Inner inserting type gas-liquid mixing spray pipe device

A gas-liquid mixing and interpolation technology, which is applied in the direction of mixers, fluid mixers, transportation and packaging, etc., can solve the problems of high corrosiveness of the solution, inability to mix the gas-solid three-phase medium uniformly, and can only be replaced. Achieve the effects of reducing labor intensity of workers, ensuring process continuity and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

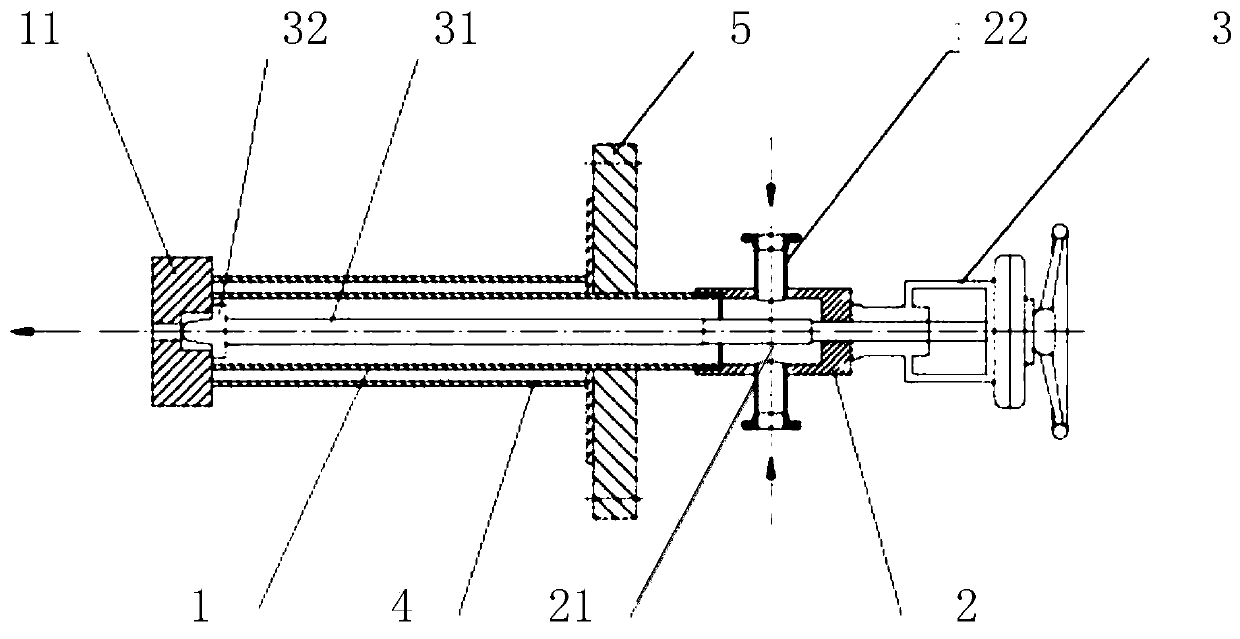

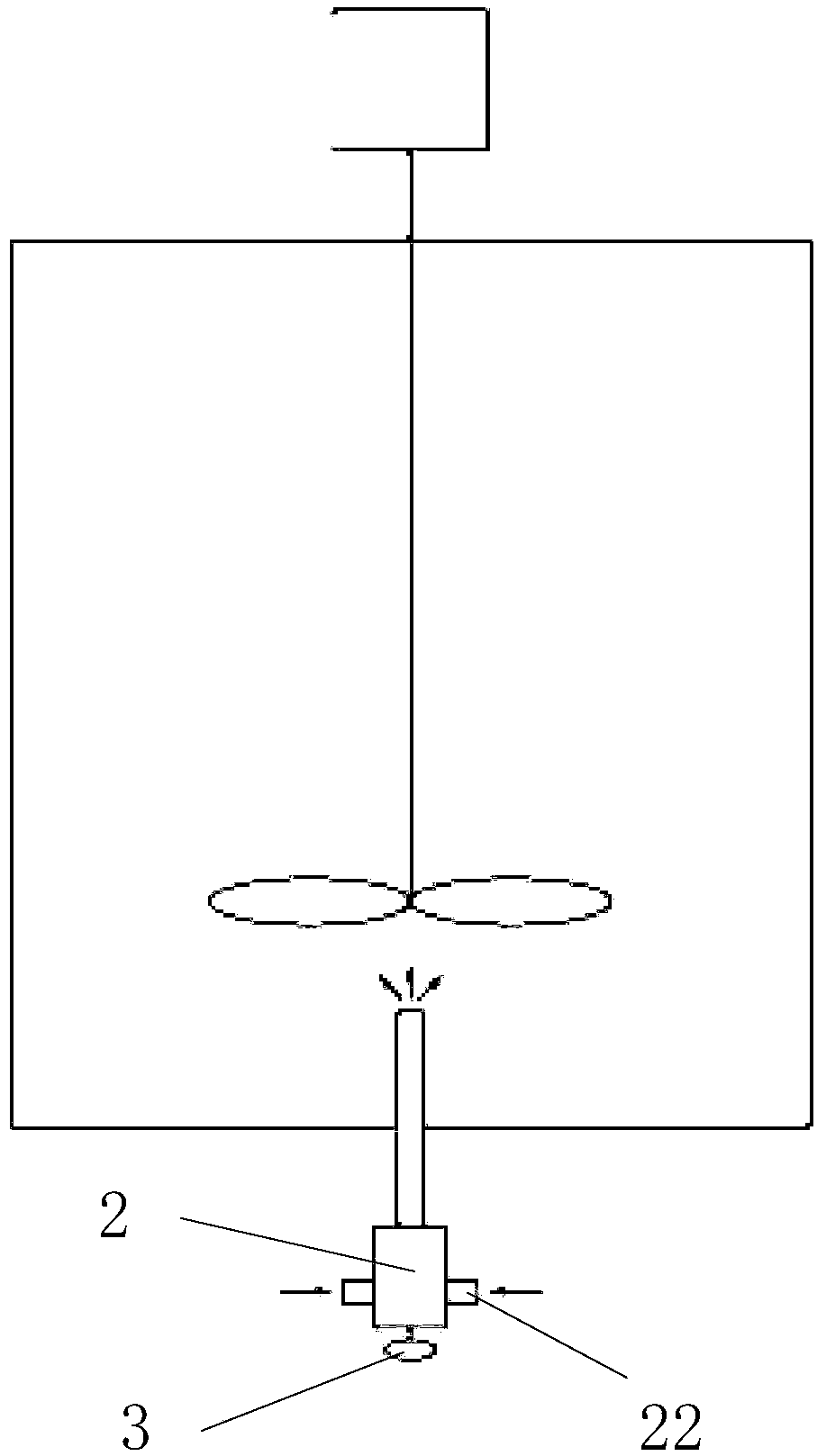

[0026] Embodiment one, such as figure 1 As shown, an interpolated gas-liquid mixing nozzle device according to the present invention includes an inner pipe 1, and two ends of the inner pipe 1 are respectively provided with a one-way nozzle and an air intake mechanism 2, and the one-way nozzle It includes a valve seat 11 connected to the inner pipe 1, the air intake mechanism 2 includes a mixing chamber 21 communicating with the inner pipe 1, and several air inlet pipes 22 communicating with the mixing chamber 21, and the air intake mechanism 2 is far away from the inner pipe 1 One end is provided with an actuator 3, and the output end of the actuator 3 is connected with a valve stem 31 that moves along the axial direction of the inner pipe 1, and the valve stem 31 passes through the mixing chamber 21 and is arranged in the inner pipe 1, The end of the valve stem 31 close to the valve seat 11 is provided with a valve core 32 matched with the nozzle of the valve seat 11 , the su...

Embodiment 2

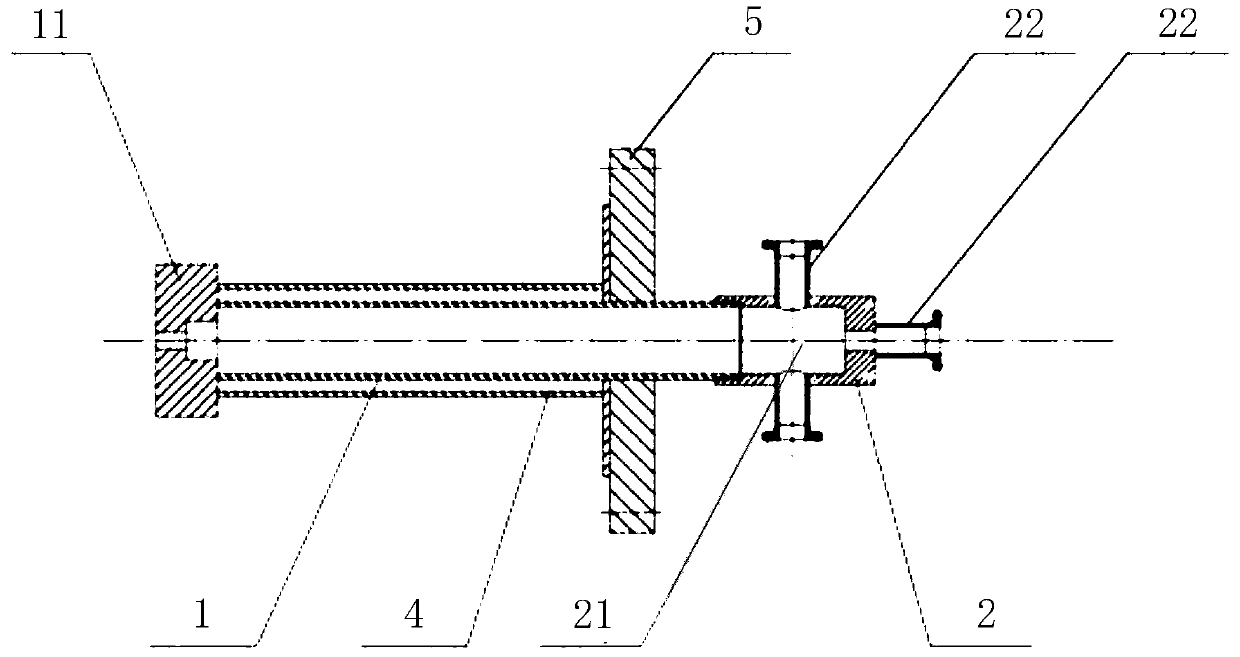

[0033] Embodiment 2 is an interpolated gas-liquid mixing nozzle device as described in Embodiment 1. The difference of this embodiment is that according to the process requirements, for some simple working conditions, the actuator 3 can be disassembled, or Change to manual actuator; image 3 As shown, the original actuator 3 is canceled. In this embodiment, there are three intake pipes 22, and different gases enter the mixing chamber from each intake pipe 22 for pre-mixing, and then spray from the one-way nozzle through the inner pipe 1. into the container.

Embodiment 3

[0034] Embodiment three, as described in embodiment two, a kind of interpolated gas-liquid mixing nozzle device, the difference of this embodiment is that: as Figure 4 As shown, according to specific working conditions, the outer tube 2 is disassembled and used. The specific usage steps and usage methods are the same as those in the second embodiment, and will not be repeated here.

[0035] In summary, with the help of the above technical solution of the present invention, an interposed gas-liquid mixing nozzle device of the present invention has excellent corrosion resistance and corrosion resistance, and can be used for high temperature, high pressure and acid corrosion processes for a long time. The device can be used to mix the gas and liquid evenly and then transport it into the container, and the device has automatic shut-off and automatic adjustment according to the intake situation, which can effectively prevent the medium in the container from entering the inner tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com