Printing cylinder of self-cleaning type printer

A technology for printing cylinders and printing machines, applied to printing machines, general parts of printing machinery, rotary printing machines, etc., can solve the problems of affecting service life, incomplete cleaning, time-consuming and labor-intensive, etc., to prolong service life and save installation time , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

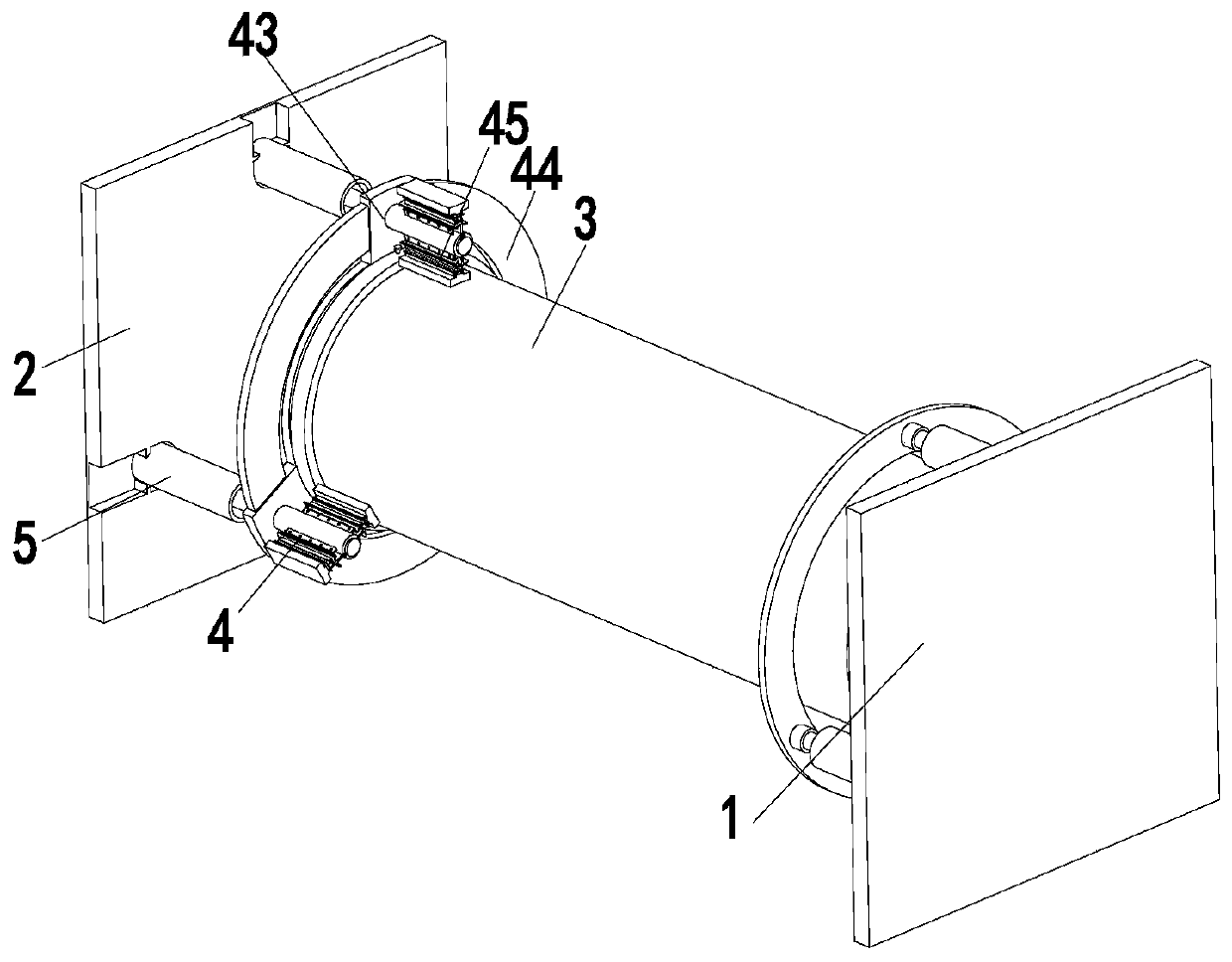

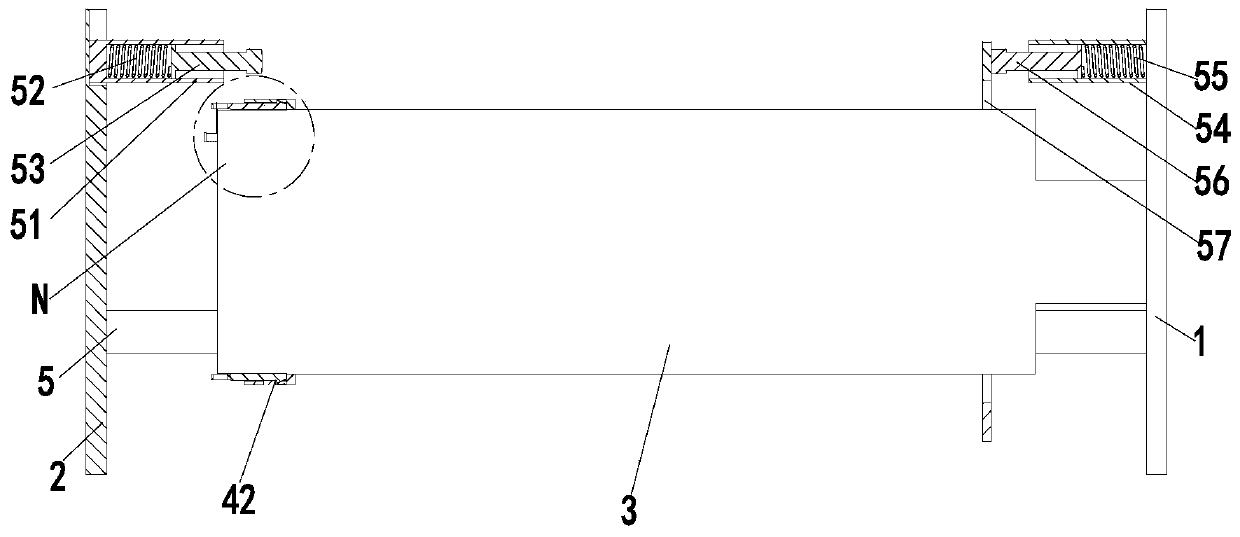

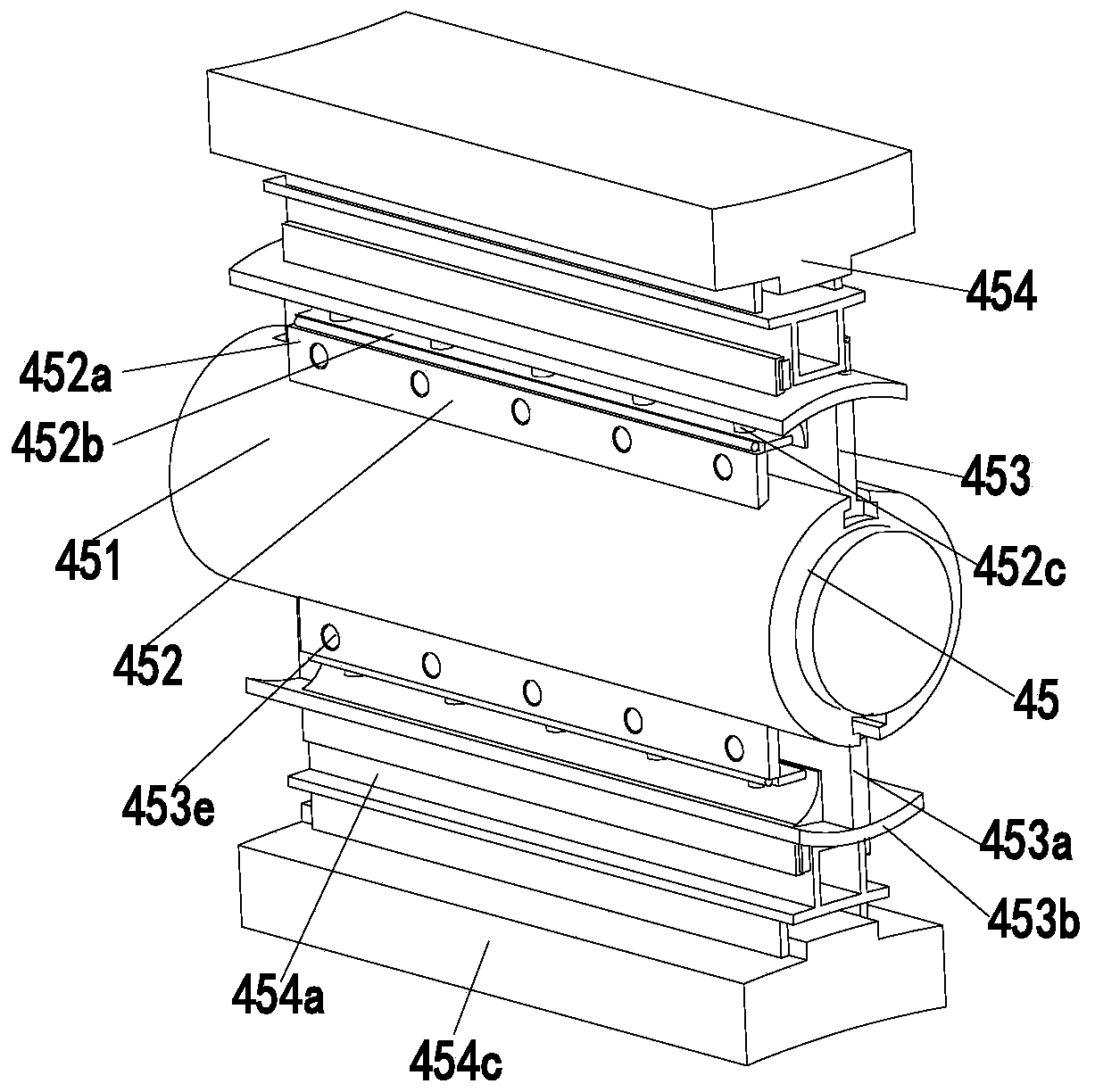

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0028] A printing cylinder of a self-cleaning printing machine, comprising a No. 1 mounting plate 1, a No. 2 mounting plate 2, a printing cylinder body 3, a cleaning mechanism 4 and an ejection mechanism 5, and the side wall of the No. 1 mounting plate 1 is installed by a bearing There is a printing cylinder body 3, a cleaning mechanism 4 is installed on the printing cylinder body 3, and an ejection mechanism 5 is arranged at the left end of the cleaning mechanism 4, and the ejection mechanism 5 is installed on the second mounting plate 2; wherein:

[0029] The cleaning mechanism 4 includes a linear bearing 41, an installation branch chain 42, a rotating block 43, an electric turntable 44 and a cleaning branch chain 45. The upper and lower ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com