Search and rescue robot used in pit

A robot and mechanical technology, which is applied in the field of robots, can solve the problems of non-explosion-proof protection design and inappropriateness, and achieve the effects of avoiding cable constraints, reducing weight, and improving the ability to overcome obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

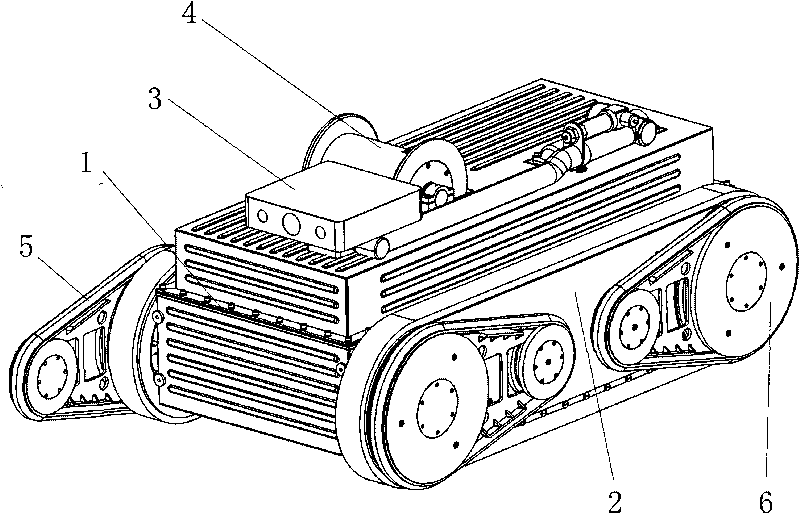

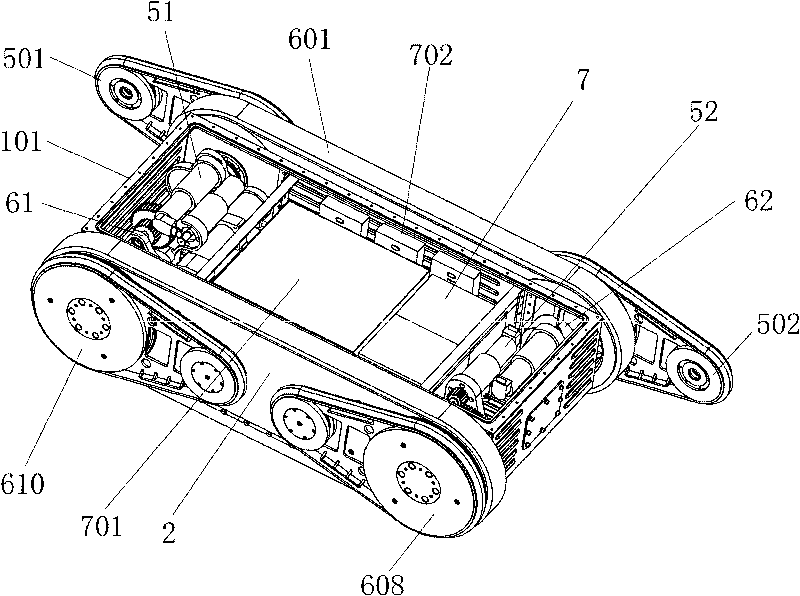

[0051] Example: such as figure 1 , figure 2 As shown, it includes an explosion-proof casing 1, two sets of symmetrical walking systems 6, independent swing arm systems 5 and control systems 7, and the driving mechanisms of the control system 7, walking system 6 and swing arm systems 5 are placed in the explosion-proof casing 1, The control system 7 is connected to the drive mechanism, and a mechanical pan-tilt 3 and an optical fiber application device 4 are also arranged above the explosion-proof enclosure 1. The mechanical pan-tilt 3 is electrically connected to the control system 7, and the optical fiber application device 4 is connected to the control system 7 through an optical fiber. . .

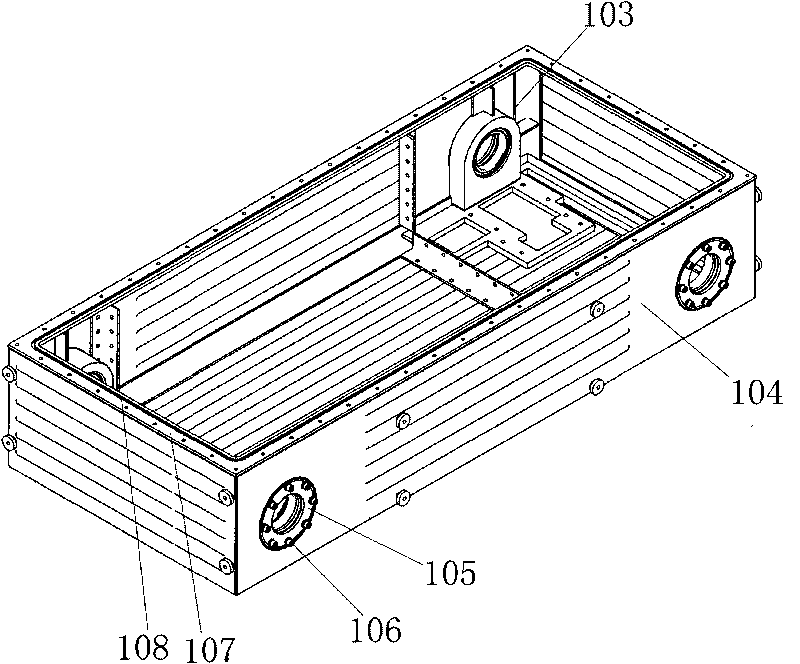

[0052] Such as image 3 , Figure 4 As shown, the explosion-proof enclosure 1 includes a mobile platform 101 and a positive-pressure upper cover 102 connected with it by screws. Both the mobile platform 101 and the upper cover 102 are frames welded by angle steel, which play a main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com