Ultrasonic pipe flaw detection device

A flaw detection device, ultrasonic technology, used in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, cleaning hollow objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the content of the present invention easier to be understood clearly, the following further describes the present invention in detail based on specific embodiments in conjunction with the accompanying drawings.

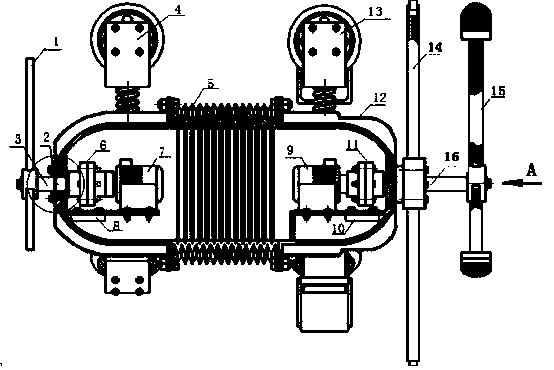

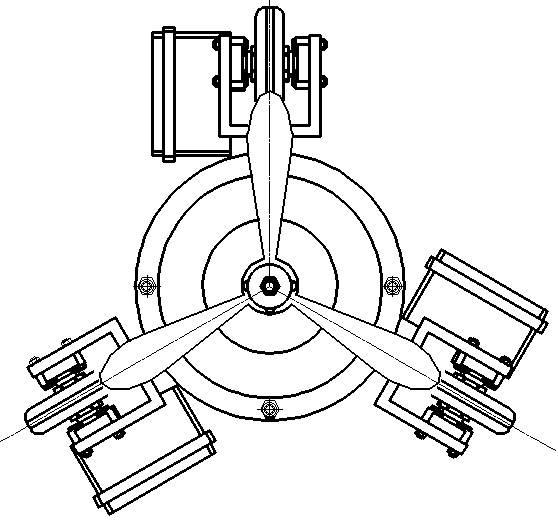

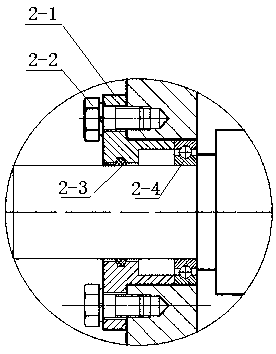

[0029] Such as Figure 1~3 As shown, an ultrasonic pipeline flaw detection device includes a drive impeller 1, an impeller drive shaft 3, a drive wheel set 13, a driven wheel set 4, an impeller drive coupling 6, an impeller drive DC motor 7, a fastening screw 2, an impeller drive battery 8. Steel brush drive DC motor 9, steel brush 16, ultrasonic detection component 14, rubber bellows 5, steel brush drive shaft 15, steel brush drive shaft coupling 11, steel brush drive battery 10, and body 12. The fuselage 12 serves as a base to fix and connect the main components. The impeller 1 is driven by the impeller-driven DC motor 6 through the coupling 6 to drive the impeller drive shaft 3. The impeller-driven DC motor 7 is fixed on the support plate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com