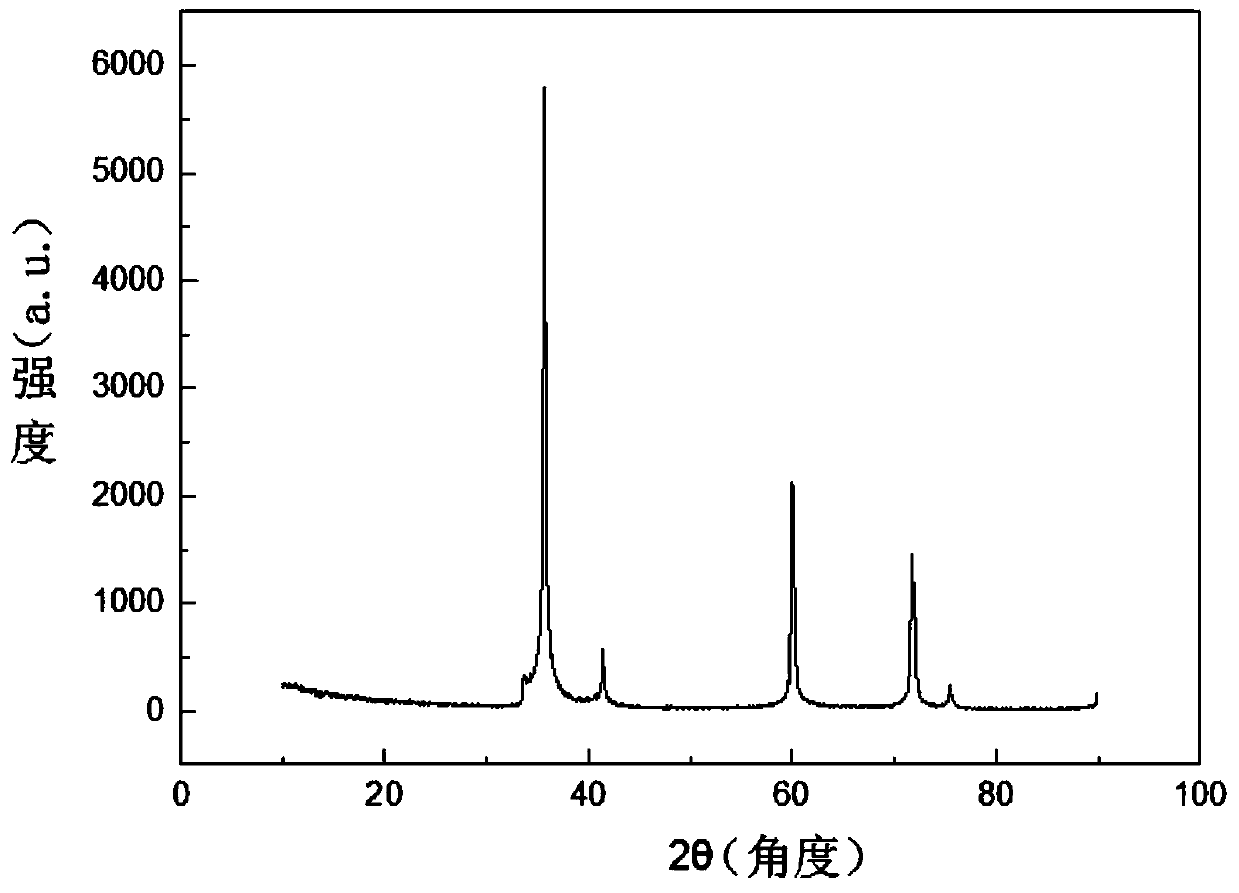

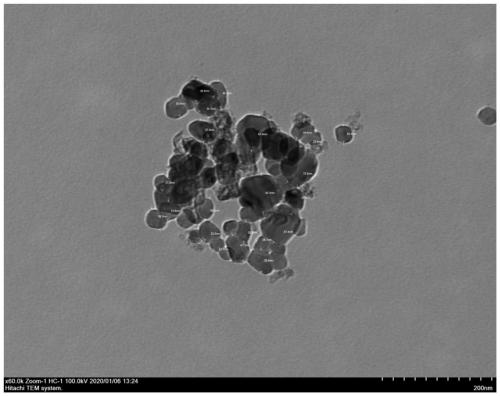

Preparation method of nano silicon carbide particles based on NaF shape regulator

A nano-silicon carbide and regulator technology, which is applied in the field of semiconductor material preparation and silicon carbide preparation, can solve the problems of uneven particle size distribution, difficult process control, and high reaction temperature, and achieves inhibition of linear growth, easy process, and particle size. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the present embodiment is a kind of preparation method based on the nano-silicon carbide particle of NaF shape regulator, and it realizes according to the following steps:

[0018] 1. Preparation of carbon precursor:

[0019] Glucose is placed in a tube furnace, heated to 400-800°C under the protection of nitrogen and carbonized for 1-4 hours to obtain a carbon precursor;

[0020] 2. Place the carbon precursor, NaF, nano-silicon micropowder and ethanol solution with a mass concentration of 20-30% obtained in step 1 in a ball mill for ball milling, take it out and spray dry it to obtain a mixed material;

[0021] 3. Place the mixed material obtained in step 2 in a high-temperature sintering furnace, raise the temperature to 1200-1800° C. for 1-8 hours under the protection of nitrogen, and then cool to room temperature to obtain the pre-product;

[0022] Fourth, impurity removal treatment:

[0023] Immerse the pre-product obtained in step 3 in h...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that the particle size of the glucose in step 1 is 10-100 nm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the rate of temperature increase in step 1 is 1-10° C. / min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com