Screw blade cleaning device of building screw feeding machine

The technology of screw feeder and screw blade is applied in the field of construction screw feeder screw blade cleaning device and screw cleaning device, which can solve the problems of destroying the surface flatness, affecting the conveying efficiency, low efficiency, etc., so as to reduce wear and improve cleaning. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

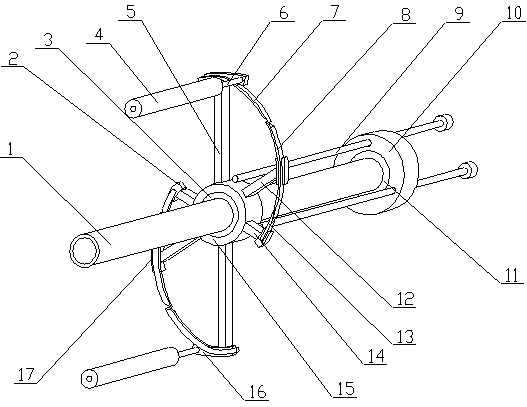

[0023]A spiral blade cleaning device for a construction screw feeder of the present invention is realized in the following way: when in use, the spiral blade is fixed, the screw rod (1) is inserted into the middle of the spiral blade, and the clamping rollers (4) on both sides are respectively mixed with the spiral blade Fix the upper stator of the outer rotor motor (10), and then start the outer rotor motor (10). When rotating, the first cleaning arm (5) first contacts the spiral blade, and drives the fixing ring through the guide rod (9) (15) rotates, the fixed ring (15) drives the screw sleeve (3) to rotate along the screw rod (1), and the screw sleeve (3) moves along the screw rod (1), so that the first cleaning arm on the fixed ring (15) ( 5), the second cleaning arm (12), the third cleaning arm (14) rotate and move, and the surface of the spiral blade is attached, and the first cleaning knife (7) on the first cleaning arm (5) rotates to the outside of the spiral blade Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com