Ultrasonic flaw detector for measuring metal workpiece

A technology for metal workpieces and flaw detection instruments, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc. It can solve problems such as easy quality accidents and large production batches of pipe fittings, so as to improve quality and efficiency, ensure quality inspection, and flaw detection. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

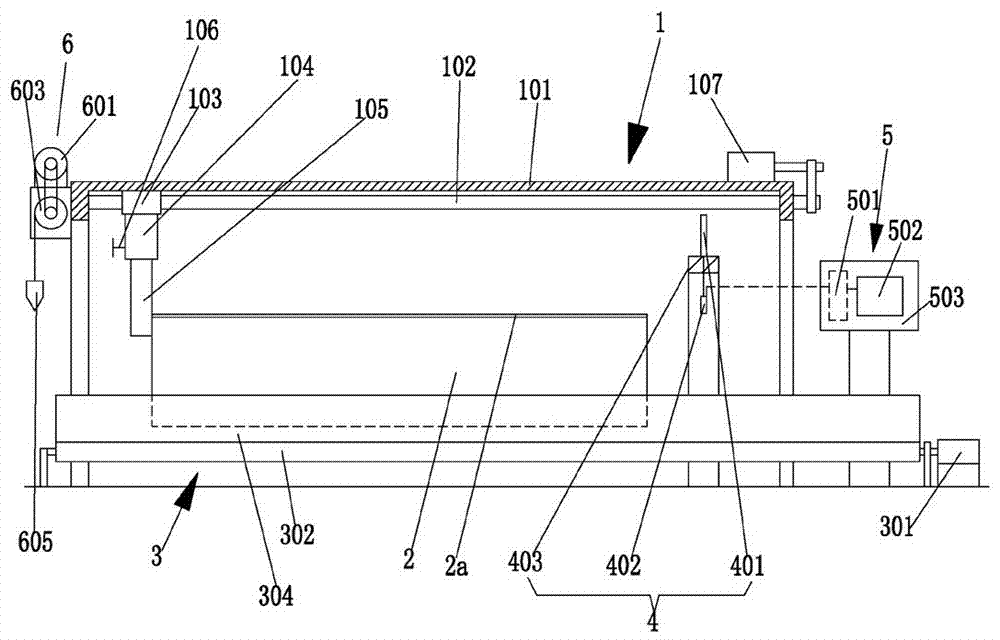

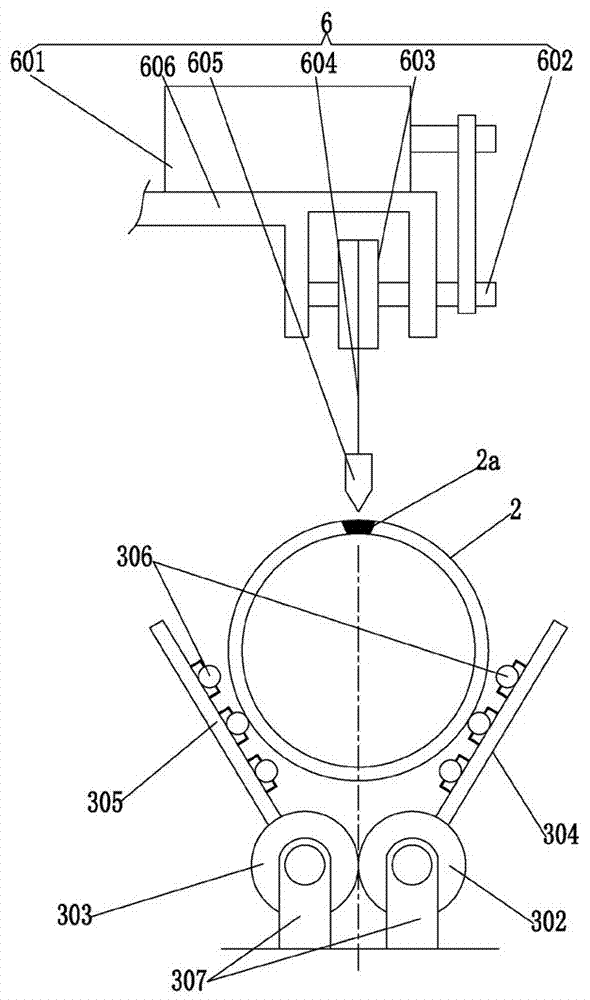

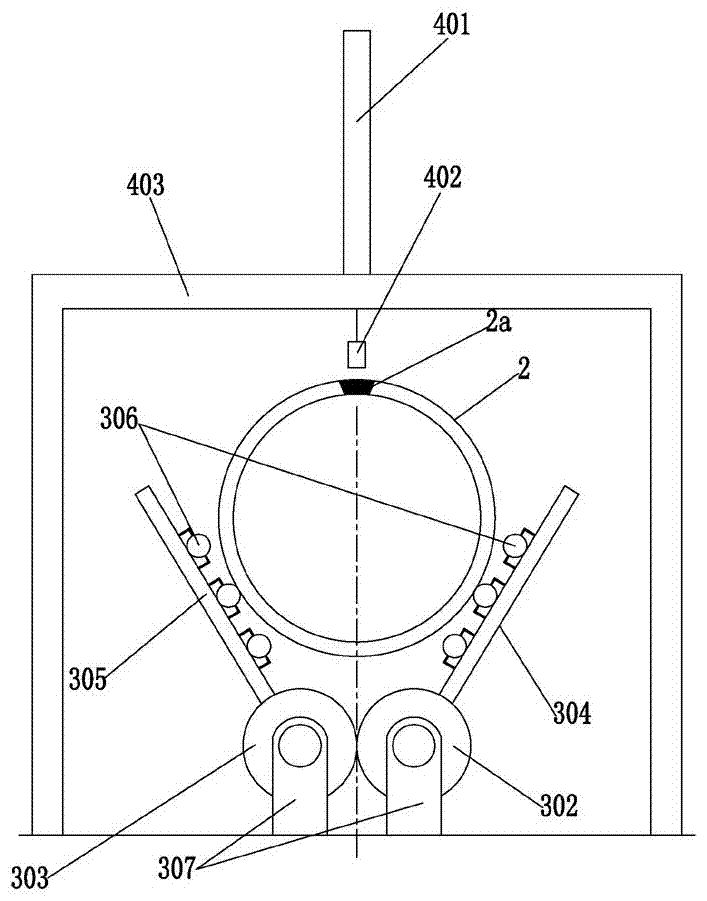

[0019] like Figure 1-4 As shown, an ultrasonic flaw detection instrument for measuring metal workpieces includes a detection actuator 4 for detecting the weld seam 2a of the pipe fitting 2, a monitoring device 5 associated with the detection actuator 4, and a pipe fitting 2 along the Its axial translation is towards the conveying mechanism 1 of the detection actuator 4, and also includes a lifting mechanism 3 for holding the pipe 2, and also includes an alignment assembly 6 for monitoring whether the weld seam 2a is facing upwards, and a remote control 7 .

[0020] The above-mentioned aligning assembly 6 includes a bracket 606 fixed on the ground, and also includes a retractable motor 601, a cylinder shaft 602, a winding drum 603, a suspension wire 604, and a correcting hammer 605. The retractable motor 601 is installed on the bracket 606, The reel 603 is a cylindrical structure, the reel 603 is rotatably mounted on the bracket 606 through the reel 602, the output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com