Curing agent composition for epoxy mortar and preparation method of curing agent composition

An epoxy mortar and curing agent technology, applied in the field of building materials, can solve the problems of PVC engineering hidden dangers, neoprene rubber can not adapt to concrete deformation joint deformation, PVC engineering failure and other problems, achieve durability and strength, and realize repair and waterproof , the effect of excellent bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

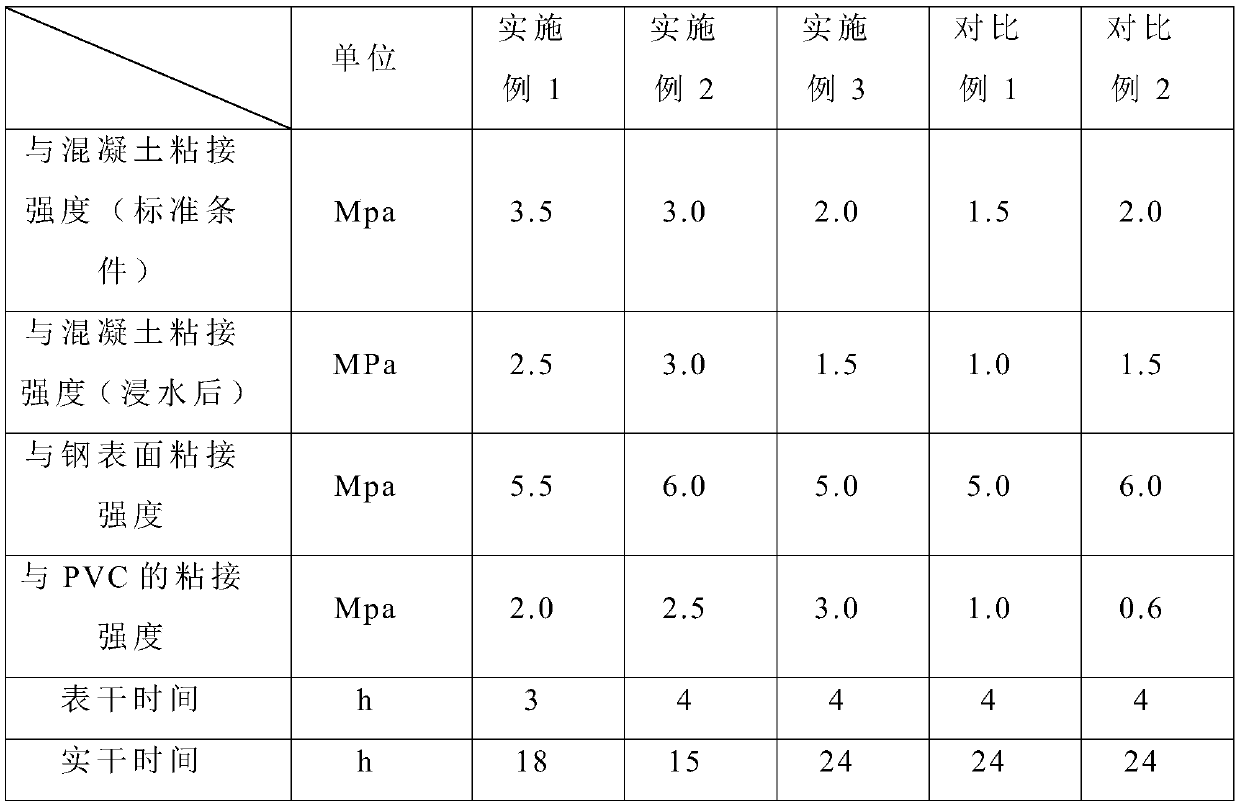

Examples

preparation example Construction

[0031] Also provide a kind of preparation method of the above-mentioned curing agent composition for epoxy mortar simultaneously, described preparation method comprises the steps:

[0032] (1) Preparation of modified polyetheramine: first react the polyetheramine curing agent, alkylphenol and 2,4,6-tris(dimethylaminomethyl)phenol to make an intermediate, then add benzyl alcohol reaction to make the modified polyetheramine;

[0033] (2) Preparation of modified fatty amine: reacting the octyl glycidyl ether and the triethylenetetramine to prepare the modified fatty amine;

[0034] (3) Weigh the modified polyether amine prepared in step (1) and the modified fatty amine prepared in step (2) according to the formula, and mix them to prepare the curing agent composition for the epoxy mortar.

[0035] According to a specific aspect of the present invention, above-mentioned curing agent composition is applied in the epoxy mortar as follows:

[0036] The raw materials of the epoxy mo...

Embodiment 1

[0052] This embodiment provides a curing agent composition for epoxy mortar, which is composed of modified polyetheramine (23 parts) and modified fatty amine (20 parts);

[0053] Wherein, the modified polyetheramine is obtained by the following method: the modified polyetheramine is reacted with polyetheramine curing agent, alkylphenol and 2,4,6-tris(dimethylaminomethyl)phenol It is produced by reacting with benzyl alcohol; specifically, pour polyetheramine 230 (50 parts) into the reaction kettle, stir at 300-500r / min at room temperature, and add nonylphenol (30 parts) and 2,4,6-tris(dimethylaminomethyl)phenol (10 parts), react for 1.5 hours, then add benzyl alcohol (10 parts), heat up to 55°C, continue to react for 1.5 hours and stop heating, vacuumize to 1KPa Next, extract volatile matter to make modified polyetheramine;

[0054] The modified fatty amine is made by reacting octyl glycidyl ether and triethylenetetramine; specifically, triethylenetetramine (1mol) is put into ...

Embodiment 2

[0064] This embodiment provides a curing agent composition for epoxy mortar, which is basically the same as in Embodiment 1, the only difference is that the modified polyetheramine is obtained by the following method: the modified polyetheramine is made of polyetheramine It is made by reacting curing agent, alkylphenol and 2,4,6-tris(dimethylaminomethyl)phenol and then reacting with benzyl alcohol; specifically, pour polyetheramine 400 (45 parts) into the reaction kettle , stirring at a speed of 300-500r / min at room temperature, adding dodecylphenol (32 parts) and 2,4,6-tris(dimethylaminomethyl)phenol (8 parts) during stirring, and reacting for 2 hours , then add benzyl alcohol (15 parts), heat up to 58°C, continue the reaction for 2 hours and stop heating, vacuumize to below 1KPa, extract volatile matter, and make modified polyetheramine.

[0065] The method that is applied to epoxy mortar is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com