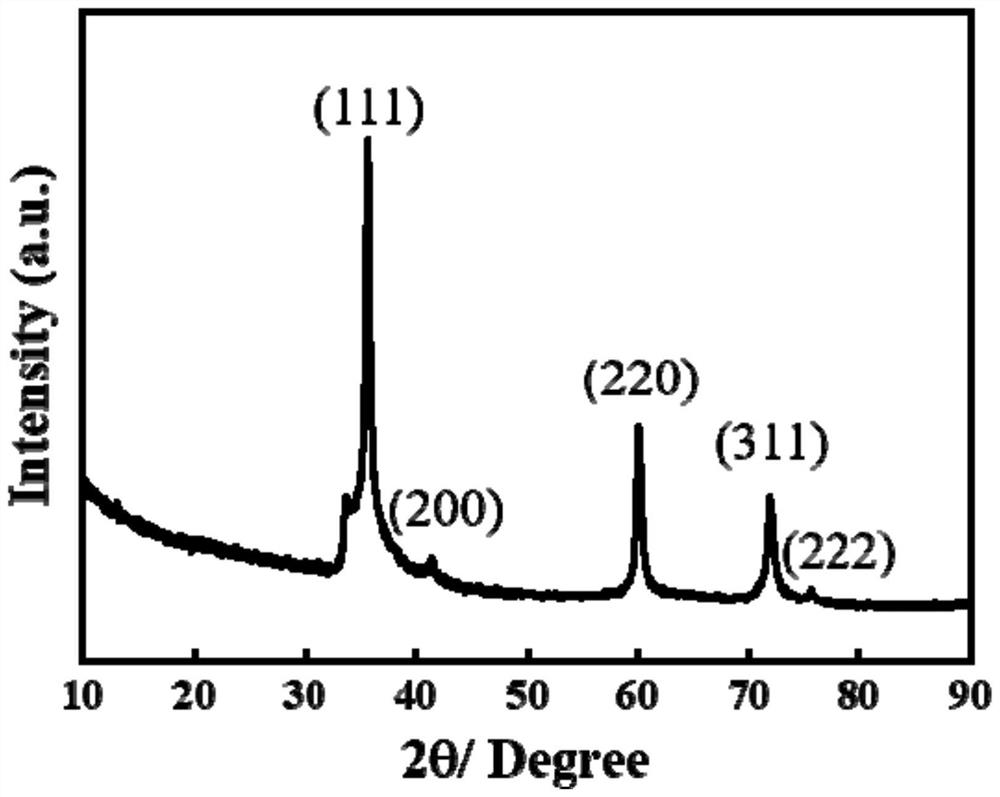

Preparation method of cubic phase silicon carbide microparticles

A technology of phase silicon carbide and micro-particles, which is applied in the field of preparation of cubic silicon carbide micro-particles, can solve the problems of high cost of cubic silicon carbide powder, uneven particle size distribution, and difficult control of the process, and achieve the suppression line shape growth, simple preparation method and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

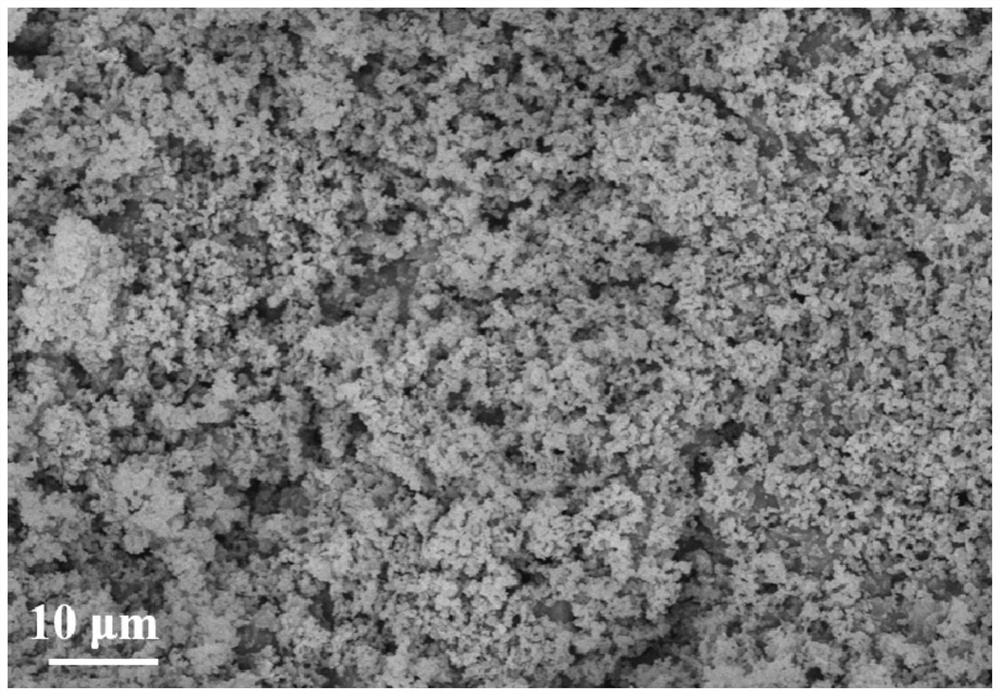

[0021] Specific embodiment 1: This embodiment is a preparation method of cubic phase silicon carbide micro-particles, which is realized according to the following steps:

[0022] 1. Disperse the silica microspheres in a hydrogen peroxide solution, take out after 1-24 hours, and dry at 60-90 °C to obtain activated silicon source particles;

[0023] 2. After the above activation, the silicon source particles are placed in a cobalt acetylacetonate solution for 5 to 20 hours to obtain silica microspheres loaded with zirconium acetylacetonate, and then a gaseous carbon source is introduced under an inert gas for high temperature treatment. After the impurity treatment, cubic-phase silicon carbide micro-particles are obtained, and the preparation method is completed.

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is different from Embodiment 1 in that the mass-volume ratio of the silica microspheres to the hydrogen peroxide solution described in step 1 is 1 g:(10-50) ml. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the size of the silica microspheres in step 1 is 0.1-5 μm. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com