Method for preparing layered iron oxide green rust in zero-emission mode

An iron oxide, zero-emission technology, applied in the direction of iron compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of increasing raw material costs, energy consumption, subsequent waste water and waste treatment costs, consuming large amounts of water and raw materials, etc., to achieve reduction Strong activity, reduced energy consumption for oxygen removal, simple and cheap synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

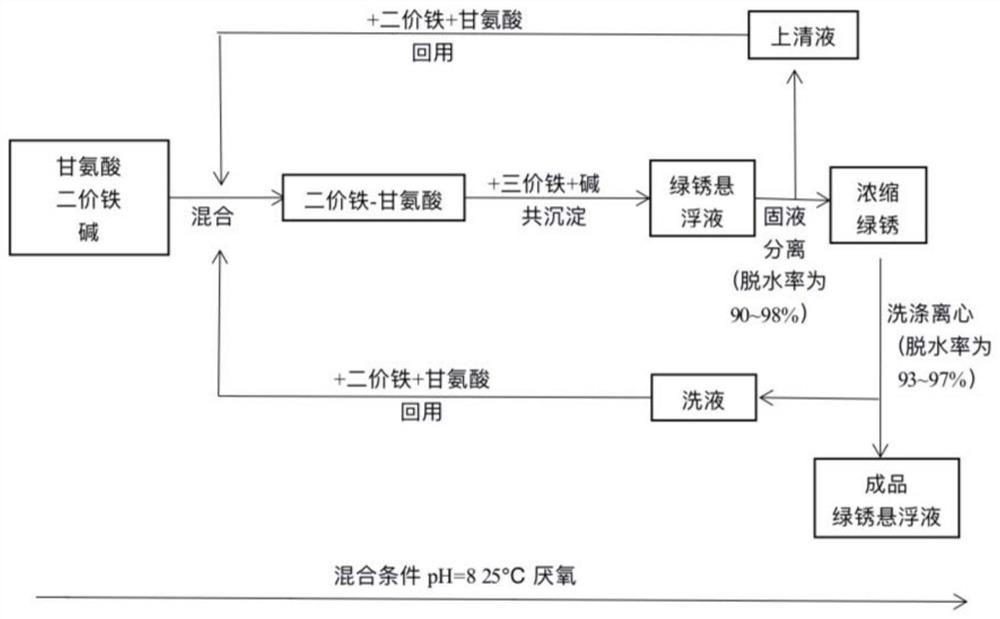

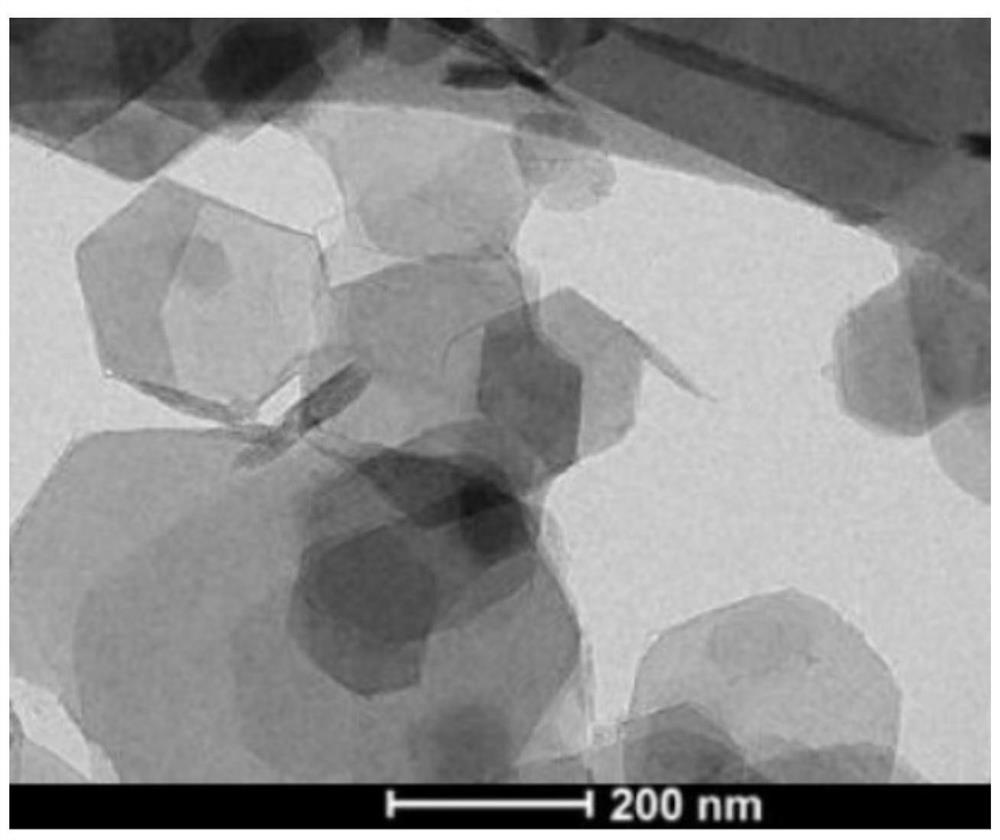

[0039] (1) Under the condition of anaerobic, room temperature and stirring, adjust the pH of 450mL glycine solution (0.07mol / L) to 8.0 with 1.0mol / L NaOH solution, then add 20mL of FeCl 2 solution (0.5mol / L), and then adjust the pH to 8.0 with 1.0mol / L NaOH solution to obtain a glycine-ferrous iron mixture; 3 The solution (0.1mol / L) was injected into the above-mentioned glycine-ferrous iron mixture at a rate of 5mL / min in four times, and 1mol / L NaOH solution (3mL / min) was added dropwise at the same time to stabilize the pH of the system at 8.0. During the process, the layered iron oxide patina will crystallize and precipitate, and after the dosing is completed, a patina suspension is obtained;

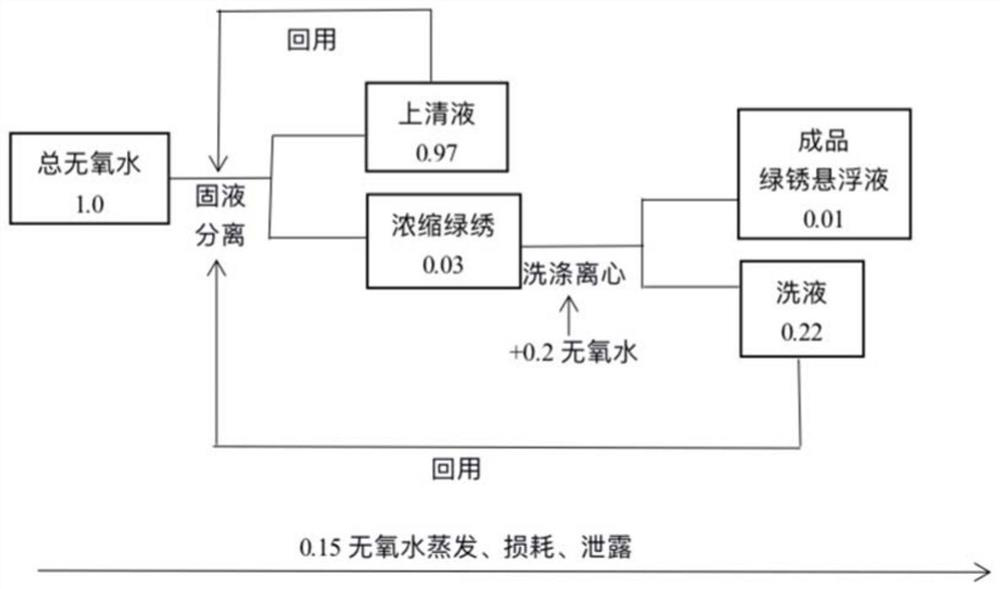

[0040] (2) The green rust suspension that step (1) is made is by centrifugation, and wherein, the rotating speed of centrifugal is 5000rpm, and the time is 3min, obtains concentrated green rust (concentration is 500mM) and supernatant; Supernatant (485mL ) to collect, then add glycine...

Embodiment 2

[0045] (1) Under the condition of anaerobic, room temperature and stirring, adjust the pH of 5400mL glycine solution (0.84mol / L) to 8.0 with 13mol / L NaOH solution, then add 240mL of FeCl 2 solution (2.2mol / L), then adjust the pH to 8.0 with 13mol / L NaOH solution to obtain a glycine-ferrous iron mixture; 3 The solution (2.75mol / L) was injected into the above-mentioned glycine-ferrous iron mixed solution at a rate of 60mL / min four times, and 13mol / L NaOH solution (36mL / min) was added dropwise at the same time to stabilize the pH of the system at 8.0. During the process, the layered iron oxide patina will crystallize and precipitate, and after the dosing is completed, a patina suspension is obtained;

[0046] (2) The green rust suspension that step (1) is made is by centrifugation, and wherein, the rotating speed of centrifugal is 5000rpm, and the time is 3min, obtains concentrated green rust (concentration is 500mM) and supernatant; Supernatant (5820mL ) to collect, then add gl...

Embodiment 3

[0050] (1) Under the condition of anaerobic, room temperature and stirring, adjust the pH of 11250mL glycine solution (1.75mol / L) to 8.0 with 27.25mol / L NaOH solution, then add 500mL of FeCl 2 solution (4.95mol / L), and then adjust the pH to 8.0 with 27.25mol / L NaOH solution to obtain a glycine-ferrous iron mixture; 3 The solution (5.6mol / L) was injected into the above-mentioned glycine-ferrous iron mixed solution at a rate of 125mL / min four times, and 27.25mol / L NaOH solution (60mL / min) was added dropwise at the same time to stabilize the pH of the system at 8.0, During this process, the layered iron oxide green rust will crystallize and precipitate out, and after the dosing is completed, the green rust suspension is obtained;

[0051] (2) the green rust suspension that step (1) is made is by centrifugation, and wherein, the rotating speed of centrifugal is 5000rpm, and the time is 3min, obtains concentrated green rust (concentration is 500mM) and supernatant; Supernatant (121...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com