Gas pipeline repairing method and system based on Beidou differential positioning

A differential positioning, gas pipeline technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as high dependence on experience of maintenance personnel, leakage of gas pipeline connection points, and low degree of soil environmental damage. Achieve the effect of reducing labor input cost, quick repair, and less soil damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

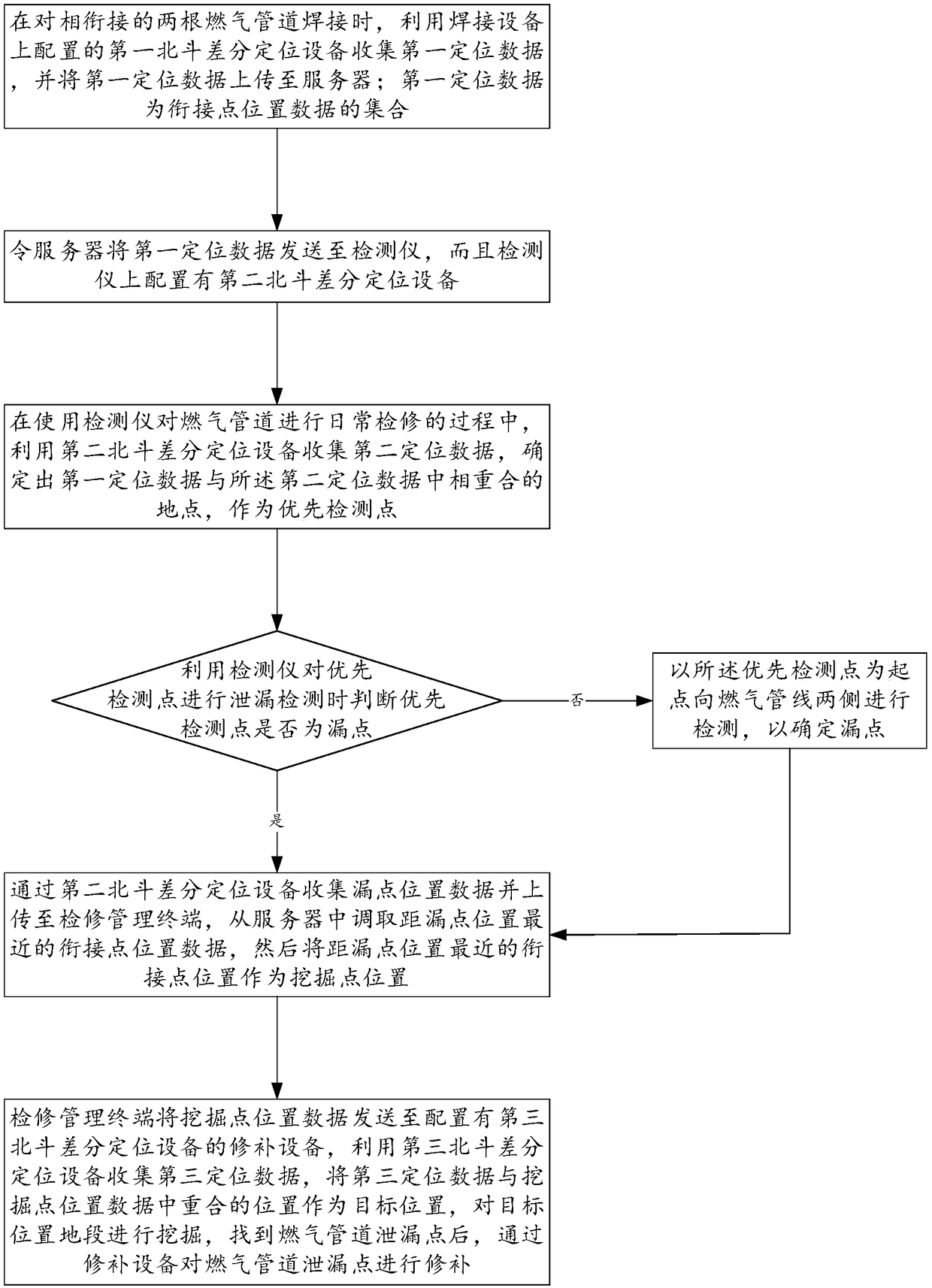

[0049] Such as figure 1 As shown in , this embodiment discloses a gas pipeline repair method based on Beidou differential positioning. The repair method is a method that can effectively improve the gas pipeline repair efficiency. The repair method specifically includes the following steps.

[0050] Step 1. When welding two connected gas pipelines, use the first Beidou differential positioning device configured on the welding equipment to collect the first positioning data, and upload the first positioning data to the server; where the first positioning data is A collection of junction point location data, the server is used to store the first location data. In this embodiment, in order to improve the accuracy of the first positioning data, the first positioning data collected by the first Beidou differential positioning device is the positioning data corrected by positioning satellites and multiple positioning base stations; in this embodiment, the server will Permanently sav...

Embodiment 2

[0058] Based on the same inventive concept as the first embodiment, this embodiment provides a repair system for realizing the above-mentioned gas pipeline repair method based on Beidou differential positioning, which is described in detail as follows. This embodiment discloses a gas pipeline repair system based on Beidou differential positioning. The system may include welding equipment, detectors, repair equipment, servers, maintenance management terminals, and browsing terminals connected to the maintenance management terminals. Among them, the welding equipment The first Beidou differential positioning device is configured on the detector, the second Beidou differential positioning device is configured on the detector, the third Beidou differential positioning device is configured on the repairing device, and the server is connected to the maintenance management terminal. The welding equipment, detector and repair equipment in this embodiment are equipped with Beidou differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com