Method for preparing titanium alloy through high-speed pressing formation

A high-speed pressing and titanium alloy technology, applied in the field of powder metallurgy, can solve the problems of high cost and complicated preparation process, and achieve the effect of low cost, simple process and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Commercially available hydrogenated dehydrogenation Ti powder, Al powder, Mo powder and Fe powder are used. The particle size of Ti powder is 12.94-53.06 μm, the particle size of Al powder is 2-3 μm, the particle size of Mo powder is 5-10 μm, and the particle size of Fe powder is 1~5μm. The steps and process conditions for preparing titanium alloy by high-speed press forming are as follows:

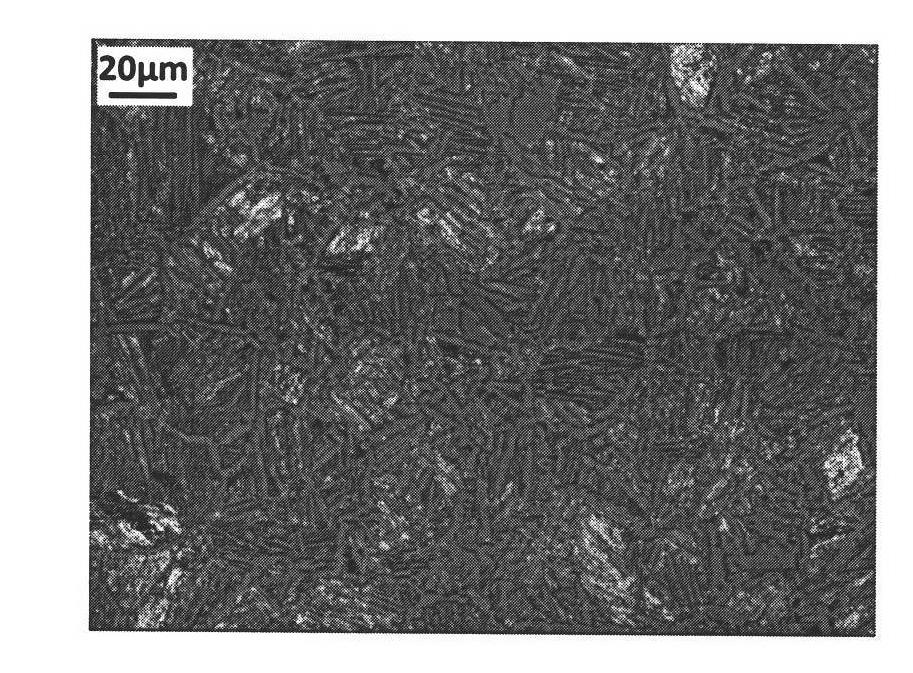

[0023] Weigh 436g of Ti powder, 22.5g of Al powder, 34g of Mo powder and 7.5g of Fe powder and place them in a ball mill jar, fill with argon gas, and ball mill on the ball mill for 8 hours to form a uniform mixed powder; use zinc stearate anhydrous Lubricate the inner wall of the mold cavity with ethanol emulsion; fill the mold cavity with mixed powder, pressurize to 60MPa, hold the pressure for 3s, and pre-press to exhaust; the impact velocity is 3.36m / s, and the ratio of impact energy to powder loading is J760J: 9.00g, prepare the compact; place the compact in a high-vacuum sin...

Embodiment 2

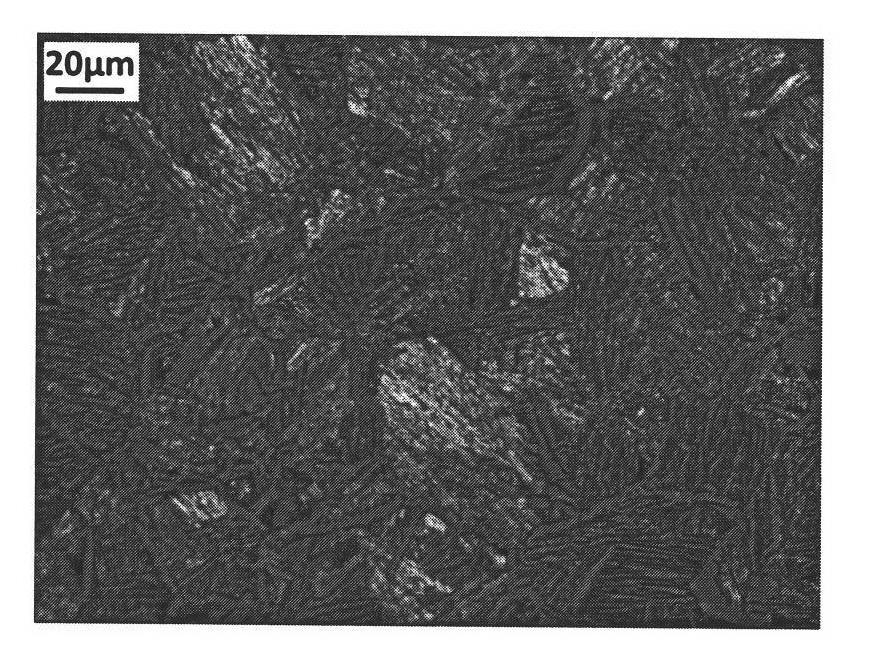

[0028] The preparation method is the same as in Example 1. The pressure in step (3) is 70MPa, and the pressure is maintained for 1s; the impact velocity is 3.68m / s, the ratio of impact energy to powder loading is 913J: 8.85g; the heating rate is 4°C / min, and the sintering holding time is 2h. The density of the prepared compact is 4.241g / cm 3 , the properties after sintering are shown in Table 2:

[0029] Table 2

[0030] Sintering temperature / ℃

Embodiment 3

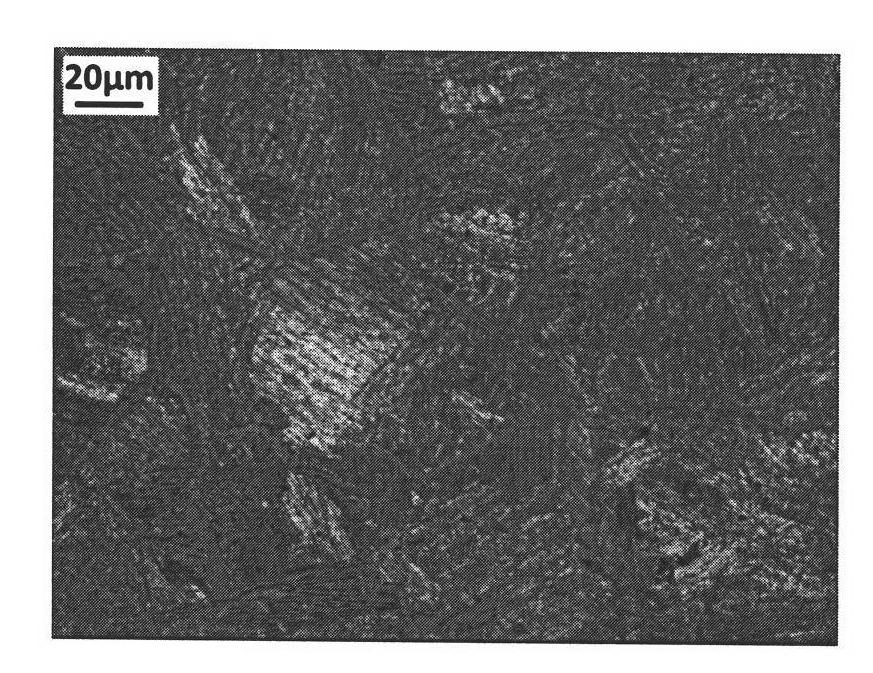

[0032] The preparation method is the same as in Example 2. The impact velocity is 3.97m / s, the ratio of impact energy to powder loading is 1065J: 8.34g, and the density of the prepared compact is 4.318g / cm 3 , the properties after sintering are shown in Table 3:

[0033] table 3

[0034] Sintering temperature / ℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com