Cloth defect detection device and real-time detection method

A detection device and cloth technology, applied in the direction of measuring devices, optical testing flaws/defects, complex mathematical operations, etc., can solve problems such as insufficient reliability, long distance, uncontrollable defect range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

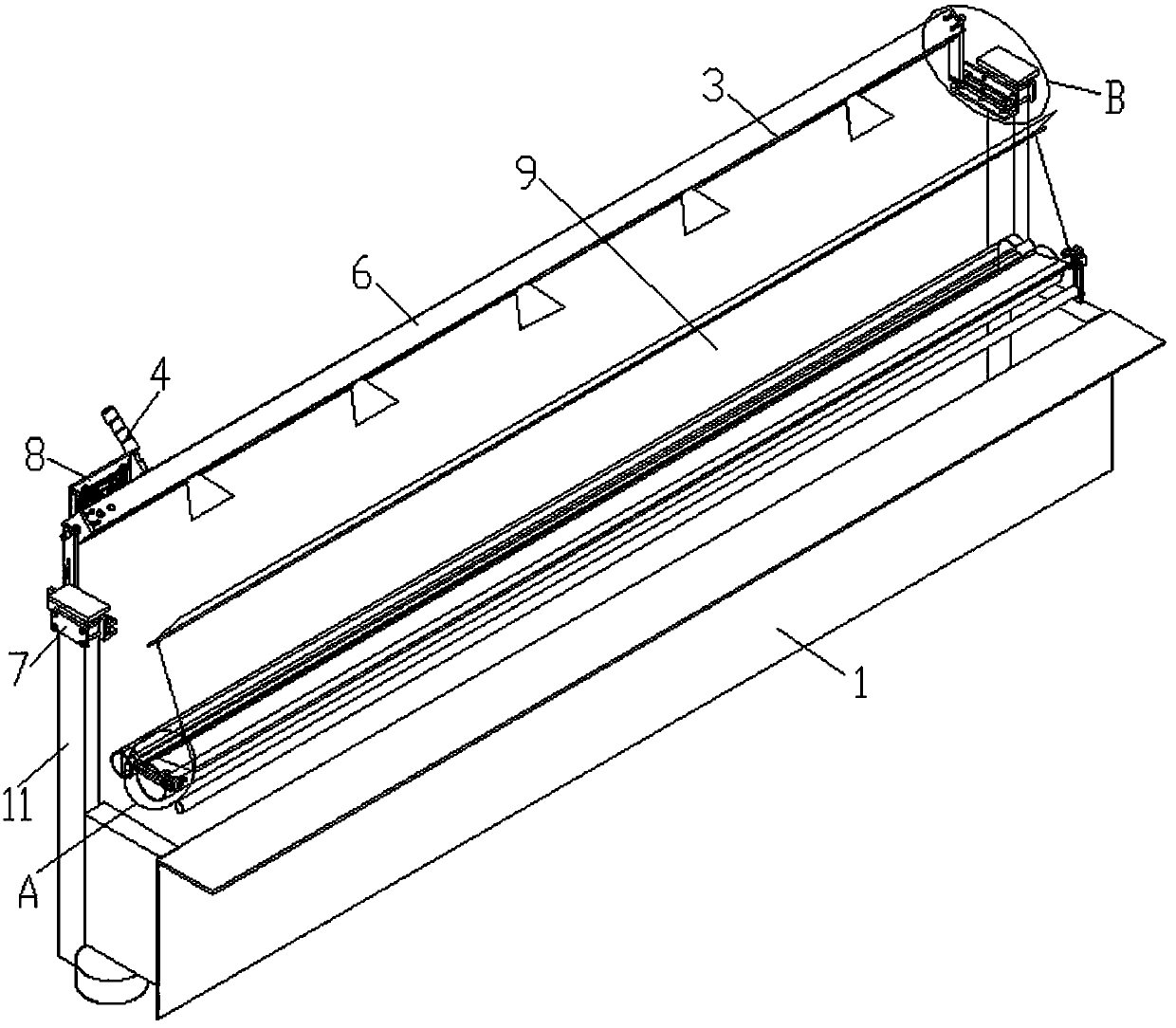

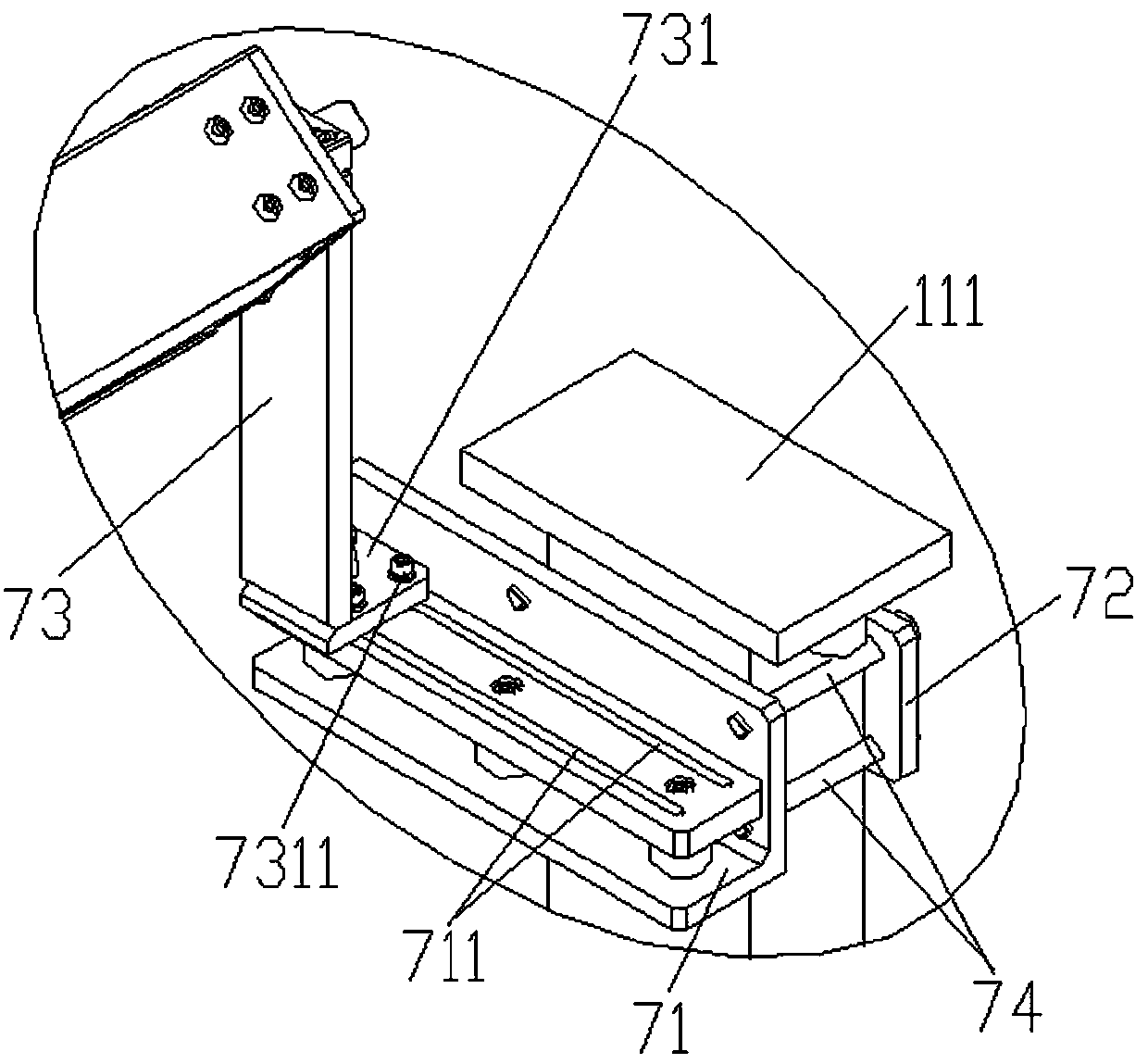

[0090] Such as Figure 1-4 As shown, a cloth defect detection device described in this embodiment includes a background component provided on the warp knitting machine 1 for providing a background for the cloth to be detected, and a light source for illuminating the cloth to be detected to provide light for the cloth. The component is used to photograph the cloth to be detected to collect the camera component of the cloth image and the main control device connected to the camera component.

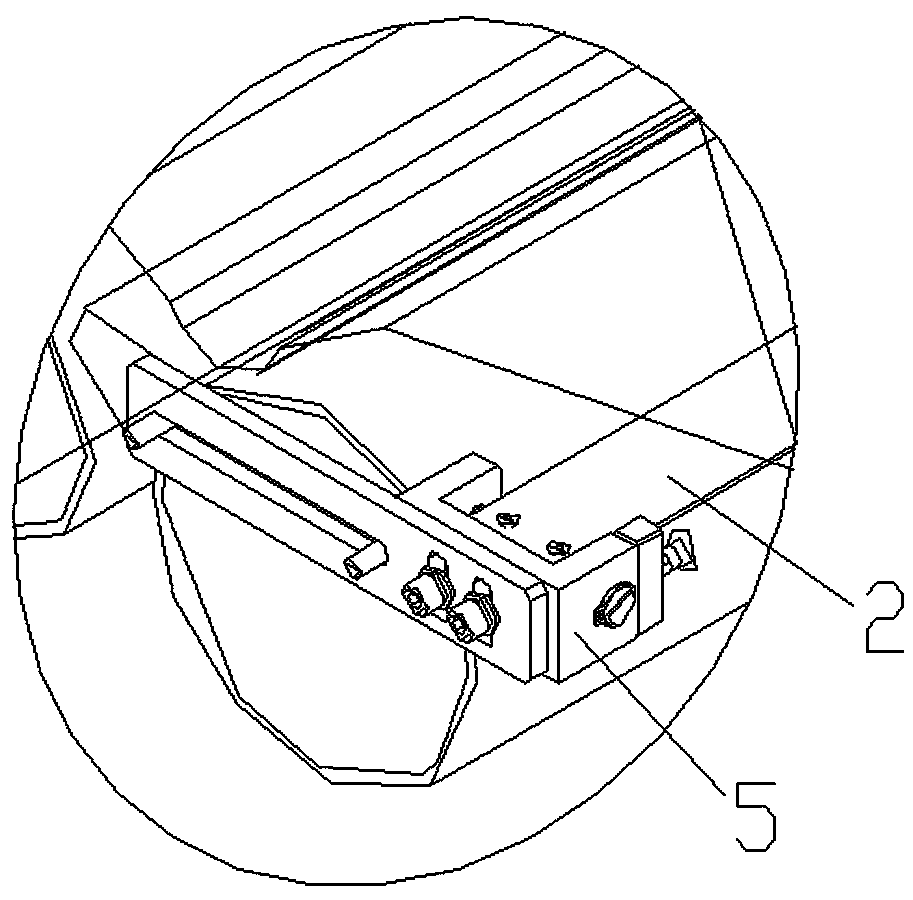

[0091] In this embodiment, the background assembly includes a background board 2 and a background board bracket 5, and the two ends of the background board 2 are respectively fixed on the warp knitting machine 1 through the background board bracket 5, and the length of the background board 2 is not less than the The width of the cloth 9 is to ensure that the cloth to be detected is in the background range provided by the background board 2 in the width direction, and the width of the backg...

Embodiment 2

[0097] A method for real-time detection of cloth defects described in this embodiment mainly includes two steps:

[0098] Step S1, collect several pictures and use the mixed Gaussian model for background modeling, obtain a defect segmentation map, and calculate the framing position in the image at the same time. Among them, the mixed Gaussian model can learn all kinds of different styles of cloth and establish its background model, so as to achieve defect segmentation; the framing positioning algorithm can automatically calculate the framing position of the cloth, which greatly simplifies the operation difficulty of the on-site workers after changing the cloth.

[0099] Further, in the step S1, the background modeling specifically includes the following:

[0100]S111. Model initialization , for the first Each pixel of an image Build a Gaussian model:

[0101] (1)

[0102] in, Indicates the first Gaussian model, , , , , it's all about The function, Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com