Surface multi-scale structure tungsten material and preparation method of material

A multi-scale, tungsten block technology, applied in the field of metal surface treatment, can solve the problems of enhanced electron scattering, decreased thermal conductivity, sacrifice of pure tungsten thermal conductivity, etc., to achieve less destructive, uniform force, and interlayer bonding good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preferably, the preparation method of the material comprises: dry rubbing the surface of the tungsten block with a grinding ball at a constant temperature of 200-500° C. for 10-60 minutes to prepare a tungsten block with a multi-scale structure on the surface.

[0031] Preferably, the grinding balls are alumina balls.

[0032] Preferably, the positive pressure and friction linear velocity of the dry grinding are respectively 10-50N and 0.1-0.6m / s.

[0033] Preferably, the preparation method of the material further includes: grinding and polishing the surface of the tungsten block before dry grinding, degreasing with acetone, ultrasonic cleaning, and drying.

[0034] In order to solve the second technical problem of the present invention, the preparation method of the surface multi-scale structure tungsten material described in the present invention comprises:

[0035] Dry rubbing the surface of the tungsten block with grinding balls at a constant temperature of 200-500...

Embodiment 1

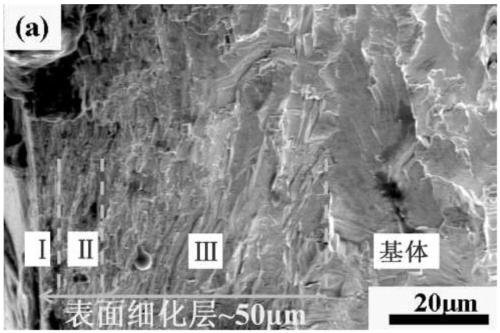

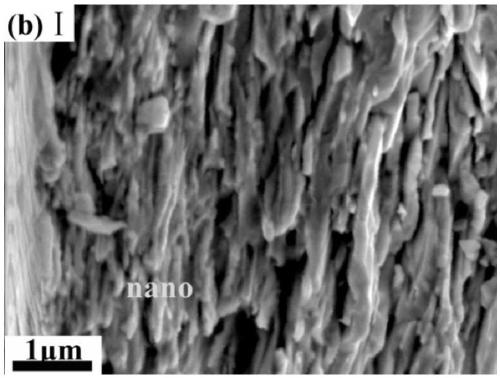

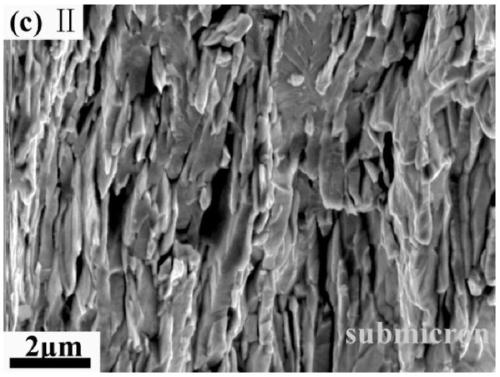

[0039] The specific steps for preparing the surface multi-scale structure tungsten material with a total layer thickness of 50 microns are:

[0040]Step 1: Polish the surface of the rolled tungsten block with P400, 800, 1500, and 2000 silicon carbide sandpaper in sequence, and then use polishing cloth and W2.5, W1 and W0.5 diamond abrasive paste to polish it finely. Use acetone to wash the residual organic matter on the polished tungsten surface, then put it into an ultrasonic machine to clean it until the surface is smooth and clean, and finally take out the tungsten block and dry it for use.

[0041] Step 2: Place the tungsten block processed in step 1 in the sample chamber of the high-temperature friction testing machine, fix and ensure that the surface is flush with the horizontal plane. The temperature of the sample chamber was raised to 500°C with a heating rate of 150°C / min. The grinding beads are alumina balls, and the positive pressure and friction linear velocity ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com