3D printing operation guide plate

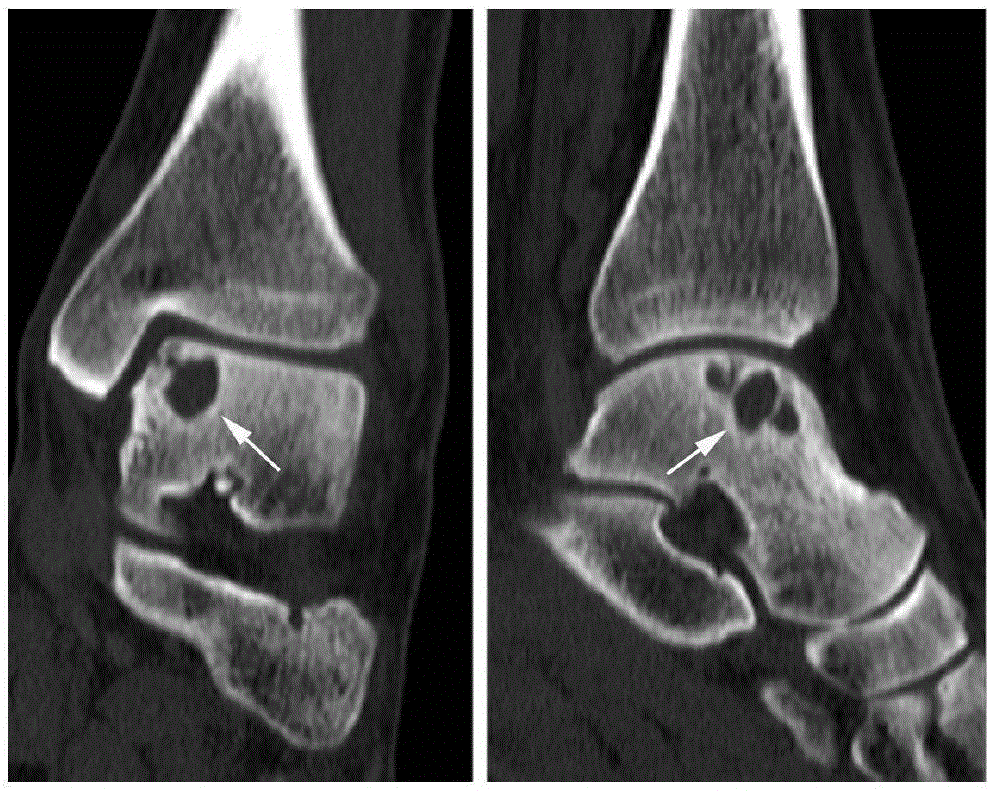

A 3D printing, guide plate technology, applied in the fields of surgery, stereotaxic surgical instruments, medical science, etc., can solve the problems of low operation accuracy, insufficient positioning accuracy, insufficient cleaning, etc., to avoid insufficient cleaning and avoid X-rays. The effect of positioning and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

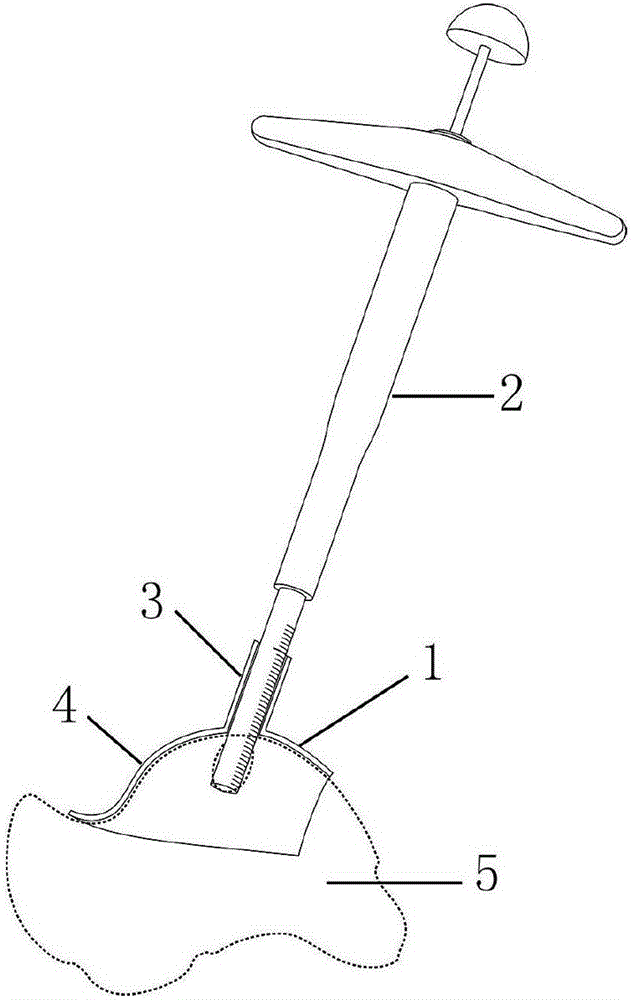

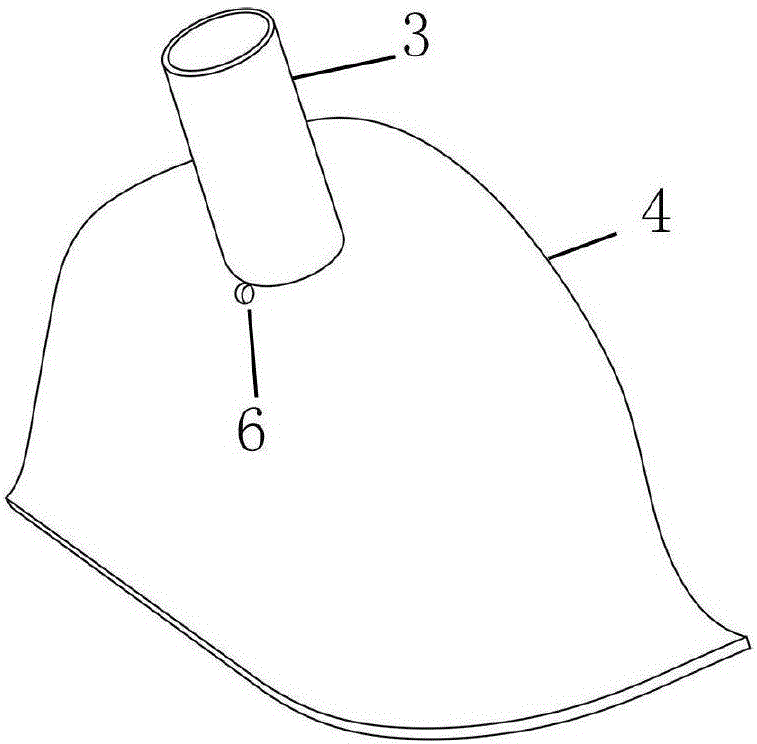

[0036] Such as figure 2 , 5 As shown, it is the components A1 and B7 of the 3D printing sports injury treatment surgical guide plate of the present invention, wherein the A component 1 is divided into upper and lower parts, the upper part is the catheter 3, and according to the spatial position of the cyst Determine the position and direction of the catheter 3, the length of the catheter 3 is 5cm, the thickness is 2mm, and the inner diameter is 6mm, 8mm, 10mm respectively, according to the size of the cyst, corresponding to the diameter of the trephine 2 used, the A component 1 The lower part is the shell 4 that is close to the surface of the talus 5, the thickness of the shell 4 is 2 mm, the shell 4 extends from the side of the talus 5 to the bottom surface of the talus 5 and the neck of the talus 5, the A component 1 is placed in the catheter 3 There is a marking hole 6 between the shell 4, and the B component 7 is a catheter adapted to the bone hole made by the trephine 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com