Method for compounding and preparing high-elastic-modulus Ti-based material based on nano ceramic particles

A nano-ceramic particle, high-elasticity technology, applied in the field of TNZS alloys, to achieve the effect of simple operation, easy implementation and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of high elastic modulus 5wt.%TiO2 / TNZS titanium base material, comprises the following steps:

[0036] 1. Two times of high-energy ball milling mixed powder preparation: first prepare Ti-24Nb-4Zr-7.9Sn (TNZS) mixed powder, the mass percentage of each component is Ti powder: 64.1%, Nb powder: 24%, Zr powder: 4 %, Sn powder: 7.9%, after the first high-energy ball mill (planetary ball mill, ball-to-material ratio 10:1, 300r / min ball mill for 48h, ball mill 1h stop for 15min), then add TiO 2 Nano-powder (particle size 40nm), prepared with a mass fraction of 5% TiO 2 / TNZS mixed powder, continue high-energy ball milling (300r / min ball milling for 1h), dry in a vacuum oven, and sieve.

[0037] 2. Conventional die-pressing method: Press the mixed powder prepared in step 1 on the YB32-100 hydraulic press manufactured by Nantong Forging Equipment Factory (compression pressure is 18Mpa, hold pressure for 5min), and the required compact (diameter is 3...

Embodiment 2

[0041] A preparation method of high elastic modulus 5wt.%HA / TNZS titanium-based material:

[0042] The present embodiment is similar to embodiment 1, and the difference is that the mass fraction is 5% TiO 2 The powder was replaced with 5wt.% HA nanopowder.

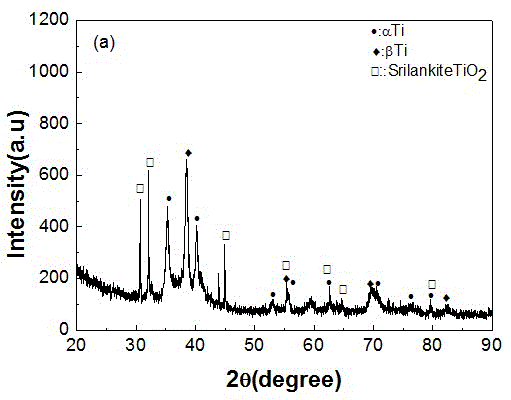

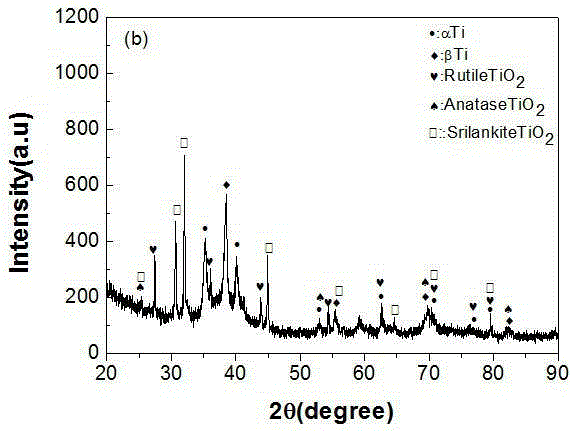

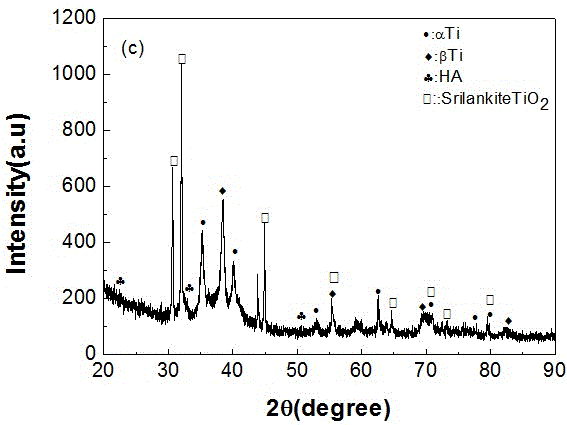

[0043] The mechanical alloying phenomenon of the 5wt.%HA / TNZS mixed powder prepared by the above steps is obvious, and SrilankiteTiO is detected in the XRD spectrum of the powder 2 The existence of, as well as RutileTiO2 and AnataseTiO 2 ( figure 1 , 3 shown); the particles appear to be agglomerated and cold welded, which makes the difficulty of powder refinement intensified and finally tends to a stable ellipsoidal structure; the particles are refined by crushing, extrusion and mechanical grinding, and the size is obvious reduced, the maximum particle size does not exceed 35 μm (eg Figure 4 shown in c); in addition to α-Ti, β-Ti and HA, Ti was also detected in the 5wt.%HA / TNZS titanium-based material prepared by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com