Tunnel and city pipe gallery leakage expansion joint repairing method and expansion joint device

An expansion joint and urban technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as exceeding the allowable deformation range of the waterstop, damage to the waterstop of the expansion joint, and failure to achieve compactness, and achieve easy control of construction quality. , prolong the service life, the effect of simple and wide construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

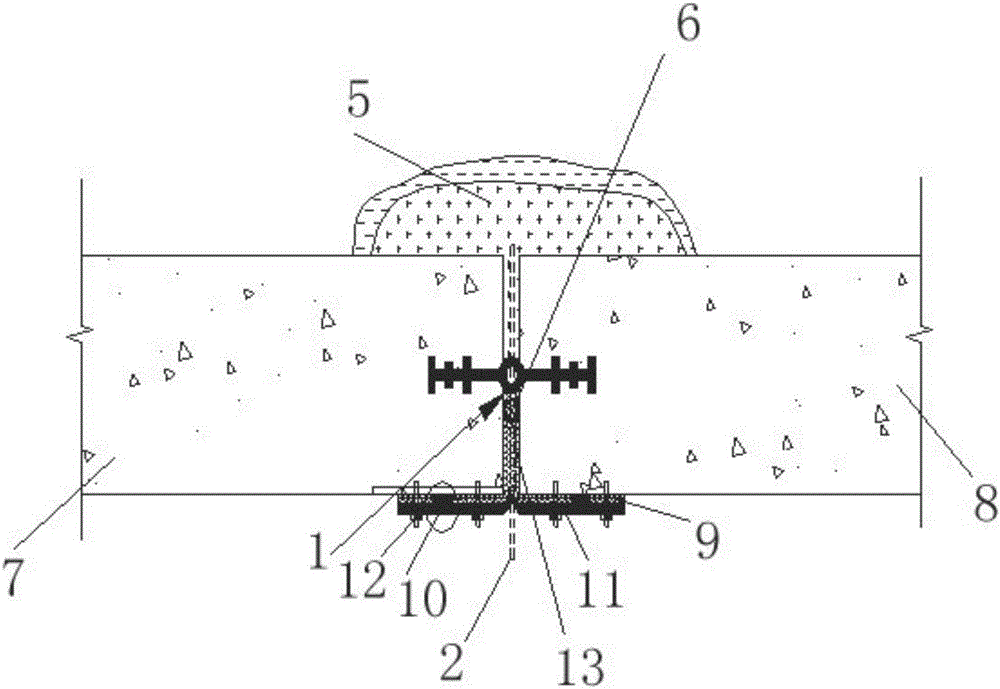

Embodiment 1

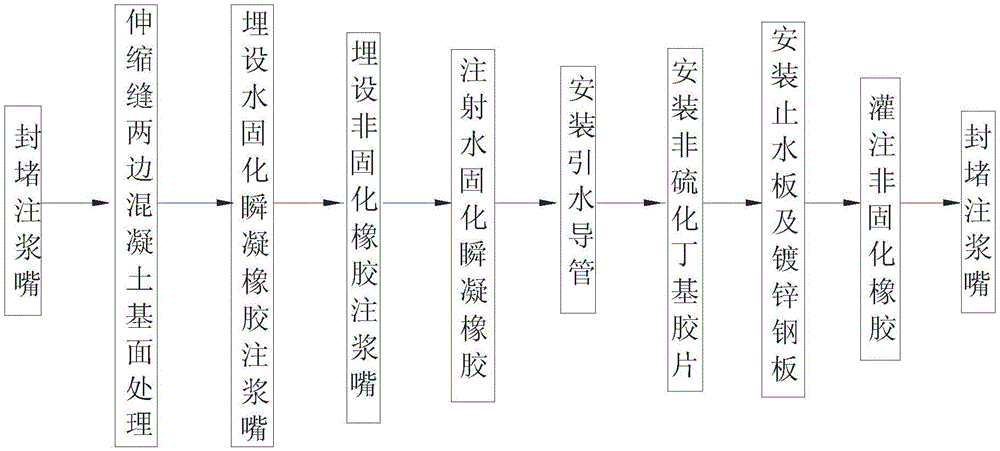

[0034] The first step is to check expansion joints 1; after confirming that the expansion joints, deformation, and settlement of the structure are stable, repair them according to the management principle of "mainly drawing and supplementing plugging" for waterproofing and leak prevention;

[0035] The second step is to treat the concrete base surface on both sides of the expansion joint 1; excavate the concrete along the 10cm on both sides of the expansion joint 1 to a depth of 4cm, and chisel the base surface and keep it relatively flat;

[0036] In the third and fourth steps, the water-curing instant-setting rubber grouting nozzle 2 and the non-curing rubber grouting nozzle 3 are evenly spaced at 5 cm on both sides of the expansion joint 1, and the water-curing instant-setting rubber grouting nozzle 2 and the non-curing rubber grouting nozzle 2 are evenly spaced. The grouting nozzle 3 has a linear arrangement structure, and one end of the linear arrangement structure is prov...

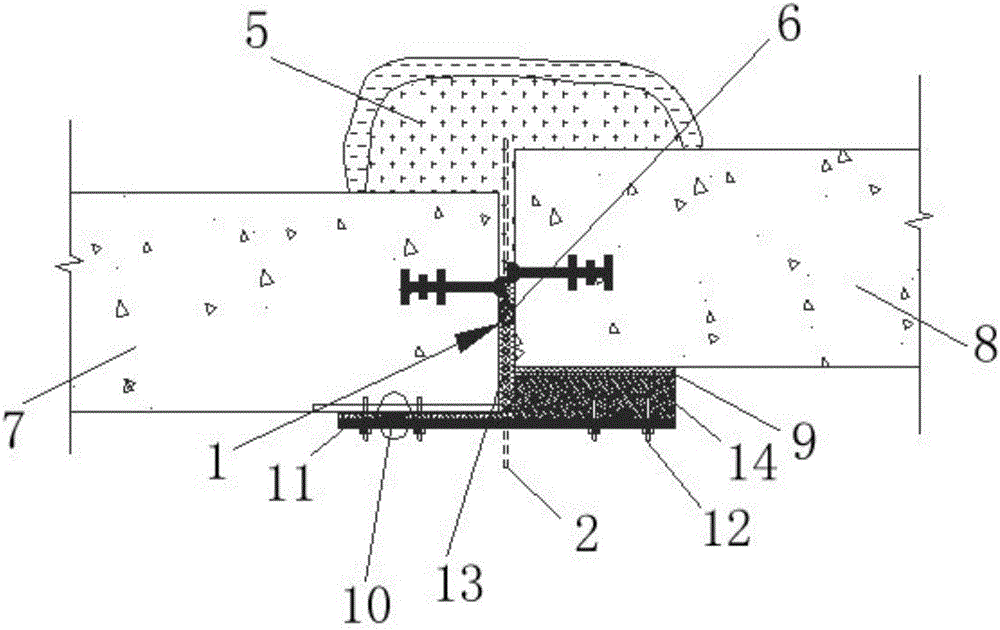

Embodiment 2

[0044] Embodiment 2 (body 7 and ontology Expansion joint repair method when the stagger of 8 is greater than 5cm)

[0045] The first step is to inspect expansion joints 1; after confirming that the expansion joints, deformation, and settlement of the structure are stable, repair them according to the management principle of "mainly drawing and supplementing plugging" for waterproofing and leak prevention;

[0046] The second step is to treat the concrete base surface on both sides of the expansion joint 1; excavate the concrete along the 10cm on both sides of the expansion joint 1 to a depth of 4cm, and chisel the base surface and keep it relatively flat;

[0047] In the third and fourth steps, at 5cm on both sides of the expansion joint 1, the water-curing instant-setting rubber grouting nozzle 2 and the non-curing rubber grouting nozzle 3 are evenly spaced, and the water-curing instant-setting rubber grouting nozzle 2 and the non-curing rubber The grouting nozzle 3 is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com