A superimposed rotating electromagnet with a curved surface rotating shaft

A technology for rotating electromagnets and rotating shafts, which is applied in the directions of electromagnets and electromagnets without armatures, can solve problems such as being unsuitable for cylinder control and detection processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now the present invention is further described in conjunction with description of drawings and embodiments:

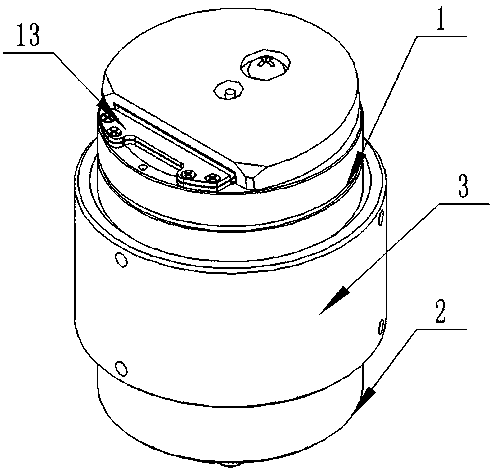

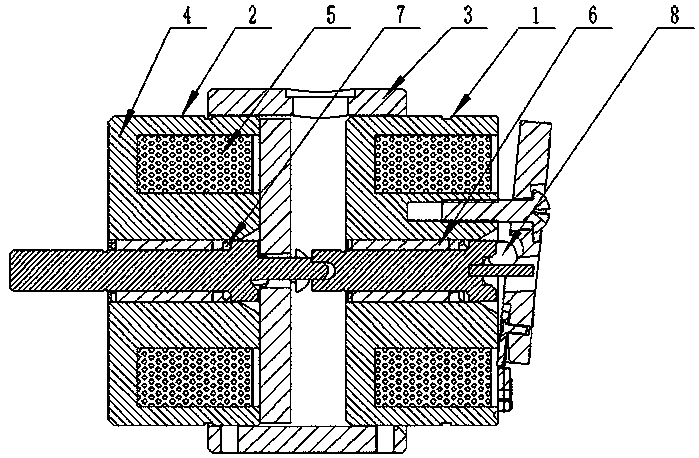

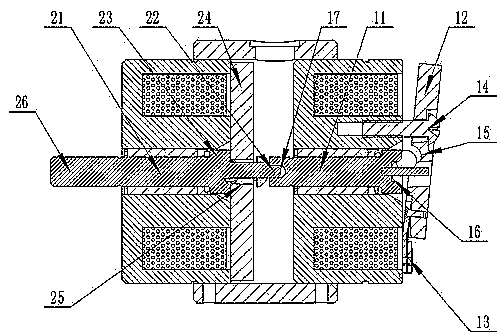

[0028] refer to Figures 1 to 8 , a superimposed rotating electromagnet with a curved surface rotating shaft, where:

[0029] Including the main rotating electromagnet 1: the main rotating electromagnet 1 has a yoke 4, a coil 5, a main shaft 11, a cover plate 12 and a universal ball 8; the yoke 4 has a hollow central column 41 and a concentric outer wall 42, and the hollow central column 41 and The bottom end of the concentric outer wall 42 is closed to form an annular groove 43, and the coil 5 is wound in the groove 43; the hollow of the hollow center column 41 is provided with a bearing 6; one end of the cover plate 12 is provided with a spring piece 13, and the other end is opened There is a fixing hole 19, a central circular hole 18 is provided in the middle, and a cover plate curved sliding groove 15 is provided on the edge of the central circular hole 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com