Liner making technique for casting lander of blast furnace with single iron notch, and free from baking casting material for iron notch

An iron ditch castable, no-bake technology, applied in the direction of discharge devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

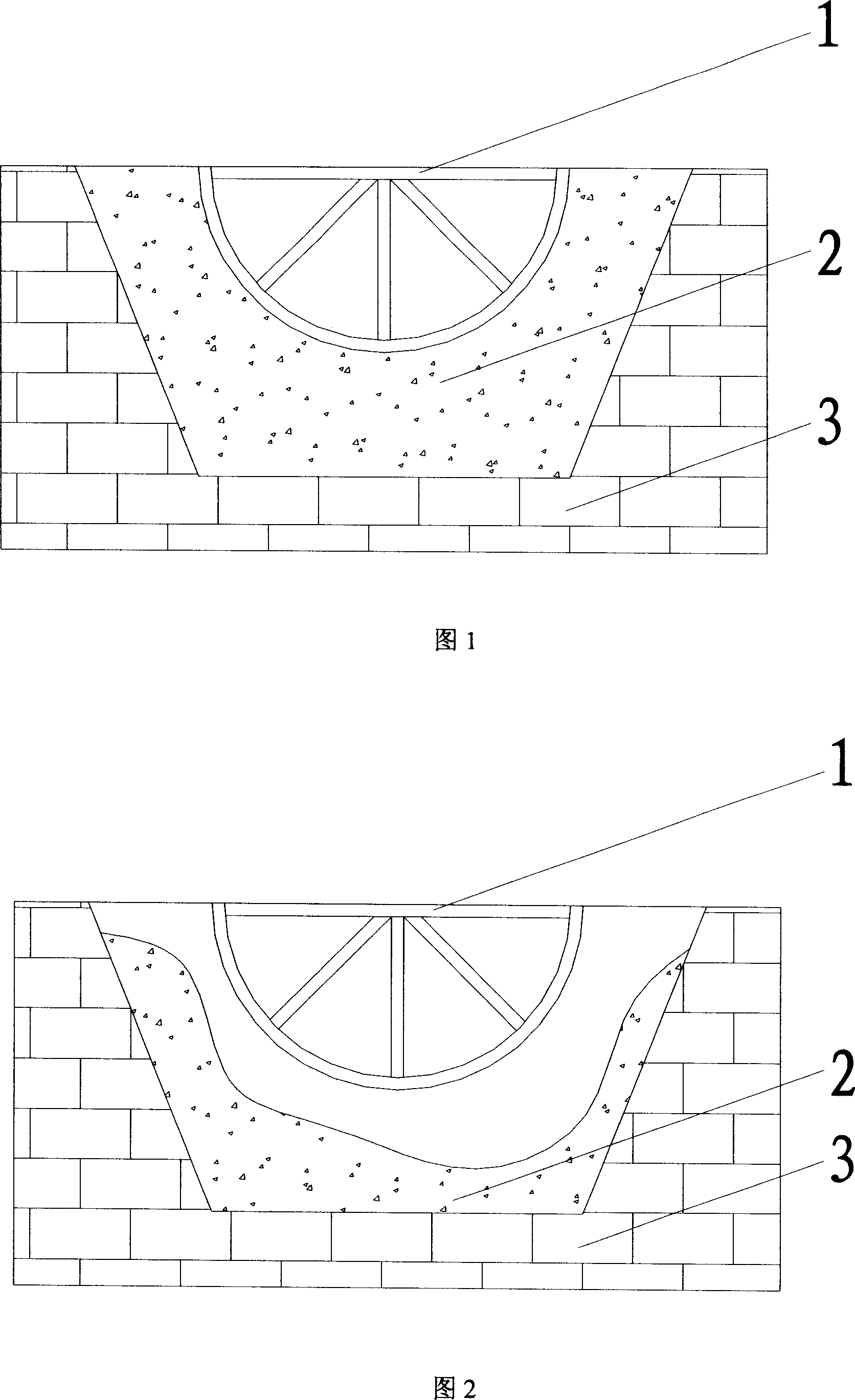

Image

Examples

Embodiment 1

[0036] For a volume of 500m 3 ~1000m 3 Between blast furnaces, the material ratio for main ditch pouring is as follows:

[0037] serial number

raw material name

Granularity

Proportion

1

Brown fused alumina

8~5mm

25 copies

2

5~3mm

16 copies

3

3~1mm

20 copies

4

1~0mm

7 copies

5

SIC95

1~0mm

5 copies

6

325 mesh

12 copies

7

Fused white corundum

325 mesh

6 servings

8

High temperature asphalt

0.5mm

3 copies

[0038] 9

Silica powder

3 copies

10

raw clay

3 copies

11

Silicon metal(97)

2 to 3 servings

12

Polypropylene fibers

0.1 part

13

Activated Magnesium Oxide

0.5 parts

14

Industrial phosphoric acid solution

3 copies

15

Phenolic Resin

6.5 servings

[0039] The first 13 materia...

Embodiment 2

[0050] For a blast furnace with a volume of 500m 3 For the following blast furnaces, the material ratio for main ditch pouring is as follows:

[0051] serial number

raw material name

Granularity

Proportion

1

High alumina bauxite

8~5mm

25 copies

2

5~3mm

16 copies

3

3~1mm

20 copies

4

1~0mm

7 copies

5

SIC95

1~0mm

5 copies

6

325 mesh

12 copies

7

Fused white corundum

325 mesh

6 servings

8

High temperature asphalt

0.5mm

3 copies

[0052] 9

Silica powder

3 copies

10

raw clay

3 copies

11

Silicon metal(97)

2 to 3 servings

12

Polypropylene fibers

0.1 part

13

Activated Magnesium Oxide

0.8 parts

14

Industrial phosphoric acid solution

3 copies

15

Phenolic Resin

8.5 servings

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com