Construction method for rapidly repairing expansion joint heightening leveling layer

A construction method and technology of expansion joints, applied in road repair, bridge parts, roads, etc., can solve the problems of difficult control of construction quality, complicated construction process, long time, etc., and achieve easy control of construction quality, fast construction, and high early strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

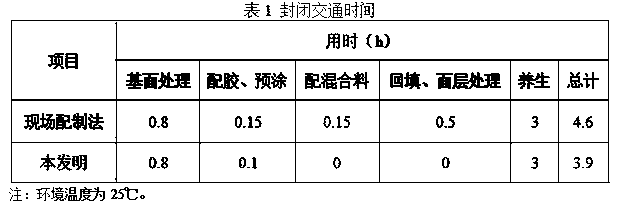

[0044] The thickness of the heightened leveling layer for the measured expansion joints is 2cm, and the damage range is within 20cm from the edge of the expansion joints. Specific steps are as follows:

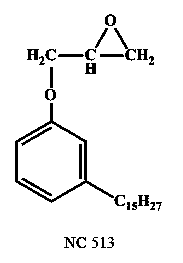

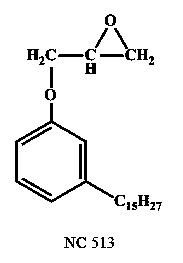

[0045] (1) Preparation of repair material prefabricated panels: Put epoxy resin E51, reactive diluent NC 513, diatomaceous earth, phenalkamine curing agent, and ultraviolet light absorber UV 329 into the mixing bucket in sequence, and stir evenly to form epoxy resin glue . Epoxy resin glue and aggregate are mixed into a repair material at a mass ratio of 1:4, mixed for 5 minutes, and then laid on a steel floor with a size of 180cm×20cm×0.2cm that has been sandblasted on the surface until the overall thickness is 2cm, and Curing at a constant temperature of 30° C. for 3 days, and obtaining a repair material prefabricated plate of 180 cm×20 cm×0.2 cm after curing.

[0046] The content of each component in the epoxy resin glue is:

[0047] Component A: 100 parts by mass of epo...

Embodiment 2

[0056] The thickness of the heightening and leveling layer of the measured expansion joint is 4cm, and the damage range is within 20cm from the edge of the expansion joint. Specific steps are as follows:

[0057](1) Preparation of repair material prefabricated panels: Put epoxy resin E51, reactive diluent NC 513, diatomaceous earth, phenalkamine curing agent, and ultraviolet light absorber UV 329 into the mixing bucket in sequence, and stir evenly to form epoxy resin glue . Epoxy resin glue and aggregate are mixed into a repair material at a mass ratio of 1:4.5 and mixed for 5 minutes, and then laid on a steel base plate with a size of 180cm×20cm×0.2cm that has been sandblasted on the surface until the overall thickness is 4cm, and Curing at a constant temperature of 30° C. for 3 days, and obtaining a repair material prefabricated plate of 180 cm×20 cm×0.2 cm after curing.

[0058] The content of each component in the epoxy resin glue is:

[0059] Component A: 100 parts by ...

Embodiment 3

[0068] The thickness of the heightening and leveling layer of the measured expansion joint is 4cm, and the damage range is within 20cm from the edge of the expansion joint. Specific steps are as follows:

[0069] (1) Preparation of repair material prefabricated panels: Put epoxy resin E51, reactive diluent NC 513, diatomaceous earth, phenalkamine curing agent, and ultraviolet light absorber UV 329 into the mixing bucket in sequence, and stir evenly to form epoxy resin glue . Epoxy resin glue and aggregate are mixed into a repair material at a mass ratio of 1:5, mixed for 5 minutes, and then laid on a steel base plate with a size of 180cm×20cm×0.2cm that has been sandblasted on the surface until the overall thickness of the plate is 4cm, and Curing at a constant temperature of 30° C. for 3 days, and obtaining a repair material prefabricated plate of 180 cm×20 cm×0.2 cm after curing.

[0070] The content of each component in the epoxy resin glue is:

[0071] Component A: 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com