Method for sintering La-Mg-Ni based type AB3 hydrogen storage alloy in magnetic field

A hydrogen storage alloy and magnetic field technology, applied in the field of metal functional materials and powder metallurgy, can solve the problems of complex process, unpredictable and controllable magnesium volatilization, high energy consumption, etc., achieve good kinetic performance, shorten synthesis time, reduce The effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

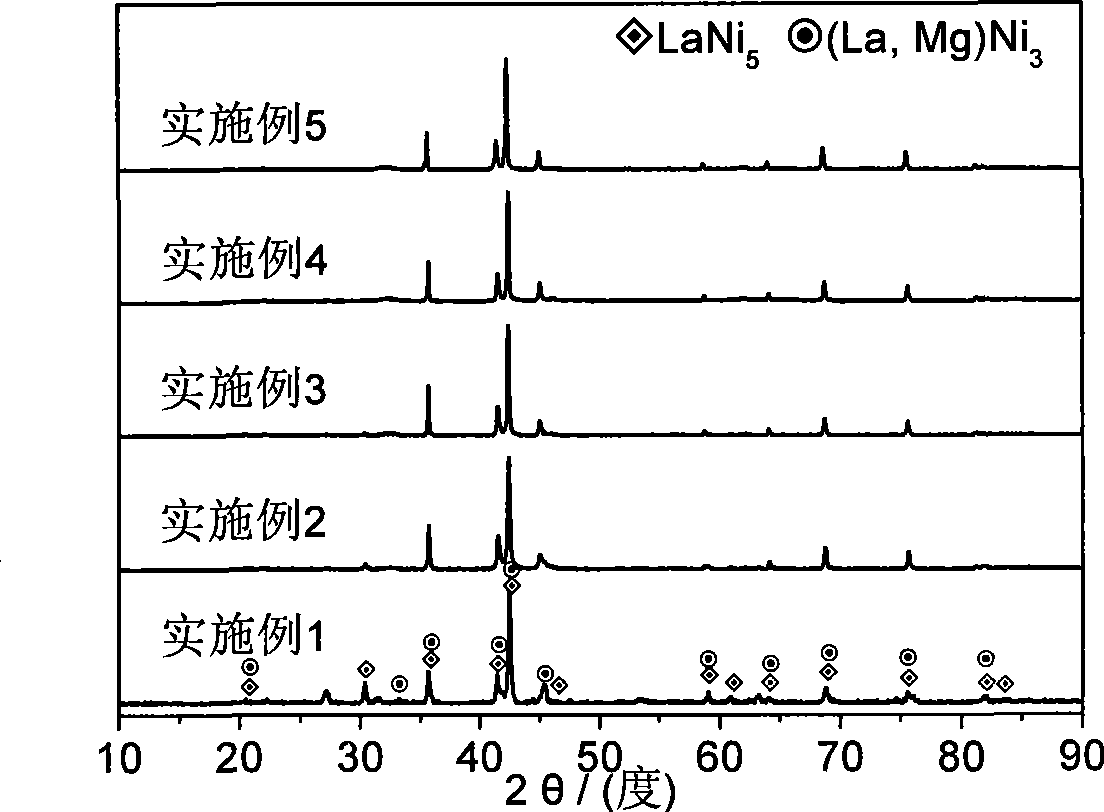

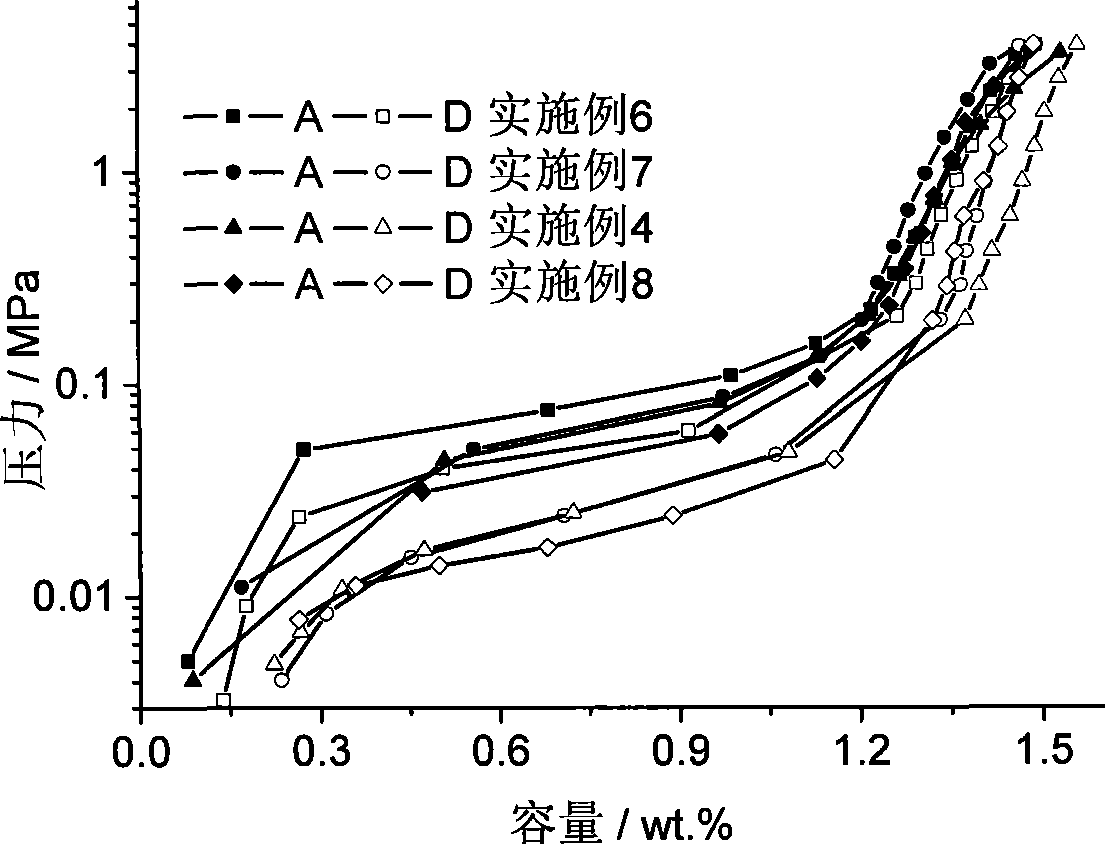

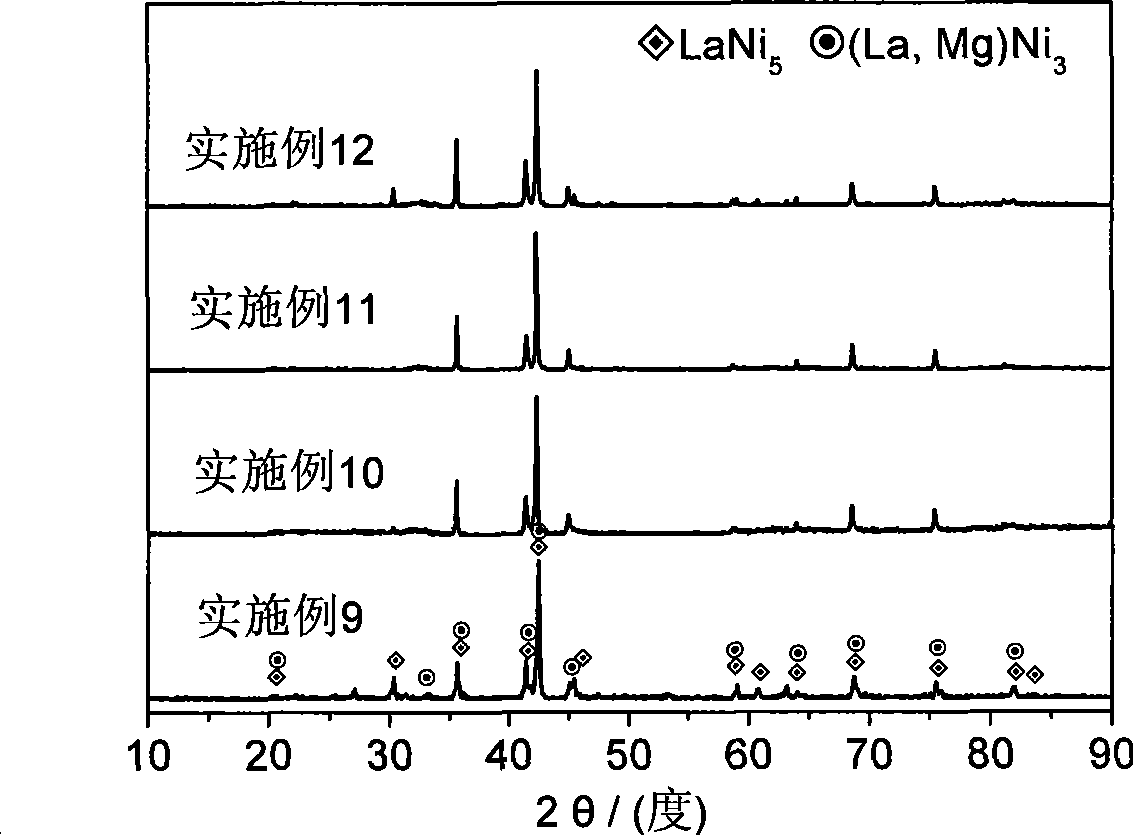

Embodiment 1

[0024] Example 1: According to La 2 MgNi 9 Weigh 10g of La, Mg and Ni metal powders in total; use a planetary ball mill to pre-mill the mixed raw material powder, the ball milling speed is 200rpm, the method is reverse rotation, the time is 4h, mill for 10min and rest for 10min, the ball-to-material ratio is 10:1. The pre-milled raw material powder is pressed into a round cake of Φ15mm×(3~5)mm by 200MPa, then placed in a high-pressure reactor and sealed, and then filled with 0.5MPa argon after repeated vacuuming for 3 times; In a steady strong magnetic field of 4T, the material is heated through a tubular heating furnace, the heating rate is 20°C / min, the sintering temperature is 610°C, and the temperature is kept for 4h. After slowly cooling down with the furnace, La 2 MgNi 9 hydrogen storage alloy.

Embodiment 2

[0025] Example 2: The sintering temperature in the preparation process of this example is 680° C., and the others are the same as in Example 1.

Embodiment 3

[0026] Embodiment 3: The sintering temperature in the preparation process of this embodiment is 750° C., and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com