Vacuum induction smelting furnance

A vacuum induction smelting and vacuum smelting technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve problems such as poor pouring cooling effect and insufficient production capacity, and achieve the effects of ensuring consistency, balanced material cooling effect, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

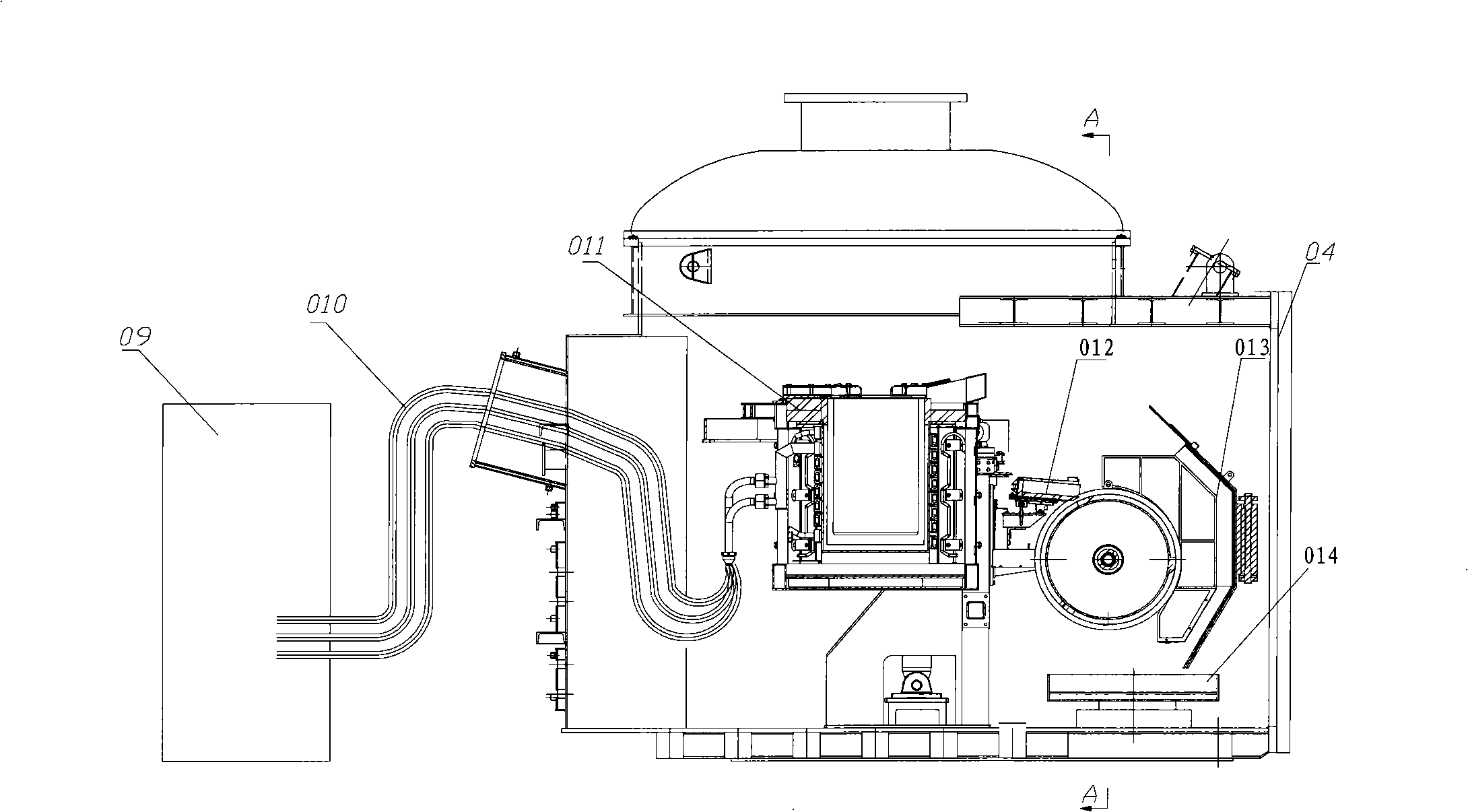

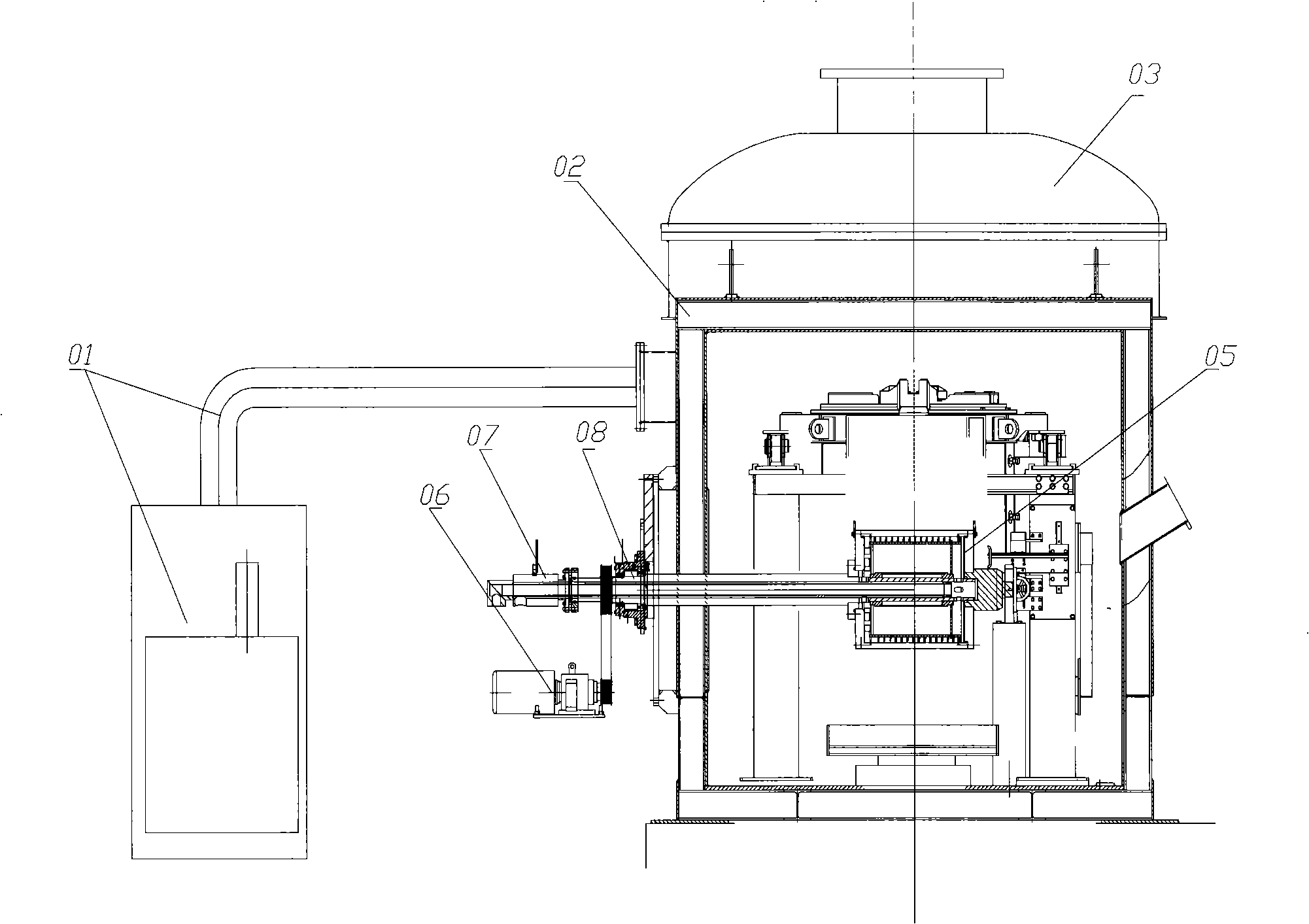

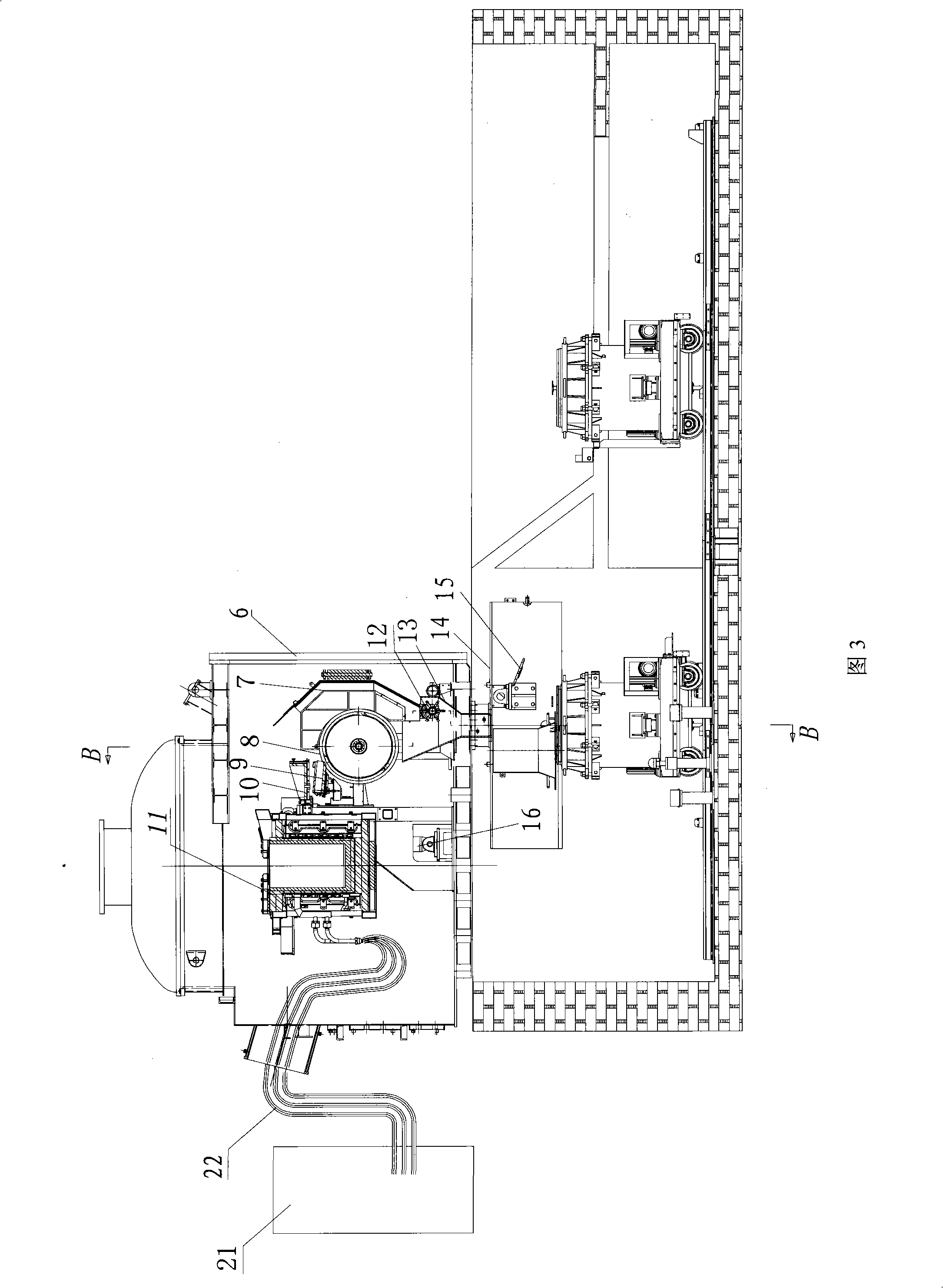

[0033] The following embodiments will further illustrate the structural composition of the present invention in conjunction with the accompanying drawings.

[0034] The invention is equipped with a vacuum melting chamber, an intermediate frequency coil furnace body (including a crucible), a vacuum pump group and related vacuum pipeline systems, an electrical control system, an intermediate frequency power supply system, a hydraulic cylinder control system, a cooling system and a pit discharge system.

[0035] Referring to Figures 3 and 4, the vacuum melting chamber is provided with an upper cover 4, a furnace chamber 5 and a furnace door 6, and the intermediate frequency coil furnace body 11 is provided with a crucible.

[0036] The cooling system is used to provide uniform material distribution, cooling and secondary cooling equipment and operating mechanism for the hydrogen storage alloy material smelted to high temperature melting by the intermediate frequency power supply. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com