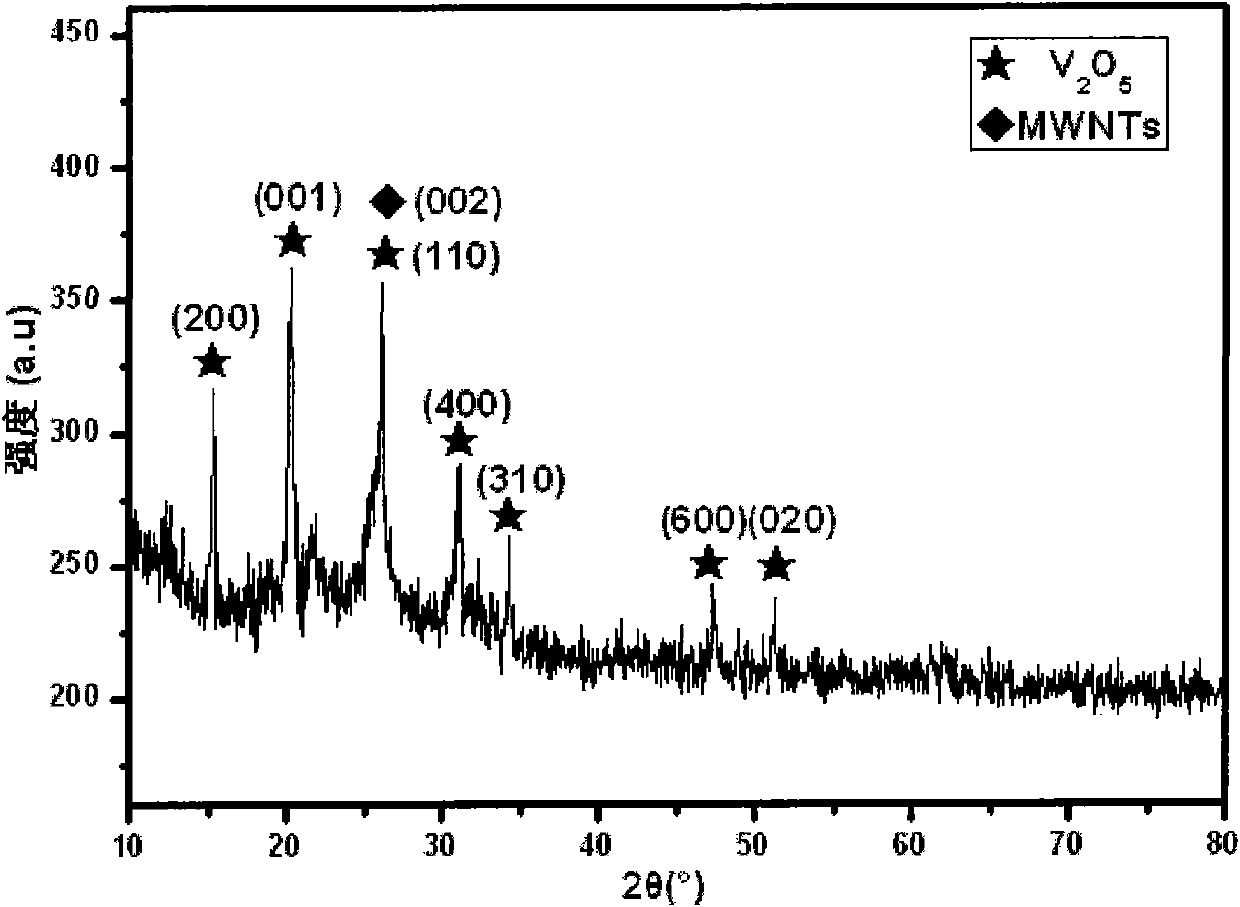

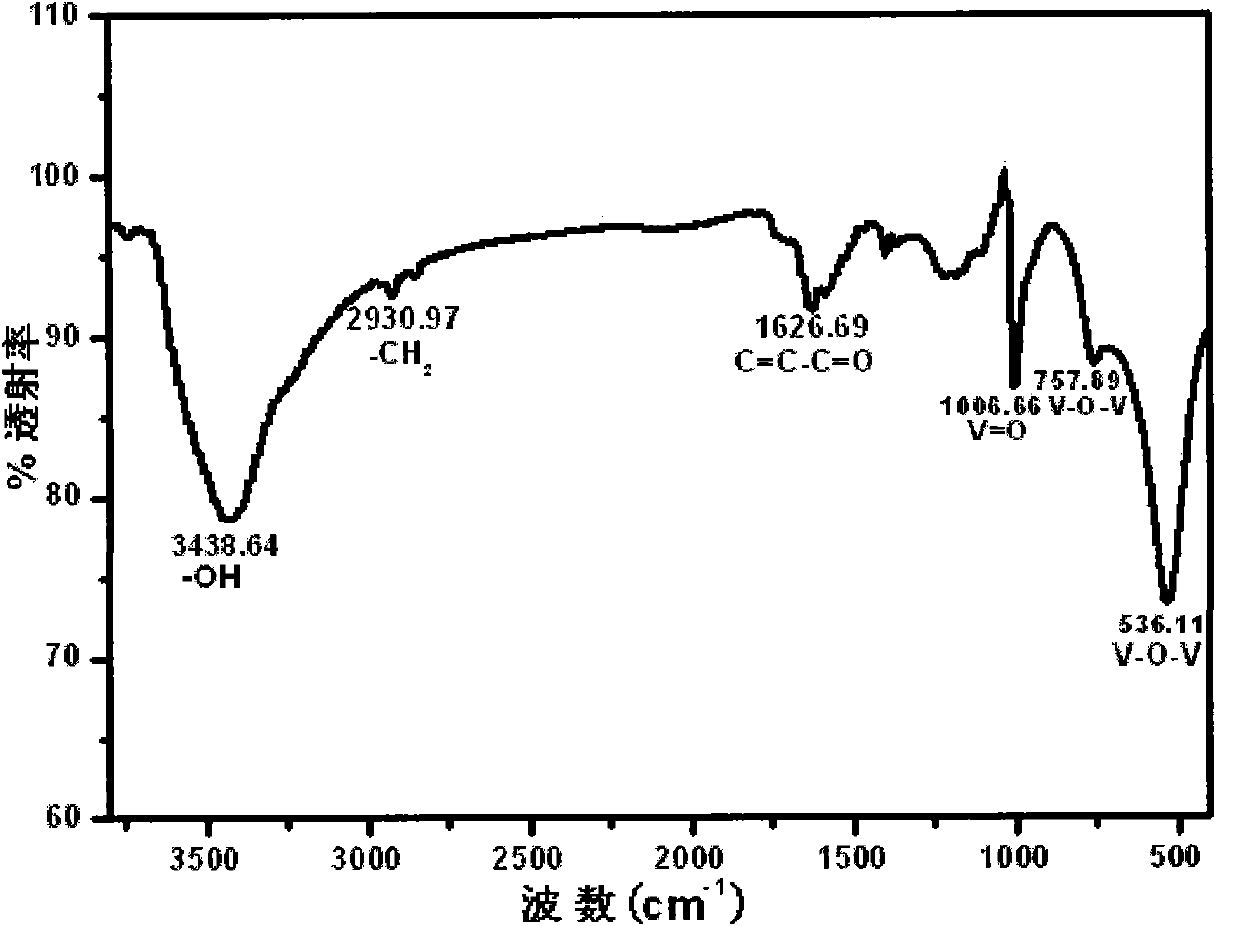

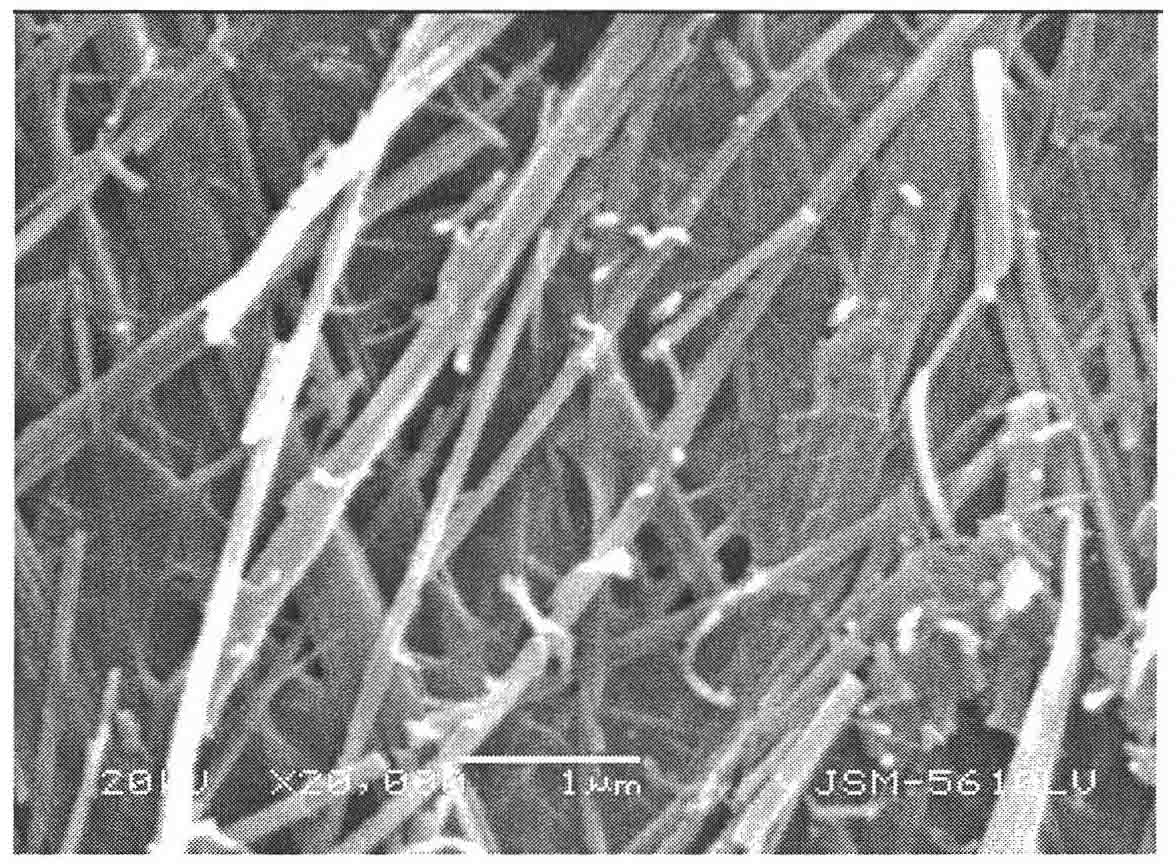

Preparation method of vanadium oxide/carbon nanometer tube composite materials with interpenetrating network structures

A technology of interpenetrating network structure and carbon nanotubes, which is applied in the field of preparation of inorganic nanocomposite materials, can solve the problems of low electrical conductivity and application limitations, and achieve the effect of simple preparation method, good reproducibility and less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 1.0 g of carbon nanotubes to 60 mL of concentrated H with a volume ratio of 3:1 2 SO 4 : HNO 3 In the mixed acid, stir for 30 minutes and ultrasonic treatment for 7 hours, then dilute with deionized water, centrifuge and wash to neutral, and dry at 80°C to obtain the modified carbon nanotubes;

[0026] (2) Prepare V by melting and quenching method 2 o 5 Sol, coming V 2 o 5 After the powder is melted at 800°C, it is quickly poured into deionized water, heated to boiling, stirred and cooled to a deep red V 2 o 5 Sol;

[0027] (3) the carbon nanotubes obtained in step (1) and step (2) and V 2 o 5 The sol was mixed and stirred for more than 1 hour according to the mass ratio of 0.2:60, and then transferred to a stainless steel reaction kettle with a polytetrafluoroethylene substrate, hydrothermally reacted at 150-190°C for 1-7 days, washed and filtered with deionized water for 2-5 times, Dry at 80°C to obtain a vanadium oxide / carbon nanotube composite mate...

Embodiment 2~ Embodiment 9

[0030] Example number

[0031] Referring to the method of Example 1 according to the above experimental parameters, a vanadium oxide / carbon nanotube composite material with an interpenetrating network structure of corresponding proportion components can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com