Pipe creeping robot

A crawling robot and pipeline technology, applied in the field of robots, can solve the problems of affecting the use effect, the robot cannot detect the pipeline, and the pipeline crawling robot is easily hindered, so as to improve the ability to adapt to changes in the size of the pipeline and the effect of stable crawling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below.

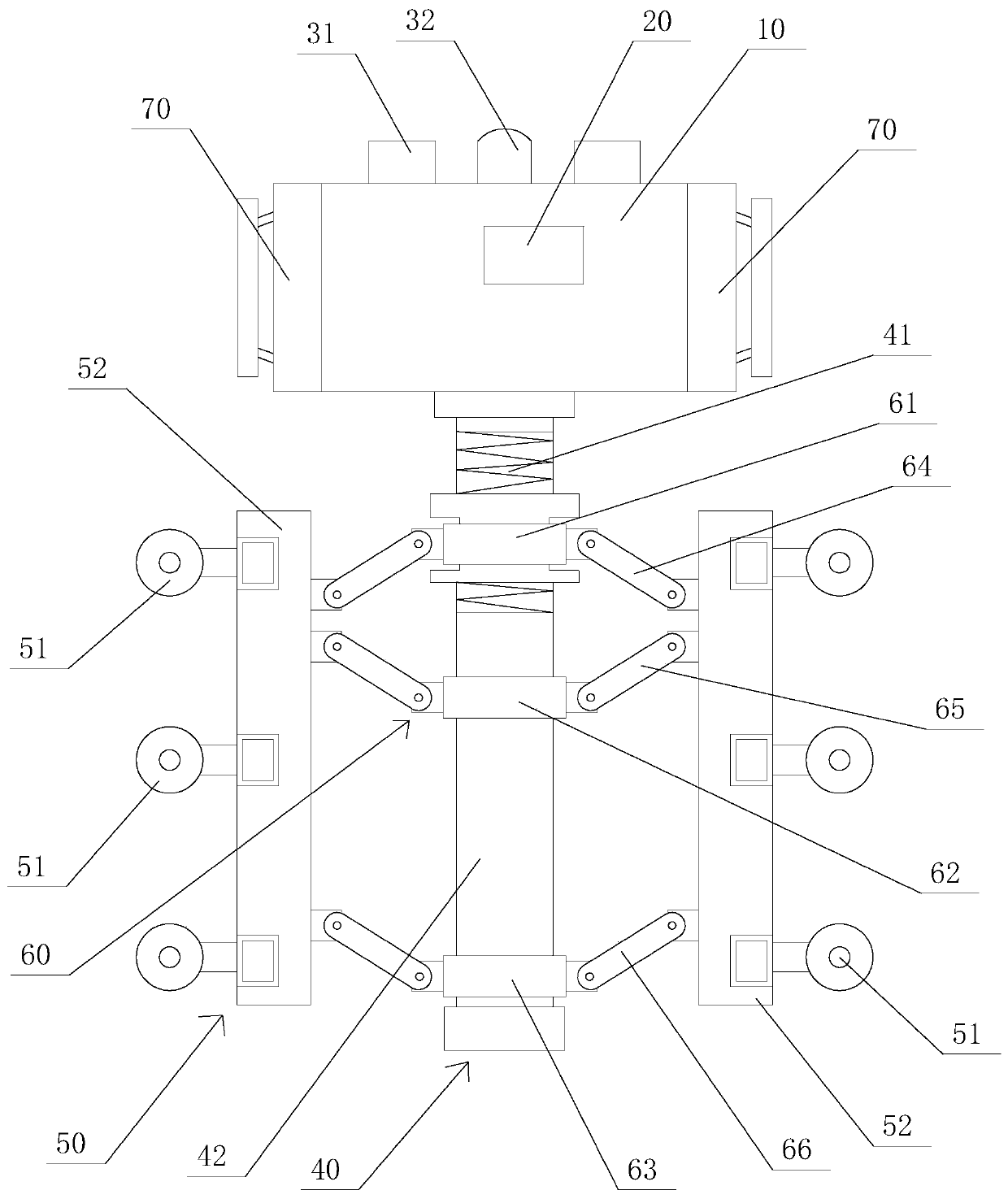

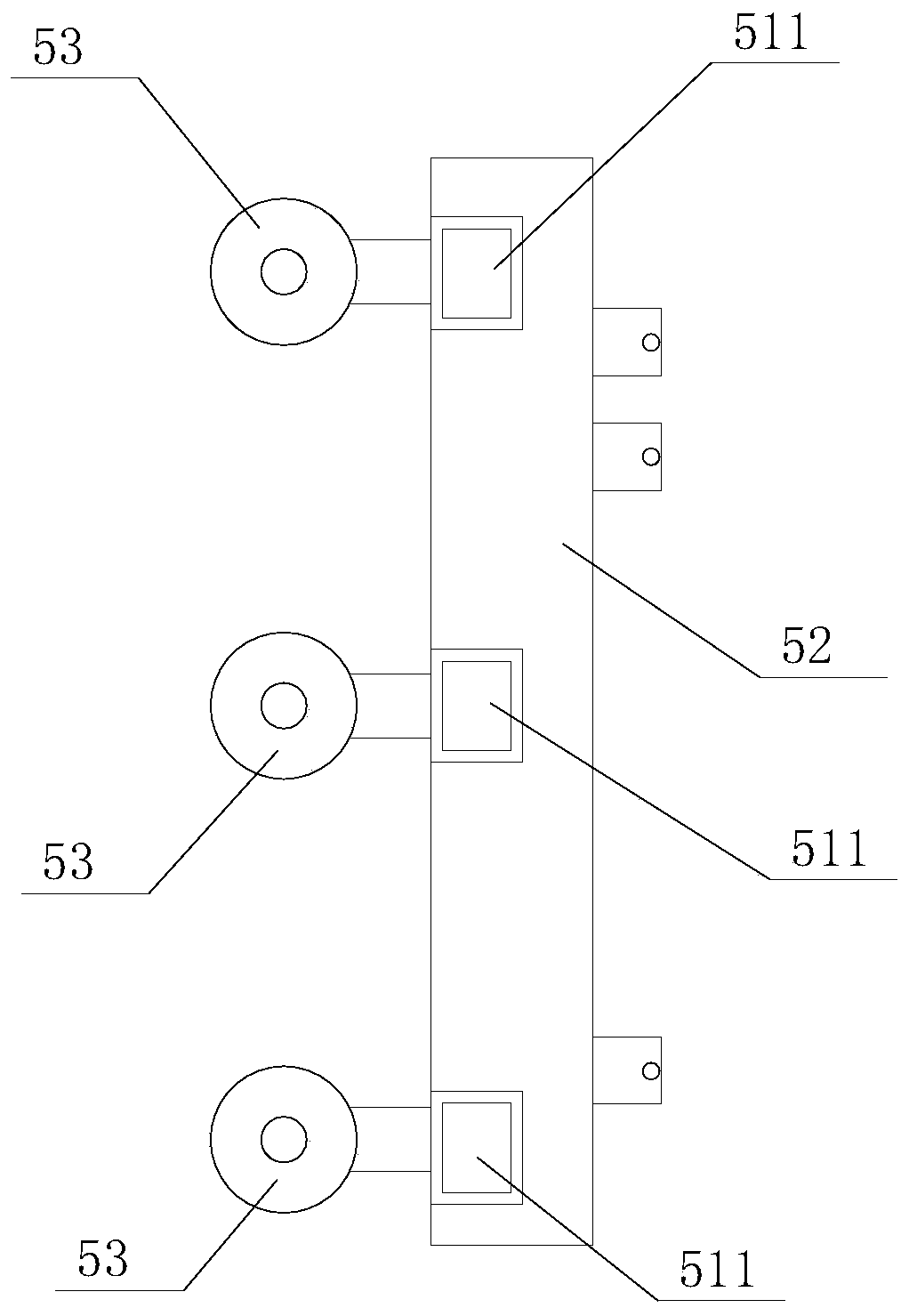

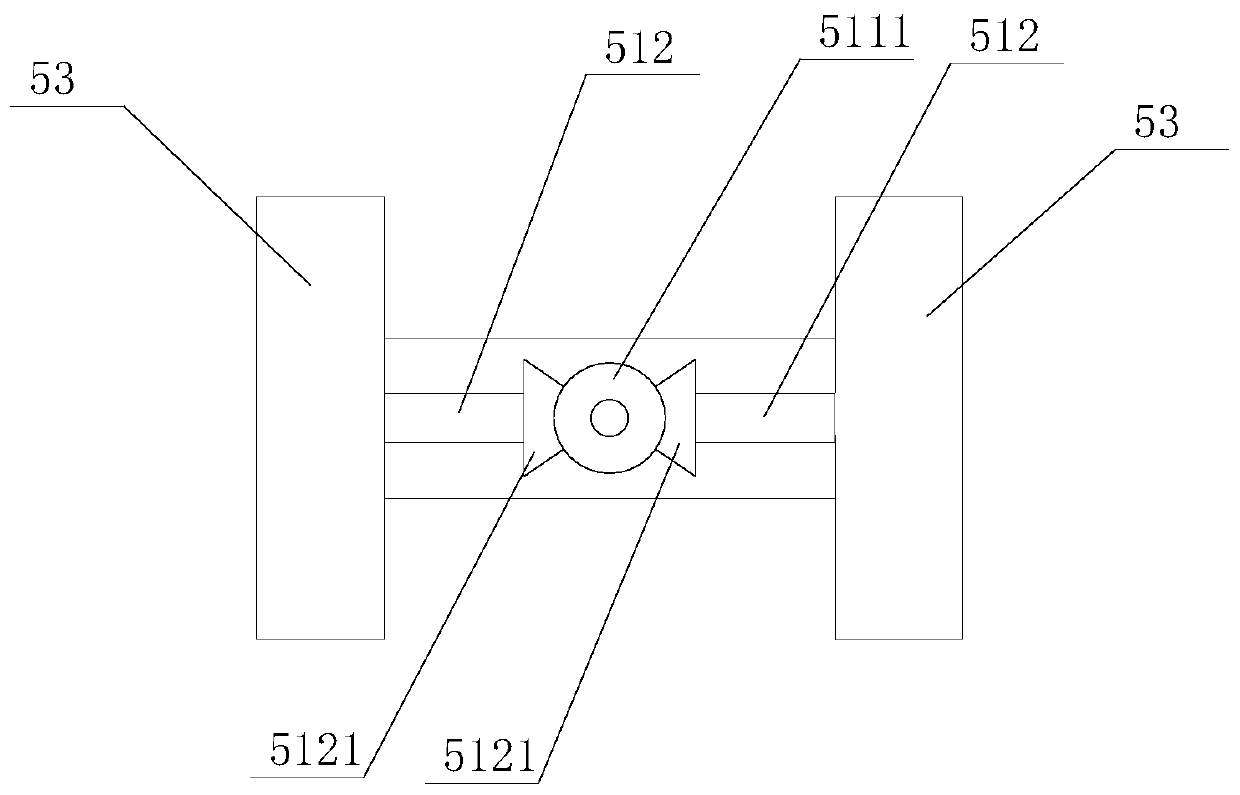

[0040] Such as figure 1 As shown, the pipeline crawling robot includes a box body 10, a control mechanism 20, a detection mechanism, a fixed column 40, a plurality of obstacle crawling mechanisms 50, a telescopic link device 60, and two detection fixed support frames 70. The detection mechanism is installed in the box. At the front end of the body 10, two detection and fixing support frames 70 are respectively installed on both sides of the box body 10, the control mechanism 20 is installed in the box body 10, the fixed column 40 is installed at the rear end of the box body 10, and a plurality of obstacle crawling mechanisms 50 is telescopically connected to the fixed column 40 through the telescopic link device 60, and the detection mechanism, the obstacle crawling mechanism 50, and the detection and fixing support frame 70 are electrically connected to the control mechanism 20 respectively. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com