Method for producing claw type unscrewing cover by pre-printing color coated iron

A film-coated iron and pre-printing technology, which is applied in the post-processing of printing, printing, capping, etc., can solve the problems of multiple roller coatings, high VOCs emissions, and long production chains, and achieve small color difference on the layout and coating process Simplicity and the effect of increasing printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for producing claw-type unscrewed caps from pre-printed colored coated iron, comprising the following steps:

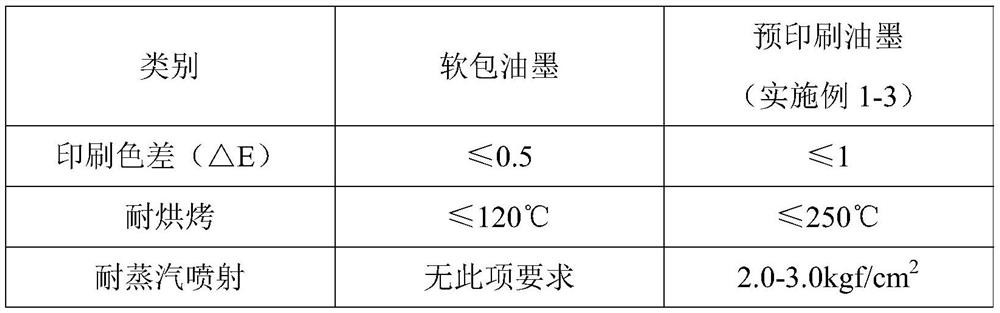

[0044] (1) Printing film: use an engraving plate to print the ink on the polyethylene terephthalate film, and keep the printed film at 70°C for 72 hours to completely cure the ink on the film and make it The ink and the film form a firm combination to obtain a printed film; during the printing process of the film, the printing speed is 180 m / min, and the deviation range of the film is controlled within -0.5 ~ 0.5mm;

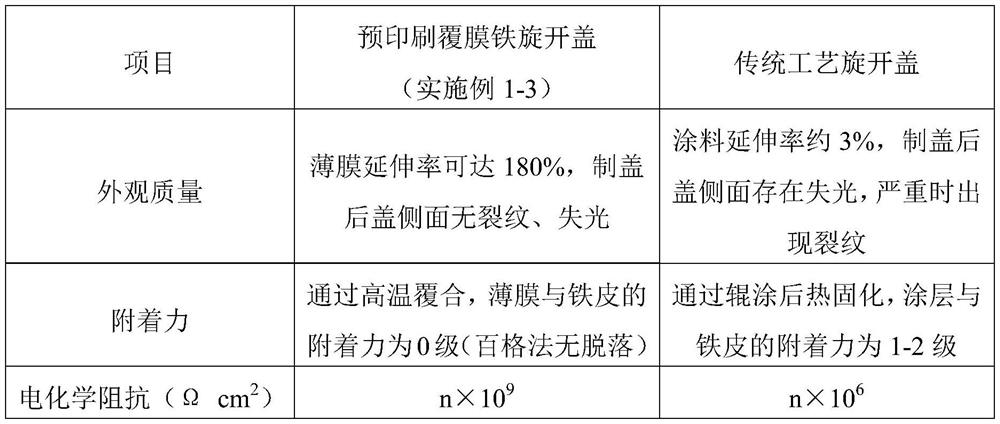

[0045] (2) Lamination: The film printed in step (1) is attached to the chrome-plated tinplate iron sheet by means of thermal lamination through the lamination roller to obtain the lamination iron; the lamination pressure is 2 tons, and the lamination temperature is 230 ℃, the hardness of the coated roller is adjusted to 60HR;

[0046] (3) Cutting: Cutting according to the pattern size requirements of the printing layout;

[0047] (4) Co...

Embodiment 2

[0054] A method for producing claw-type unscrewed caps from pre-printed colored coated iron, comprising the following steps:

[0055](1) Printing film: use an engraving plate to print the ink on the polyethylene film, and keep the printed film at 80°C for 48 hours to completely cure the ink on the film and form a firm bond between the ink and the film , to obtain the printed film; the film is in the printing process, the printing speed is 100 m / min, and the deviation range of the film is controlled within -0.5 ~ 0.5mm;

[0056] (2) Lamination: The film printed in step (1) is attached to the chrome-plated tinplate iron sheet by means of thermal lamination through the lamination roller to obtain the lamination iron; the lamination pressure is 5 tons, and the lamination temperature is 260 ℃, the hardness of the coated roller is adjusted to 90HR;

[0057] (3) Cutting: Cutting according to the pattern size requirements of the printing layout;

[0058] (4) Covering: coating a laye...

Embodiment 3

[0065] A method for producing claw-type unscrewed caps from pre-printed colored coated iron, comprising the following steps:

[0066] (1) Printing film: Print the ink on the polyethylene terephthalate film with an engraving plate, and keep the printed film at 75°C for 60 hours to completely cure the ink on the film and make the The ink and the film form a firm bond to obtain a printed film; during the printing process of the film, the printing speed is 150 m / min, and the deviation range of the film is controlled within -0.5 ~ 0.5mm;

[0067] (2) Lamination: The film printed in step (1) is attached on the chrome-plated tinplate iron sheet by means of thermal lamination through the lamination roller to obtain the lamination iron; the lamination pressure is 3 tons, and the lamination temperature is 240 ℃, the hardness of the coated roller is adjusted to 75HR;

[0068] (3) Cutting: Cutting according to the pattern size requirements of the printing layout;

[0069] (4) Covering: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com