Process for preparing patina

A green rust and solution technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of increased operating costs, research difficulties, product yields to be improved, etc., to achieve mild reaction conditions and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: With 2.5×10 -4 mol / L ascorbic acid (Vc) aqueous solution as solvent, FeSO 4 and Fe 2 (SO 4 ) 3 The concentration is 0.03M.

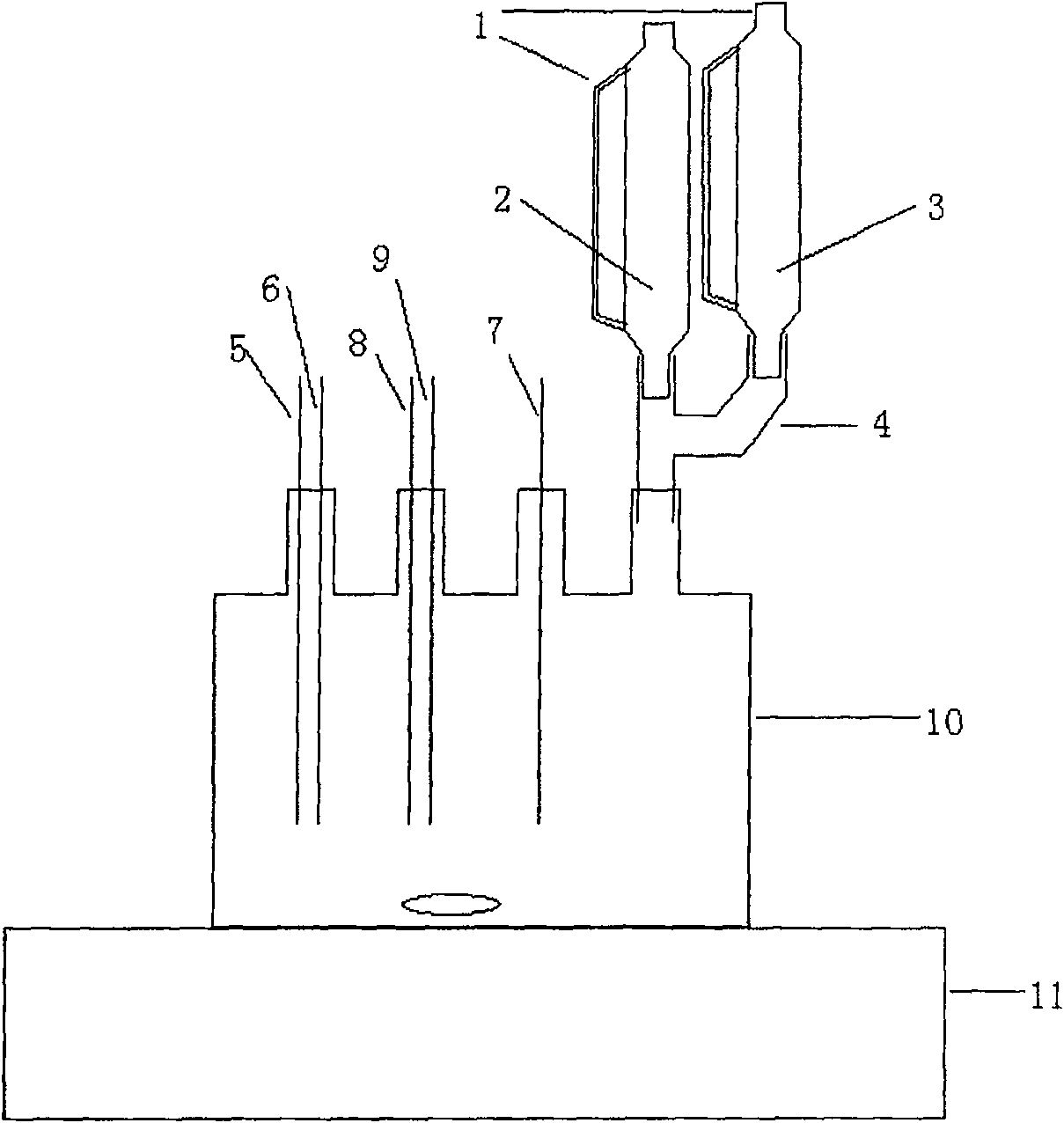

[0030] a, set up the reaction device, the first port of the four-necked flask 10 is connected with two connecting pipes 4, and the top of the two connecting pipes 4 is respectively connected with constant pressure titration funnel 1, and Fe is added respectively in the two constant pressure titration funnels 1 2 (SO 4 ) 3 Solution 2 and NaOH solution 3, the upper port of the constant pressure titration funnel 1 is plugged tightly with a rubber stopper to prevent air from entering; the second port in the four-neck flask is connected to the calomel electrode 5 and the nitrogen inlet tube 6 respectively, and the third port The port is connected to the pH electrode 7, the fourth port is respectively connected to the counter electrode 8 and the working electrode 9, and the four-necked flask 10 is placed on the electromagnetic stirrer 1...

Embodiment 2

[0038] Example 2: with 5.0×10 -4 mol / L ascorbic acid (Vc) aqueous solution as solvent, FeSO 4 and Fe 2 (SO 4 ) 3 The concentration is 0.05M.

[0039] a, set up the reaction device, the first port of the four-necked flask 10 is connected with two connecting pipes 4, and the top of the two connecting pipes 4 is respectively connected with constant pressure titration funnel 1, and Fe is added respectively in the two constant pressure titration funnels 1 2 (SO 4 ) 3Solution 2 and NaOH solution 3, the upper port of the constant pressure titration funnel 1 is plugged tightly with a rubber stopper to prevent air from entering; the second port in the four-neck flask is connected to the calomel electrode 5 and the nitrogen inlet tube 6 respectively, and the third port The port is connected to the pH electrode 7, the fourth port is respectively connected to the counter electrode 8 and the working electrode 9, and the four-necked flask 10 is placed on the electromagnetic stirrer 11...

Embodiment 3

[0052] Example 3: With 7.5×10 -4 mol / L ascorbic acid (Vc) aqueous solution as solvent, FeSO 4 and Fe 2 (SO 4 ) 3 The concentration is 0.07M as an example:

[0053] a, set up the reaction device, the first port of the four-necked flask 10 is connected with two connecting pipes 4, and the top of the two connecting pipes 4 is respectively connected with constant pressure titration funnel 1, and Fe is added respectively in the two constant pressure titration funnels 1 2 (SO 4 ) 3 Solution 2 and NaOH solution 3, the upper port of the constant pressure titration funnel 1 is plugged tightly with a rubber stopper to prevent air from entering; the second port in the four-neck flask is connected to the calomel electrode 5 and the nitrogen inlet tube 6 respectively, and the third port The port is connected to the pH electrode 7, the fourth port is respectively connected to the counter electrode 8 and the working electrode 9, and the four-necked flask 10 is placed on the electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com