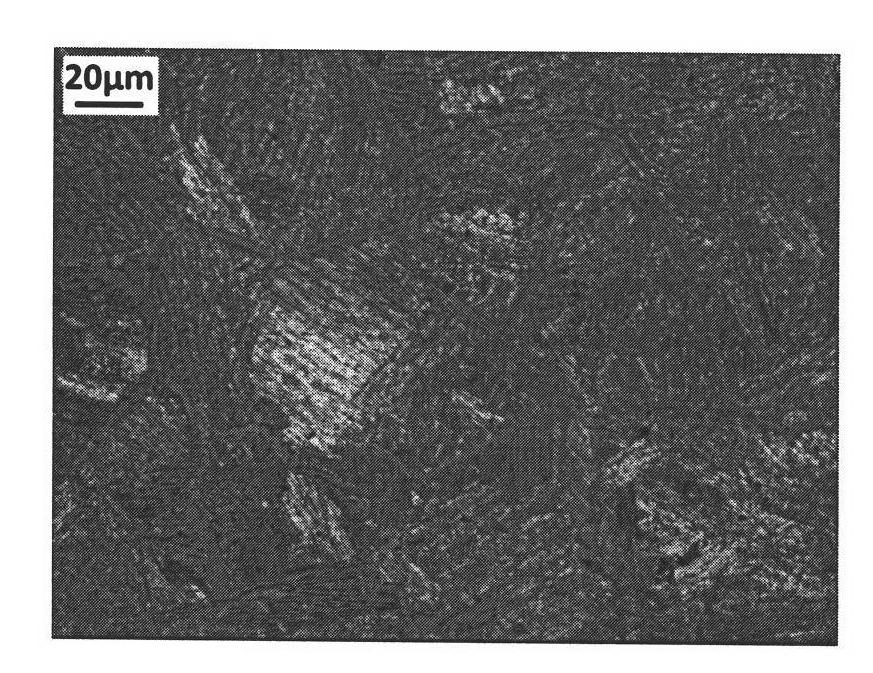

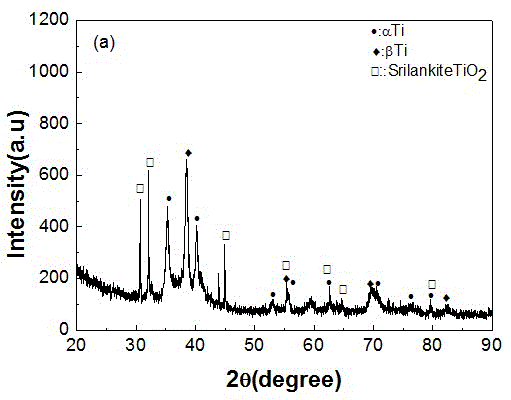

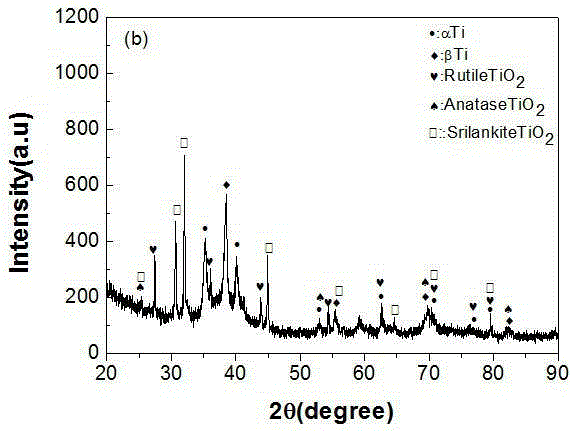

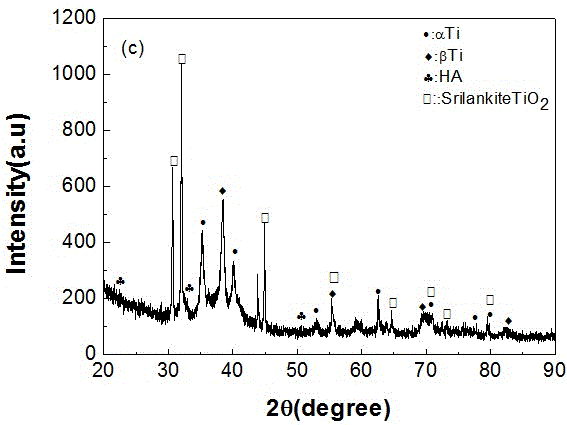

Method for compounding and preparing high-elastic-modulus Ti-based material based on nano ceramic particles

The invention relates to a TNZS alloy and particularly relates to a method for compounding and preparing high-elastic-modulus Ti-based material based on nano ceramic particles. The method comprises the following steps: firstly taking Ti, Nb, Zr, Sn, TiO2 and HA powder as raw material, carrying out high-energy ball milling twice to prepare mixed powder; then carrying out normal die pressing treatment on the mixed powder; and finally vacuum sintering pressed blocks obtained by die pressing without pressure to obtain uniform-surface-component and high-elastic-modulus Ti-based material containing 5wt% of TiO2 / TNZS and 5wt% of HA / TNZS. As a preparation method of the Ti-based material, the problem with insufficient elastic modulus of the TNZS alloy can be effectively solved; the preparation process is simple; the application range of the titanium material in the fields of aerospace, traffic transportation and weapon equipment is expanded.

Owner:JIANGSU UNIV

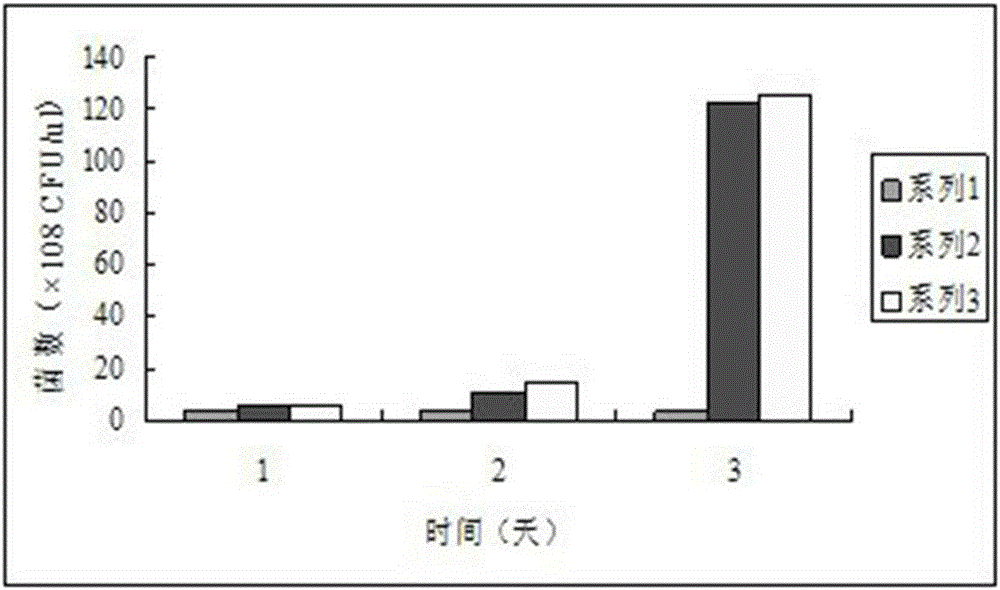

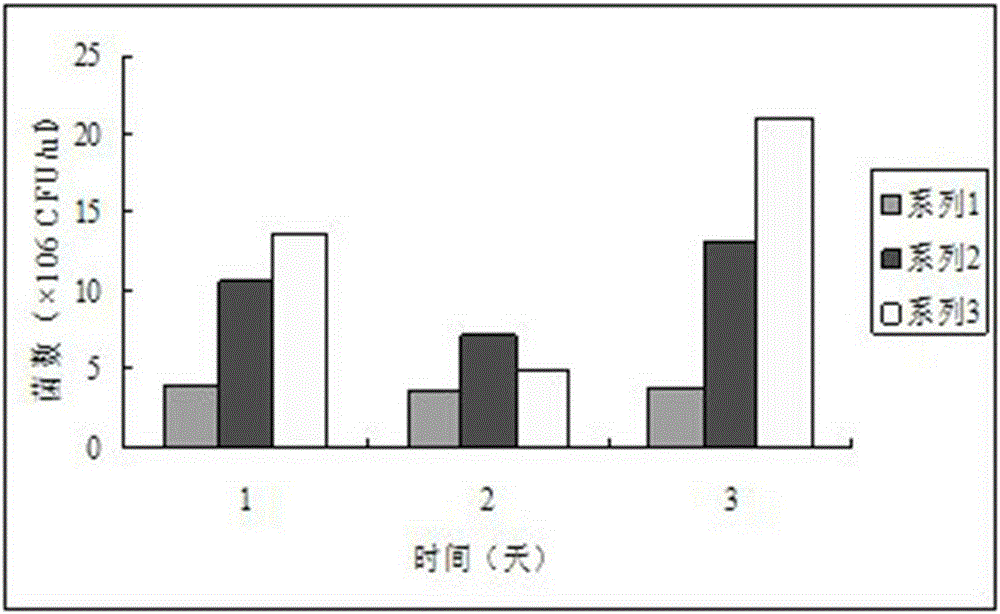

Lactobacillus acidophilus and bifidobacterium fermented active lactobacillus beverage and preparation method thereof

The invention discloses a lactobacillus acidophilus and bifidobacterium fermented active lactobacillus beverage and a preparation method thereof. The adopted optimal inoculation proportion of lactobacillus acidophilus and bifidobacterium is (1-100):1; compared with the conventional strain fermented active lactobacillus beverage, the lactobacillus acidophilus and bifidobacterium fermented active lactobacillus beverage not only has a higher probiotic function, but also has excellent flavor; the blank of the pure probiotic fermented active lactobacillus beverage on the market is filled. An antioxidant is added before fermentation to consume excessive oxygen in a fermentation base material in the fermentation process, so that anaerobic lactobacillus acidophilus and bifidobacterium can grow better, and the fermentation time is shortened. The method is suitable for preparation of the active lactobacillus beverage.

Owner:JUNLEBAO DAIRY GRP CO LTD

Method for recycling ladle slag

InactiveCN102337379AAvoid cloggingArgon blowing obstacleRecycling and recovery technologiesProcess efficiency improvementSlagAlloy

The invention provides a method for recycling ladle slag, comprising the following steps: carrying out solidification and fragmentation on the ladle slag, and then carrying out iron election, allowing residues after iron election as refining slag to contact with molten steel containing added alloy for LF refining. According to the invention, the recycle of the ladle slag is realized, and slag component in the recycle process can be accurately controlled, so that effect of refining of the molten steel is further improved; by adding the refining slag in the alloyed molten steel, the problem of argon blowing fault generated in tapping after adding the ladle slag in the empty ladle, and the time of refining of the molten steel is greatly reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

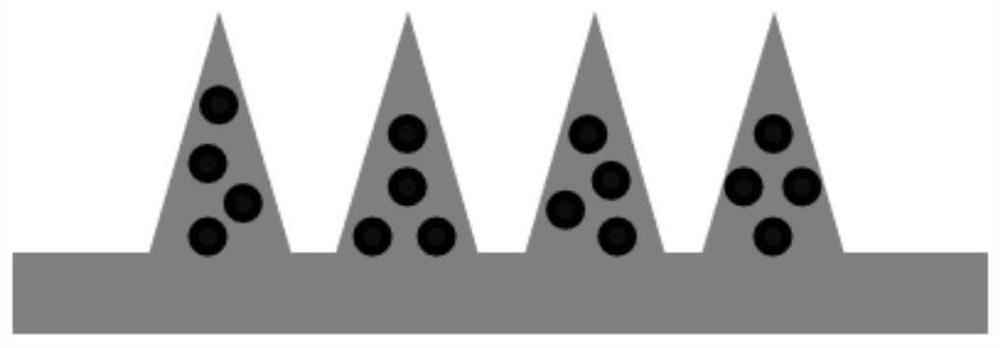

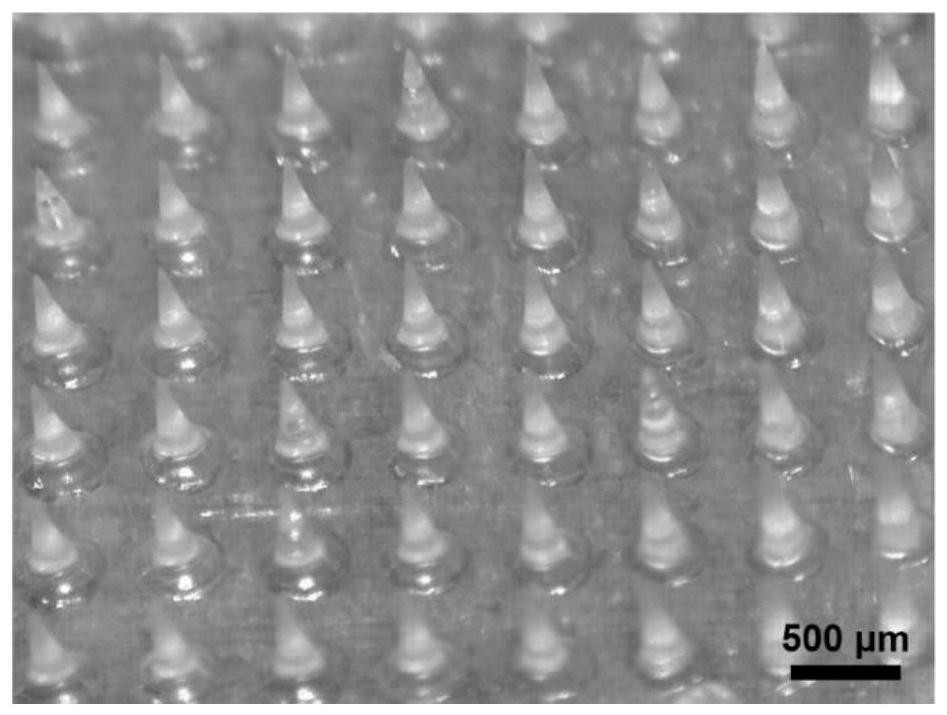

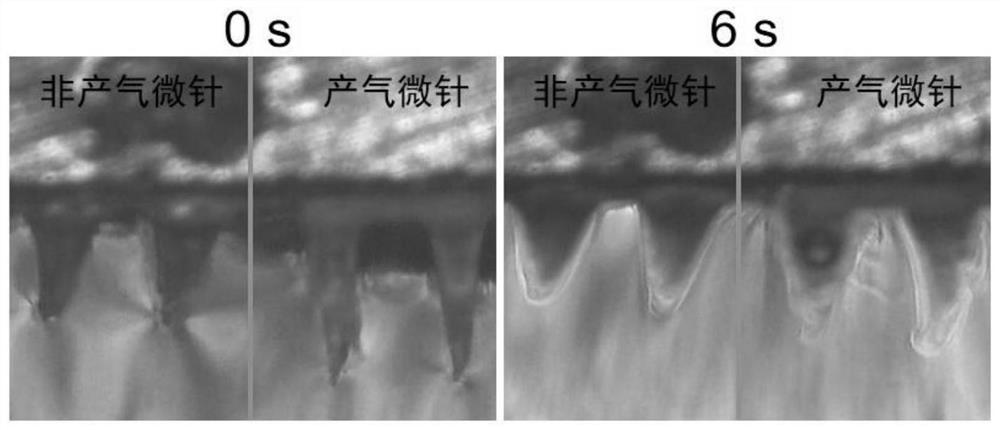

Micro-needle array patch capable of generating gas to take effect quickly and preparation and application thereof

PendingCN113679692AImprove solubilityIncrease the speed of diffusionOrganic active ingredientsPeptide/protein ingredientsTissue fluidBiocompatibility

The invention belongs to the field of biomedical polymer materials, and discloses a micro-needle array patch capable of generating gas to take effect quickly and preparation and application thereof. The micro-needle array patch comprises a substrate and a needle tip located on the substrate, the substrate is composed of a biocompatible matrix, the needle tip is mainly composed of the biocompatible matrix and inorganic particles capable of generating gas, and the inorganic particles capable of generating gas are formed on the surface and / or in the biocompatible matrix of the needle tip; the needle tip part of the micro-needle array patch can interact with skin tissue fluid to generate gas during application, rapid dissolution of micro-needles and diffusion of drugs to a corium layer are promoted, and the drugs can be efficiently and rapidly delivered to subcutaneous parts and take effect without the help of external equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

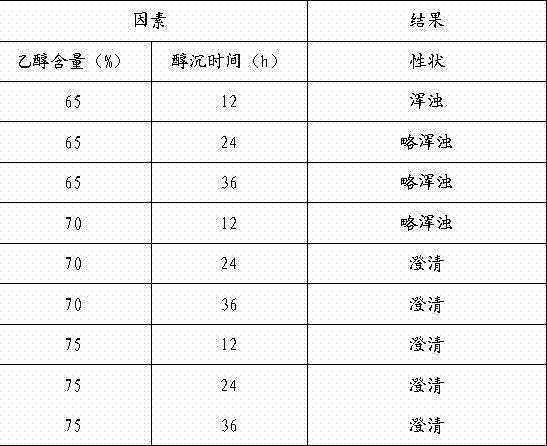

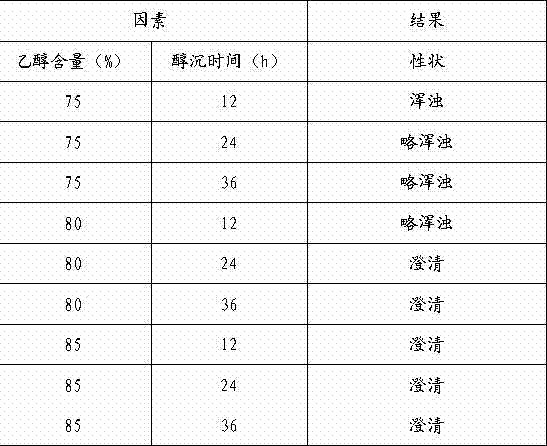

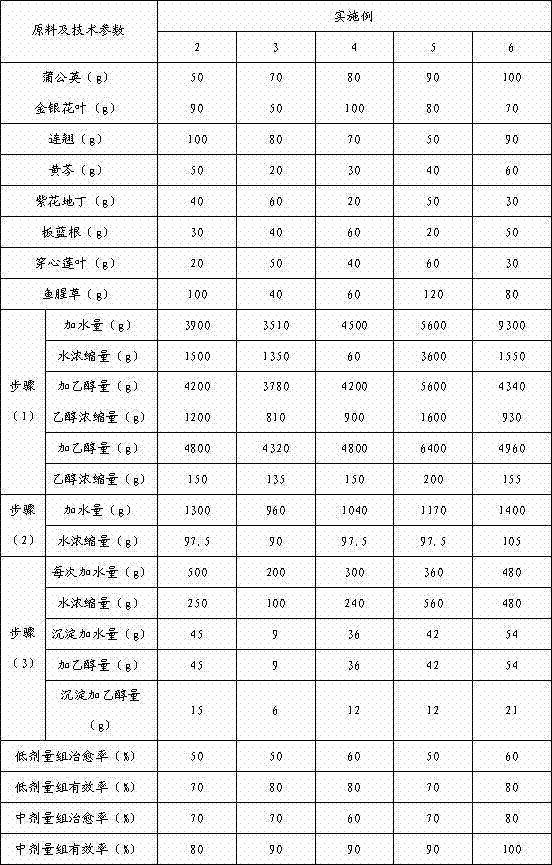

Traditional Chinese medicine perfusate for treating cow mastitis and preparation method thereof

ActiveCN104288356AHigh in lactoneGood antipyretic effectPharmaceutical delivery mechanismPharmaceutical non-active ingredientsBiotechnologyViola yedoensis

The invention discloses traditional Chinese medicine perfusate for treating cow mastitis and a preparation method thereof. The traditional Chinese medicine perfusate is prepared from eight raw materials: dandelion, honeysuckle, fructus forsythia, scutellaria baicalensis, Chinese violet, radix isatidis, common andrographis herb leaves and cordate houttuynia, and belongs to a pure traditional Chinese medicine preparation; the pure traditional Chinese medicine preparation is safe in administration, and efficient in treatment; cordate houttuynia and radix isatidis in the preparation process are subjected to water extraction; impurity removal is carried out by adopting a ZTC1+1 clarifying agent; compared with impurity removal by using ethanol, the operation is simple; the production cost is low; each 1ml of prepared perfusate is equivalent to 1g of crude drugs, and has the characteristics of being low in toxicity, and free of residues; an animal body does not easily generate drug resistance; and the preparation method is suitable for preparation of the perfusate for treating cow mastitis.

Owner:HEBEI GREENLAND ANIMAL PHARMA CO LTD

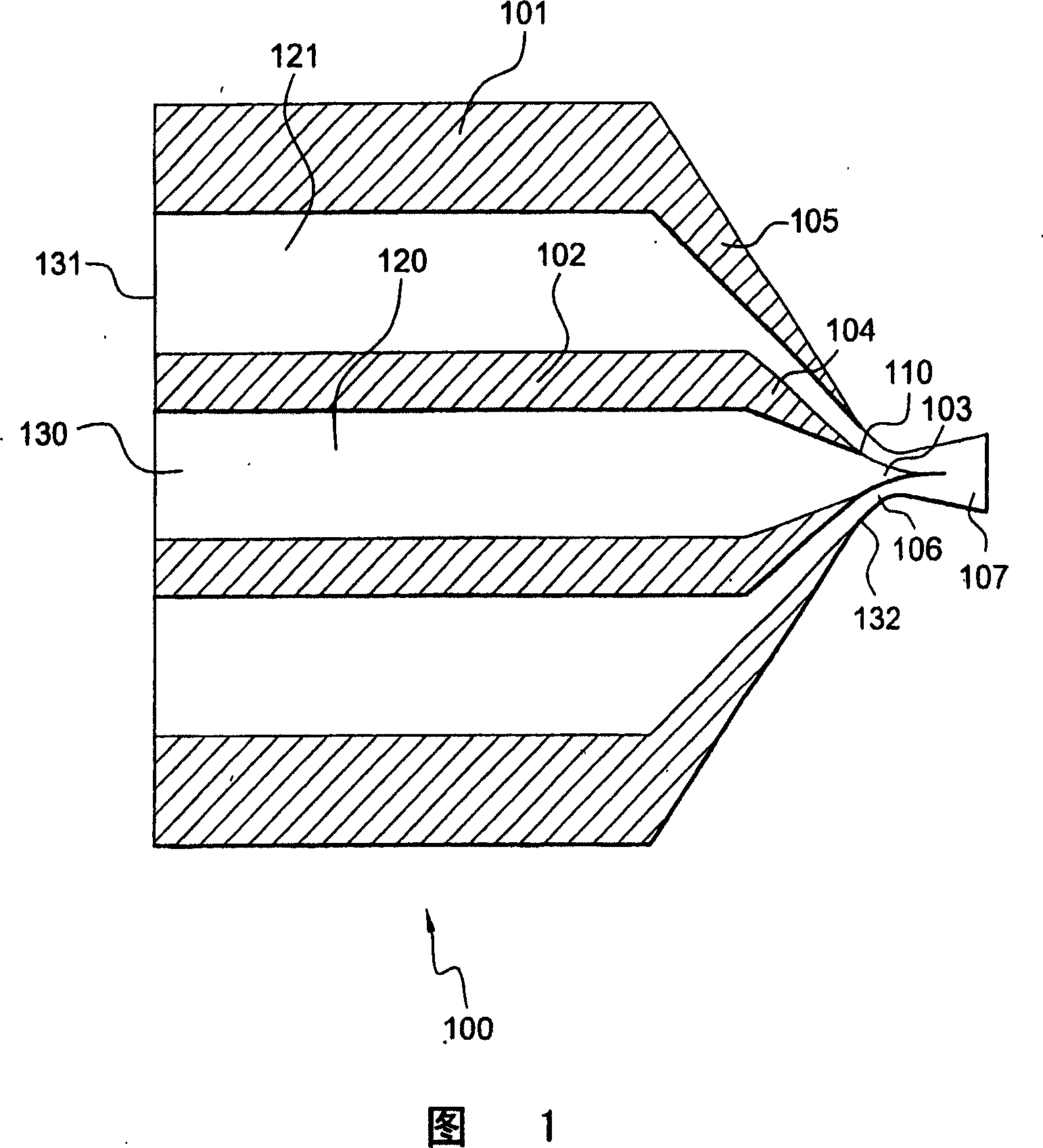

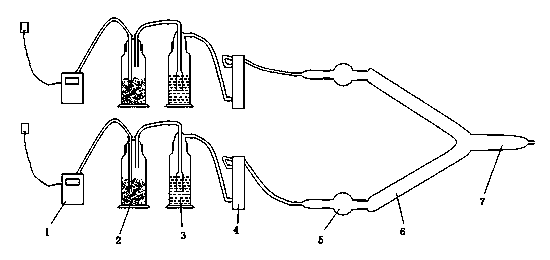

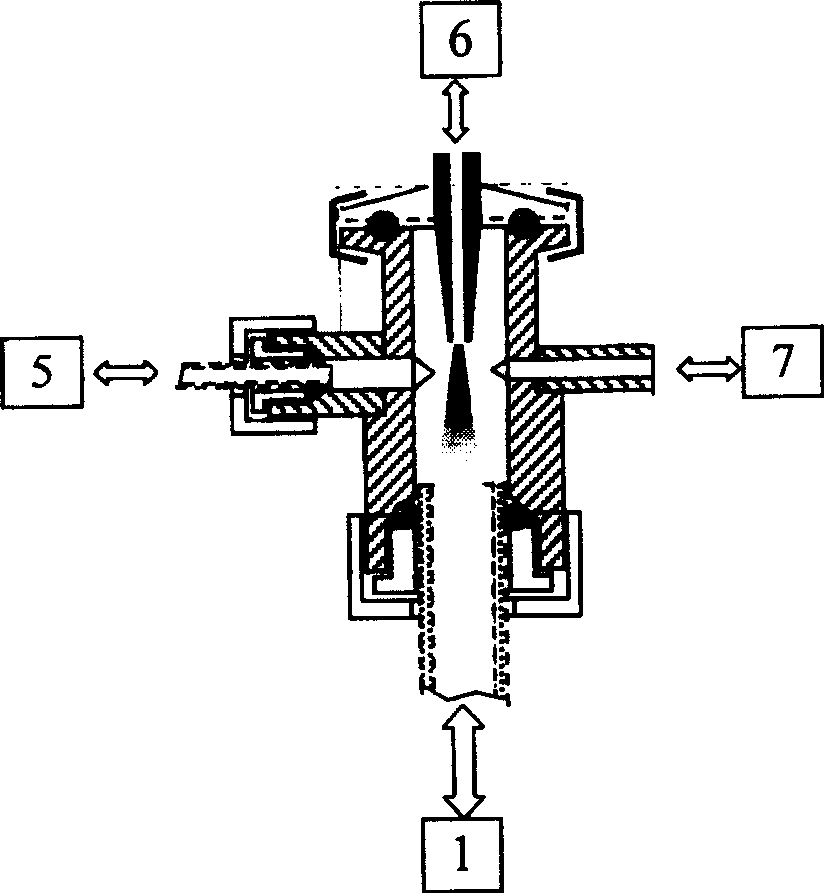

Mixer nozzle and method for mixing two or more fluids and process for manufacturing isocyanates

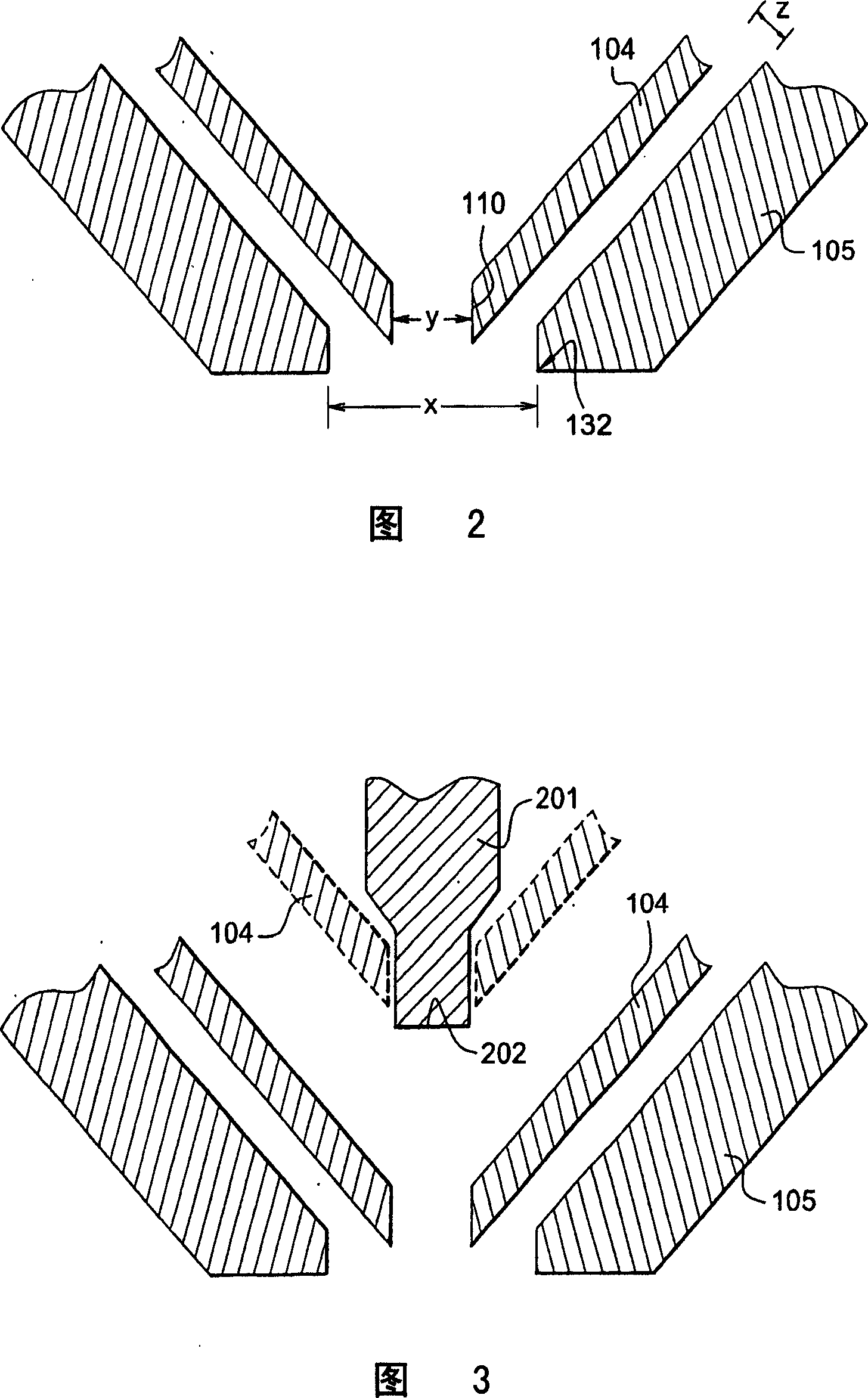

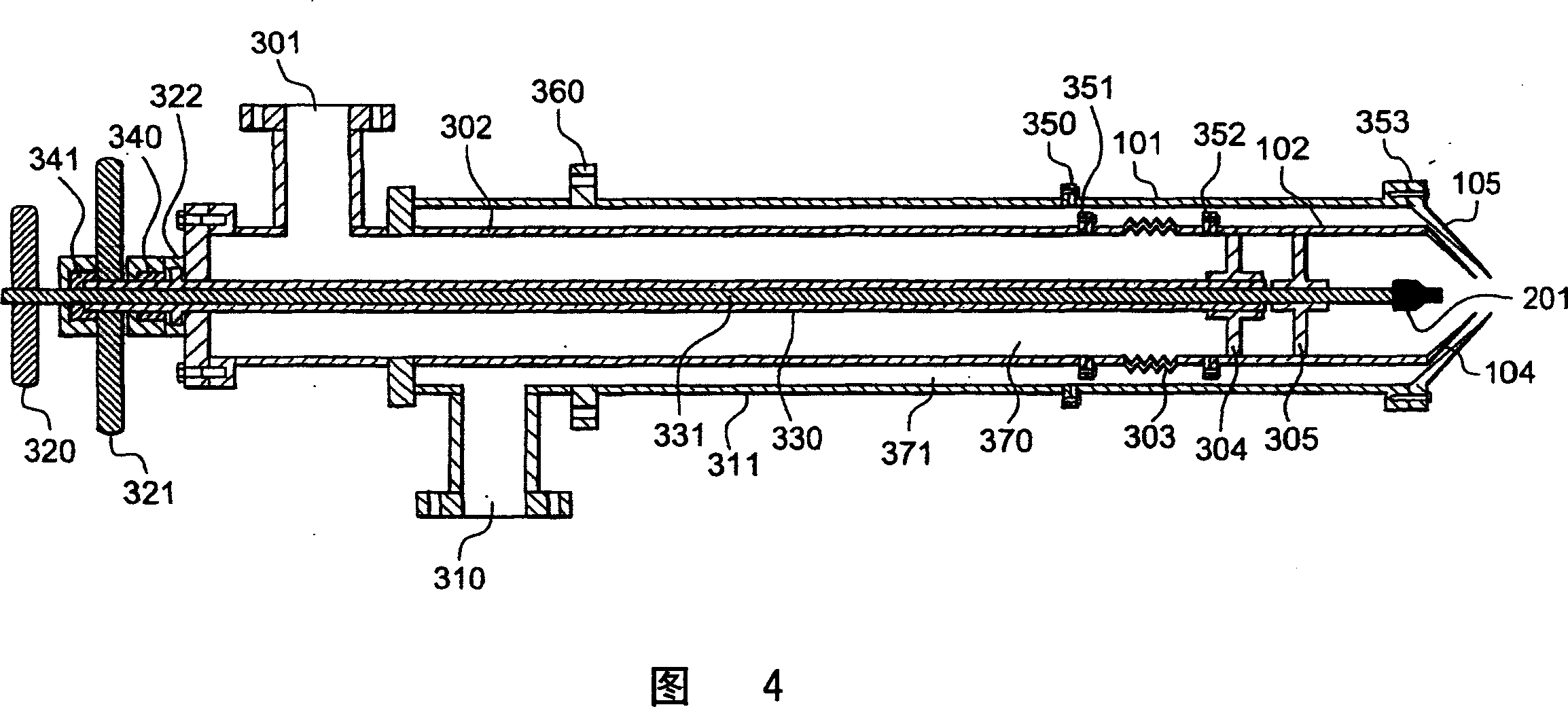

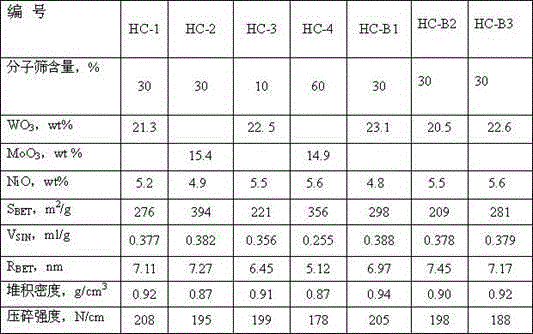

InactiveCN1964776AApplicable preparationIsocyanic acid derivatives preparationFlow mixersEngineeringPhosgene

A mixing apparatus includes coaxial first and second nozzles (104,105) that taper toward respective discharage ends (110,132) and that have rectangular cross sections. The apparatus may be used to mix fluids, for example to mix phosgene with amines to produce and isocyanates.

Owner:HUNTSMAN INT LLC

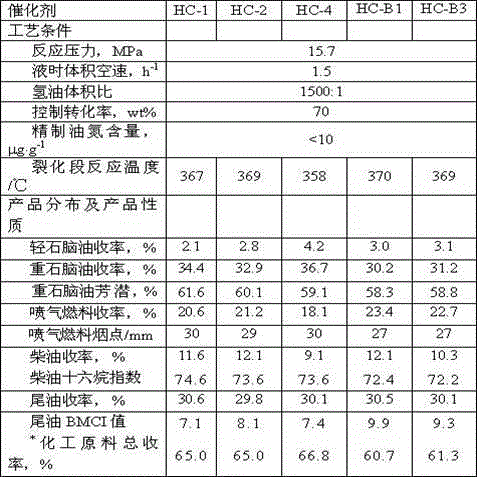

High-quality chemical raw material hydrocracking catalyst and preparation method thereof

ActiveCN104549427AImprove performanceRapid solid-liquid separationMolecular sieve catalystsMolecular sieveActive component

The invention discloses a preparation method of a hydrocracking catalyst. The preparation method comprises the following steps: (1) pulping raw material powder of a hydrocracking catalyst carrier component, performing high-temperature and high-speed stirring treatment while pulping, filtering, and drying a filter cake, wherein the hydrocracking catalyst carrier component comprises a molecular sieve, and further comprises at least one of aluminum oxide, amorphous aluminium silicon, amorphous magnesium silicon and clay; (2) shaping the dried material, drying, roasting for activating, and preparing into a catalyst carrier; (3) loading a hydrogenating active component by an impregnation method to obtain the hydrocracking catalyst. Compared with the prior art, the preparation method of the hydrocracking catalyst has the advantage as follows: by the preparation method, a synergistic effect between different components can be further promoted, so that the using performance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

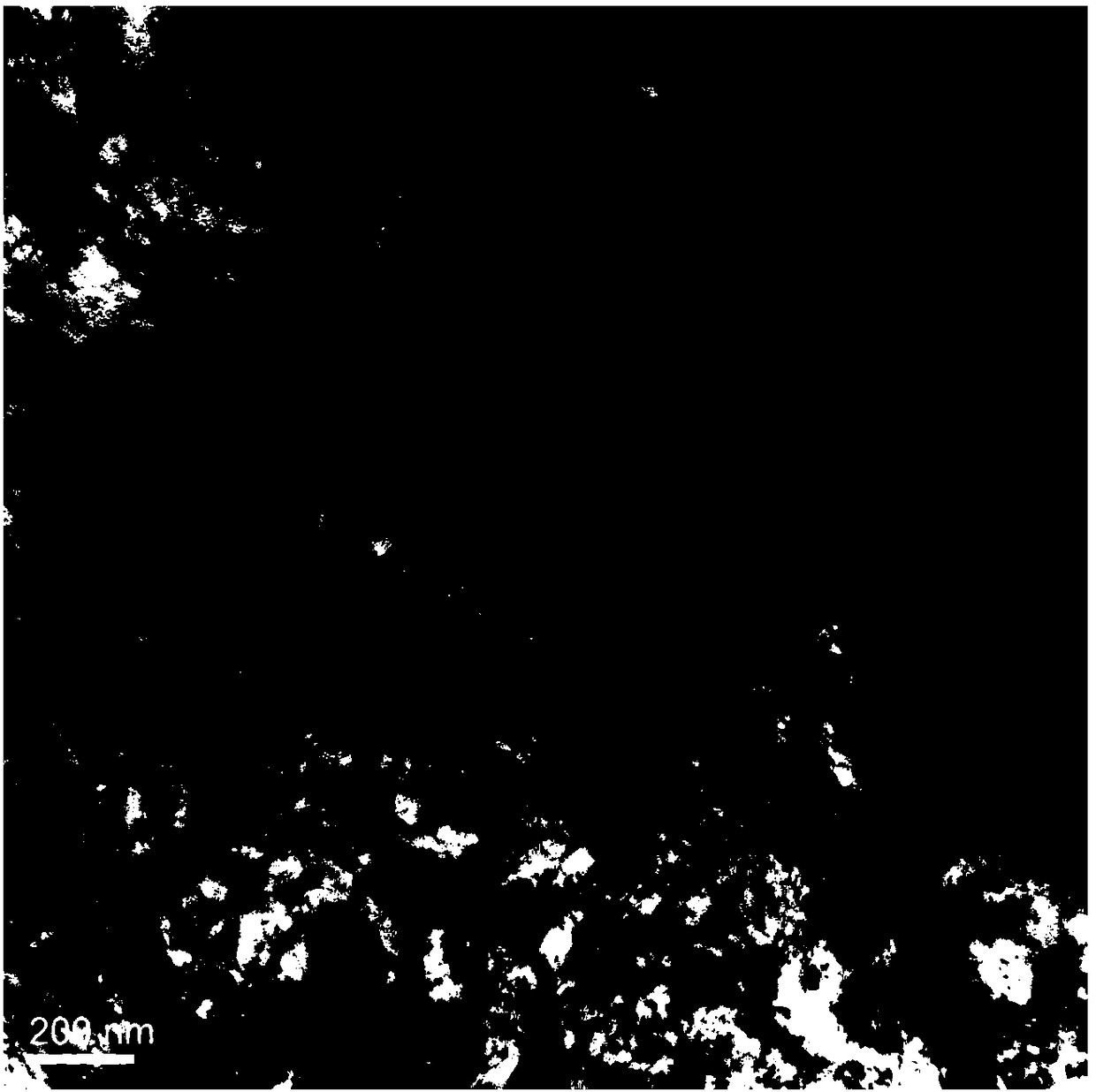

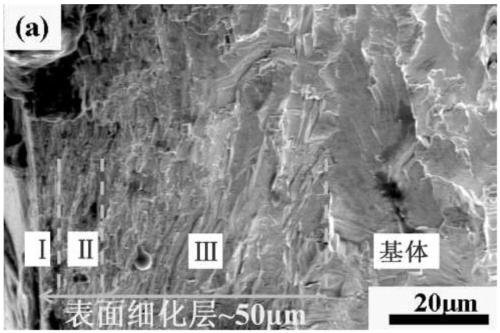

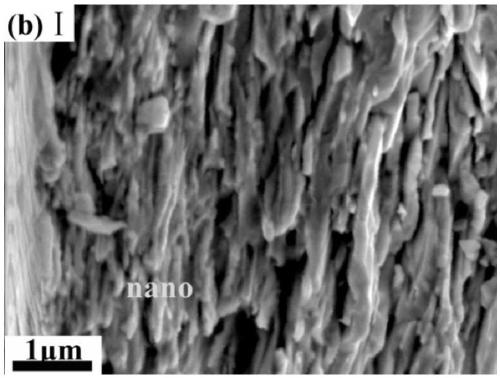

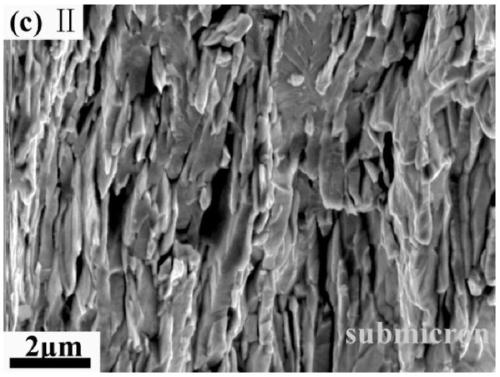

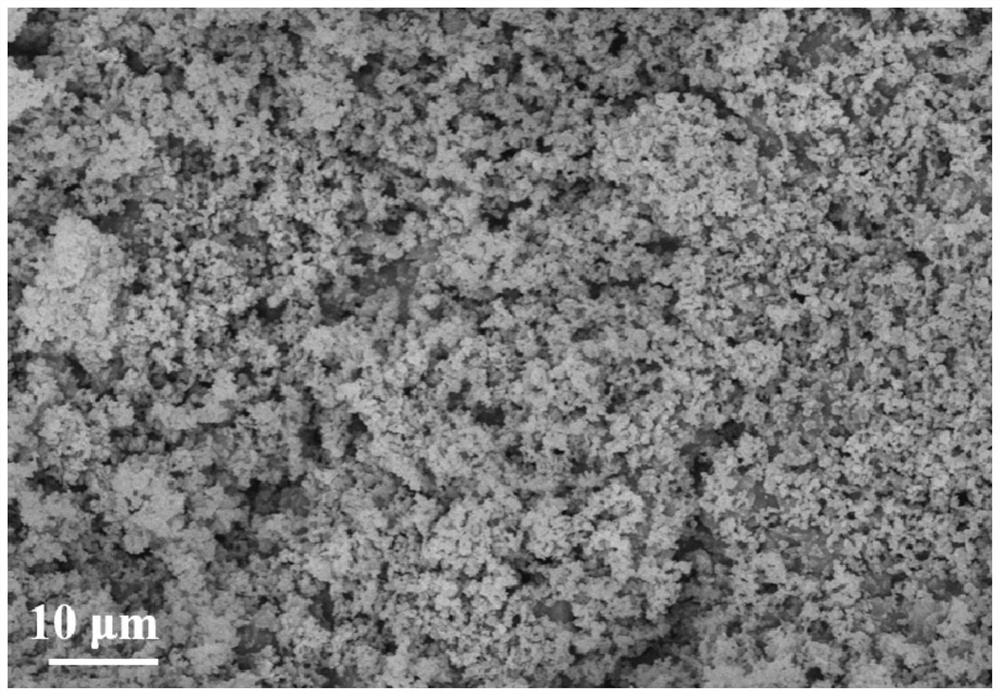

Surface multi-scale structure tungsten material and preparation method of material

The invention relates to a surface multi-scale structure tungsten material and a preparation method of the material, and belongs to the technical field of metal surface treatment. A gradient layer isarranged between the surface structure of the surface multi-scale structure tungsten material and the matrix structure, the grain size of the gradient layer is changed in a gradient mode, and the gradient layer from the surface structure to the matrix structure sequentially comprises a nano-layer, a sub-micron layer and a micro-layer, wherein the grain sizes of the nano-layer, the sub-micron layerand the micron layer are in a nanometer level, a sub-micron level and a micron level respectively. According to the surface multi-scale structure tungsten material, binding between the scale layers is good, no obvious interface exists, and micro-cracking, delamination and other phenomena are avoided. The method is easy and quick to use and suitable for preparing bulk samples.

Owner:PANZHIHUA UNIV

Aurum-nickel doped monocrystalline silicon sheet type negative temperature coefficient heat-variable resistor and method for making same

InactiveCN101399106AImprove consistencyGood repeatabilityNegative temperature coefficient thermistorsResistor manufactureDiffusion methodsOxide ceramic

The invention relates to gold and nickel doped monocrystal line silicon wafer thermistor. The thermal resistor adopts a coating source high temperature diffusion method. Transition metals of gold and nickel are used as doping agents and are doped in n-type monocrystal line silicon. The electrical compensation performance of gold and nickel in the n-type monocrystal line silicon is used for preparing negative temperature coefficient thermal-sensitive material. The scribing is implemented on a precise scribing machine. Electrodes are prepared on two ends of a chip. Two-layer structure of nickel and silver is adopted by the electrodes. The ohmic contact between silicon crastal and the electrons is realized. The silicon thermal-sensitive functional material bases on a monocrystal line silicon semiconductor and is doped with gold and nickel metal ions. A deep level capture center is formed. The material generates thermal characteristics. Through the strict control on the concentration and the distribution of the doped irons in silicon, high B value low resistance elements which are hard realized by oxide ceramic thermal-sensitive material can be realized easily. The consistency, the repeatability and the stability of the high thermal-sensitive material and the elements are improved.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

High-concentration erbium ion doped tellurium tungstate glass capable of emitting light at mid-infrared 2.7 microns

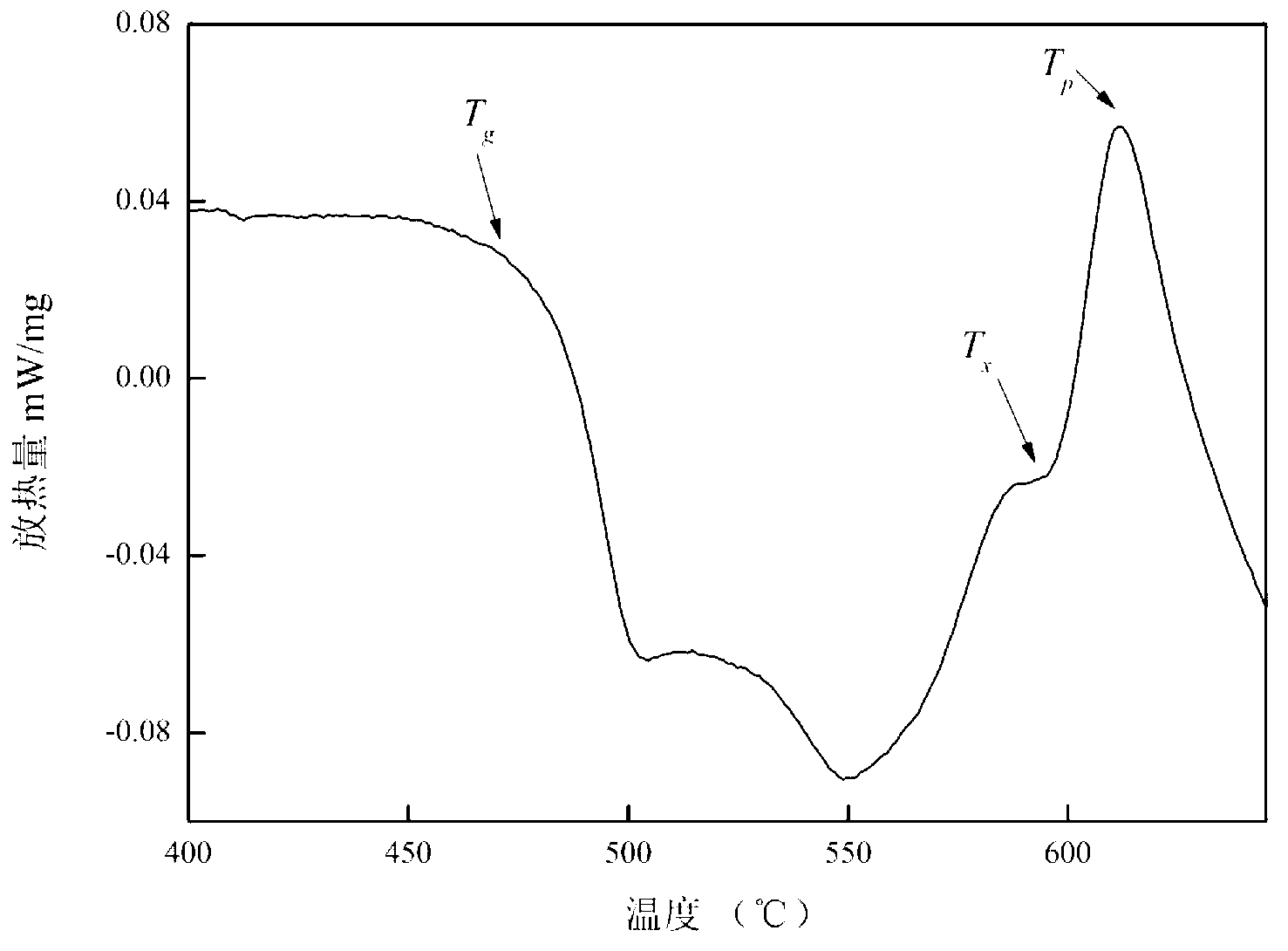

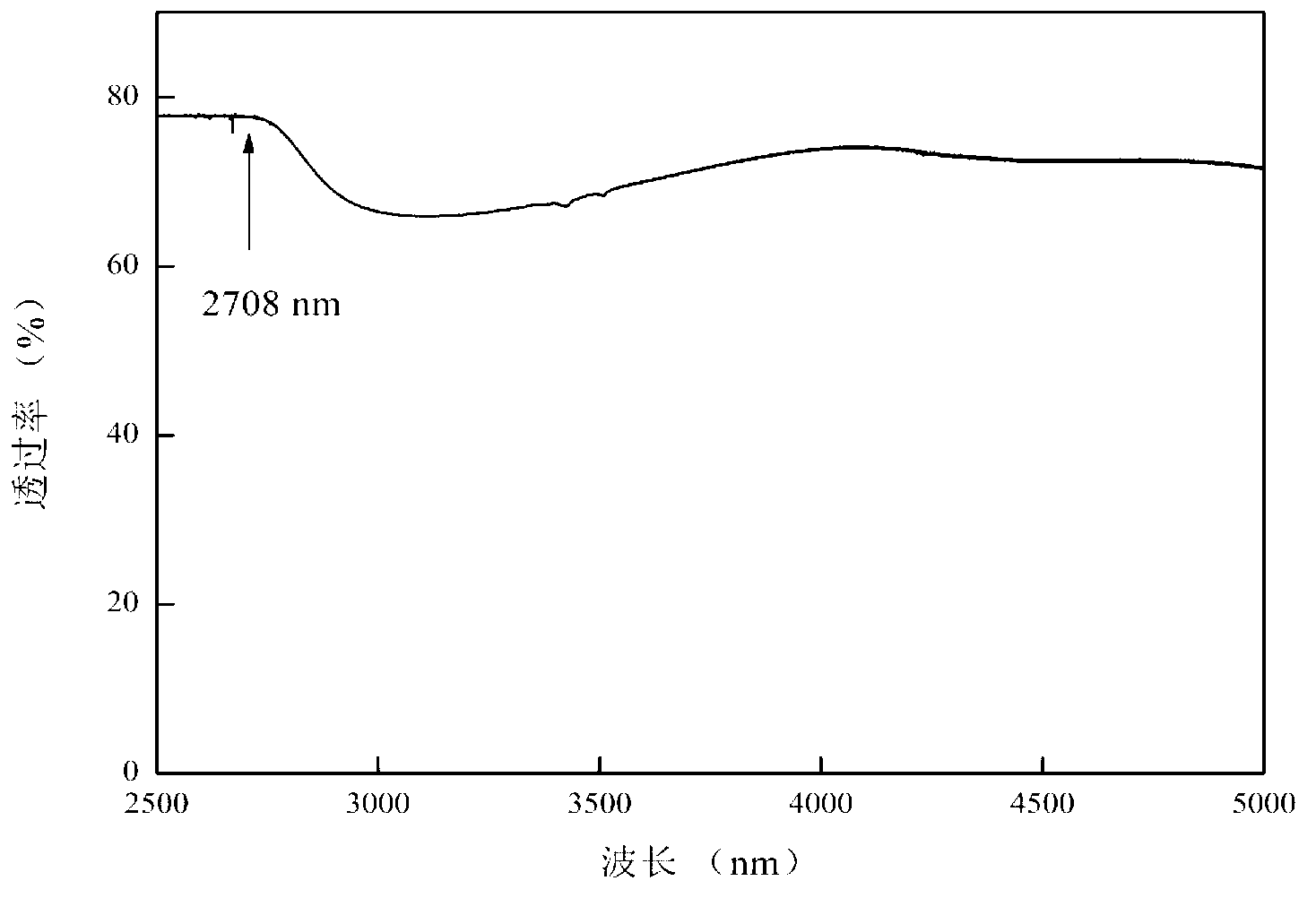

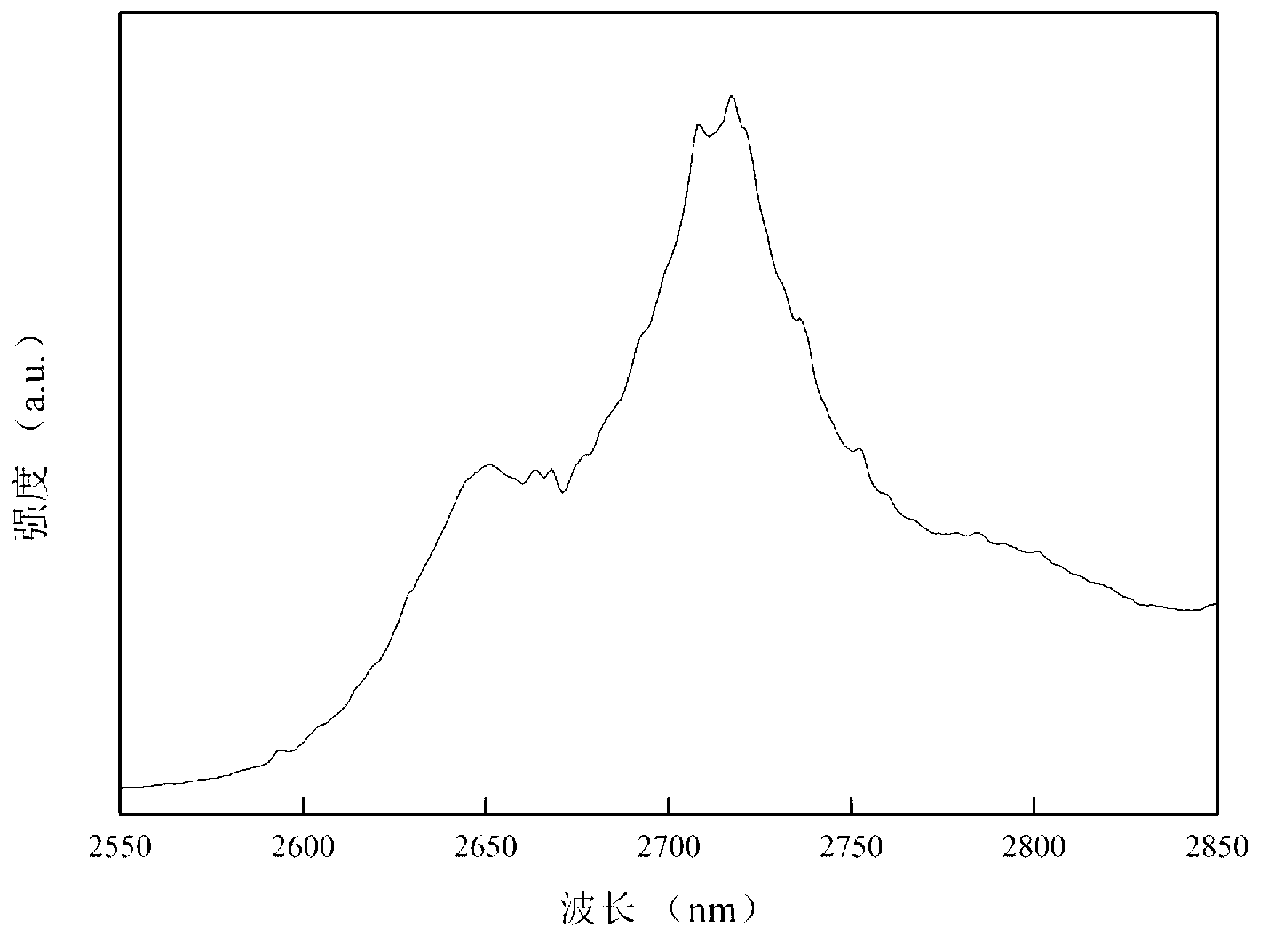

InactiveCN103058516AIncrease the doping concentrationPreparation strongStability parameterHigh concentration

The invention discloses a high-concentration erbium ion doped tellurium tungstate glass capable of emitting light at mid-infrared 2.7 microns. The glass comprises the following components by molar percent: 58-70% of TeO2, 15-25% of WO3, 0-15% of La2O3, 0-15% of LaF3 and 2-4% of Er2O3. The glass is prepared by adopting an electric furnace melting method of a corundum crucible and a silicon carbide rod. The glass is high in doping concentration of erbium ion, high in infrared transmittance near to the mid-infrared 2.7 microns and good in physicochemical properties; and the stability parameter delta T is not less than 180 DEG C. Strong mid-infrared 2.7 microns fluorescence is obtained under pumping of a laser diode with a wavelength of 980 nm; and the glass is suitable for preparation and application of erbium ion doped special glass and optical fiber materials capable of emitting light at mid-infrared 2.7 microns.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Micron macromolecular particle based on low eutectic solvent emulsion and preparation method thereof

ActiveCN109692634ARaw materials are cheap and easy to getSimple methodPharmaceutical non-active ingredientsMicroballoon preparationPolymethyl methacrylateSolvent

The invention discloses a micron macromolecular particle based on a low eutectic solvent emulsion and a preparation method thereof. A low eutectic solvent is a continuous phase and a macromolecular solution is a dispersed phase. The low eutectic solvent is a low eutectic solvent prepared with choline chloride as a hydrogen bond acceptor and DL-malic acid as a hydrogen bond donor; the macromoleculeis polymethyl methacrylate or a poly(lactic acid)-hydroxyacetic acid copolymer. The novel green solvent-low eutectic solvent is used as the continuous phase of the emulsion, a surfactant does not need to be used, the raw materials are cheap and easy to obtain, and the method is simple and has low toxicity and environmental protection. Through selection of an antisolvent, an 'anhydrous' method canbe extended, and is especially suitable for preparation of macromolecular microcapsules of unstable drugs in water.

Owner:HEFEI UNIV OF TECH

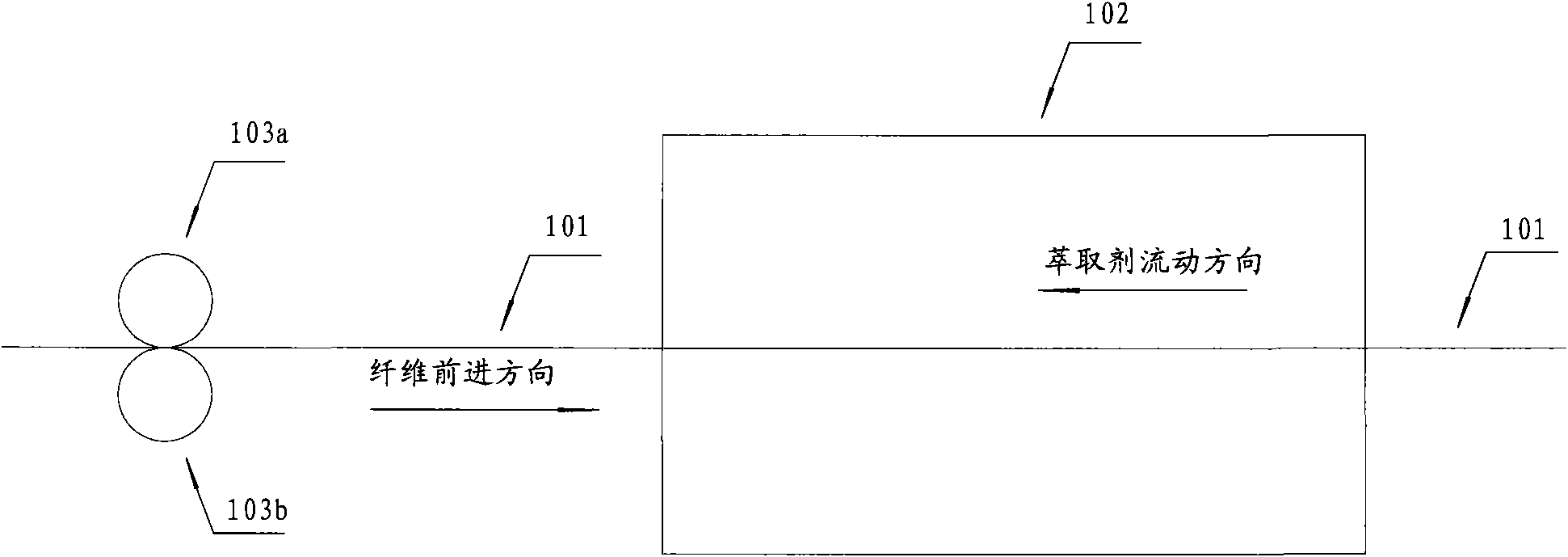

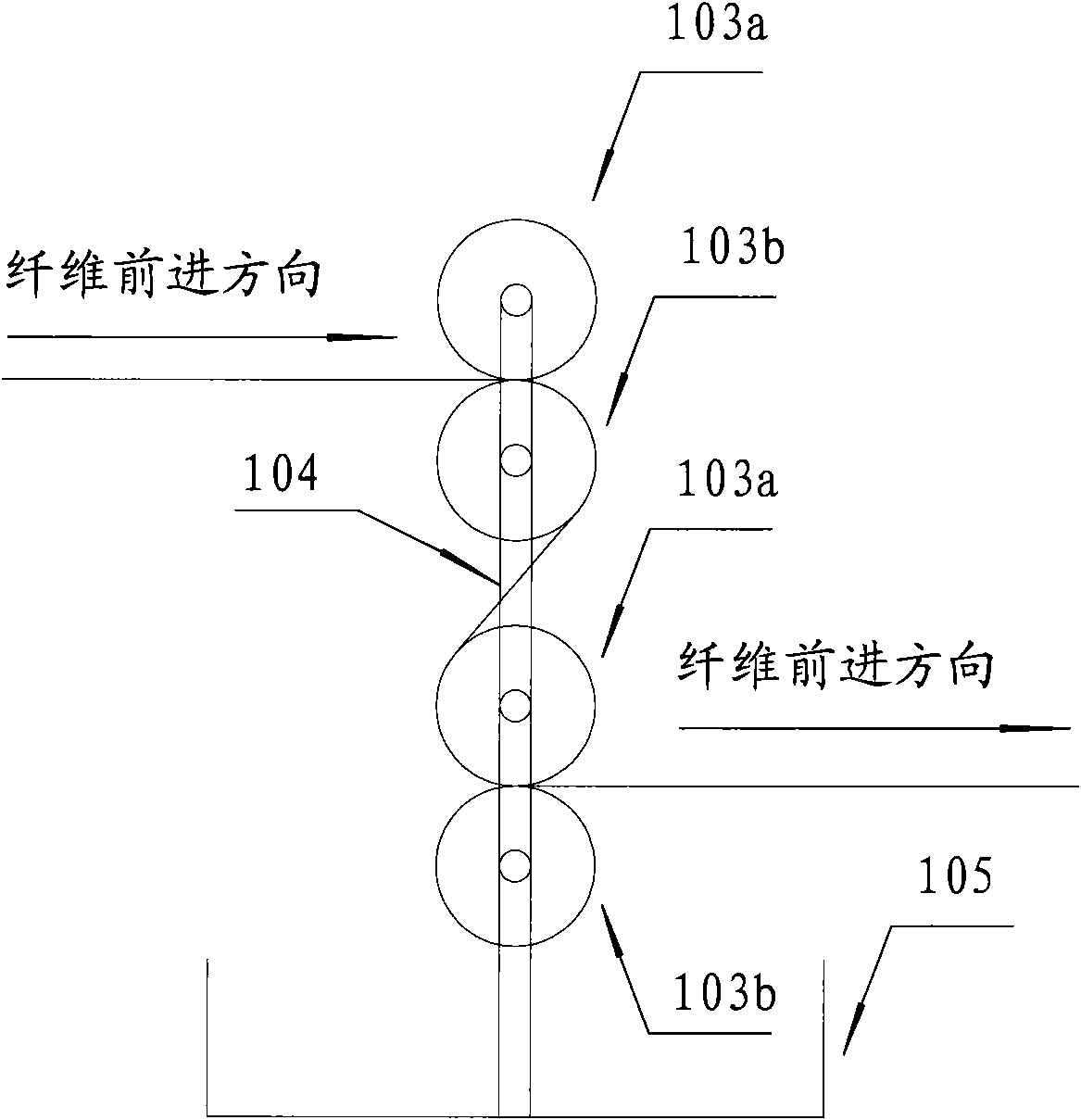

Method and device for removing solvent from polyethylene fiber

InactiveCN101629329AImprove performanceSave extraction agentArtificial thread manufacturing machinesArtificial filament washing/dryingFiberPolymer science

The invention discloses a method for removing a solvent from polyethylene fiber. The method comprises the following steps of: a) extruding polyethylene fiber; and b) extracting the solvent in the polyethylene fiber extruded in the step a). The invention also discloses a process for producing the polyethylene fiber by utilizing the method and the polyethylene fiber prepared by the method. The invention also discloses a device for removing the solvent in the polyethylene fiber; and the device comprises two or more rolls, wherein two rolls can be contacted under a certain pressure. Compared with the prior art, the method for removing the solvent in the polyethylene fiber, the device for removing the solvent in the polyethylene fiber and the process for producing the polyethylene fiber have the advantages of saving an extracting agent and improving extracting efficiency, and are particularly used for preparing the polyethylene fiber.

Owner:宁波荣溢化纤科技有限公司

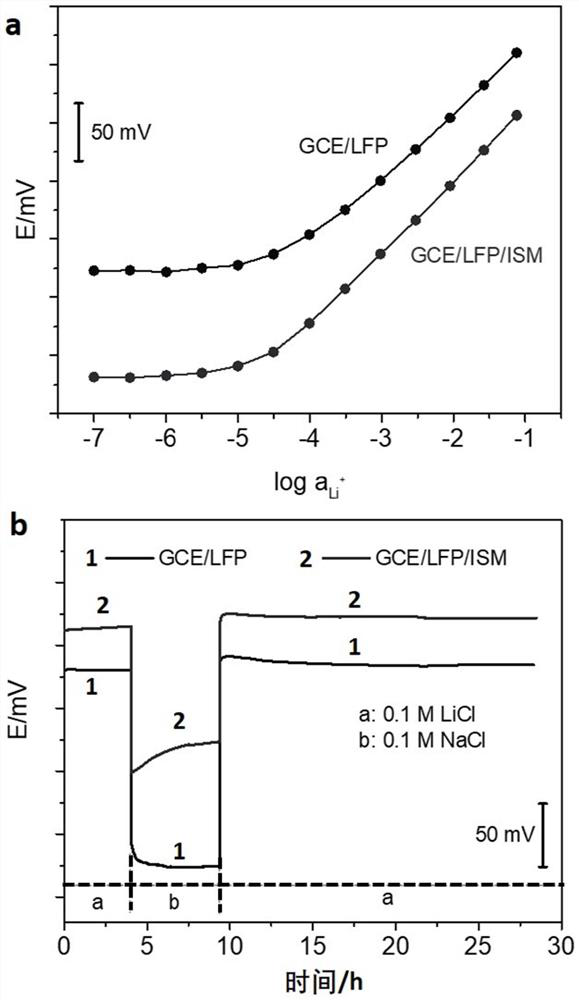

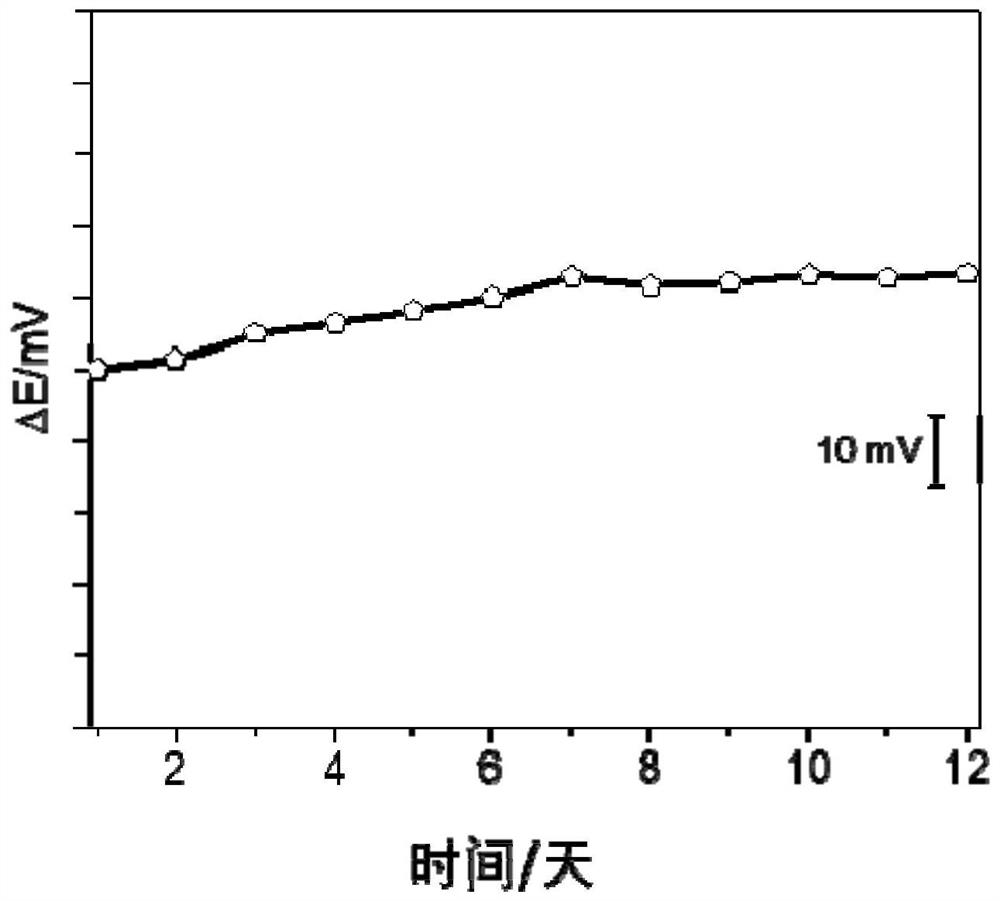

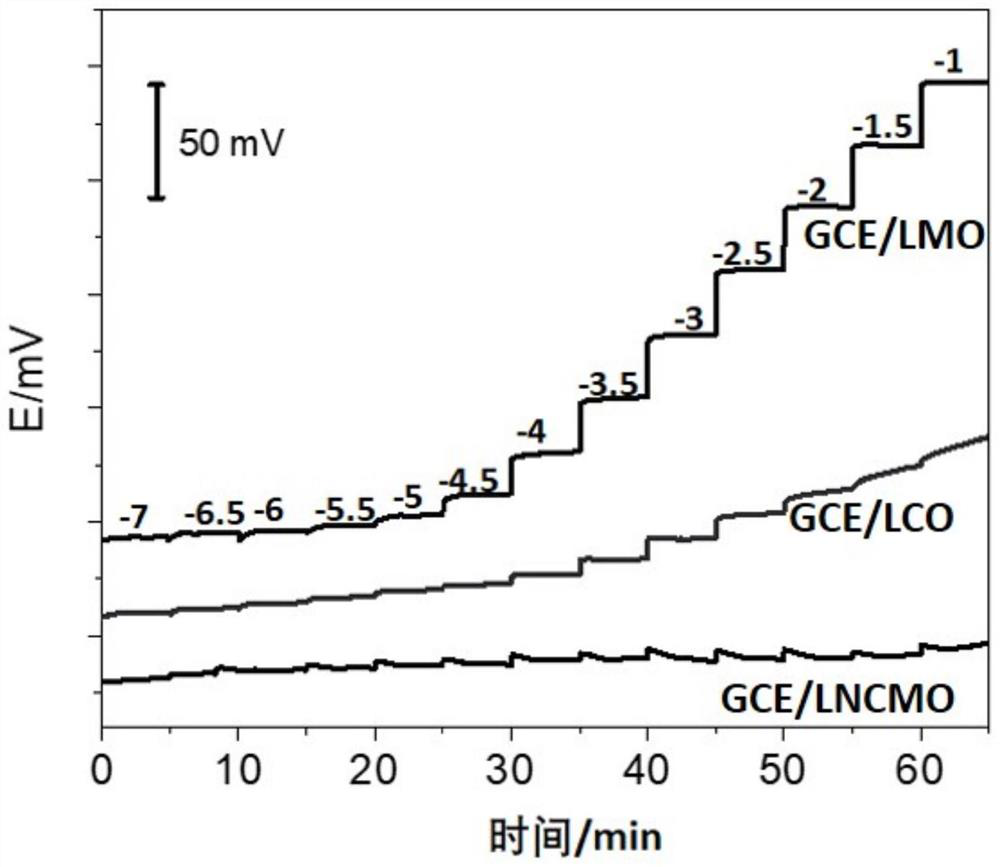

Membraneless all-solid-state ion selective electrode as well as preparation method and application thereof

PendingCN112285183AImprove mechanical propertiesSuitable for mass productionMaterial analysis by electric/magnetic meansAll solid stateLithium iron phosphate

The invention discloses a membraneless all-solid-state ion selective electrode and a preparation method and application thereof. The membraneless all-solid-state ion selective electrode is composed ofan electrode substrate and a lithium ion positive electrode material loaded on the electrode substrate. The lithium ion positive electrode material is selected from at least one of lithium iron phosphate and lithium manganate. The membraneless all-solid-state ion selective electrode shows excellent lithium ion selectivity, potential long-term stability and detection limit, and also shows excellent stability and Nernst response in artificial plasma detection. As no ion selective membrane is contained, the mechanical property of the electrode is improved, and the method is suitable for preparing a microminiaturized electrode and is high in feasibility; the raw materials are easy to prepare, can be produced in batch and are very suitable for industrial application to clinical diagnosis.

Owner:GUANGZHOU UNIVERSITY

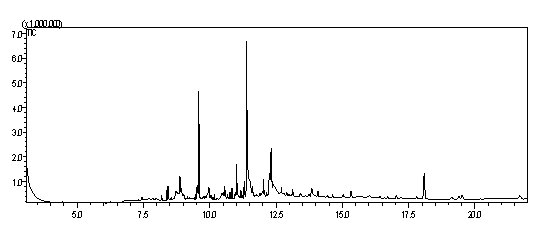

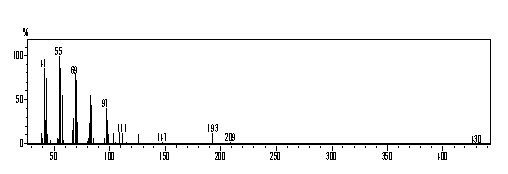

Bactrocera minax sex pheromone, and extraction method and application thereof

The invention relates to bactrocera minax sex pheromone, and an extraction method and an application thereof. A main active component of the bactrocera minax sex pheromone provided by the invention is undecanol. The extraction method of the bactrocera minax sex pheromone comprises the steps of immersing bactrocera minax sex pheromone in a mating season in ethyl ether for 20 s-300 s; analyzing by using a gas chromatography-mass spectrometer to obtain chemical components of an extract liquid; and determining activities of the chemical components in the extract liquid by using a Y-type olfactometer. The bactrocera minax sex pheromone provided by the invention can be used as a sex attractant for monitoring field occurrence conditions of the bactrocera minax and disturbing mating of the bactrocera minax by mating disruption, and can be used as an attractant to trap and kill the bactrocera minax. The extraction method of the bactrocera minax sex pheromone is simple in operations, high in reproducibility and small in required bactrocera minax amount. Besides, a preparation period is short and result reliability is high.

Owner:HUNAN NORMAL UNIVERSITY

Fire extinguishing device and seal method thereof

The invention discloses a fire extinguishing device and a seal method thereof. The fire extinguishing device comprises a fire extinguishing device container, a fire extinguishing agent, a detonating pipe and a lead, wherein the top of the detonating pipe is provided with a groove which is matched with an opening of the fire extinguishing device container in shape and fused with the opening of the fire extinguishing device together. Compared with the prior art, the fire extinguishing device has the advantages that the top of the detonating pipe is provided with the groove which is matched with the opening of the fire extinguishing device container in the shaps; when the groove is fused with the opening of the fire extinguishing device together, a plurality of matching surfaces are formed, and the contact area is increased; the force for resisting the fire-extinguishing agent from leaking out of the fire extinguishing device is greatly increased, and the formation of a bending line after matching also increases the difficulty of the fire-extinguishing agent leaking out of the fire extinguishing device, thereby greatly reducing the liquid leaking efficiency of the fire extinguishing device. The fire extinguishing device is particularly suitable for preparing an explosive fire extinguishing device.

Owner:安徽成威消防科技有限公司

Method for transforming N-cyanomethyl bis(trifluoromethyl) nicotinamide into flonicamide and application thereof

ActiveCN107417606ASuitable for industrial productionEasy to operateOrganic chemistryMedicinal chemistryImpurity

The invention discloses a method for transforming N-cyanomethyl bis(trifluoromethyl) nicotinamide into flonicamide. A transforming reagent is adopted, so that transformation rate of transforming the N-cyanomethyl bis(trifluoromethyl) nicotinamide into the flonicamide is 98.1-99.8%, and purity is 97.1-99.5%. The invention also provides application of the method for transforming the N-cyanomethyl bis(trifluoromethyl) nicotinamide into the flonicamide, not only impurities can be transformed into the flonicamide with pharmaceutical value, but also the impurities produced in a transformation process can be recycled, so that the final yield of the flonicamide is 69.59-75.83%, and the method is more applicable to industrial production. The method disclosed by the invention is applicable to preparation of the flonicamide.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

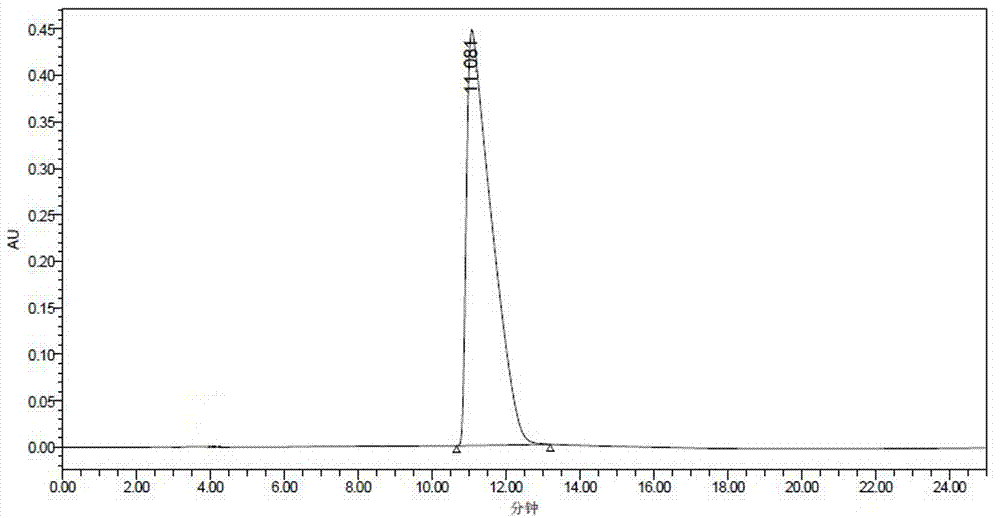

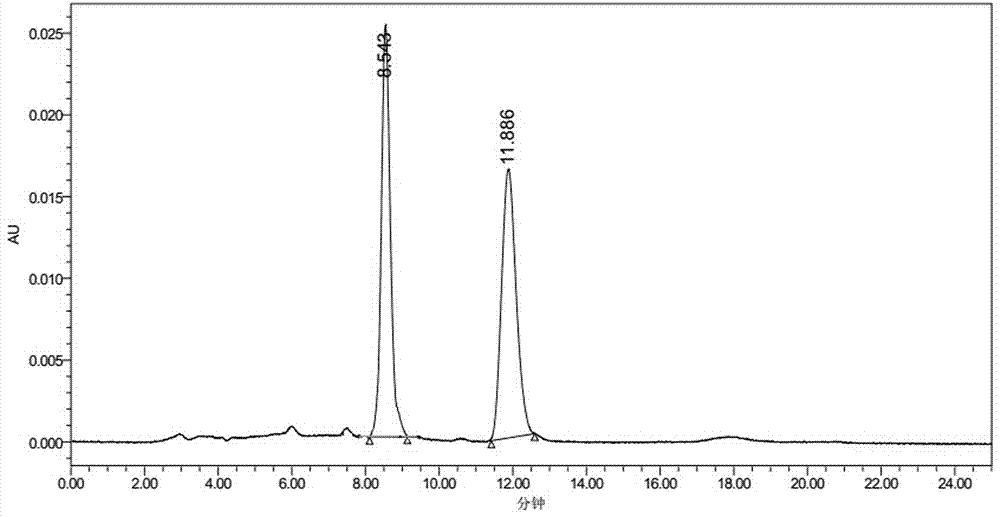

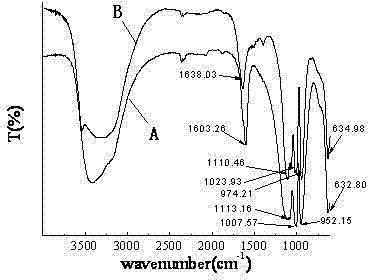

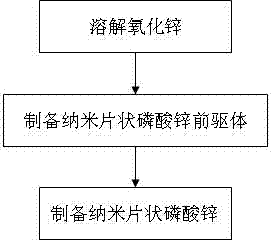

Preparation method of nanometer sheet-shaped zinc phosphate

ActiveCN104495776ASimple structureNo apparent reunionMaterial nanotechnologyPhosphorus compoundsZinc phosphateMaterials science

The invention discloses a preparation method of nanometer sheet-shaped zinc phosphate. The preparation method comprises 1, dissolving zinc oxide, 2, preparing a nanometer sheet-shaped zinc phosphate precursor and 3, preparing nanometer sheet-shaped zinc phosphate. The nanometer sheet-shaped zinc phosphate has an obvious lamellar structure and no obvious agglomeration. The nanometer sheet-shaped zinc phosphate is used in paint, produces labyrinth effects, increases water transmission paths and prolongs a coating service life. The preparation method has simple requirements on experiment conditions, utilizes the raw materials with a wide source, realizes recovery and recycle of a waste liquid, saves an economic cost and has environmental protection benefits. The preparation method is suitable for preparation and production of the nanometer sheet-shaped zinc phosphate.

Owner:STATE GRID CORP OF CHINA +2

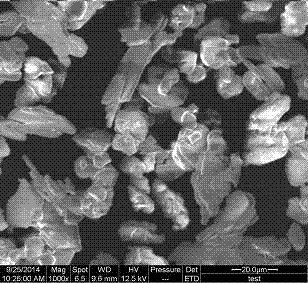

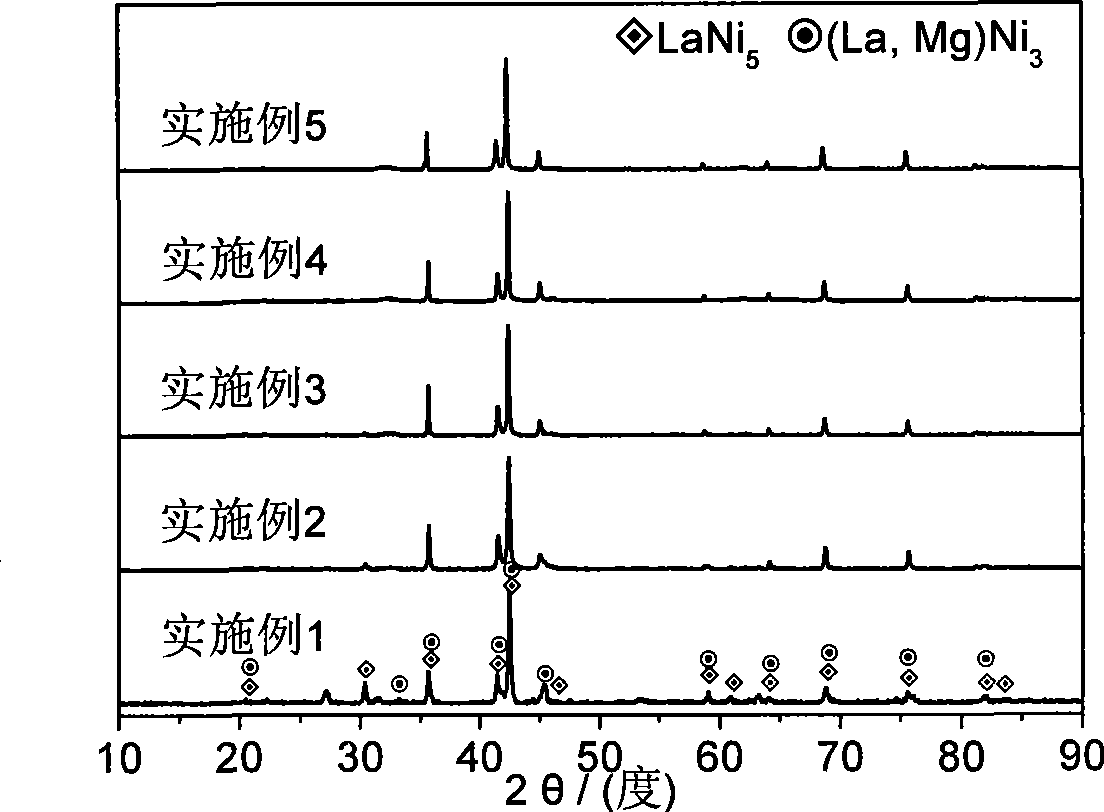

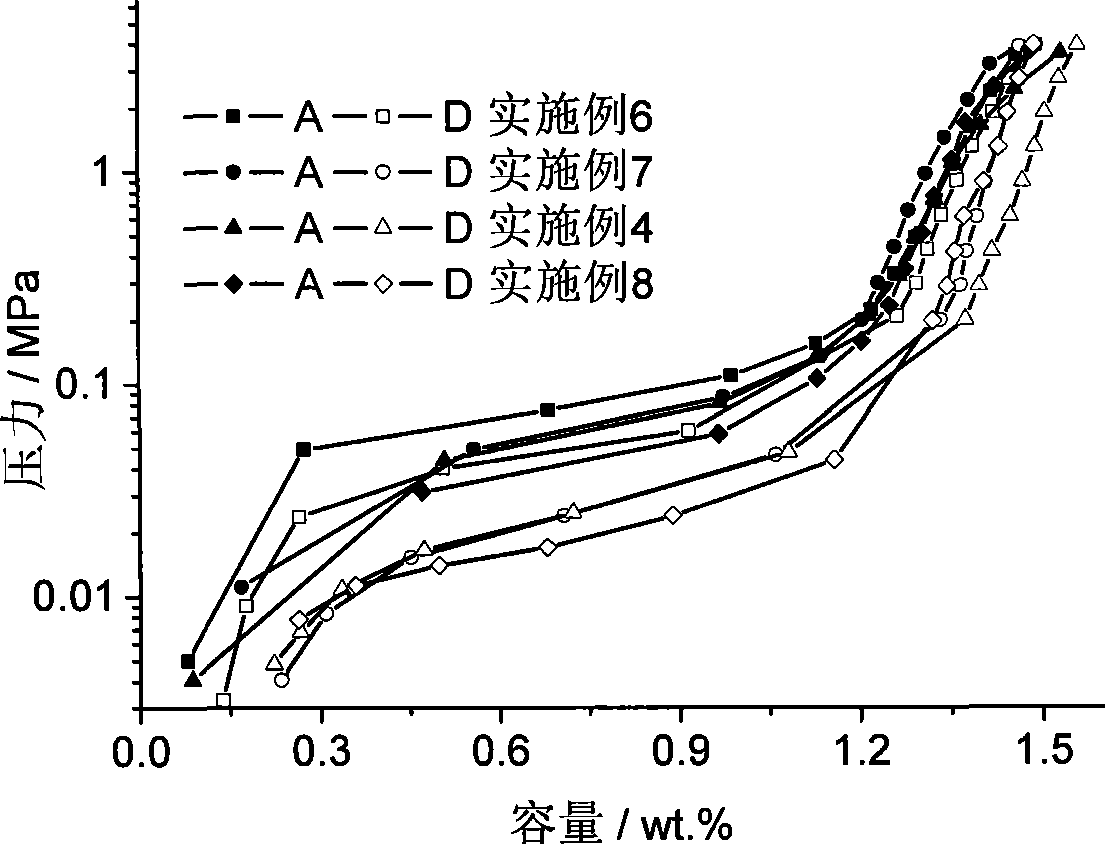

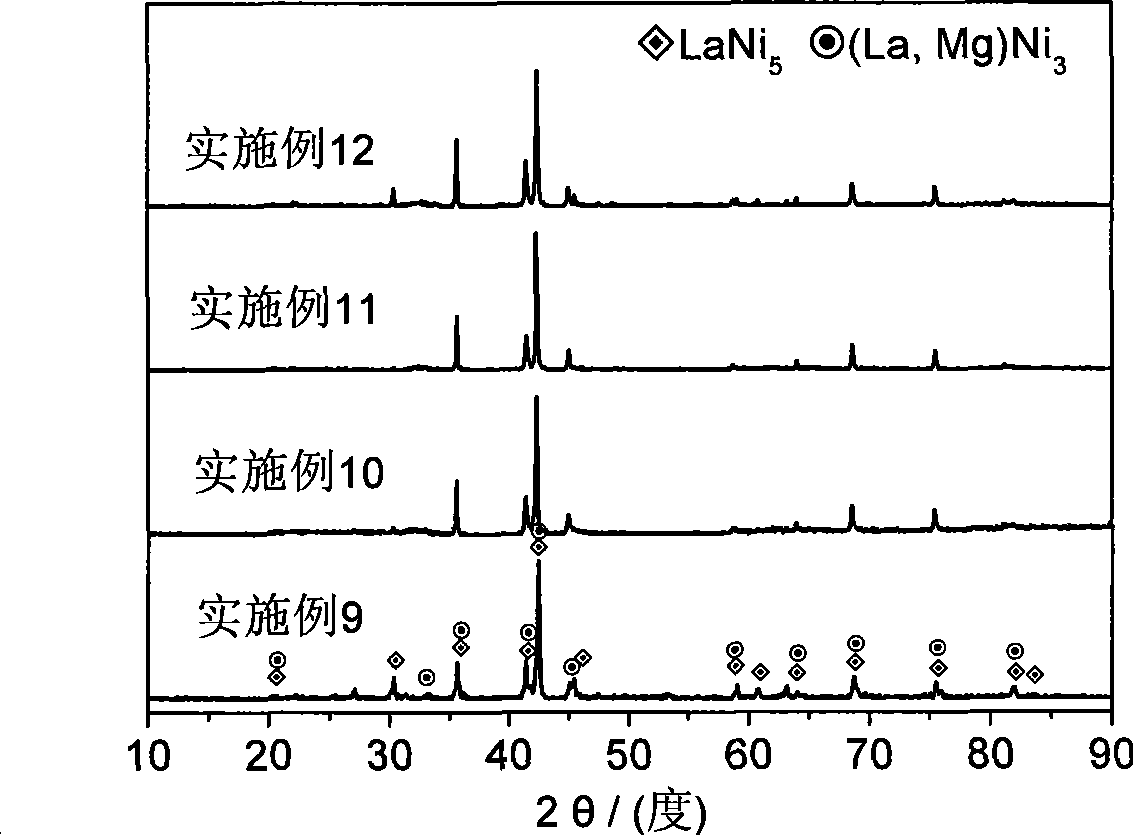

Method for sintering La-Mg-Ni based type AB3 hydrogen storage alloy in magnetic field

The invention relates to a method for preparing La-Mg-Ni based AB3 type hydrogen storage alloy by magnetic field sintering, which belongs to the technical field of metallic functional material and powder metallurgy. The method mainly comprises the following steps: firstly, mixing La and Mg metal powder or master alloy La2Mg prepared by a molten salt method with one or two of Ni powder, Co powder or Cu powder according to the atom molar mass proportion of AB3, and pre-ball milling the mixture by adopting proper technology; secondly, pressing the milled and mixed raw material powder under a pressure of between 200 and 500MPa into a cake of Phi 15mmx(3-5)mm, putting the cake into a self-made high-pressure reaction kettle and filling 0.5MPa argon after repeated vacuum pumping; and finally putting the high-pressure kettle into a steady high magnetic field of between 1 and 8T and heating to between 610 and 850 DEG C, sintering the cake and slowly reducing the temperature to obtain the La-Mg-Ni based AB3 type hydrogen storage alloy. The material prepared by the method has the advantages of high activity, even compositions, low impurity content and the like. Electrochemistry and PCT tests find that the hydrogen storage material has high capacity and better comprehensive performance.

Owner:SHANGHAI UNIV

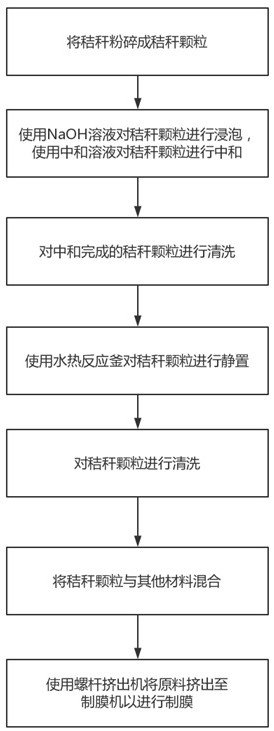

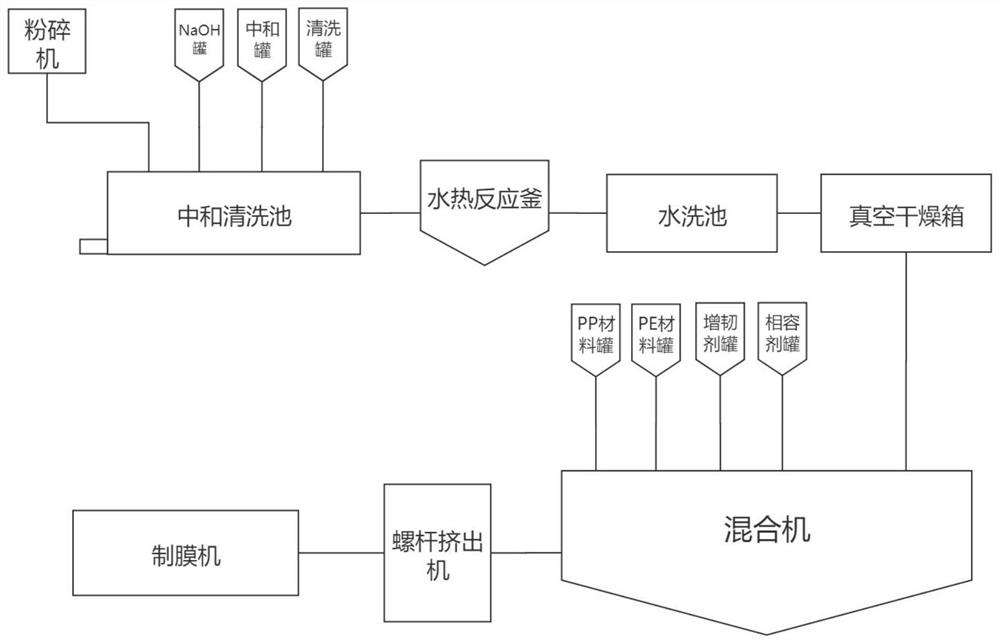

Preparation process for polypropylene composite film based on bio-based wheat straw

ActiveCN112123620AApplicable preparationQuality improvementPolymer chemistryPolypropylene composites

The invention relates to a preparation process for a polypropylene composite film based on a bio-based wheat straw. The preparation process comprises the following steps of conveying crushed straw particles to a neutralizing and cleaning tank; neutralizing and cleaning the straw particles in the neutralizing and cleaning tank; making the straw particles stand in a hydrothermal reactor at constanttemperature; drying the straw particles through a vacuum drying box; mixing the straw particles with raw materials through a mixing machine; and outputting the materials to a film making machine through a screw extruder for film production. According to the preparation process, a central control unit is connected with a corresponding component, a matrix Ri is established according to the comparison result of the straw mass Ma and each value in the Ma0 matrix so as to control each device to select a corresponding operation parameter, and a matrix Sj is established according to the comparison result of the straw particle mass Mb and each value in the Mb0 matrix so as to select the amount of the corresponding raw materials and a preparation process. High-quality composite materials can be rapidly prepared while it is ensured that the content of straw particles is within a preset range, and the preparation efficiency of the process is improved.

Owner:瑞年科技(广东)有限公司

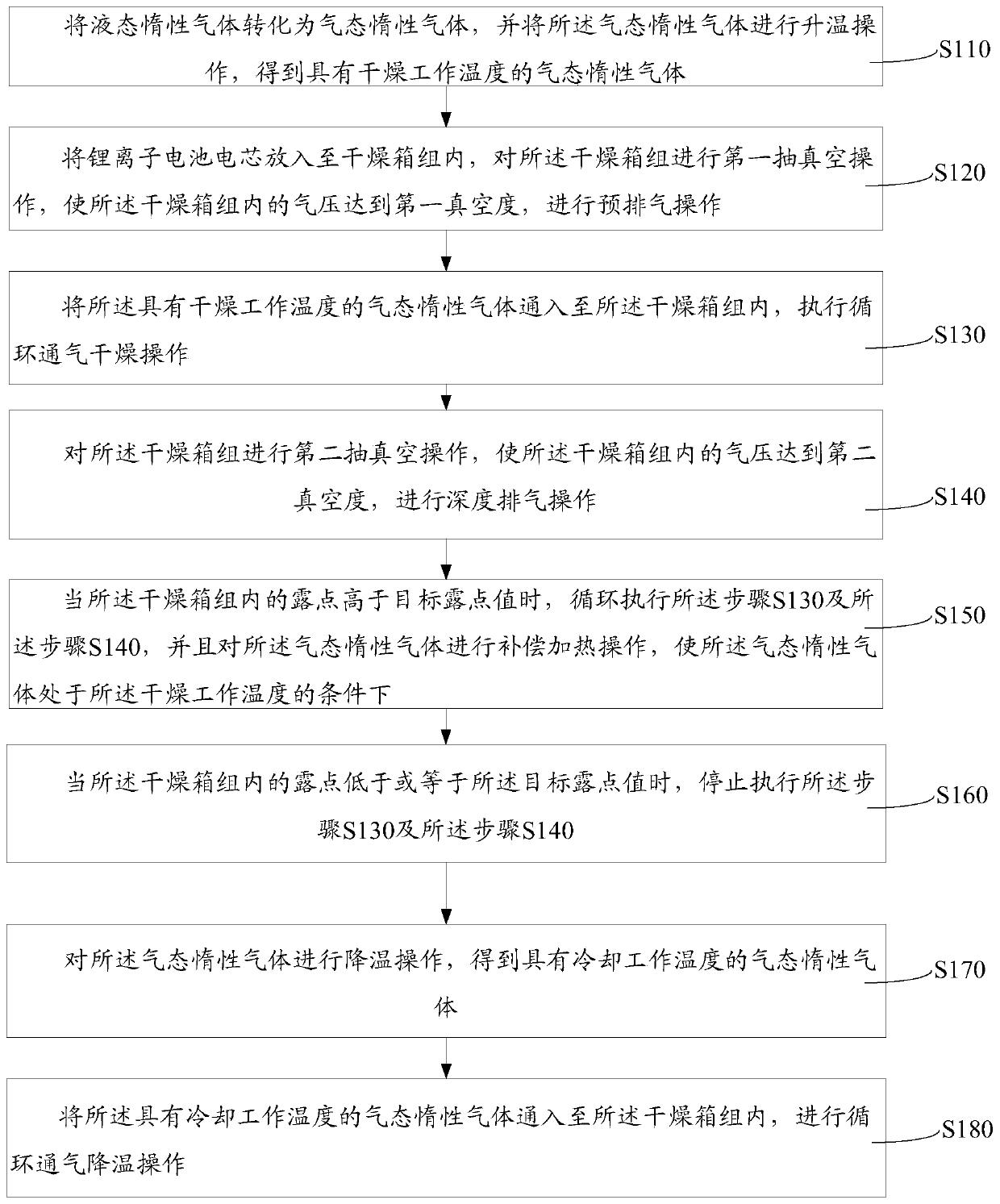

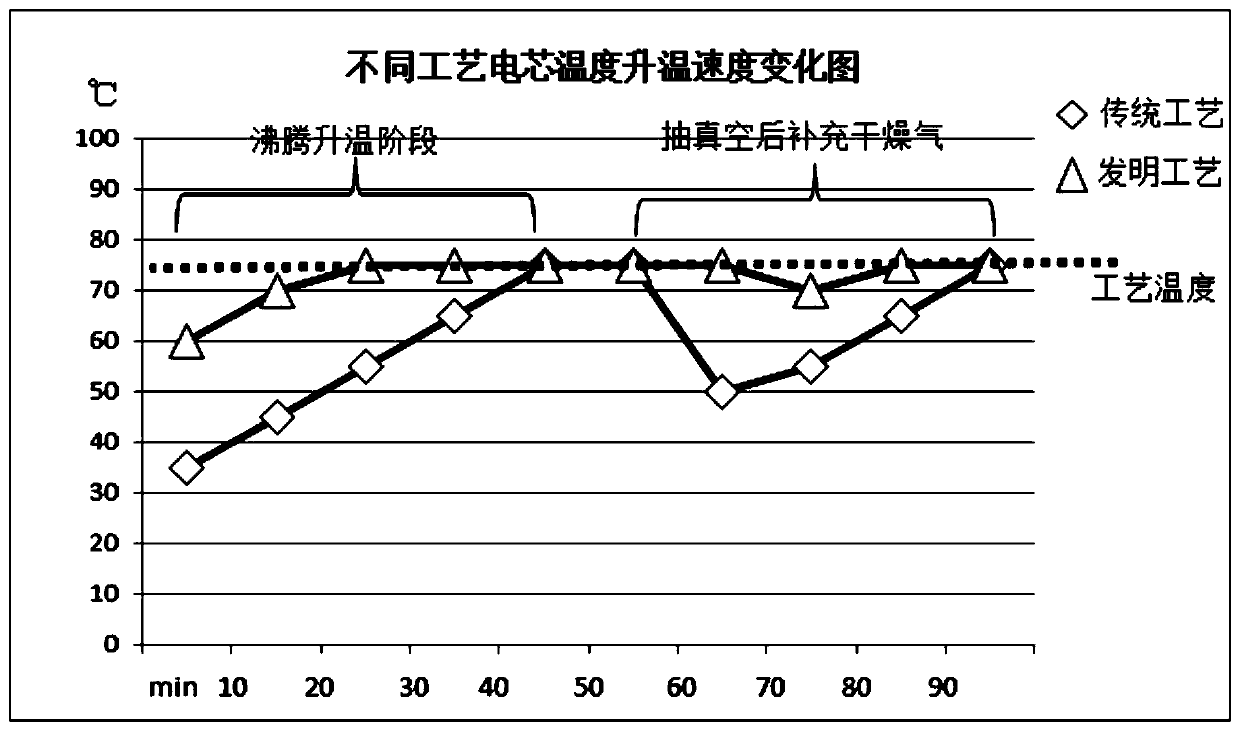

Method for drying lithium ion battery cell before liquid injection

ActiveCN110425825AImprove drying efficiencyEnsure consistencyFinal product manufactureDrying solid materials without heatElectrical batteryWorking temperature

The invention relates to a method for drying a lithium ion battery cell before liquid injection. The method comprises the steps of converting liquid inert gas into gaseous inert gas, and then carryingout temperature rising operation to obtain the gaseous inert gas with a drying working temperature; putting the lithium ion battery cell into a drying box group, and carrying out first vacuumizing operation on the drying box group; introducing the gaseous inert gas with the drying working temperature into the drying box group, and carrying out circulating aeration drying operation; next, carryingout second vacuumizing operation on the drying box group, when the dew point in the drying box group is higher than the target dew point value, circularly executing the circulating aeration drying operation and the second vacuumizing operation, and compensating and heating the gaseous inert gas; stopping executing the circulating aeration drying operation and the second vacuumizing operation whenthe dew point in the drying box group is lower than or equal to the target dew point value; and finally, carrying out the circulating aeration cooling operation. Therefore, energy can be saved, the temperature of the drying gas is more stable, and the drying efficiency of the lithium ion battery cell is higher.

Owner:HUIZHOU HENGTAI TECH

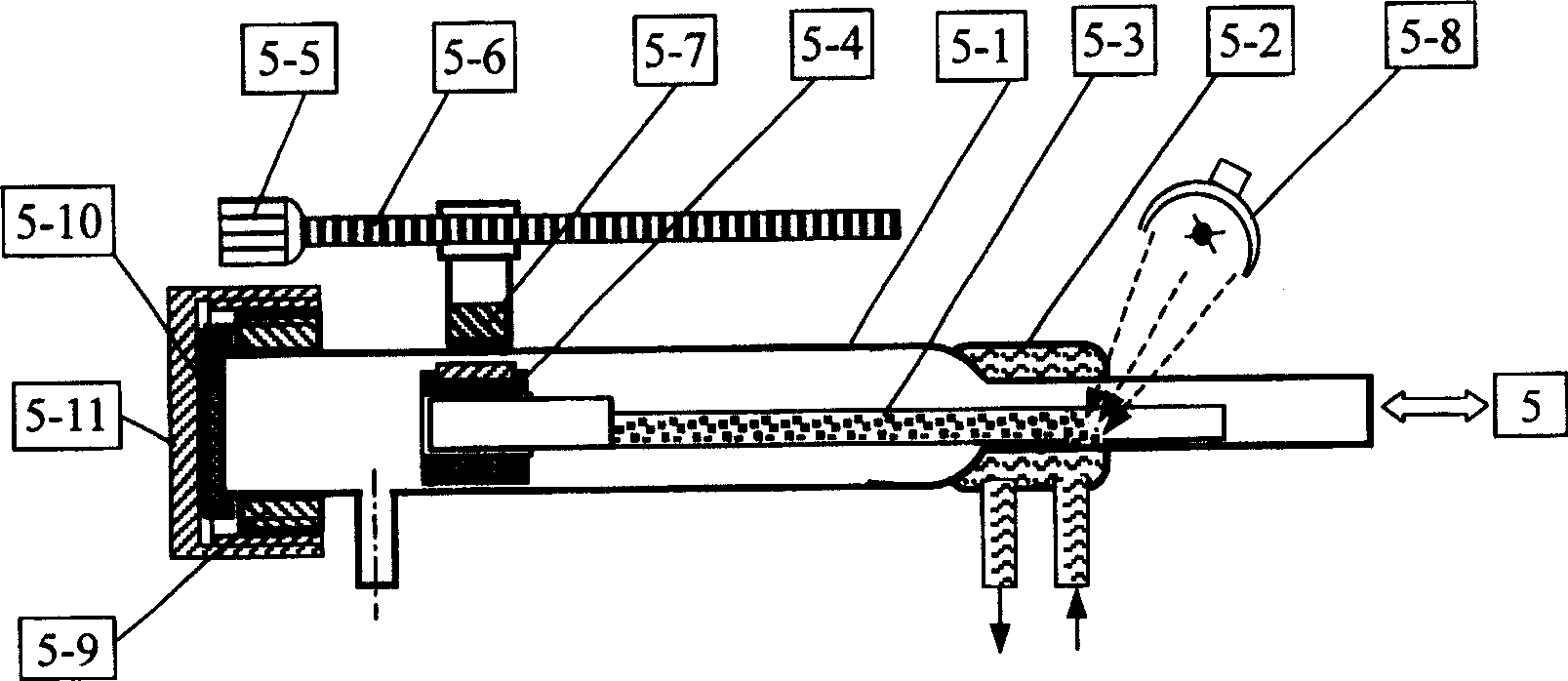

Production of multifunctional gas-phase depositer and solid oxide fuel single cell

InactiveCN100462476CImprove efficiencyReduce energy consumptionVacuum evaporation coatingSputtering coatingGas phaseSource material

The present invention discloses a multifunctional vapor deposition device and the preparation process of solid oxide fuel cell. The invention features of the multifunctional vapor deposition device and different functional ceramic film. The multifunctional vapor deposition device integrates the functions of solid source chemical vapor deposition of beta-diketone-metal complex, aerosol chemical vapor deposition of the source solution, plasma enhancing, ultraviolet source activation and heating assisted by heat light source. The functional ceramic films use prepared porous supporting cathode or anode as lining, and prepare unit cells orderly in situ at 600-1000DEG C via vapor deposition technology or the combination of multiple technologies. The invention avoids distortion, cracks or residual stress occurring in multilayer co-sintering at high temperature. The layers of unit have easily controllable composition and microstructure. The source materials is low corrosiveness and easy to prepare, has a rich resource. The invention can be applied to the preparation of tubular solid oxide cell or planar cell.

Owner:UNIV OF SCI & TECH OF CHINA

Small-site organic fertilizer preparation method

InactiveCN106631579AHigh organic contentReduce the incidence of pests and diseasesExcrement fertilisersFertilizer mixturesWater contentChemistry

The invention discloses a small-site organic fertilizer preparation method. The small-site organic fertilizer preparation method mainly includes the steps of (1), mixing animal dung with straw and / or wheat straw uniformly; (2), adding a phosphate fertilizer or powdered rock phosphate into a mixed material obtained from the step (1), and regulating the moisture content of the mixture; (3) adding facultative anaerobes into the mixture and transferring the mixture into a horizontal pulverizer to make all the materials mixed sufficiently; (4), stacking the mixed materials and conducting heat release, oxygenating, turning and fermenting so as to obtain organic fertilizer. The small-site organic fertilizer preparation method is saving in space and applicable to small sites. The organic fertilizer prepared by the method is high in organic matter content, free of stink and capable of decreasing occurrence rate of pest and disease damage after application and improving soil properties.

Owner:南充禾香生物科技有限公司 +1

Preparation method of cubic phase silicon carbide microparticles

PendingCN114835123AInhibition of linear growthEasy to prepareSilicon carbideCarbide siliconCarbon source

The invention discloses a preparation method of cubic phase silicon carbide micron particles, belongs to the technical field of silicon carbide preparation and semiconductor material preparation, and aims to solve the problems of high cost, high reaction temperature, difficulty in process control, complex process, low yield, lower purity and non-uniform particle size distribution in the existing preparation of cubic phase silicon carbide powder. The method comprises the following steps: treating silicon dioxide microspheres in a hydrogen peroxide solution to obtain activated silicon source particles; and introducing a gas carbon source in the presence of inert gas for high-temperature treatment, and removing impurities to obtain the zirconium acetylacetonate-loaded silicon dioxide microspheres. The cobalt acetylacetonate is used as a shape regulator, the silicon dioxide microspheres are used as a shape template, and the gaseous carbon source interacts with one another, so that the supersaturated linear growth of silicon carbide is effectively inhibited, and the morphology and the particle size of spherical particles are controlled. The method is simple, moderate in temperature, easy to control, high in production efficiency, high in product purity and uniform in particle size distribution. The method is suitable for preparing the micron-sized cubic phase silicon carbide particles.

Owner:内蒙古海特华材科技有限公司

Water diversion recovering device for polycarboxylic acids series dehydragent macromer preparation

InactiveCN101249317BApplicable preparationAvoid joiningNon-miscible liquid separationMolecular sieveWater discharge

The invention relates to a water separation recovery device for preparing a polycarboxylic acid type water-reducer macromonomer, including a water separator, a liquid mixing pipe, a return pipe and adischarge pipe, the discharge pipe is arranged at the bottom part of the water separator, the liquid mixing pipe is arranged at the top part of the water separator, the return pipe is arranged at theupper-middle position of the water separator, the lower part of the discharge pipe is connected with a material discharging three-way valve, the material discharging three-way valve is respectively connected with a solvent recovery pipe, an automatic water drainage pipe and a water discharge pipe, the other end of the solvent recovery pipe is connected with a dehydration molecular sieve device, the other end of the automatic water drainage pipe is connected with a water collecting barrel, a solvent recovery valve, an automatic water drainage valve and a water discharge valve are respectively arranged on the solvent recovery pipe, the automatic water drainage pipe and the water discharge pipe, and the lower part of the dehydration molecular sieve device is connected with a solvent dischargepipe and a solvent discharge valve. The device is visible and convenient in operation and comprises the solvent recovery and recycling device, which has higher production efficiency.

Owner:NINGBO QIHANG ASSISTANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com