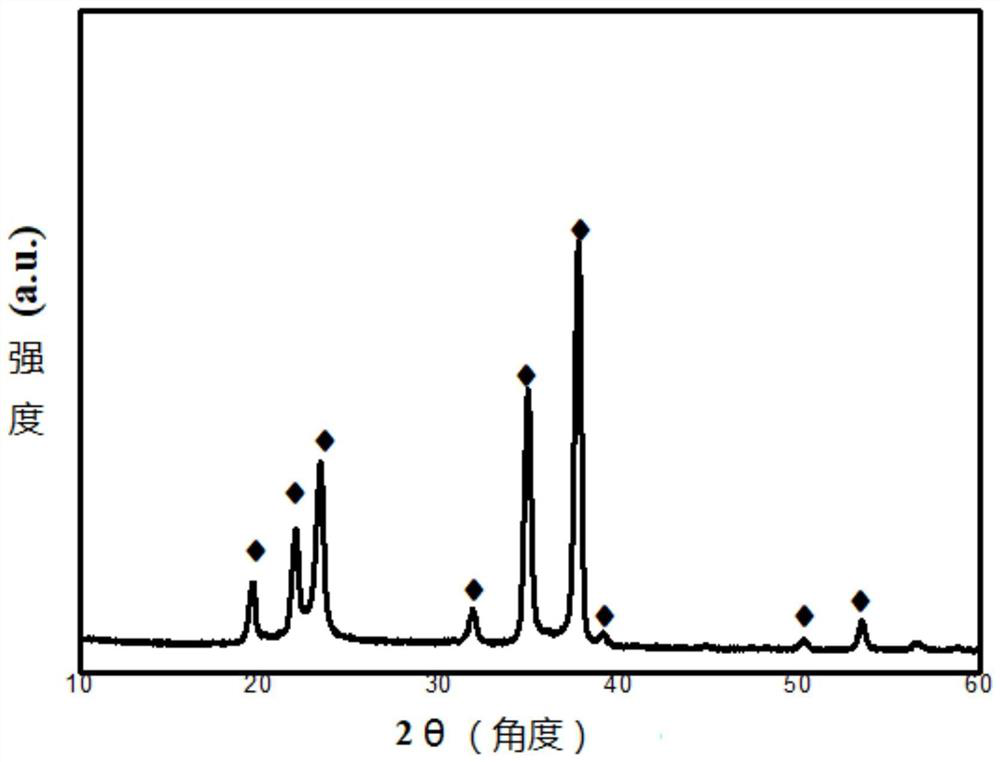

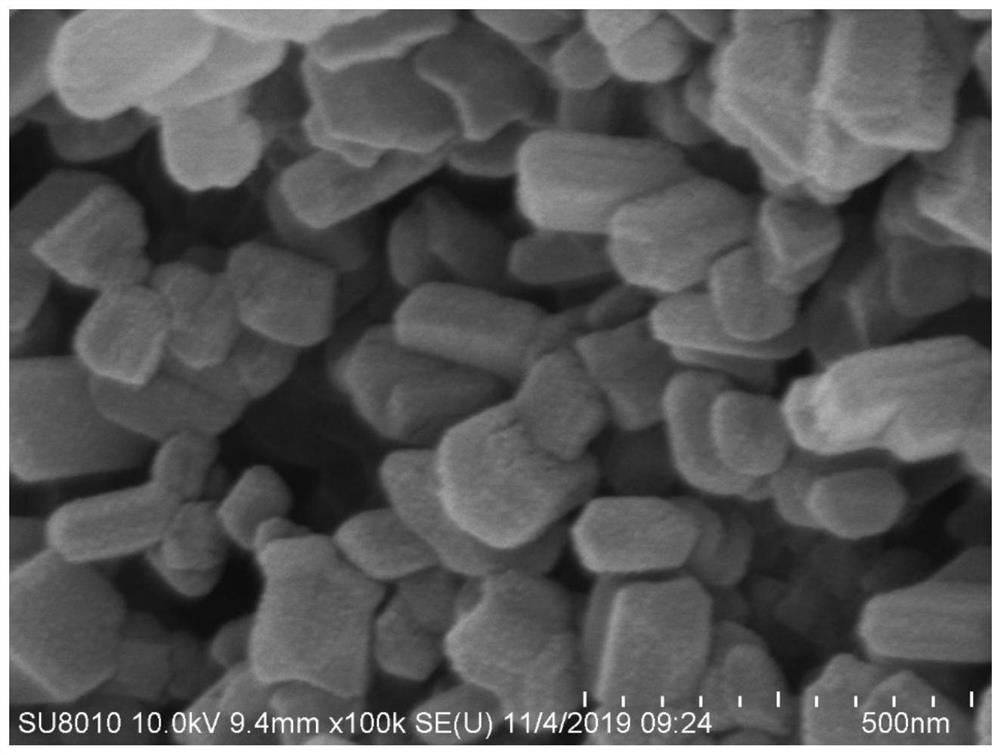

Preparation method of boron carbide nanoparticles

A nanoparticle, boron carbide technology, applied in chemical instruments and methods, carbon compounds, nanotechnology, etc., can solve the problems of large particle size, high energy consumption, low product purity, etc., and achieve uniform particle size, low energy consumption, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: present embodiment a kind of preparation method of boron carbide nanoparticles, it is realized according to the following steps:

[0022] 1. Weigh the boron source, carbon source and additives according to the molar ratio (1~10):1:(0.001~0.1), and mix them to obtain mixture A;

[0023] 2. According to the mass volume ratio of 1g: (5-1000) mL, ultrasonically dissolve the mixture A in the solvent to obtain the slurry B;

[0024] 3. Place the obtained slurry B in an HCl atmosphere, heat and dry at 30-300°C for 0.2-24 hours to obtain a dry mixture C;

[0025] 4. Put the dry mixture C in a graphite crucible, heat it to 700-1700° C. in a high-temperature furnace under an inert atmosphere and keep it warm for 0.1-6 hours, and obtain boron carbide powder after cooling in the furnace, that is, complete the preparation of boron carbide nanoparticles;

[0026] Wherein the boron source in step 1 is crystalline boron, ammonium fluoroborate, boric acid, meta...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, the boron source, carbon source and additives are weighed according to the molar ratio (2-8):1:(0.002-0.08). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the boron source, carbon source and additives are weighed according to the molar ratio of 5:1:0.05. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com