Fire extinguishing device and seal method thereof

A technology of fire extinguishing device and fire extinguishing agent, which is applied in fire rescue and other fields, can solve problems such as liquid leakage and single welding surface, and achieve the effect of reducing liquid leakage rate and increasing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

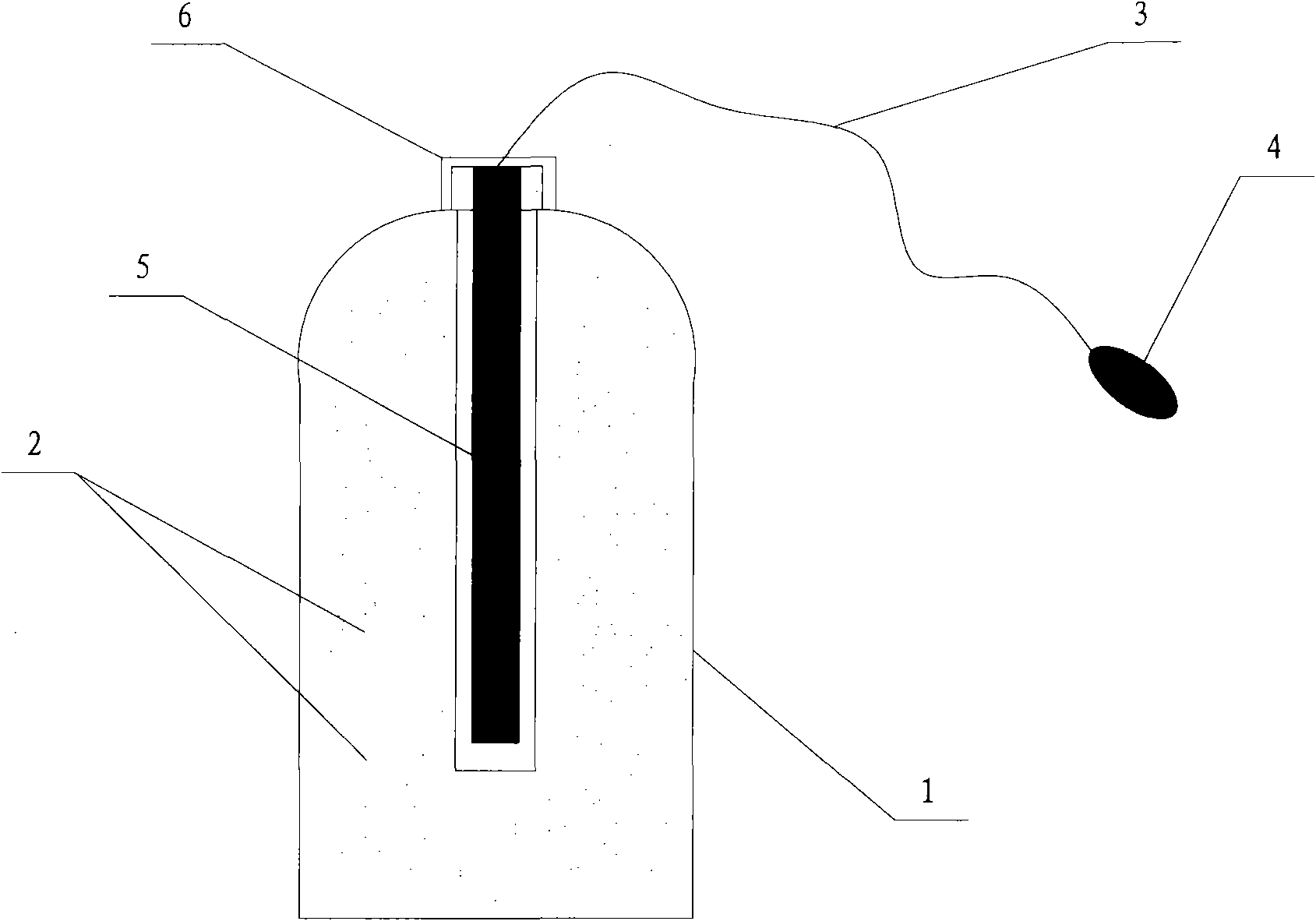

[0035] This embodiment provides a fire extinguishing device, specifically an explosive fire extinguishing device.

[0036] From the point of view of the overall structure and appearance, the fire extinguishing device provided by this embodiment is the same as figure 1 The fire extinguishing devices shown in are basically the same. This fire extinguishing device is made up of plastic container 1 (fire extinguishing device container), fire extinguishing agent 2, lead wire 3, lead wire pack 4 and detonator 5. The fuse package is optional, and the main detonation is still the fuse and the detonator.

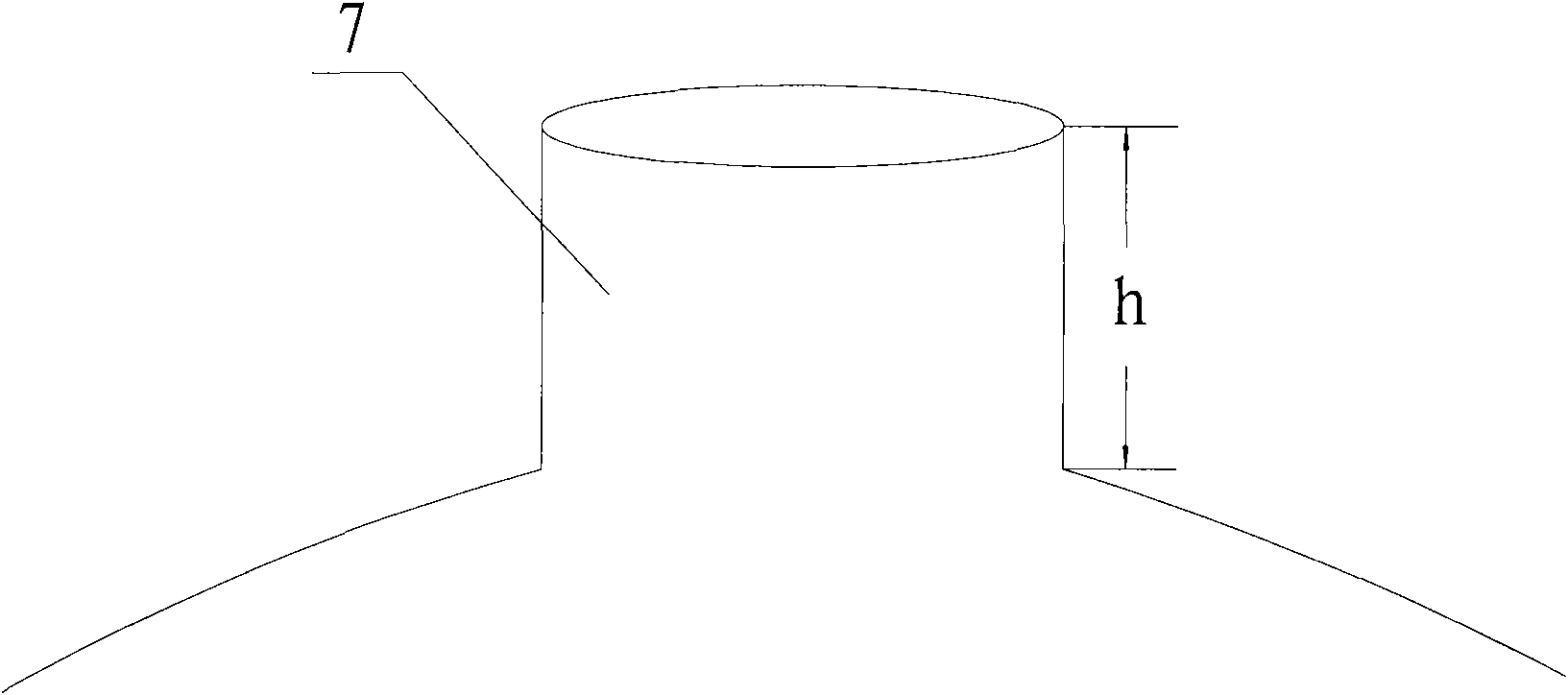

[0037] The difference between this embodiment and the prior art mainly lies in the design of the bottle mouth of the fire extinguishing device container. See figure 2 , figure 2 It is an enlarged view of the mouth of the fire extinguishing container of the fire extinguishing device provided in this embodiment. The bottleneck 7 of the fire extinguishing container of fire exting...

Embodiment 2

[0041] This embodiment provides a sealing method for a fire extinguishing device, which can be used for sealing the fire extinguishing device in Embodiment 1.

[0042] The sealing method that present embodiment 2 provides comprises the steps:

[0043] First, grooves are machined on the top of the detonator;

[0044] Then, the detonating tube is sleeved on the bottle mouth of the fire extinguishing device container for hot-melt welding; the shape of the groove needs to be able to match the shape of the bottle mouth of the fire extinguishing device container.

[0045] After hot-melt welding, the fire extinguishing device is formed, and the fire extinguishing agent therein is not easy to leak.

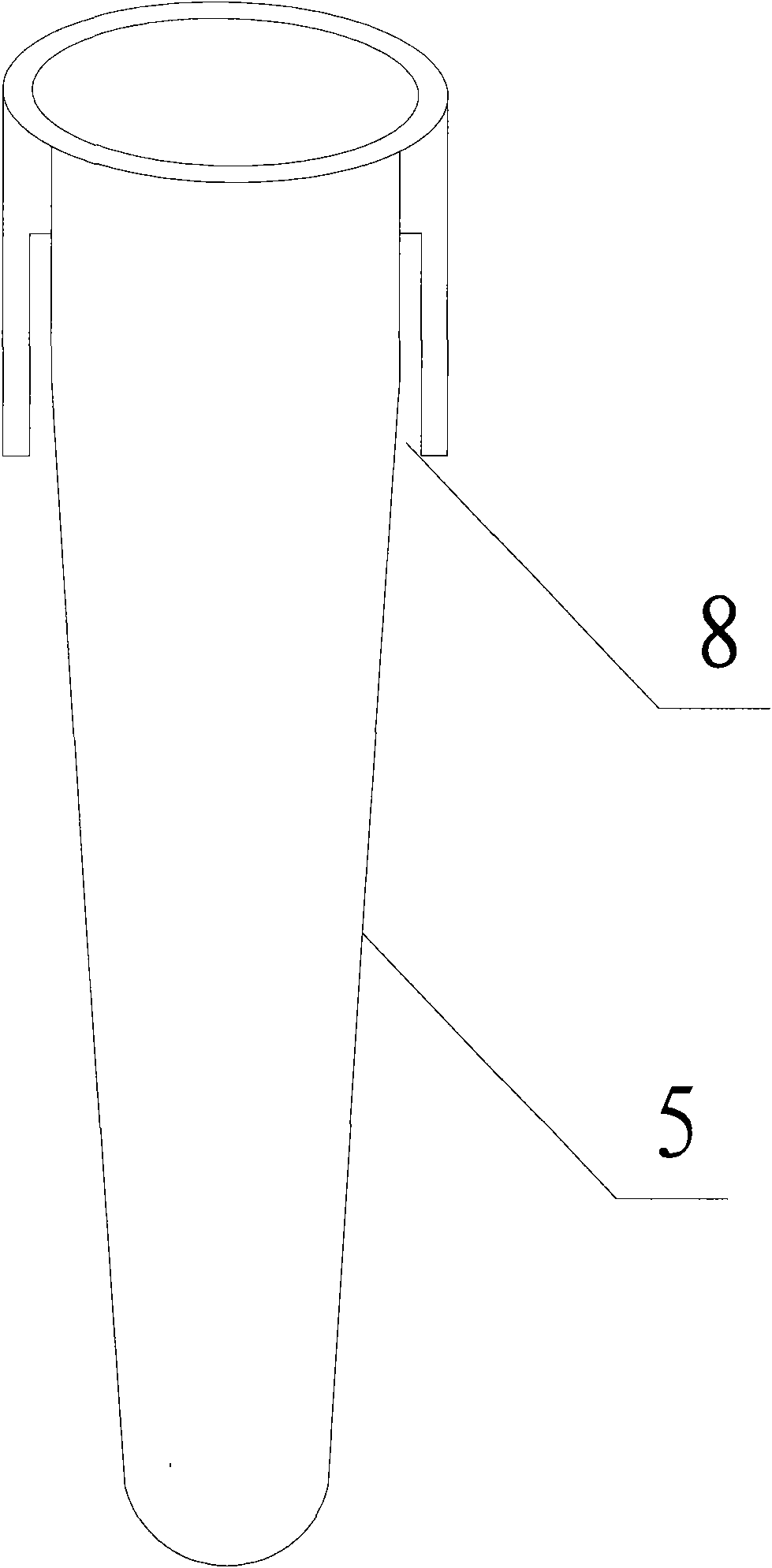

[0046]A refinement of the method is that a welding line is provided on the surface of the groove which cooperates with the mouth of the fire extinguisher container. That is to say, welding lines are set on any one or more surfaces of the first part 801, the second part 802 and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com