Method and its machine for repairing display panel bright spot

A display panel and machine technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as complex structure, large space, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

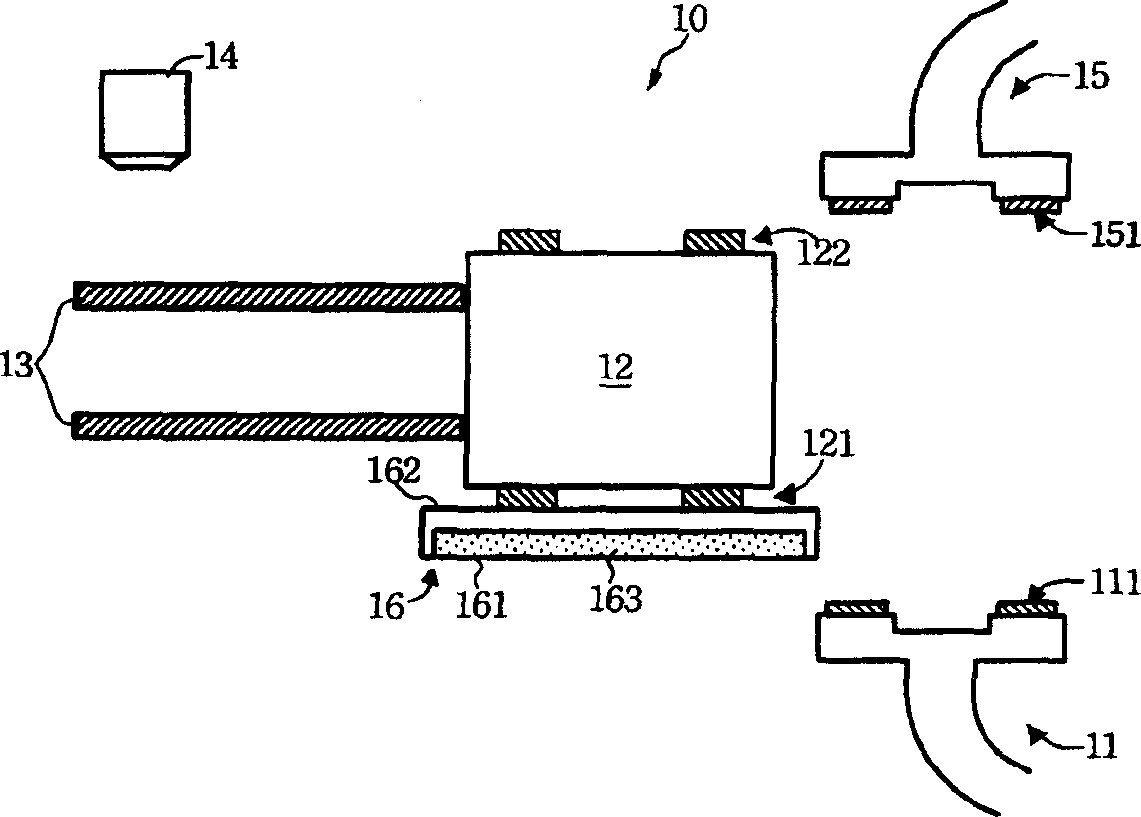

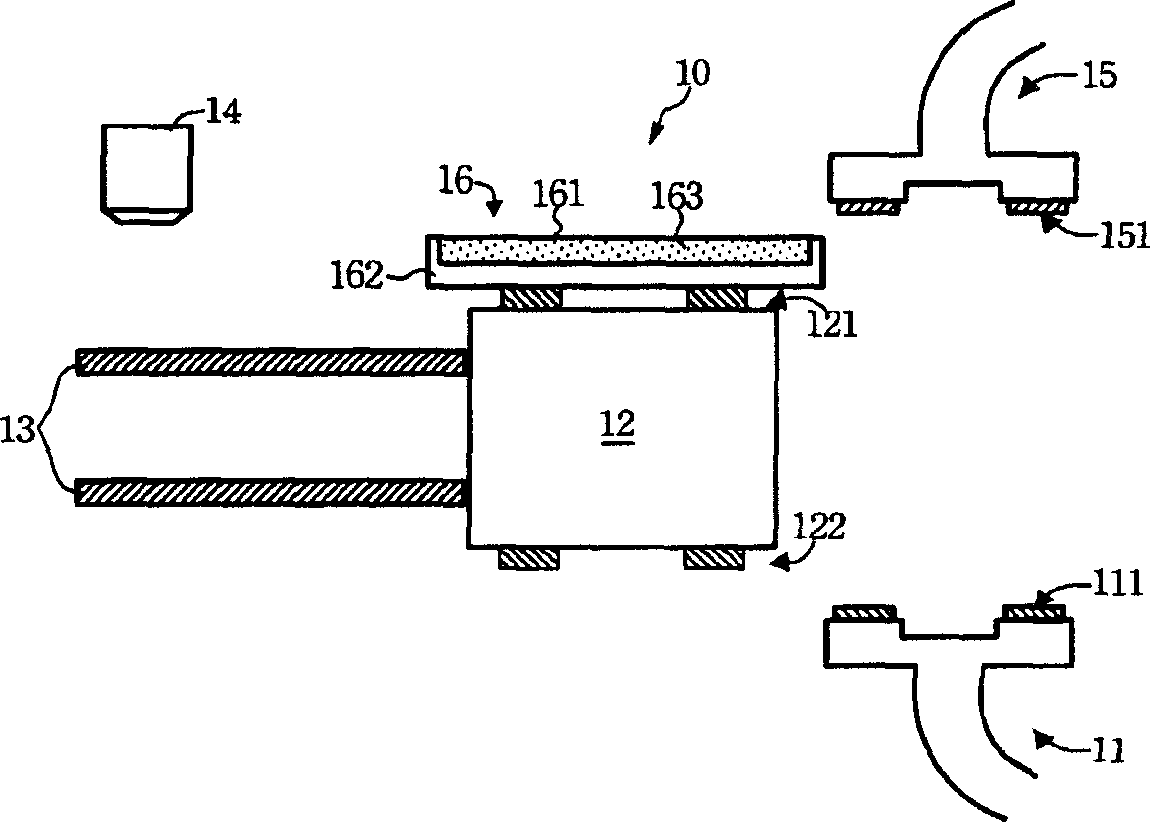

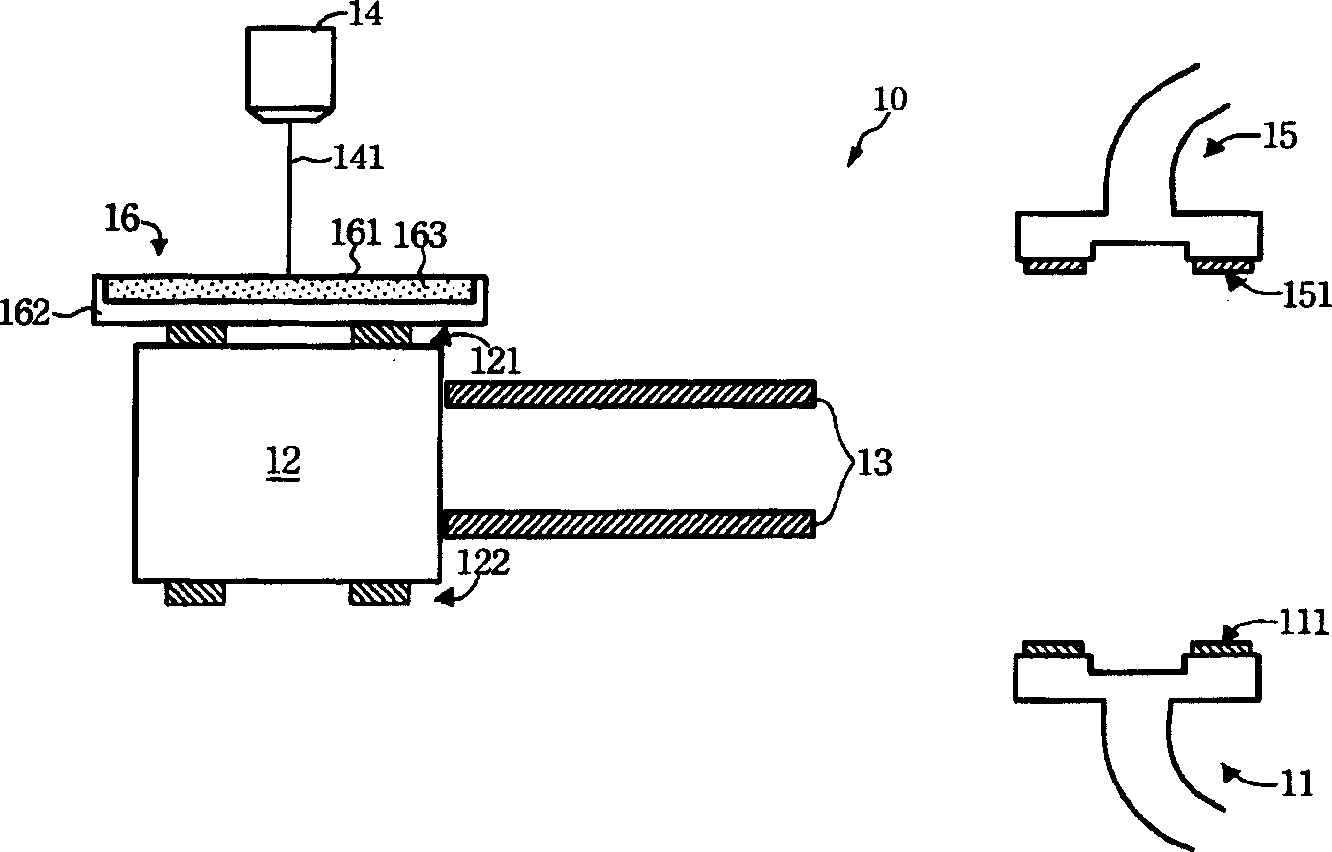

[0042] Please refer to figure 2 , figure 2 is a schematic illustration of a machine 20 of the present invention. The machine 20 of the present invention is used to repair bright spots on a display panel 26 . The machine 20 comprises a first robotic arm 21 , a working platform 22 and a laser generating device 24 . The first automatic arm 21 moves the display panel 26 to the working platform 22 . Wherein, the first automatic arm 21 has two first vacuum chucks 211 , which are adsorbed on the lower surface 261 of the display panel 30 by the first vacuum chucks 211 , so that the first automatic arm 21 can transport the display panel 26 .

[0043] Moreover, the working platform 22 is used for erecting the display panel 26 thereon. Wherein, the working platform 22 may have two adsorption components 221 , and the adsorption components 221 are disposed below the working platform 22 . The display panel 26 from the first automatic arm 21 can be adsorbed on the upper surface 262 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com