Method for clearing off brick residues at broken holes in wall of coke oven hot repair carbonization chamber

A cleaning method and carbonization chamber technology, applied in the direction of preventing/repairing bricklaying leakage, etc., can solve problems such as large inside and small outside, and achieve the effects of reducing labor intensity, quick cleaning, and saving repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific implementation, the embodiment of the present invention is further described:

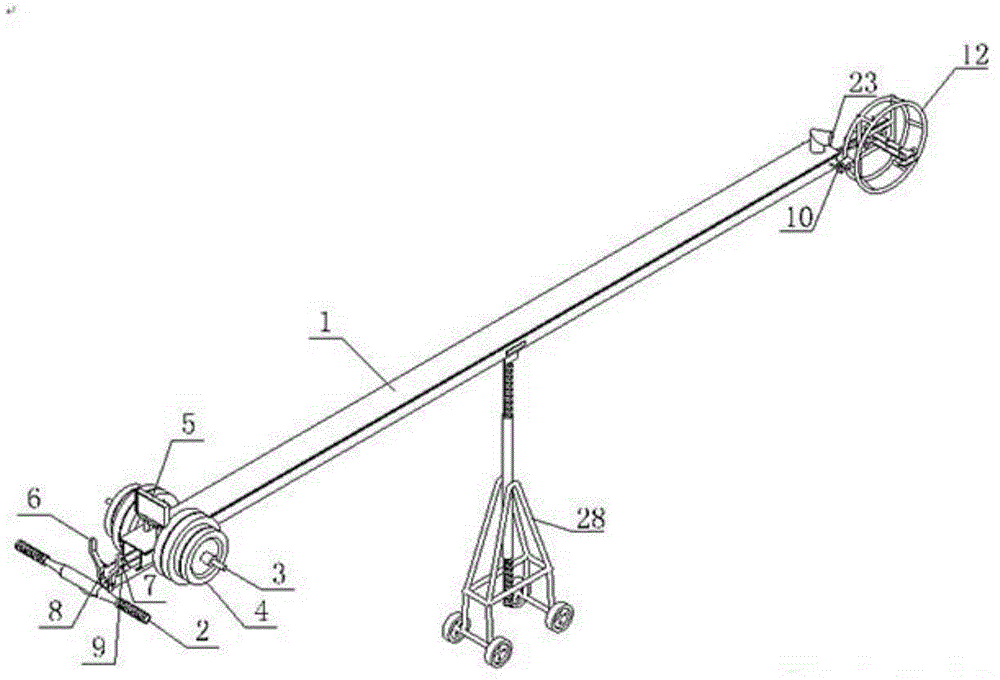

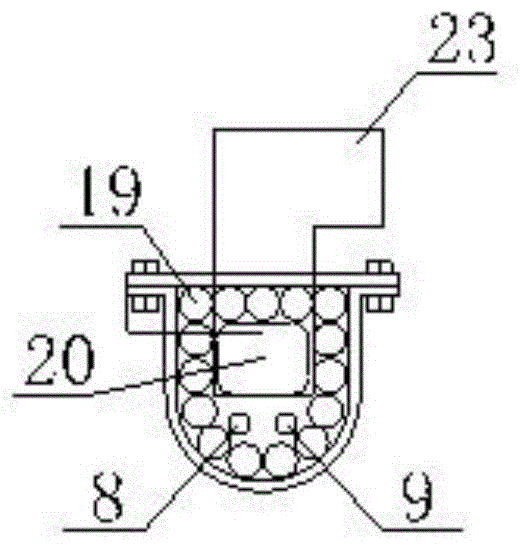

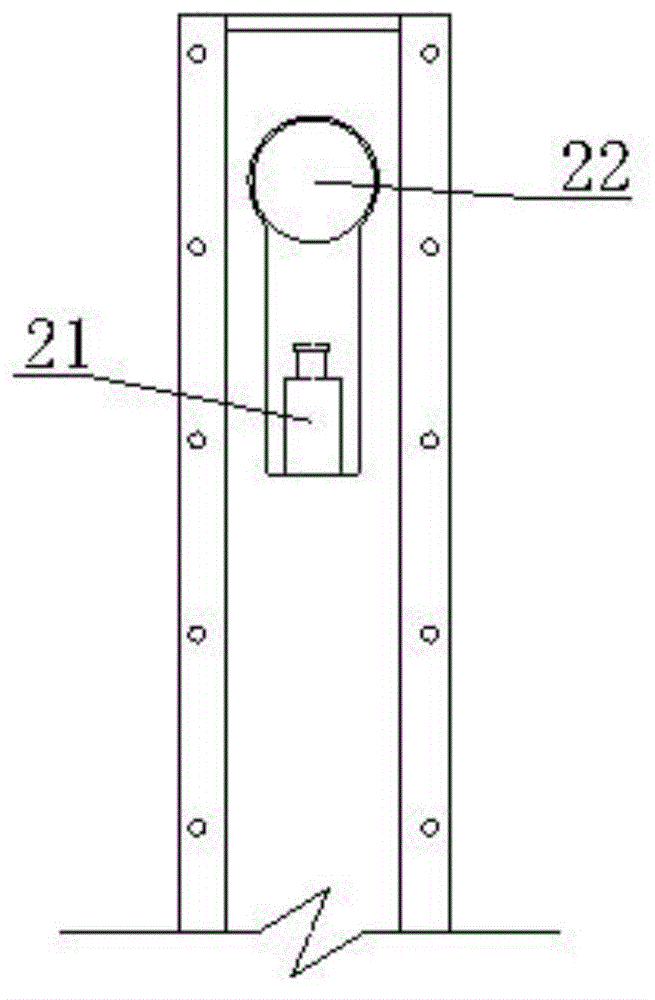

[0028] Such as Figure 1 to Figure 9 The above-mentioned brick slag cleaning device on the wall of the carbonization chamber is mainly composed of a rocker arm 1, an image acquisition system, a brick hook device and a rocker movable support frame, wherein one end of the rocker arm 1 is provided with a hand handle 2 and a counterweight cross bar 3 and the monitor 5, a counterweight 4 is provided on the counterweight bar, and a tight hook joystick 6 and a loose hook joystick 7 are arranged on the hand handle 2; The frame ear plate 10 is connected with the rocker arm 1, and the middle part of the rocker arm 1 is provided with a rocker movable support frame.

[0029] The brick hook device is mainly composed of anti-deformation frame support 11, anti-tension deformation frame 12, shaft frame 13, hook head 14, hook body 15, eccentric projection 16, hook back pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com