Laser acoustomagnetic steel rail surface defect rapid flaw detection system and method

A magnetic flaw detector, laser ultrasonic technology, applied in the direction of optical testing flaws/defects, material analysis through optical means, instruments, etc., can solve the problems of inability to realize fast flaw detection of rail tread defects, slow flaw detection speed, low detection sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

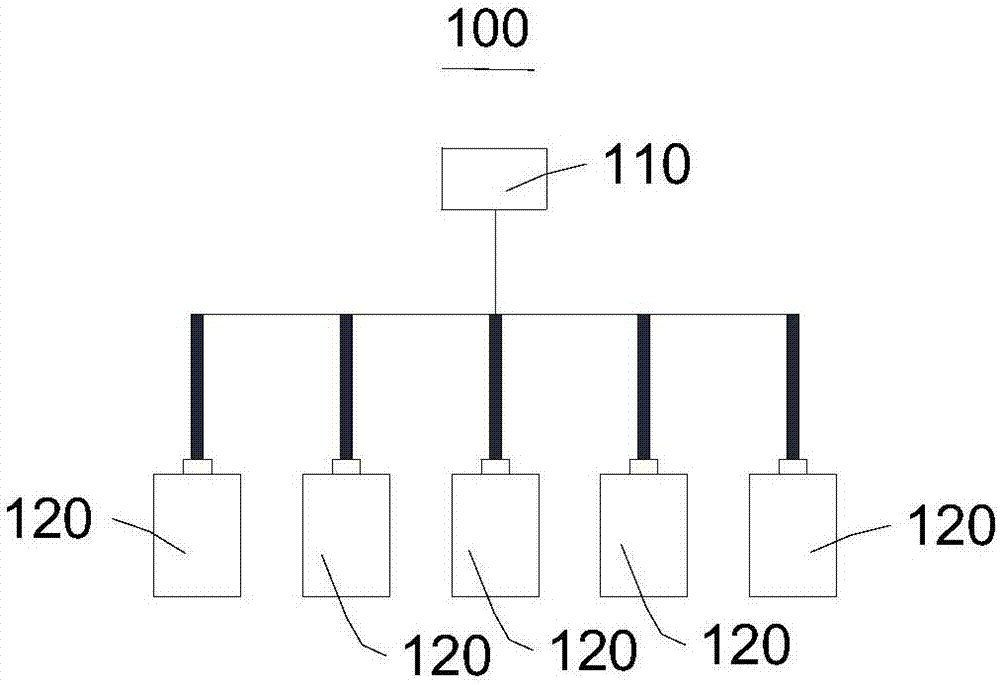

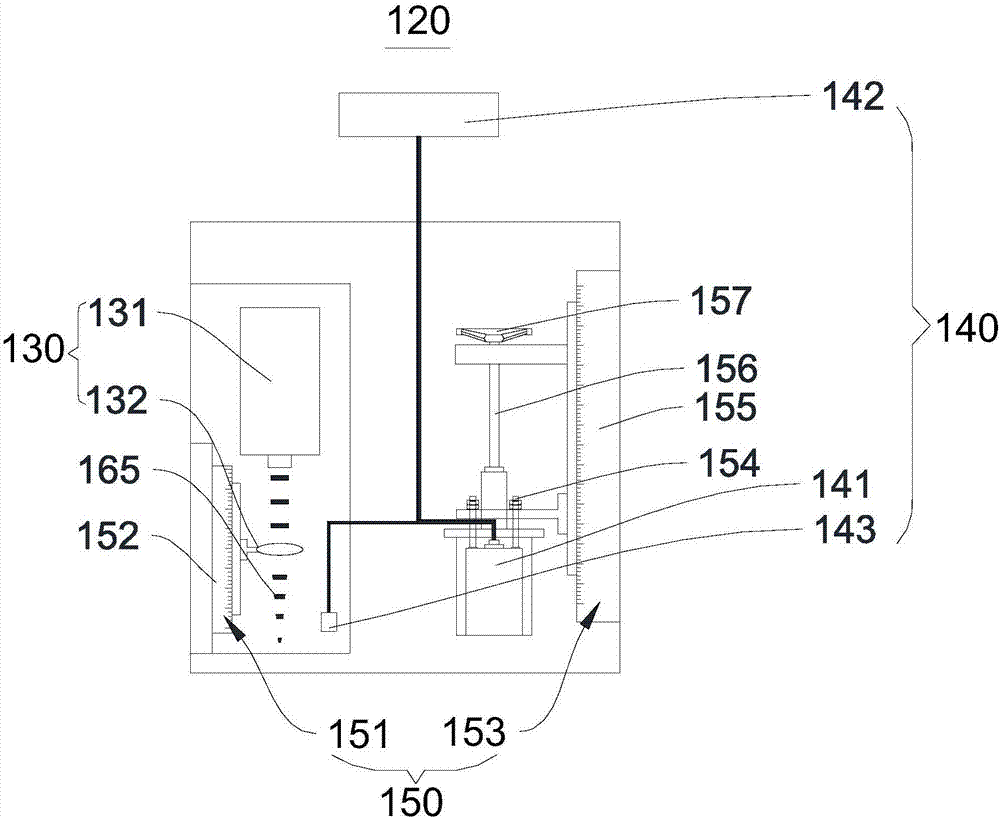

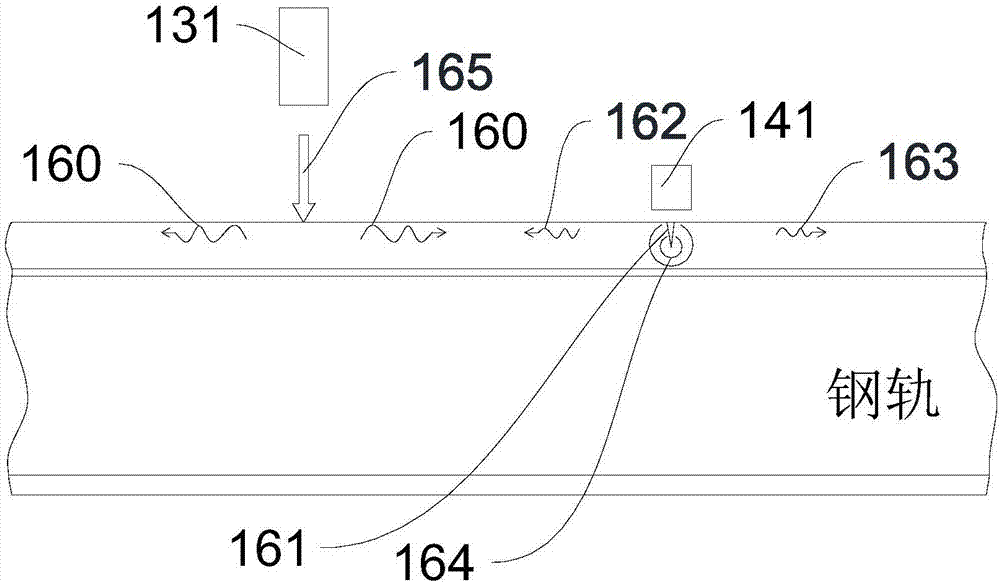

[0033] The first embodiment of the present invention provides a laser acousto-magnetic rail surface defect rapid flaw detection system 100, please refer to figure 1 , the laser acoustomagnetic rail surface defect rapid flaw detection system 100 includes a control device 110 and a plurality of laser acoustomagnetic flaw detectors 120 . A plurality of laser acoustomagnetic flaw detectors 120 are electrically connected to the control device 110, and the plurality of laser acoustomagnetic flaw detectors 120 are arranged according to a preset distance. See figure 2 , the laser acoustomagnetic flaw detector 120 includes a laser ultrasonic excitation device 130 , an ultrasonic diffraction shear wave receiving device 140 and an adjustment mechanism 150 . The laser ultrasonic excitation device 130 and the ultrasonic diffraction shear wave receiving device 140 are respectively electrically connected to the control device 110 .

[0034] In the first embodiment of the present invention...

no. 2 example

[0070] The second embodiment of the present invention provides a rapid detection method for surface defects of a laser acoustomagnetic rail, which is applied to the rapid detection system for surface defects of a laser acoustomagnetic rail provided in the first embodiment of the present invention. Such as Figure 9 As shown, the laser acousto-magnetic rail surface defect rapid flaw detection method includes:

[0071] Step S10: Use the laser acousto-magnetic rail surface defect rapid flaw detection system to conduct pre-flaw detection on the real object, and obtain the pre-flaw detection result.

[0072] Specifically, step S10 includes:

[0073] The control device controls the laser ultrasonic excitation device to emit a focused pulsed laser beam to the surface of the object; the ultrasonic diffraction shear wave receiving device receives the ultrasonic diffraction shear wave signal and transmits it to the control device; the control device judges the ultrasonic Whether the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com