Production process of semi-hard soft copper belts

A production process, soft copper strip technology, applied in the field of semi-hard soft copper strip production technology, can solve the problems of copper strip annealing is not soft, copper strip hard, different grain size, etc., to improve the strip shape Quality, meet the requirements of use, and the effect of uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

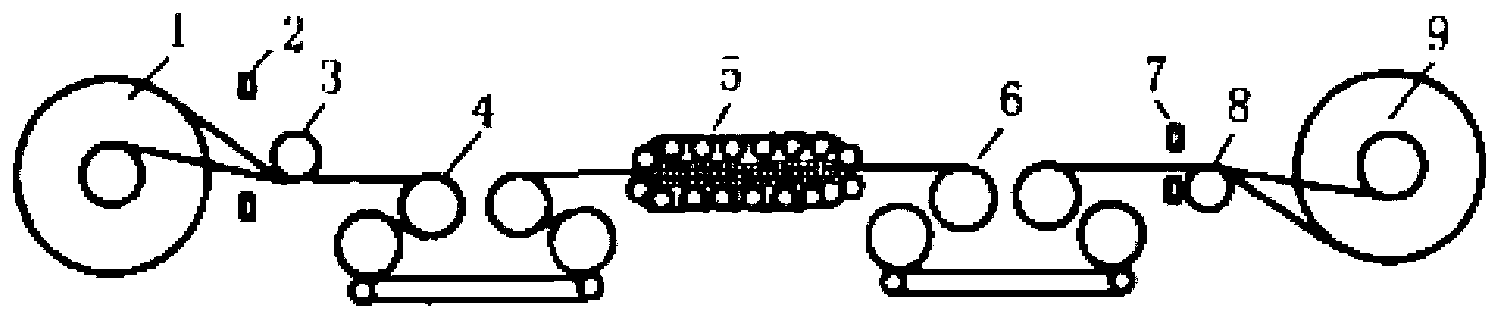

[0031] A production process of semi-hard and soft copper strip, including rough rolling process→annealing process→intermediate rolling process→annealing process→finish rolling process→normal annealing process→cleaning process→bending and straightening process→slitting process→packing process ;

[0032] Specifically:

[0033] (1) Rough rolling process:

[0034] Roll the strip with a four-high reversing rolling mill. The rolling schedule is 6 passes, the processing rate of each pass is 20%~40%, and the rolling force is controlled at 300t;

[0035] (2) Annealing process:

[0036] Anneal the strip treated in (1) in a bell-type furnace. The temperature of the outer cover of the bell-type furnace is controlled at 510°C, the temperature of the inner cover is controlled at 390°C, the heating time is controlled at 3h, the holding time is 5h, and the furnace temperature is controlled at at 100°C;

[0037] (3) Intermediate rolling process:

[0038] The strip treated in (2) is rolled...

Embodiment 2

[0057] A production process of semi-hard and soft copper strip, including rough rolling process→annealing process→intermediate rolling process→annealing process→finish rolling process→normal annealing process→cleaning process→bending and straightening process→slitting process→packing process ;

[0058] Specifically:

[0059] (1) Rough rolling process:

[0060] Roll the strip with a four-roll reversing rolling mill. The rolling schedule is 5 passes, the processing rate of each pass is 20%~40%, and the rolling force of each pass is controlled to 300t;

[0061] (2) Annealing process:

[0062] The strip treated in (1) is annealed in a bell-type furnace. The temperature of the outer cover of the bell-type furnace is controlled at 540°C, the temperature of the inner cover is controlled at 420°C, the heating time is controlled at 6h, the holding time is 8h, and the furnace temperature is controlled at 100°C;

[0063] (3) Intermediate rolling process:

[0064] Roll the strip treate...

Embodiment 3

[0081] A production process of semi-hard and soft copper strip, including rough rolling process→annealing process→intermediate rolling process→annealing process→finish rolling process→normal annealing process→cleaning process→bending and straightening process→slitting process→packing process ;

[0082] Specifically:

[0083] (1) Rough rolling process:

[0084] Roll the strip with a four-high reversing rolling mill. The rolling schedule is 6 passes, the processing rate of each pass is 20%~34%, and the rolling force is controlled at 290t;

[0085] (2) Annealing process:

[0086] The strip treated in (1) is annealed in a bell-type furnace. The outer cover temperature of the bell-type furnace is controlled at 530°C, the inner cover temperature is controlled at 410°C, the heating time is controlled at 5h, the holding time is 7h, and the furnace temperature is controlled 90°C;

[0087] (3) Intermediate rolling process:

[0088] The strip treated in (2) is rolled with a four-hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com