A Method of Improving the Grain Size of Blade Steel 2cr12mov

A technology of grain size and blade, which is applied in the field of improving the grain size of blade steel 2Cr12MoV, can solve the problems of greatly improved alloy, low plasticity and fatigue performance, coarse original grain size, etc., and achieve good comprehensive mechanical properties, Improvement of plasticity and toughness, reduction of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

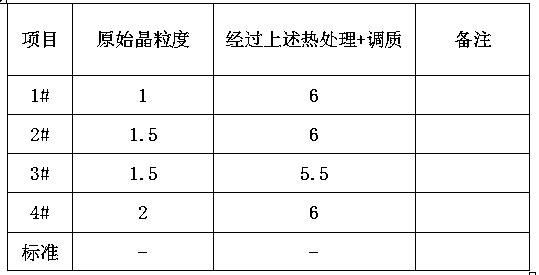

Embodiment 1

[0025] Select blade steel with an original grain size of 1 for processing, a method for improving the grain size of blade steel 2Cr12MoV, the improvement method comprising the following steps:

[0026] Step A, forging the blade steel, placing the blade steel on a forging machine for forging, when forging, the unilateral margin of the blade steel profile is 3mm, and the pressure of the forging machine is 2000N;

[0027] Step B, heating the blade steel forged in step A to a certain temperature in a heat treatment furnace, keeping it warm for a period of time, and then water cooling;

[0028] Wherein, the heat treatment furnace temperature is 850-870°C, and the holding time is 60-120min;

[0029] Step C, tempering the blade steel after water cooling in step B, heating the quenched blade steel to a certain temperature, and then air cooling;

[0030] Among them, the temperature is 830-840°C, and the holding time is 45-135min;

[0031] Step D, putting the blade steel tempered in s...

Embodiment 2

[0040] Select blade steel with an original grain size of 1.5 for processing, a method for improving the grain size of blade steel 2Cr12MoV, the improvement method comprising the following steps:

[0041] Step A, forging the blade steel, placing the blade steel on a forging machine for forging, when forging, the unilateral margin of the blade steel profile is 3.2mm, and the pressure of the forging machine is 2000N;

[0042] Step B, heating the blade steel forged in step A to a certain temperature in a heat treatment furnace, keeping it warm for a period of time, and then water cooling;

[0043] Wherein, the heat treatment furnace temperature is 850-870°C, and the holding time is 60-120min;

[0044] Step C, tempering the blade steel after water cooling in step B, heating the quenched blade steel to a certain temperature, and then air cooling;

[0045] Among them, the temperature is 830-840°C, and the holding time is 45-135min;

[0046] Step D, putting the blade steel tempered ...

Embodiment 3

[0055] Select blade steel with an original grain size of 1.5 for processing, a method for improving the grain size of blade steel 2Cr12MoV, the improvement method comprising the following steps:

[0056] Step A, forging the blade steel, placing the blade steel on a forging machine for forging, when forging, the unilateral margin of the blade steel profile is 3.4mm, and the pressure of the forging machine is 2000N;

[0057] Step B, heating the blade steel forged in step A to a certain temperature in a heat treatment furnace, keeping it warm for a period of time, and then water cooling;

[0058] Wherein, the heat treatment furnace temperature is 850-870°C, and the holding time is 60-120min;

[0059]Step C, tempering the blade steel after water cooling in step B, heating the quenched blade steel to a certain temperature, and then air cooling;

[0060] Among them, the temperature is 830-840°C, and the holding time is 45-135min;

[0061] Step D, putting the blade steel tempered i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com