Production of multifunctional gas-phase depositer and solid oxide fuel single cell

A vapor deposition and chemical vapor deposition technology, which is applied in gaseous chemical plating, metal material coating process, ion implantation plating, etc., can solve the problems of high energy consumption, high deposition temperature, labor and time, etc. , to achieve the effect of small temperature change range, low preparation temperature and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

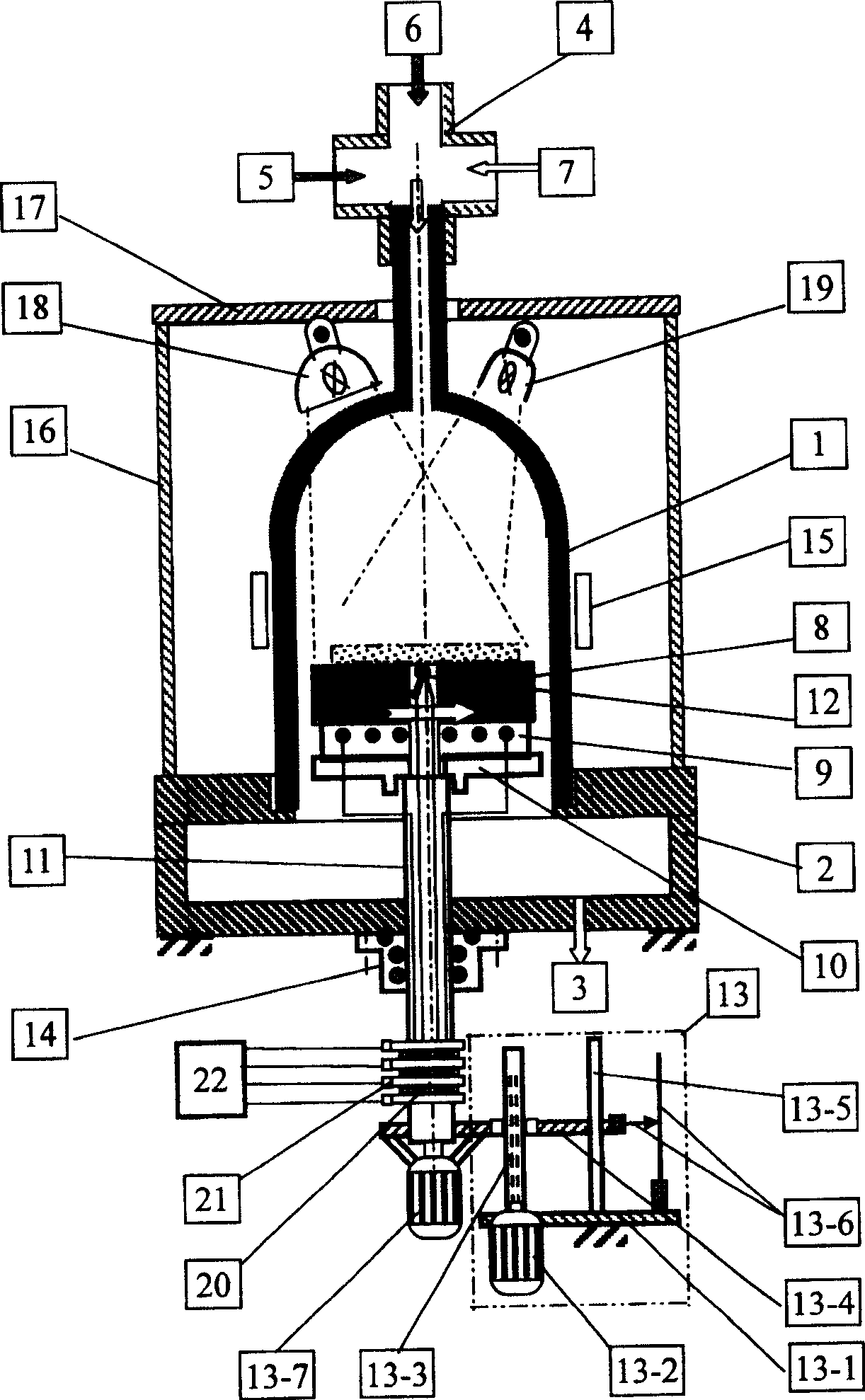

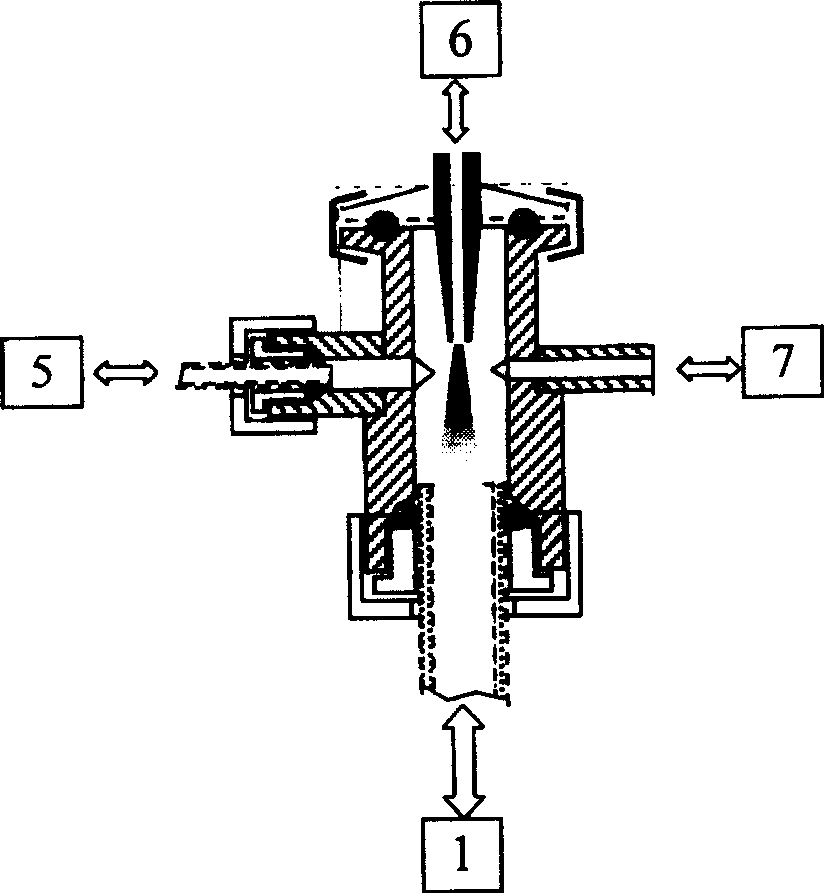

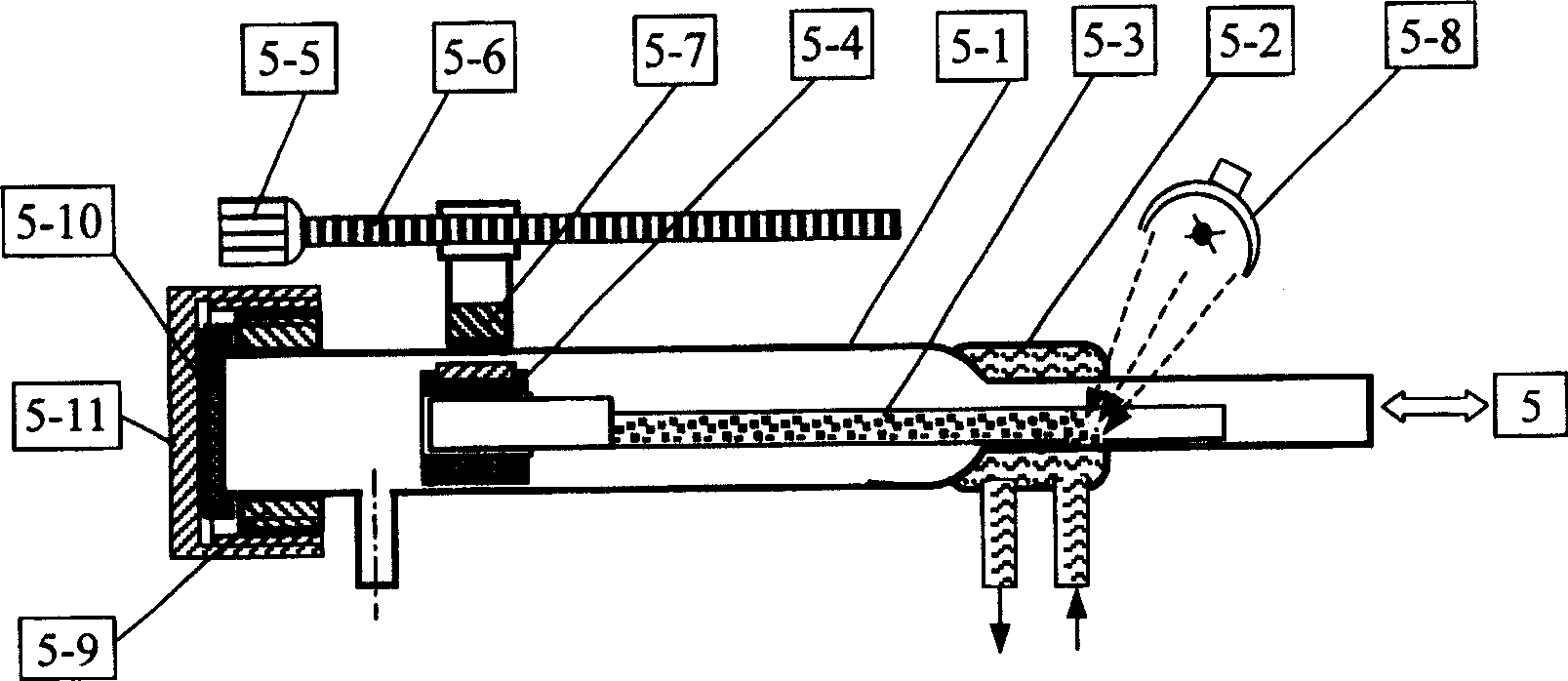

[0025] Example 1: Making a multifunctional vapor deposition device

[0026] according to figure 1The schematic diagram of the structure and principle of the multifunctional vapor deposition device is given, which combines the metal organic compound solid source chemical vapor deposition (MOCVD) and the ultrasonic atomization metal source material solution aerosol chemical vapor deposition (Aerosol-CVD), Manufacture and assembly of a multifunctional vapor deposition device supplemented by plasma enhancement, ultraviolet light source activation of reactive species, and thermal light source radiating substrate surface auxiliary heating:

[0027] 1. In this embodiment, the quartz reaction chamber 1 is formed by transitional connection of upper and lower sections of quartz tube hemispheres. The outer diameter of the lower section of the quartz tube is Φ150 mm, the height is 220 mm, and the wall thickness is 6 mm. The outer diameter of the upper section is Φ50 mm. 150mm high and 5m...

Embodiment 2

[0037] Embodiment 2: Utilizing the multifunctional vapor deposition device completed in Embodiment 1, prepare a single cell with Ni-YSZ cermet as the support body anode, YSZ as the electrolyte, LSM-YSZ 50% composite material as the cathode functional layer, and LSM as the cathode. Battery

[0038] The symbols of the multilayer ceramic membrane battery prepared in this embodiment are:

[0039] (-) Porous Ni-YSZ, Ni-YSZ modified layer, YSZ transition layer | YSZ dense layer | YSZ transition layer, porous LSM (+)

[0040] Here, YSZ is 8mol% Y 2 o 3 Doping stabilized cubic ZrO 2 , LSM is (La 0.7 Sr 0.3 ) 0.9 MnO 3 .

[0041] The detailed preparation steps are as follows:

[0042] 1. The green body of NiO-YSZ anode support body was prepared by slip casting method; after drying, it was sintered at 1300°C for 4 hours; after both sides were mechanically polished and ultrasonically cleaned, a NiO-YSZ porous anode support body with a thickness of 1.5mm and a diameter of Φ80mm w...

Embodiment 3

[0064] Example 3: Using the multifunctional vapor deposition device completed in Example 1, prepare a multilayer ceramic membrane single cell with LSCF cathode as support, SDC as electrolyte, and composite Cu-SDC as anode

[0065] The multilayer ceramic membrane single cell prepared in this embodiment is expressed as:

[0066] (-) Porous Cu-SDC 60vol%, SDC transition layer | dense SDC electrolyte layer | LSCF-SDC 50 vol% cathode transition layer, LSCF cathode modification layer, porous LSCF cathode support (+)

[0067] The SDC here is samarium-doped ceria (Sm 0.2 Ce 0.8 o 1.9 , SDC); Cu-SDC is copper cermet, wherein the volume content of Cu is 40%; LSCF represents La 0.6 Sr 0.4 co 0.2 Fe 0.8 Composite oxide; LSCF-SDC (50vol%) is a composite cathode of LSCF and SDC, wherein the volume ratio of SDC is 50%;

[0068] The preparation steps are as follows:

[0069] 1. The green body of LSCF cathode support was prepared by tape casting, and after drying, it was burned at 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com