Metal conducting wire repairing method and repairing apparatus

A metal wire and metal thin film technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem that the microscopic metal wire cannot be directly repaired, and achieve the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

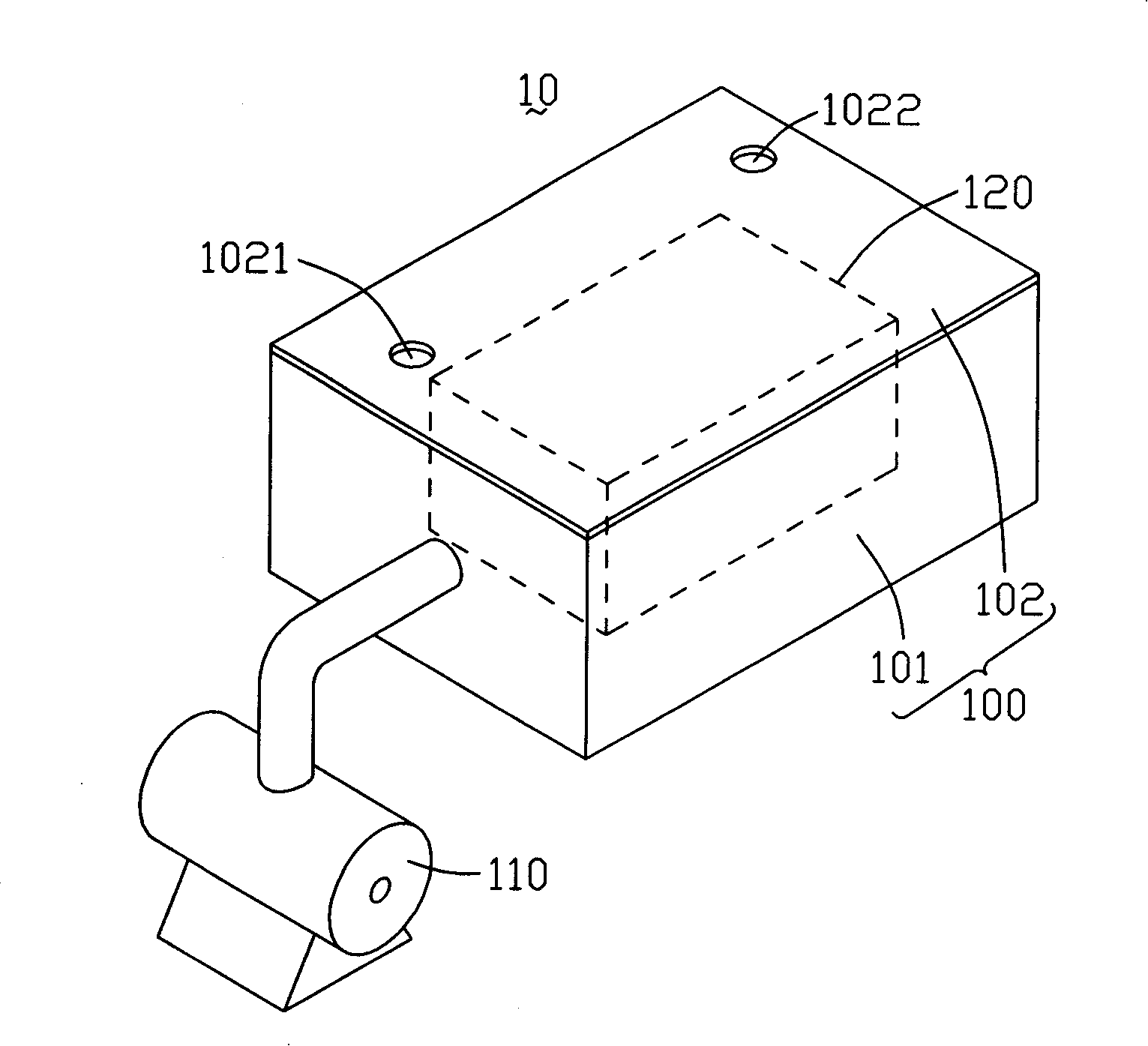

[0015] see figure 1 , is a three-dimensional schematic view of the metal wire repairing device of the present invention. The repair device 10 includes a cavity 100 , a vacuum mercury 110 and a main body 120 . The cavity 100 is a rectangular parallelepiped structure consisting of a box body 101 and a cover body 102 . The main body 120 is located in the receiving space formed by the box body 101 and the cover body 102 of the cavity body 100 . The cover 102 includes a first air guiding hole 1021 and a second air guiding hole 1022 .

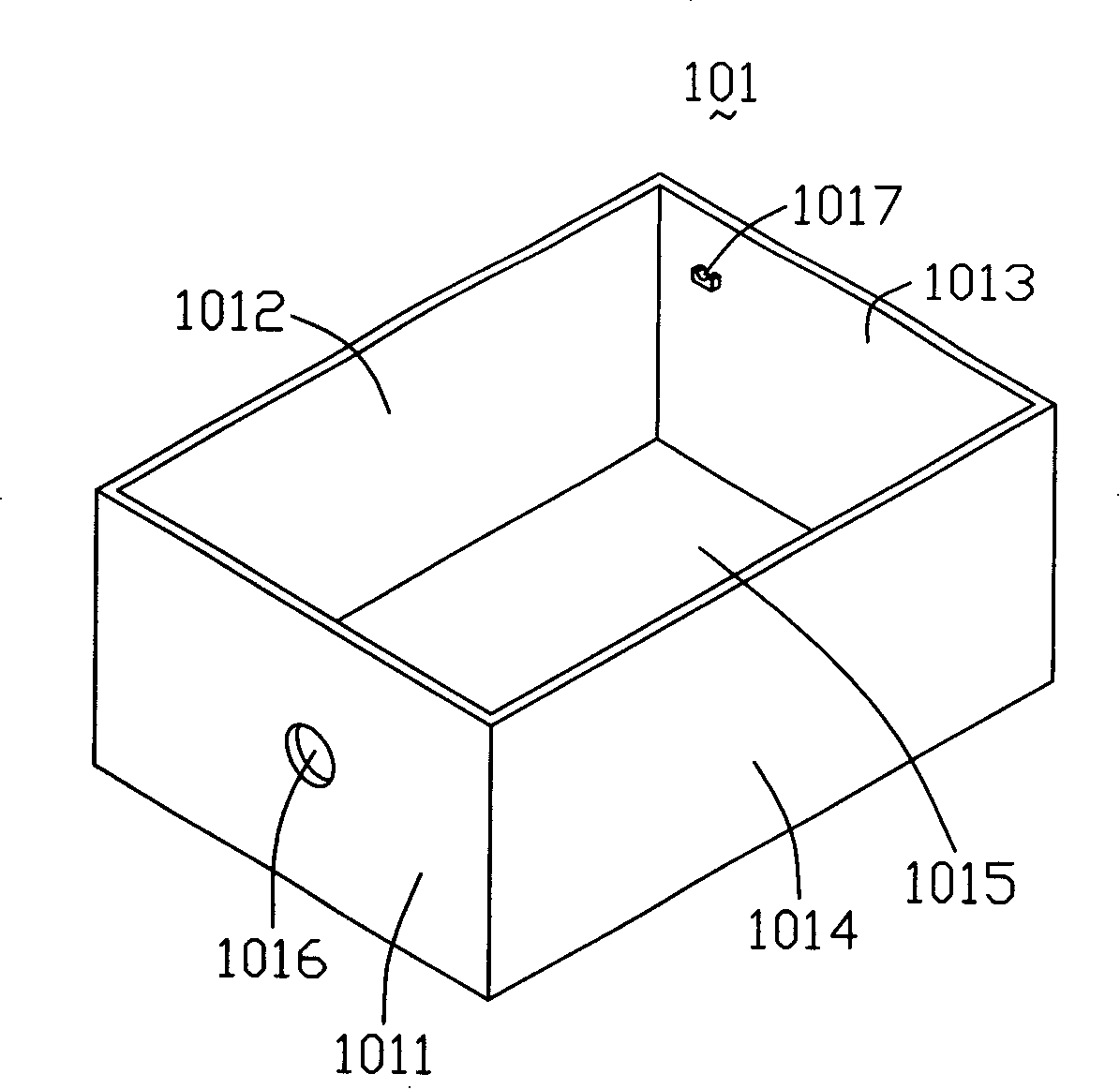

[0016] see figure 2 , is a three-dimensional schematic diagram of the box body 101 . The box body 101 includes a first side wall 1011 , a second side wall 1012 , a third side wall 1013 , a fourth side wall 1014 and a bottom plate 1015 . The first sidewall 1011 is provided with a suction hole 1016 . The inner surface of the first side wall 1011 is provided with two support structures 1017 , and the inner surface of the third side wall 1013 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com