Sliding support for through fixing multi core tubes in one sleeve

A sliding bracket and core tube technology, applied in the direction of pipeline bracket, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of many construction procedures, poor reliability, complicated calculation, etc., to improve the anti-overturning ability and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

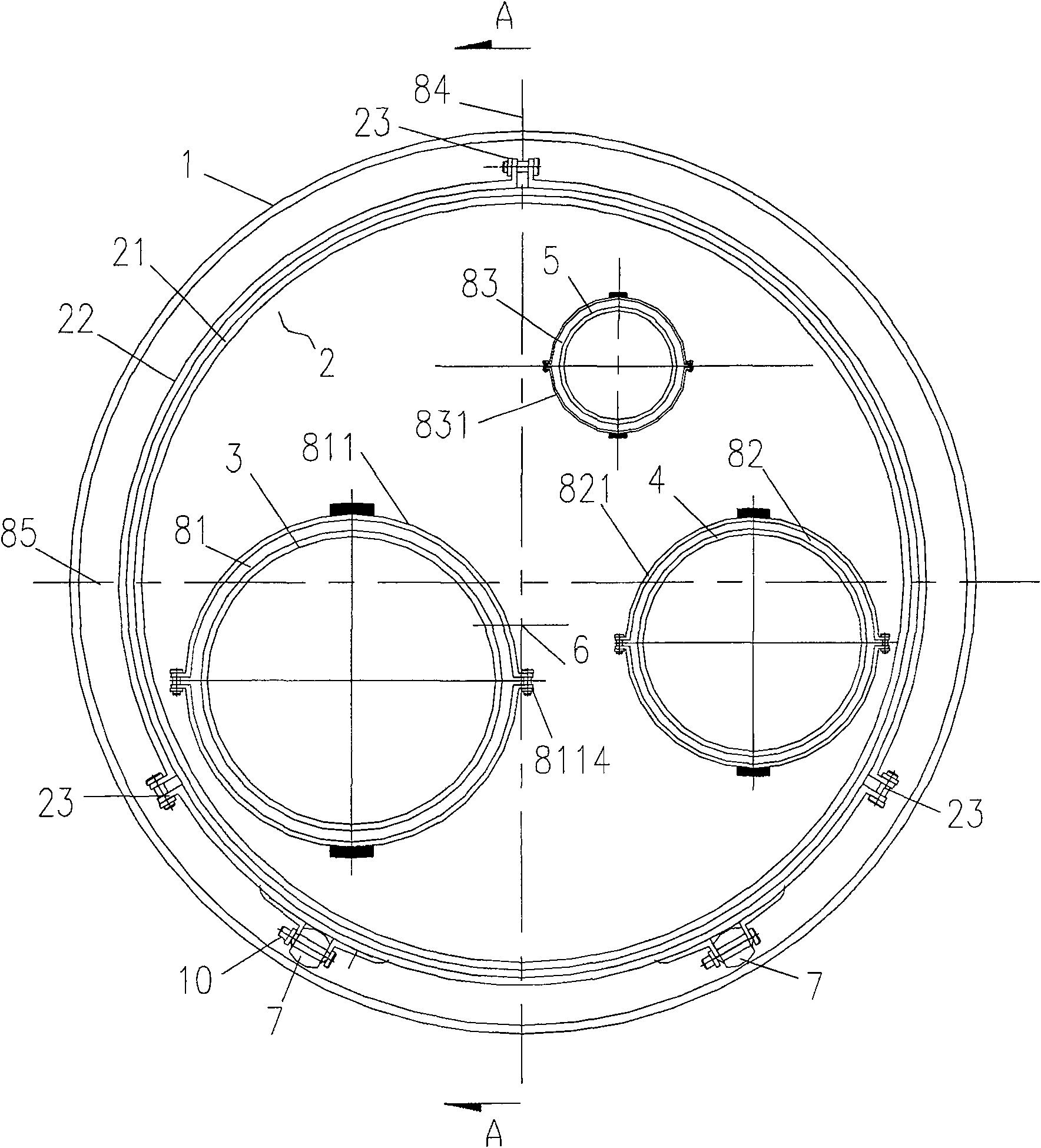

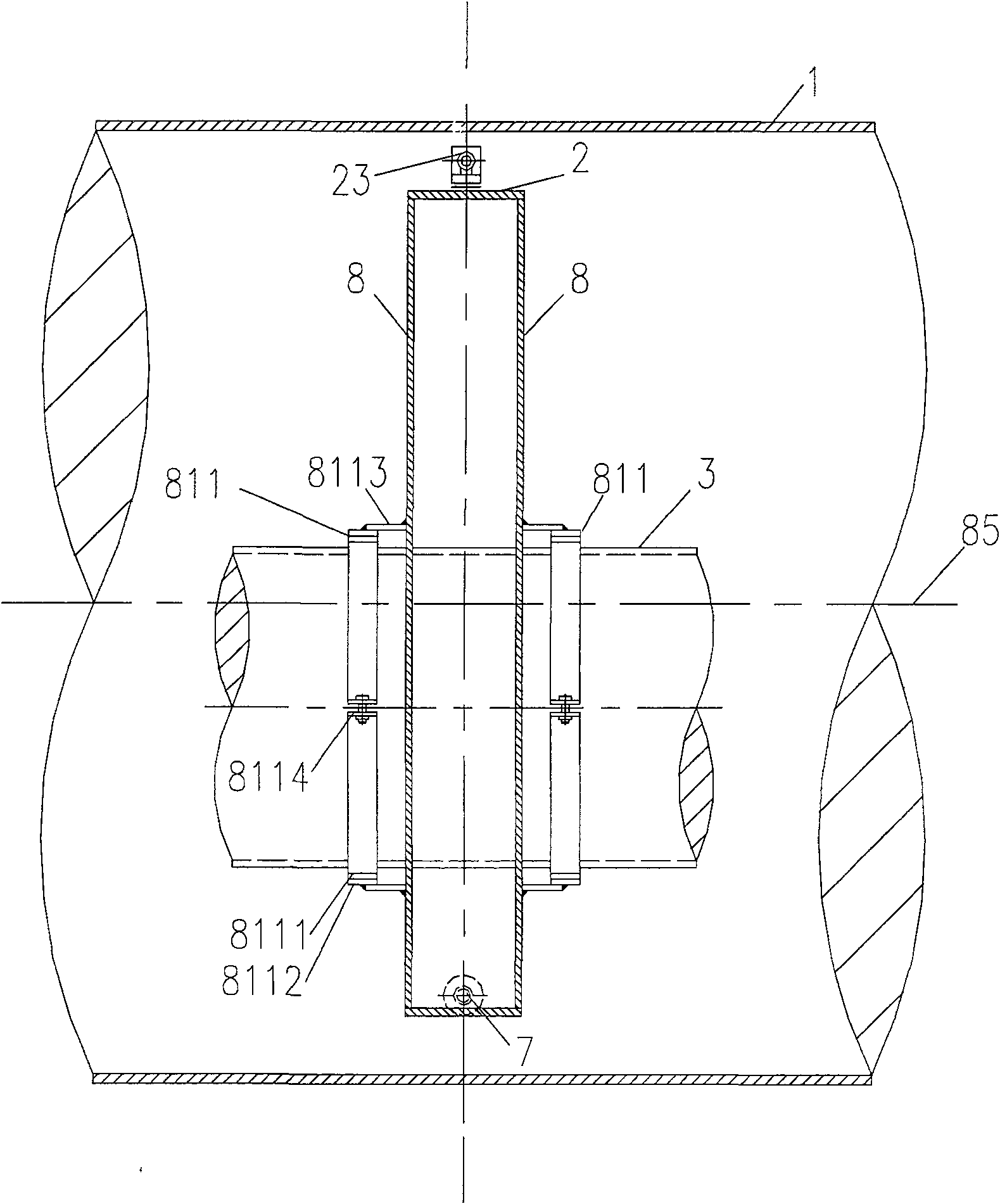

[0018] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the use state of a specific embodiment of the present invention. The sliding bracket of the present invention is a sliding bracket for simultaneously piercing three core tubes in a casing 1 with a large diameter. The core tube 4 and the third core tube 5 .

[0019] The sliding bracket includes two parallel substrates 8 , the substrates 8 are circular steel plates with a diameter smaller than the inner diameter of the casing 1 . The distance between the two substrates 8 is determined according to empirical data, and generally mainly depends on the diameter of the core tube.

[0020] Three through holes are opened on the base plate 8, corresponding to the first through hole 81, the second through hole 82 and the third through hole for penetrating through the first core tube 3, the second core tube 4 and the third core tube 5 respectively. 83.

[0021] The key of the present invention lies in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com