Method for preparing uranium ion trapping agent

A technology of ion trapping agent and chelating agent, which is applied in the field of preparation of uranium ion trapping agent, can solve the problems of low adsorption amount, complex preparation process, high environmental sensitivity, etc., and achieve the effect of rapid removal and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

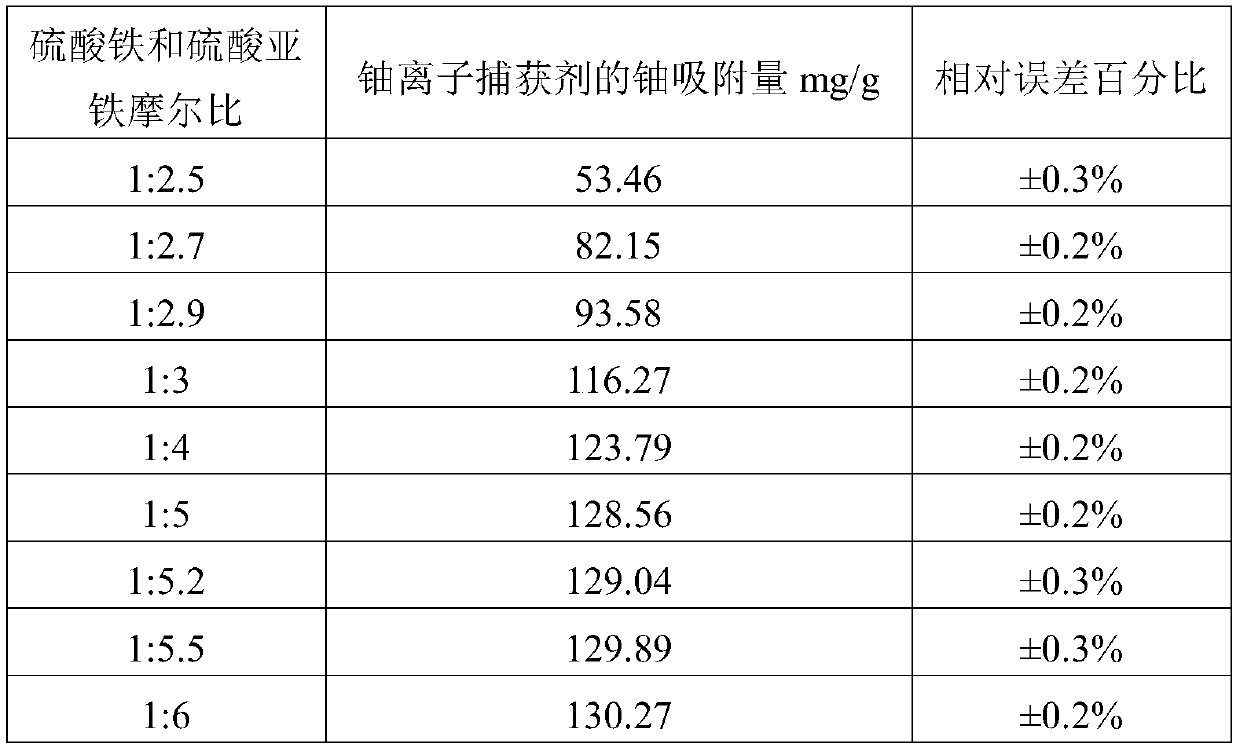

[0017] Effect of Molar Ratio of Ferric Sulfate and Ferrous Sulfate on Uranium Adsorption Amount of Uranium Ion Scavenger

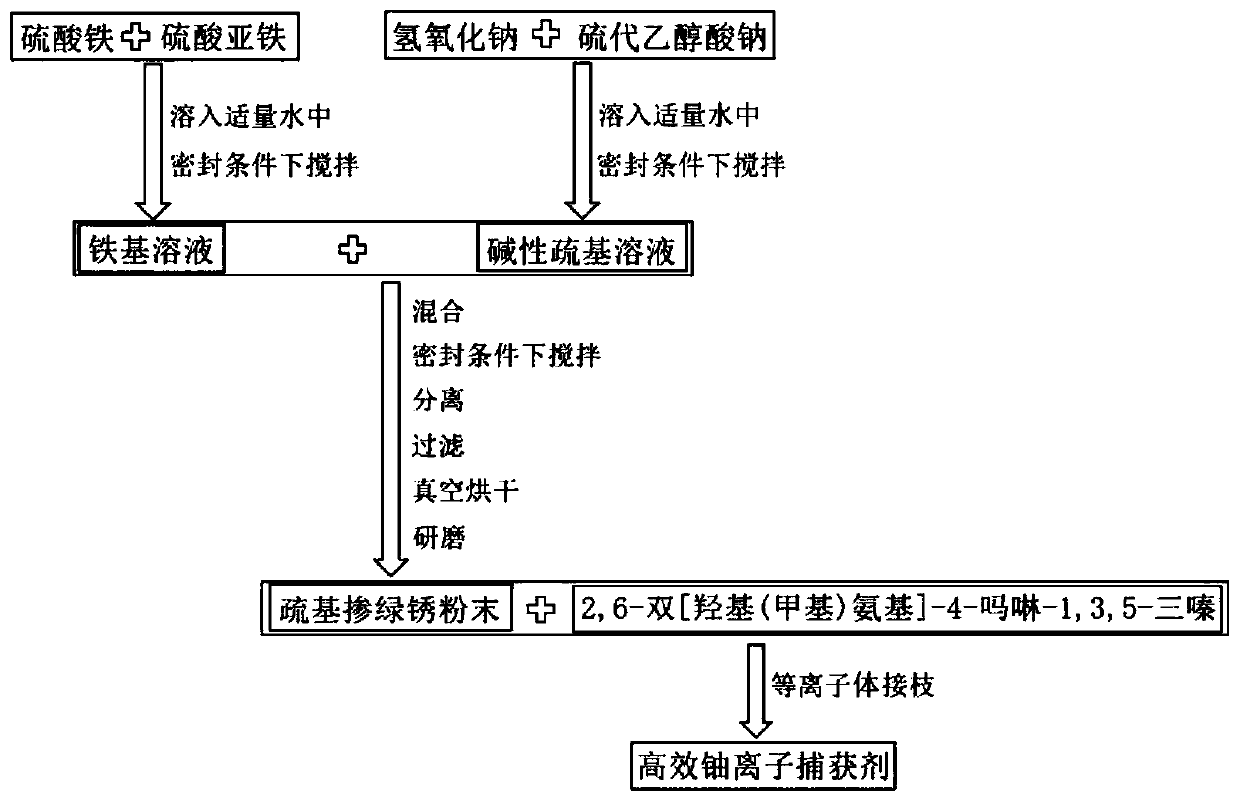

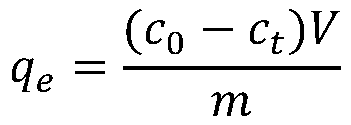

[0018] Preparation of uranium ion capture agent: such as figure 1 As shown, according to the molar ratio of ferric sulfate and ferrous sulfate is 1:2.5, 1:2.7, 1:2.9, 1:3, 1:4, 1:5, 1:5.2, 1:5.5, 1:6 respectively Take ferric sulfate and ferrous sulfate. Weigh sodium hydroxide according to the molar ratio of ferric sulfate and sodium hydroxide is 1:6. Sodium thioglycolate was weighed according to the molar ratio of iron sulfate and sodium thioglycolate at 1:0.5. According to the solid-liquid ratio of 1:1 (g / mL), ferric sulfate and ferrous sulfate were dissolved in the solution, and stirred under sealed conditions until completely dissolved to obtain an iron-based solution. Sodium hydroxide and sodium thioglycolate were dissolved in the solution according to the solid-liquid ratio of 1:1 (g / mL), and stirred under sealed conditions until completely dissolv...

Embodiment 2

[0029] Effect of Molar Ratio of Ferric Sulfate and Sodium Hydroxide on Uranium Adsorption Amount of Uranium Ion Scavenger

[0030] Preparation of uranium ion trapping agent: Weigh ferric sulfate and ferrous sulfate respectively according to the molar ratio of ferric sulfate and ferrous sulfate is 1:5. According to the molar ratio of ferric sulfate and sodium hydroxide is 1:5.5, 1:5.7, 1:5.9, 1:6, 1:7, 1:8, 1:8.2, 1:8.5, 1:9 respectively weigh the hydroxide sodium. Sodium thioglycolate was weighed according to the molar ratio of iron sulfate and sodium thioglycolate being 1:0.75. According to the solid-liquid ratio of 1:1 (g / mL), ferric sulfate and ferrous sulfate were dissolved in the solution, and stirred under sealed conditions until completely dissolved to obtain an iron-based solution. Sodium hydroxide and sodium thioglycolate were dissolved in the solution according to the solid-liquid ratio of 1:1 (g / mL), and stirred under sealed conditions until completely dissolved t...

Embodiment 3

[0036] Effect of Molar Ratio of Ferric Sulfate and Sodium Thioglycolate on Uranium Adsorption Amount of Uranium Ion Scavenger

[0037] Preparation of uranium ion trapping agent: Weigh ferric sulfate and ferrous sulfate respectively according to the molar ratio of ferric sulfate and ferrous sulfate is 1:5. Sodium hydroxide was weighed according to the molar ratio of ferric sulfate and sodium hydroxide being 1:8. According to the molar ratio of ferric sulfate and sodium thioglycolate 1:0.2, 1:0.3, 1:0.4, 1:0.5, 1:0.75, 1:1, 1:1.2, 1:1.5, 1:2, weigh Sodium Thioglycolate. According to the solid-liquid ratio of 1:1 (g / mL), ferric sulfate and ferrous sulfate were dissolved in the solution, and stirred under sealed conditions until completely dissolved to obtain an iron-based solution. Sodium hydroxide and sodium thioglycolate were dissolved in the solution according to the solid-liquid ratio of 1:1 (g / mL), and stirred under sealed conditions until completely dissolved to obtain an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com