Water diversion recovering device for polycarboxylic acids series dehydragent macromer preparation

A technology of polycarboxylate and water reducer, which is applied in the field of water separation and recovery devices for synthetic resins, can solve the problems of poor application, reduced production efficiency, and incomplete discharge, etc., and achieves continuous controllable and economical drainage process. The cost and structure are more scientific and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific examples.

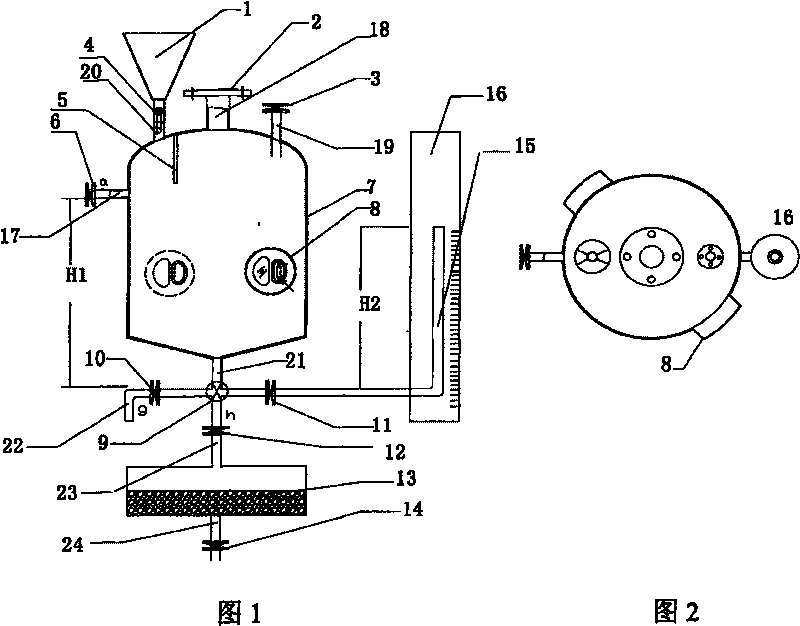

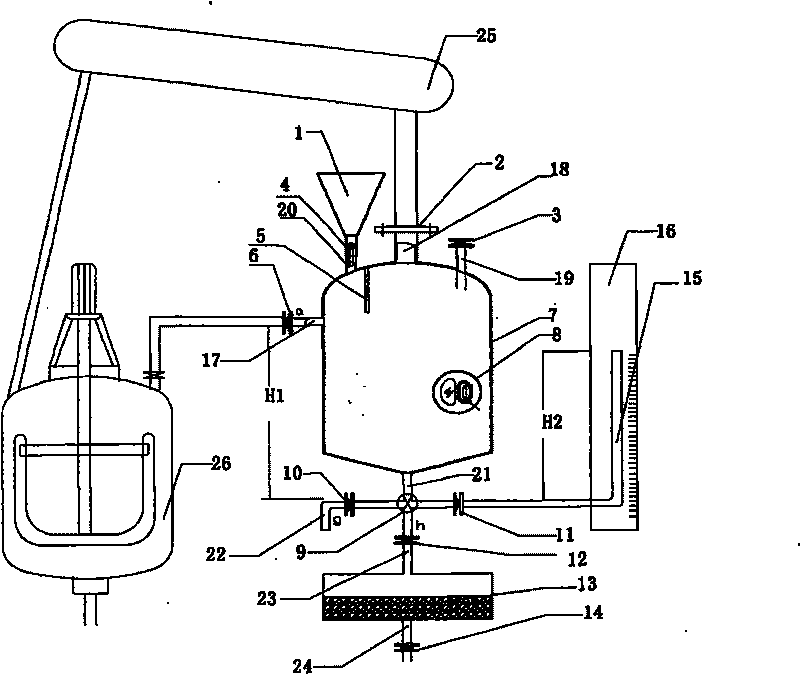

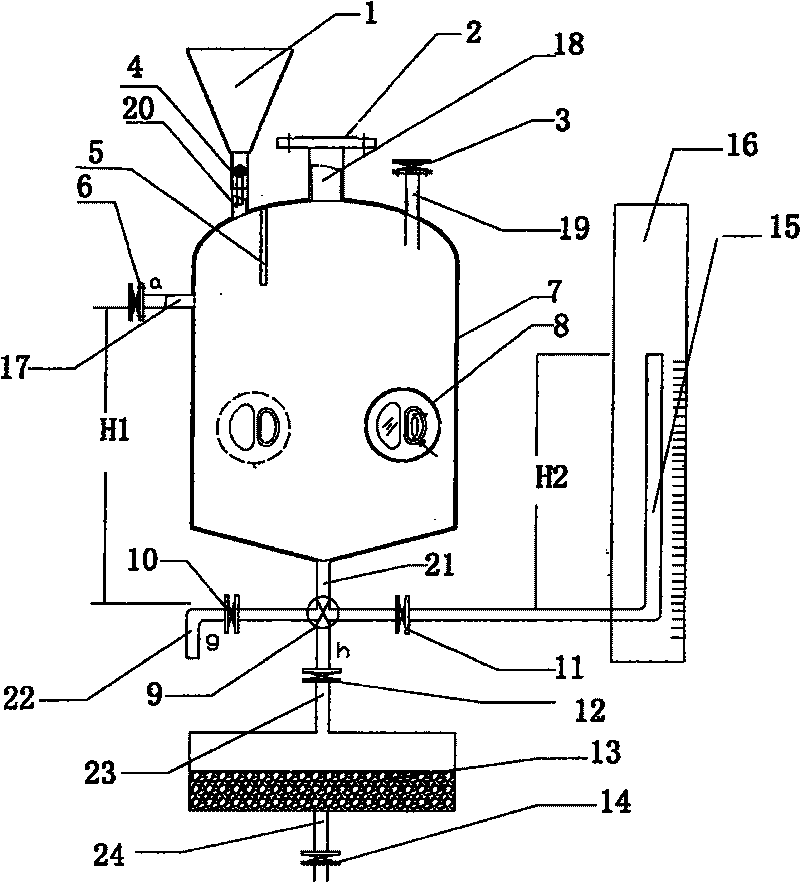

[0025] figure 1 , figure 2 It is the water separation and recovery device for the preparation of polycarboxylate water reducer macromonomer according to the present invention. The device consists of the following parts: as shown in the figure, the discharge pipe 21 is installed at the bottom of the water separator 7, the liquid mixing pipe 18 and the mixing pipe valve 2 are installed at the top of the water separator 7, and the solvent return pipe 17 is installed at the middle of the water separator 7 Up position. A discharge three-way valve 9 is connected to the lower part of the discharge pipe 21, and the discharge three-way valve 9 is connected to the solvent recovery pipe 23, the automatic drain pipe 15 and the water discharge pipe 22 respectively. The other end of the solvent recovery pipe 23 is connected to the dehydration molecular sieve device 13, the oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com