Reinforcing protection treatment method for tunnel lining defects

A technology for lining and tunneling, which is applied in the field of tunnel lining concrete repair technology, and can solve problems such as less thickness of invasion, non-invasion, and falling off of lining concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

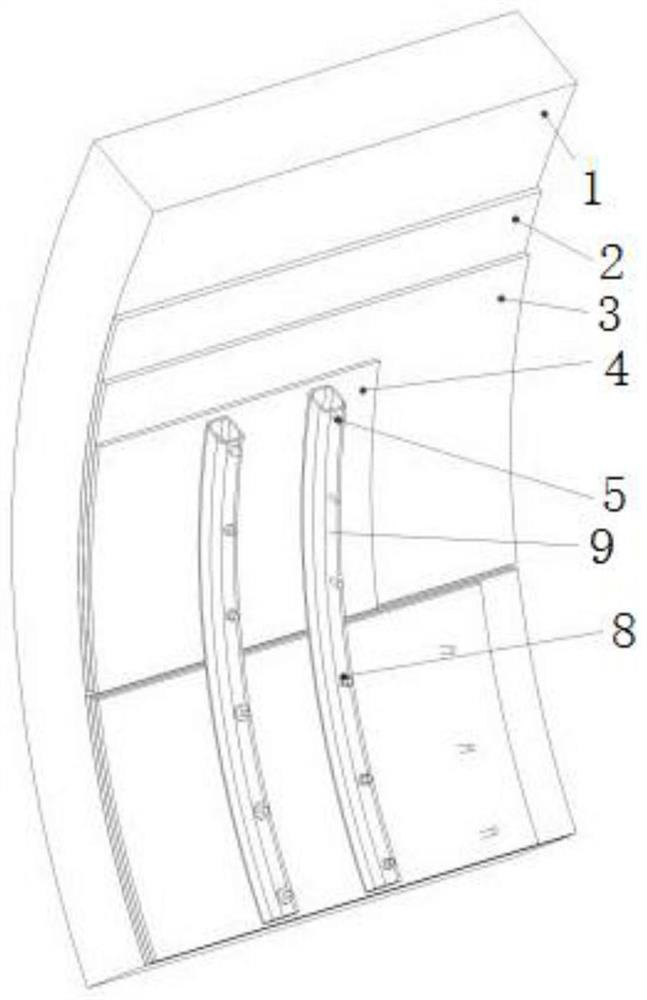

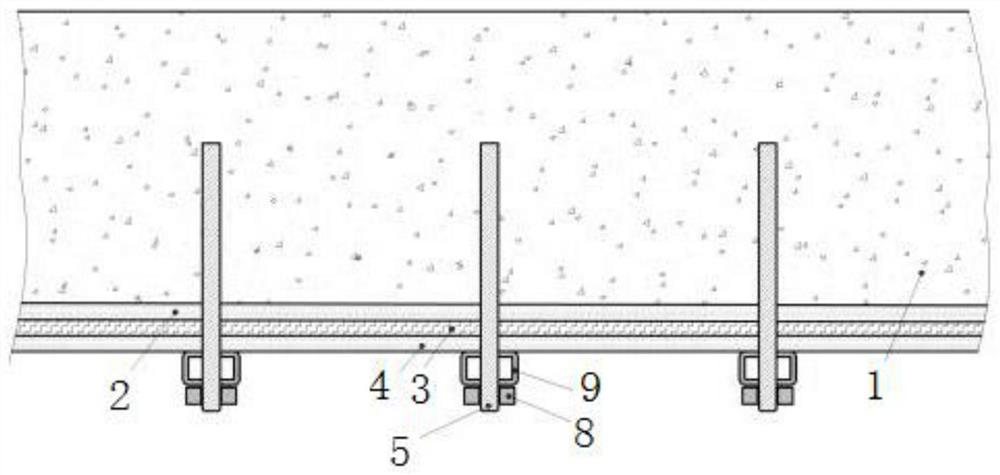

[0089] refer to figure 1 and figure 2 , this embodiment provides a treatment method for reinforcement and protection of tunnel lining defects, that is, a treatment method for serious defects such as falling blocks or falling off of railway tunnel lining, which is suitable for situations where there is no requirement for intrusion limit and the strength of concrete is slightly better. include:

[0090] S10. Lining concrete surface treatment

[0091] In this embodiment, in the area where the defects of the lining concrete 1 need to be treated, the surface protrusions or bosses of the lining concrete 1 are polished. For defects such as potholes (such as potholes with a diameter greater than 10cm) on the surface of the tunnel, it is necessary to use repair materials such as cement-based repair mortar, epoxy repair mortar, etc. to fill and repair until the surface concrete is smooth.

[0092] Alternatively, in the area where the defect treatment of the lining concrete is requir...

Embodiment 2

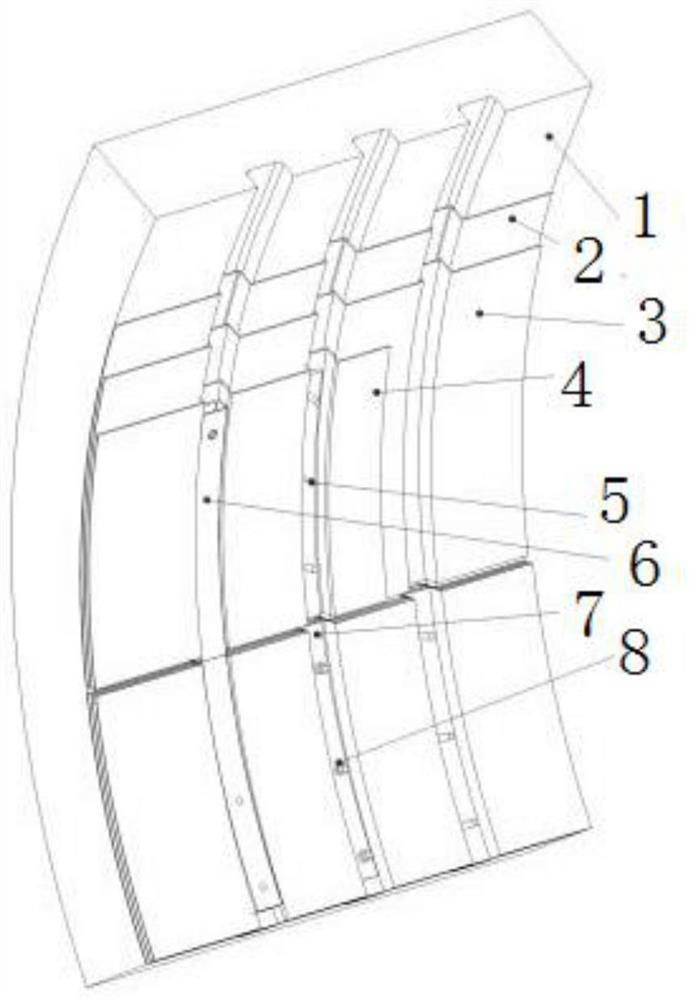

[0110] refer to image 3 with Figure 4 , this embodiment provides a reinforcement protection treatment method for tunnel lining defects, that is, a treatment method for railway tunnel lining to prevent serious defects such as falling blocks or falling off. include:

[0111] S10. Lining concrete surface treatment

[0112] In the area where the defect treatment of the lining concrete 1 is required, the surface protrusions or bosses of the lining concrete 1 are polished. For defects such as potholes (such as potholes with a diameter greater than 10cm) on the surface of the tunnel, it is necessary to use repair materials such as cement-based repair mortar, epoxy repair mortar, etc. to fill and repair until the surface concrete is smooth.

[0113] Alternatively, in the area where the defect treatment of the lining concrete is required, the floating soil on the surface of the lining concrete is cleaned, and the loose concrete blocks are removed to complete the surface treatment ...

Embodiment 3

[0130] refer to Figure 5 with Image 6 , this embodiment provides a reinforcement and protection treatment method for tunnel lining defects, that is, a treatment method for serious defects such as falling blocks or falling off of railway tunnel lining, which is suitable for cases where there is an invasion limit requirement and the concrete strength is slightly better, including :

[0131] S10, Second lining concrete surface treatment and grooving

[0132] In the area where the defect treatment of the lining concrete is required, the protrusions or bosses on the surface of the lining concrete are polished. For defects such as potholes (such as potholes with a diameter greater than 10cm) on the surface of the tunnel, it is necessary to use repair materials to fill and repair until the surface concrete is flat. The repair materials can be cement-based repair mortar or epoxy repair mortar.

[0133] Alternatively, in the area where the defect treatment of the lining concrete i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com