Grouting pipe and concrete defect repairing method

A technology for grouting pipes and concrete, which is applied in earthwork drilling, soil protection, wellbore lining, etc., and can solve problems such as easy falling and thin secondary lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

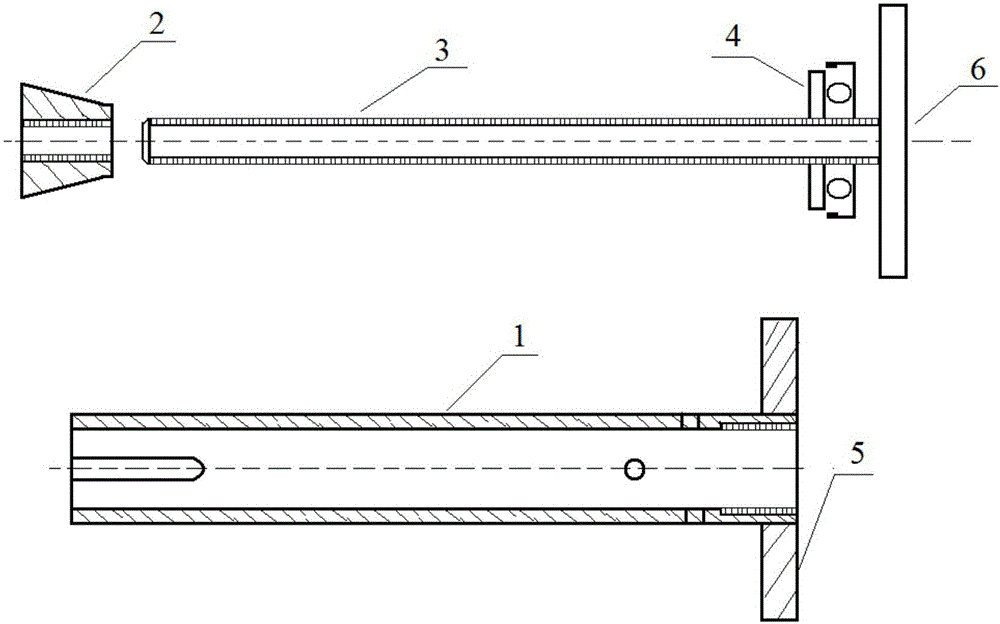

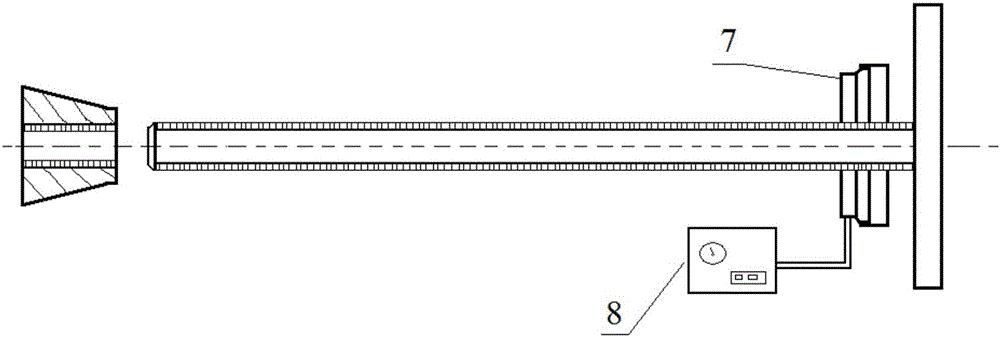

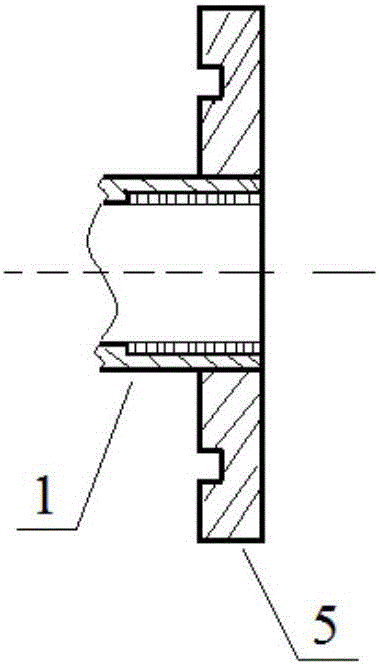

[0073] This embodiment provides a grouting pipe, which includes an expansion grouting pipe, a conical head, a fastening screw, a thrust bearing, a fixed pressure plate and a wheel disc.

[0074] The expansion grouting pipe is a hollow cylinder with a plurality of grouting holes on its side wall; at least two gaps are opened on the side wall of one end of the expansion grouting pipe along its axial direction, and the other One end is provided with a thread for connecting the grouting machine; the thread can be an internal thread or an external thread, as long as the connection between the grouting fixed connection pipe of the grouting machine and the expansion grouting pipe can be realized, of course, the expansion The other end of the grouting pipe may not be provided with threads, and at this time, the other end of the expansion grouting pipe may be connected to the grouting fixed connection pipe of the grouting machine by welding or the like; in this embodiment, preferably T...

Embodiment 2

[0086] This embodiment provides a method for repairing concrete defects (punching first, then strengthening), that is, a grouting method using the grouting pipe described in Embodiment 1, which includes the following steps:

[0087] S10. Drilling of the second-lined concrete: After detecting the position of the cavity by radar or other means, punch holes in the part that needs to be reinforced by grouting. The diameter of the hole is 1-5mm larger than the expansion grouting pipe. Note: the depth of the hole must be certain To exceed the thickness of the second lining concrete here. The drilling depth is based on the actual design. One is that the depth does not exceed the design thickness of the lining, that is, it does not exceed the waterproof board; the other is that the depth penetrates the waterproof board and extends into the surrounding rock.

[0088] S20, apply bonding material in the hole: apply bonding glue in the hole punched in step S10, for bonding and fixing the ...

Embodiment 3

[0109] When the grouting pipe in embodiment 1 includes a reinforcing pipe, the concrete defect repair method (perforating first and then strengthening), that is, a grouting method using the grouting pipe described in embodiment 1, comprises the following steps :

[0110] S110. Drilling holes in the second-lined concrete: After detecting the position of the cavity by radar or other means, punch holes in the part that needs to be reinforced by grouting. To exceed the thickness of the second lining concrete here. The drilling depth is based on the actual design. One is that the depth does not exceed the design thickness of the lining, that is, it does not exceed the waterproof board; the other is that the depth penetrates the waterproof board and extends into the surrounding rock.

[0111] S120, apply bonding material in the hole: apply bonding glue in the hole punched in step S110, for bonding and fixing the expansion grouting pipe in the hole of the secondary lining concrete, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com