Method and device for repairing oil/gas drilling bushing

A technology for oil and gas drilling and casing, which is used in earth-moving drilling, wellbore/well components, etc., can solve the problems of inability to remove the scraped pipe surface, small clearance of subsidized liner, and difficulty, and achieves simple, reliable and economical repair process. The effect of construction cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

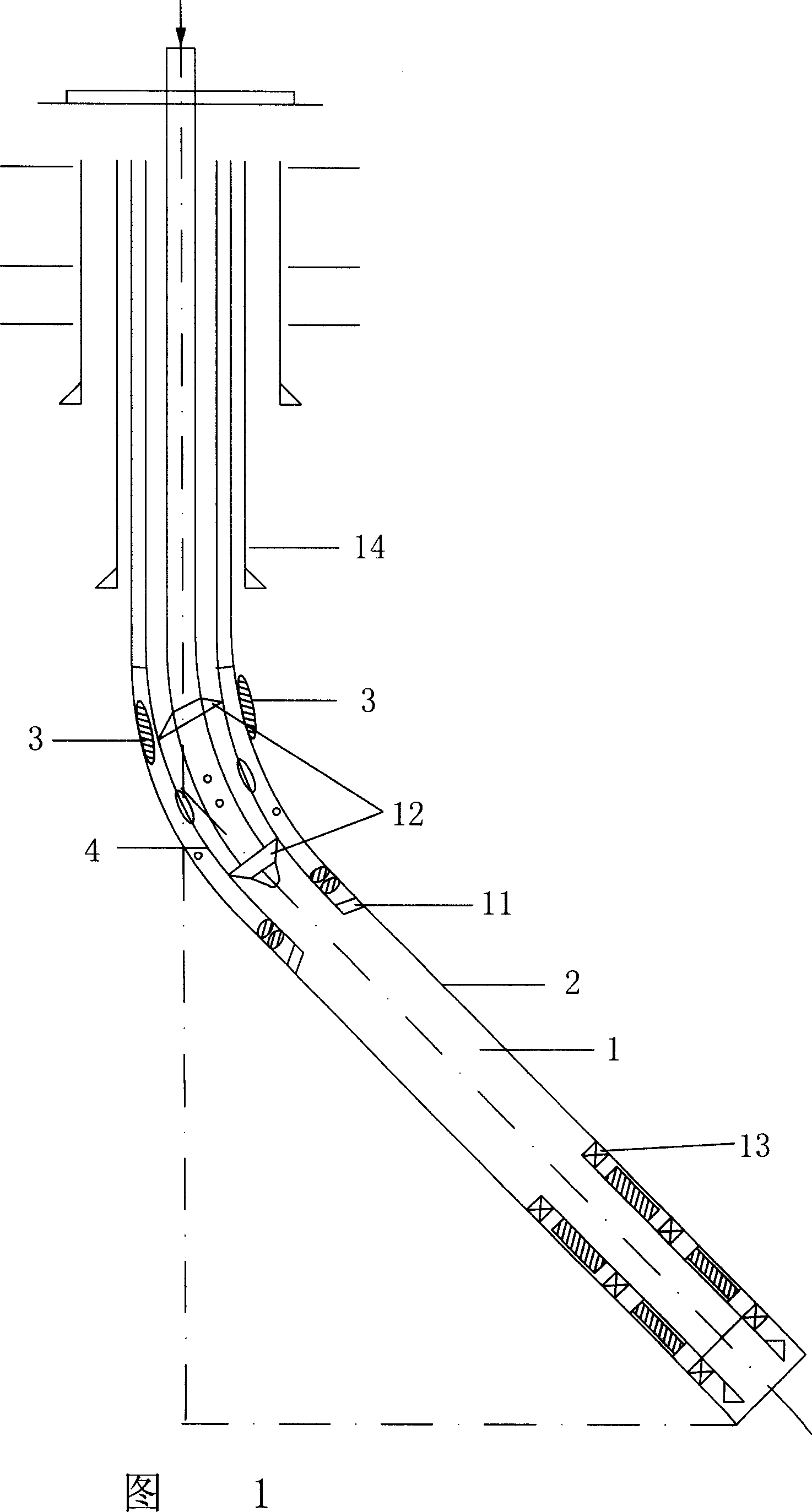

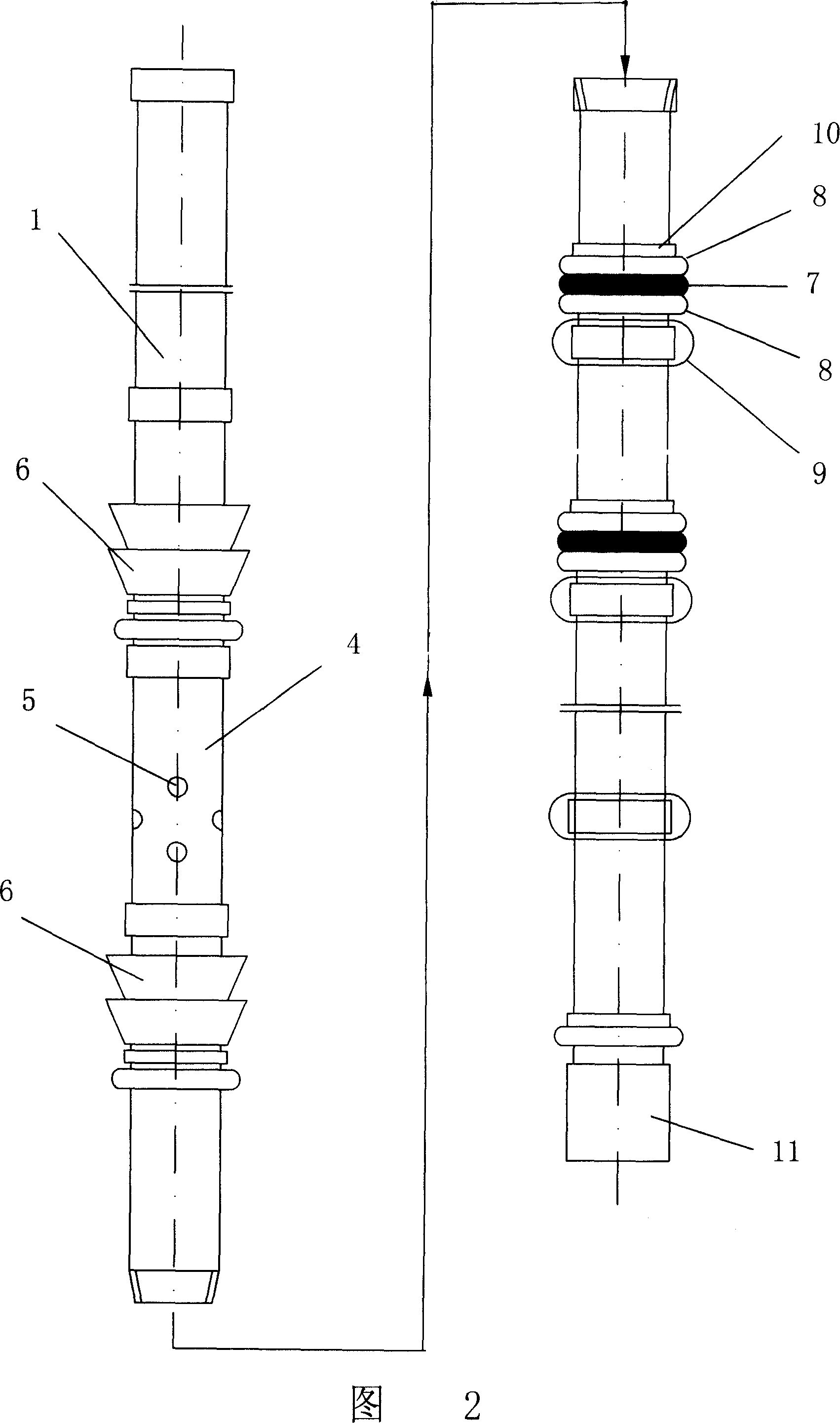

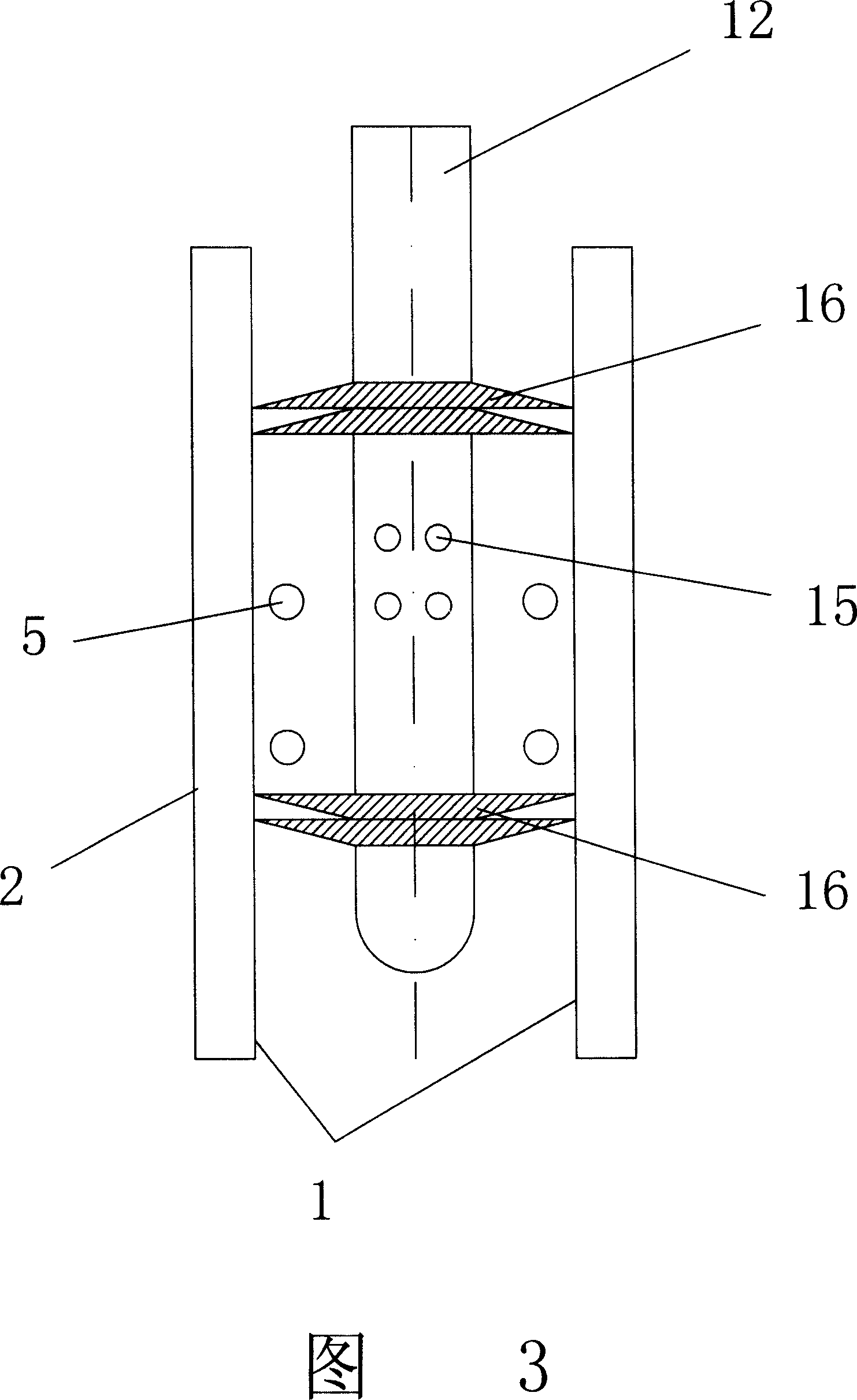

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] The present invention selects two wells in which casing abrasion accidents occurred during the drilling process and the well completion process as examples for illustration. During the drilling process of one of the wells, the completed 9-5 / 8” casing was drilled at 469m when the upper deflected well section penetrated the upper dense well pattern. The other well was drilled during the completion scraping process During the pressure test of the 9-5 / 8" casing, it was found that the casing was damaged. After inspection, it was found that the 9-5 / 8" casing of the well had two breaches at 323m and 325m. The casing was worn out by the drill bit during the process. The relevant technical data of the two wells with casing abrasion accidents are as follows (as shown in Table 1).

[0032] Table 1: Casing damage and borehole conditions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com