Quick repair device for damaged position of corrugated paper

A technology for corrugated paper and damage, which is applied in the field of rapid repair devices for corrugated paper damage, which can solve the problems of troublesome manual application of glue, high labor intensity, and low efficiency, and achieve the effects of saving manpower, speeding up labor efficiency, and quickly spraying glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

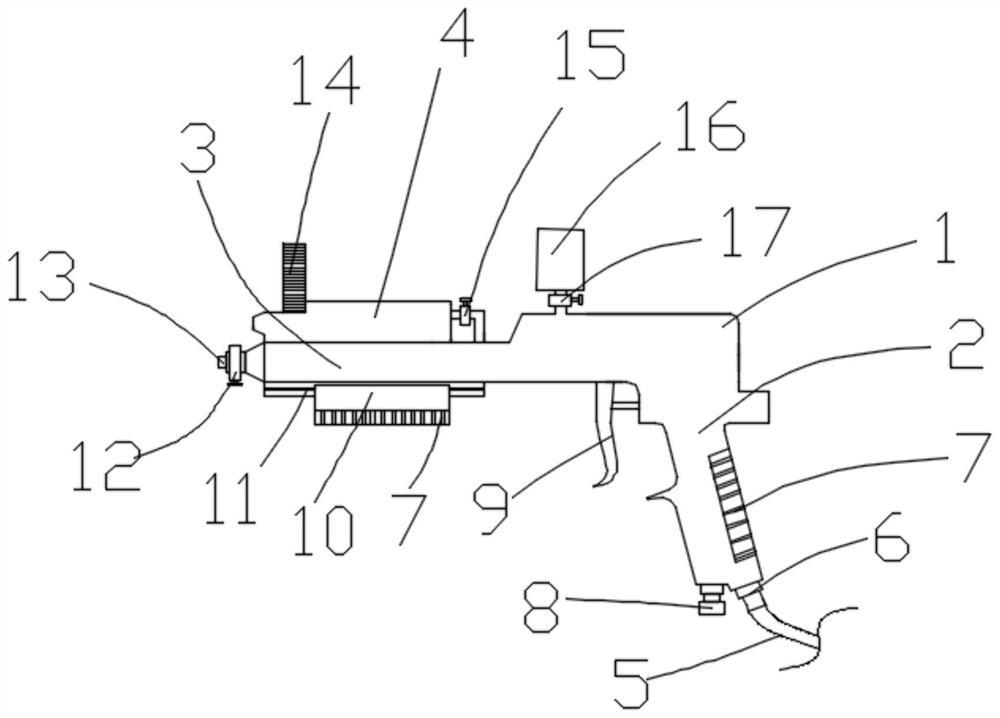

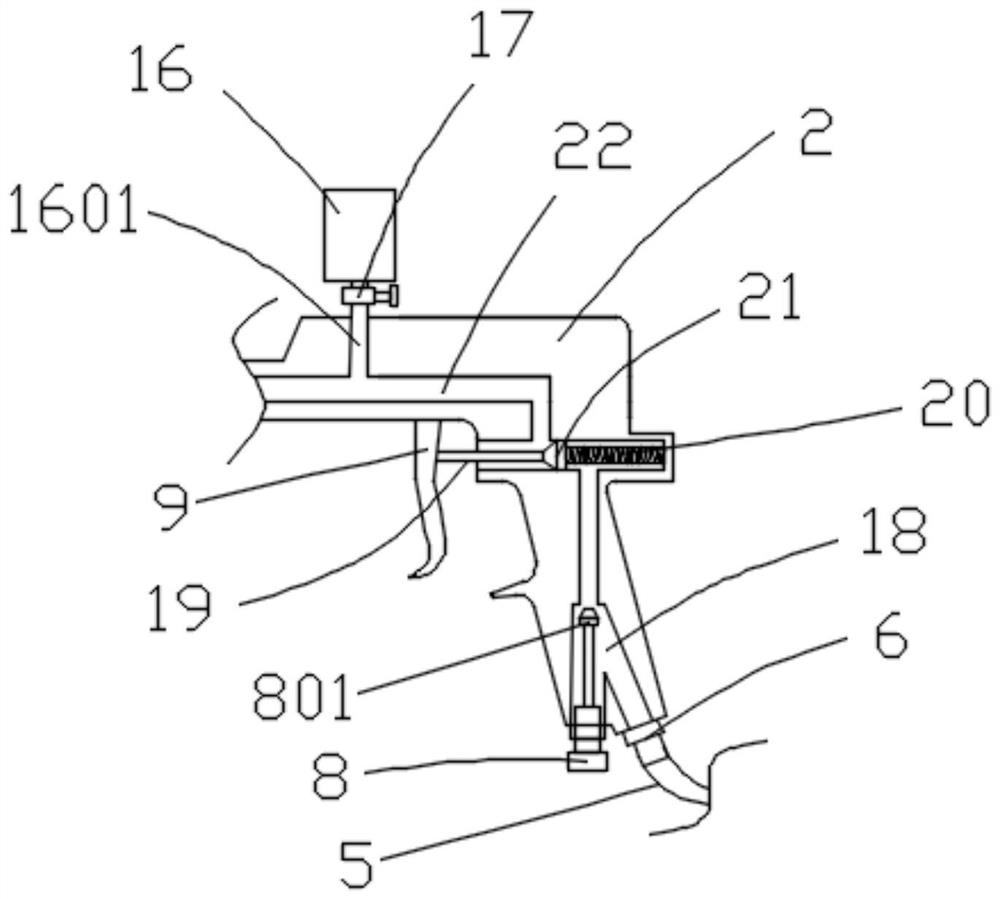

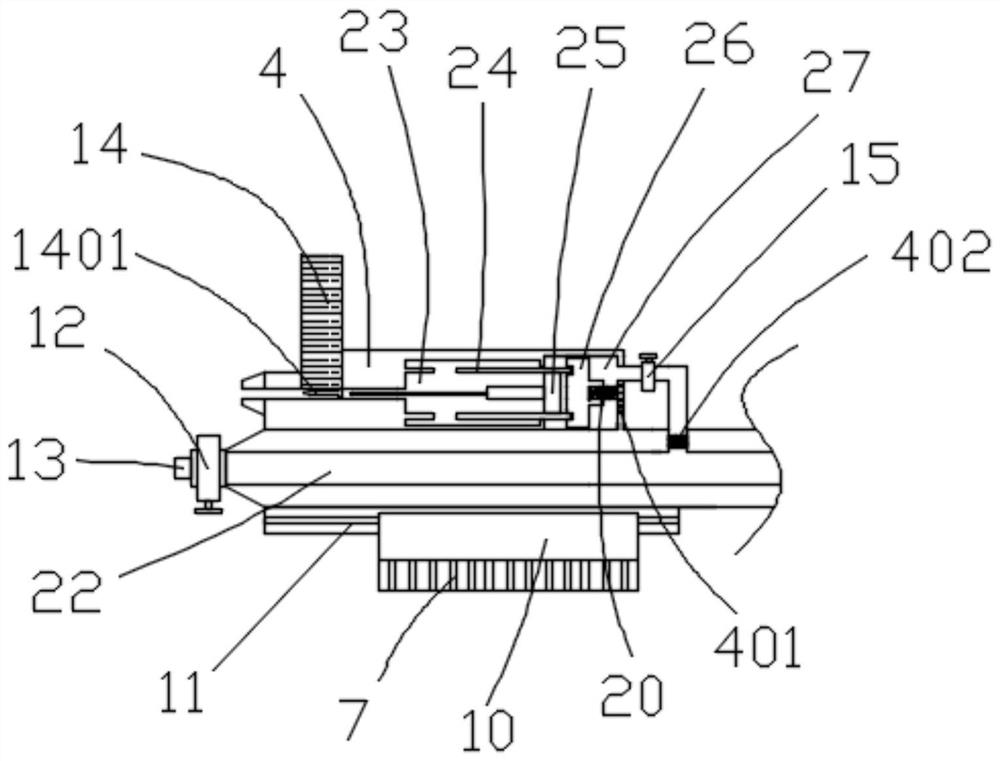

[0028] see figure 1 to attach Figure 7 , a rapid repair device for damaged corrugated paper, comprising a spray gun 1 and a shooting block 4, the spray gun 1 is composed of a gun body 2, a gun barrel 3, a shooting block 4, a trigger 9, and a gun stock 10, and the bottom of the gun body 2 is provided with an air Regulating valve 8 and air inlet 6, hose 5 is provided below air inlet 6, trigger 9 is located on the left wall of gun body 2 and is connected with air inlet block 21 through telescopic rod 19, and air outlet channel is arranged on the upper left of air inlet block 21 The bottom right of 22 is provided with an air inlet passage, the glue tank 16 is provided with a glue tank valve 17 and the feed passage 1601 and is connected with the air outlet passage 22, the top of the gun barrel 3 is provided with a shooting block 4 and the bottom is provided with a gun stock 10, and the shooting block 4 An air storage chamber 27 is provided at the bottom, and an air outlet 401 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com