Mixer nozzle and method for mixing two or more fluids and process for manufacturing isocyanates

A technology of nozzles and fluids, applied in the preparation of organic compounds, fluid mixers, chemical instruments and methods, etc., which can solve the problems of unattractive manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Other purposes, features and beneficial effects will be more apparent after referring to the following description.

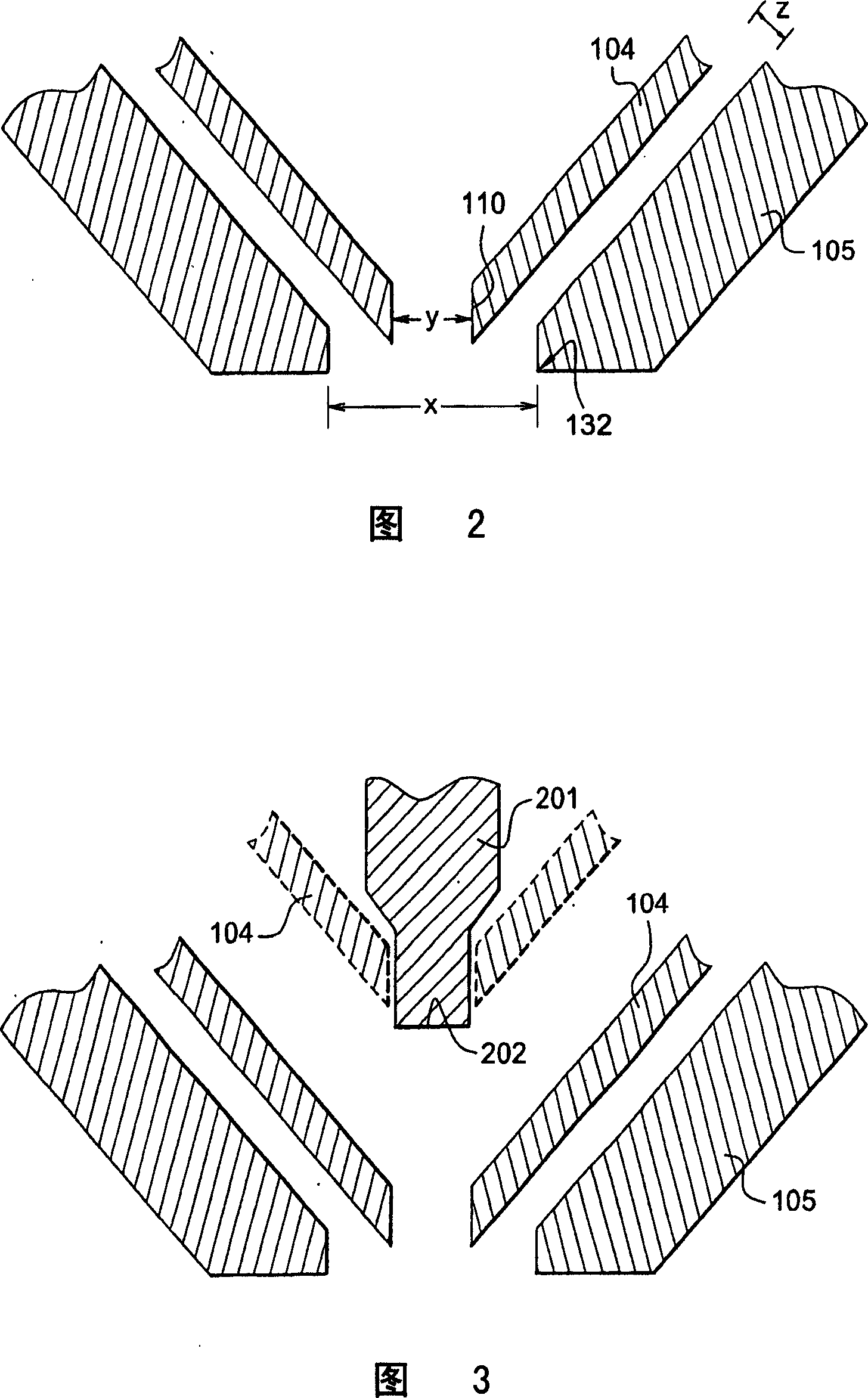

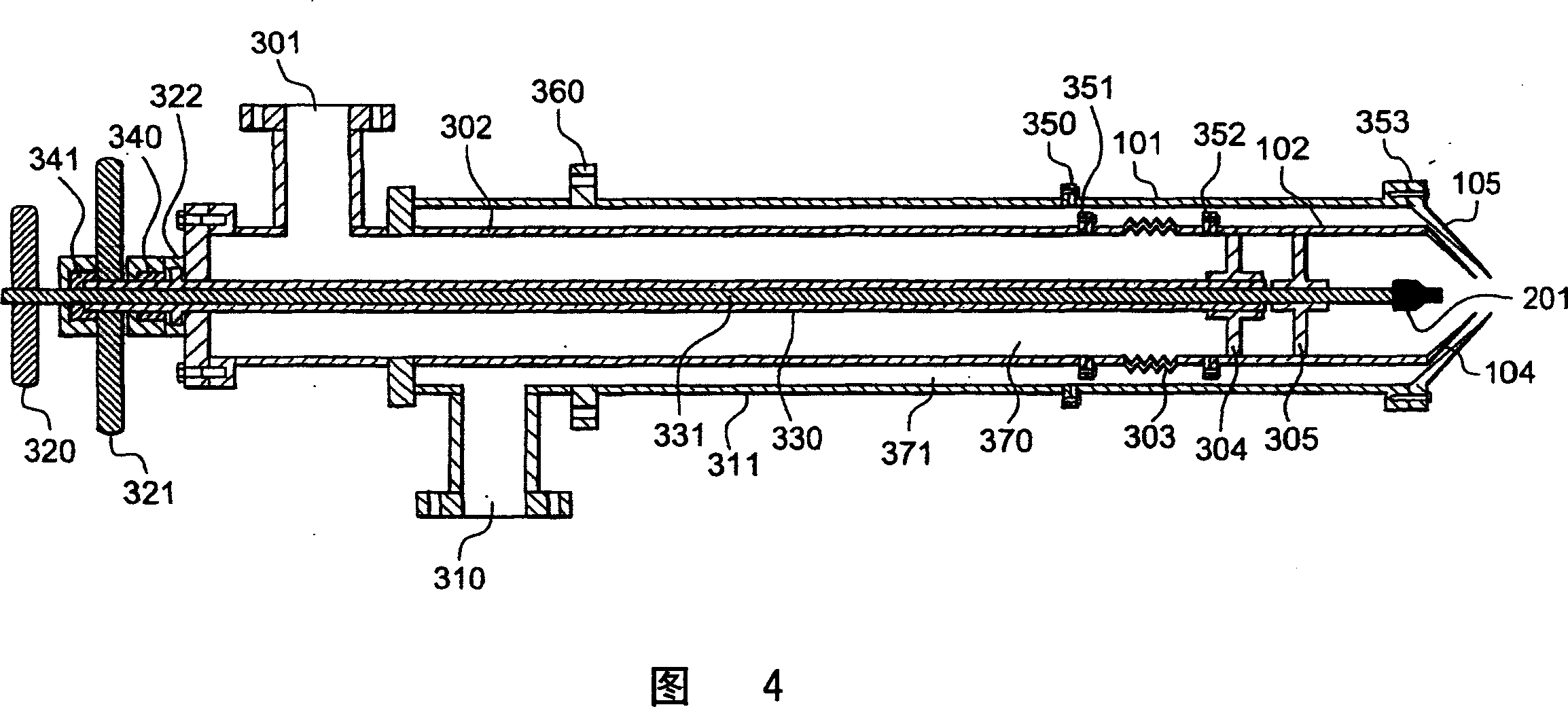

[0022] The invention is based on the use of rectangular nozzles referred to hereinafter as slot nozzles. The special geometry allows for fine flows while at the same time avoiding central protruding elements.

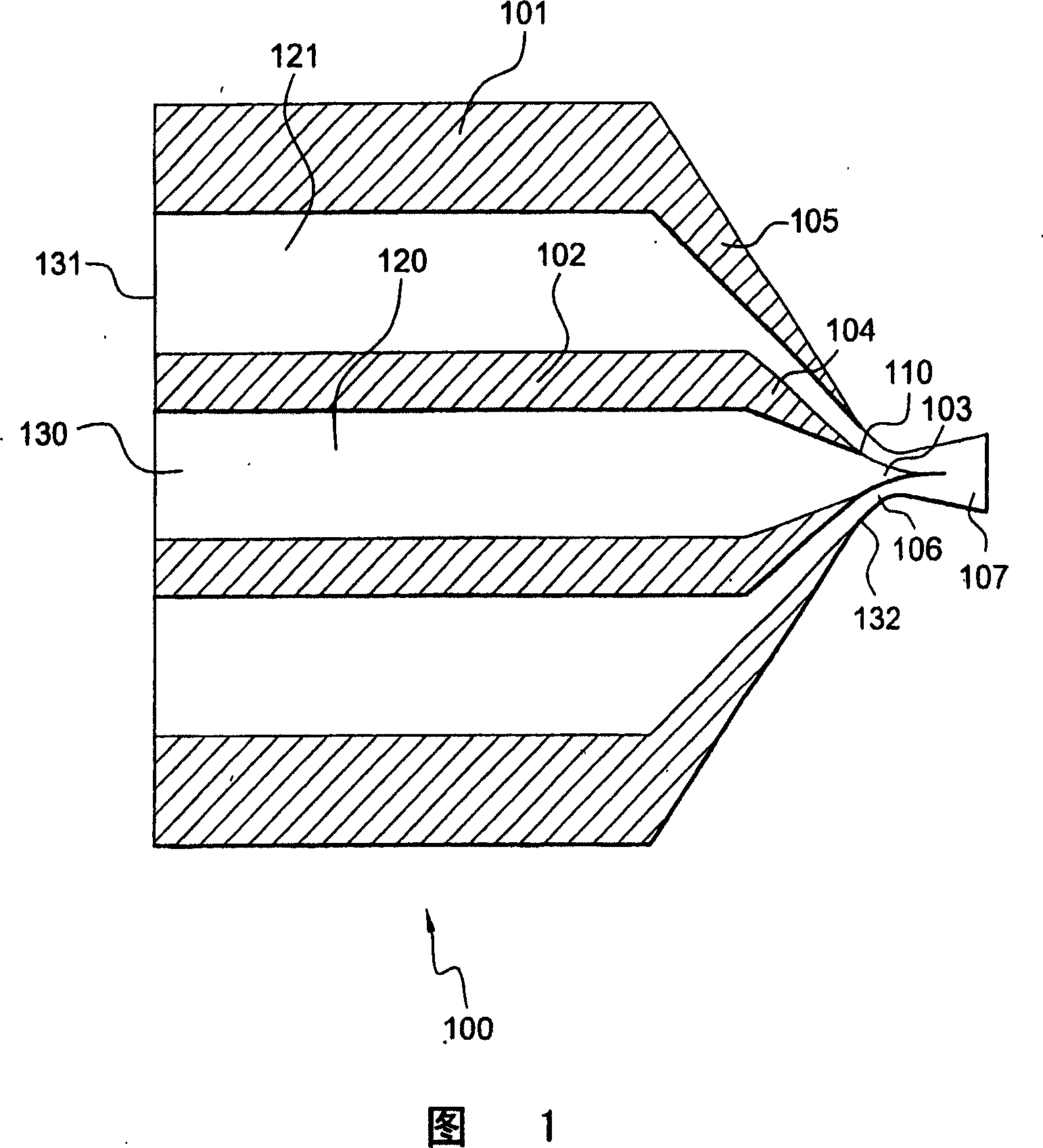

[0023] As shown in FIG. 1, there is shown a coaxial impinging jet mixer nozzle assembly 100 for mixing two fluids. The coaxial impinging jet mixer nozzle assembly 100 includes an inner flow conduit 102 and an inner flow conduit nozzle tip 104 disposed coaxially inside an outer flow conduit 101 and an outer flow conduit nozzle tip 105 . Flow chamber 120 is defined as a rectangular space inside inner flow conduit 102 and inner flow conduit nozzle tip 104 . The flow chamber 120 has two ends, a supply end 130 and a discharge end 110 . The discharge end 110 of the flow chamber 120 is formed by the discharge end of the inner flow conduit nozzle tip 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com