Patents

Literature

62results about How to "Repair process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

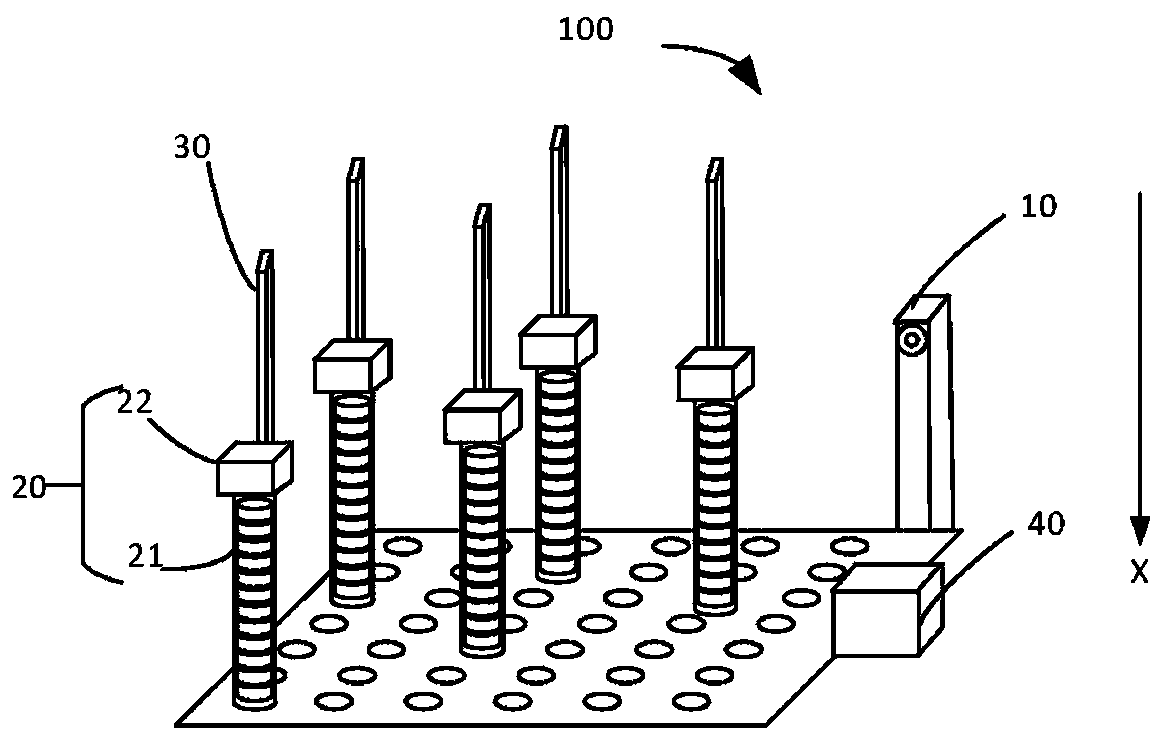

Movable laser cladding and repairing system

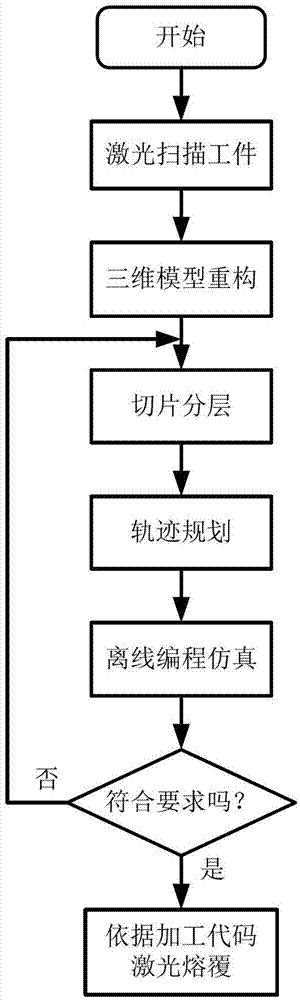

ActiveCN103074625AAchieve claddingAchieve fixMetallic material coating processesLaser scanningLaser sensor

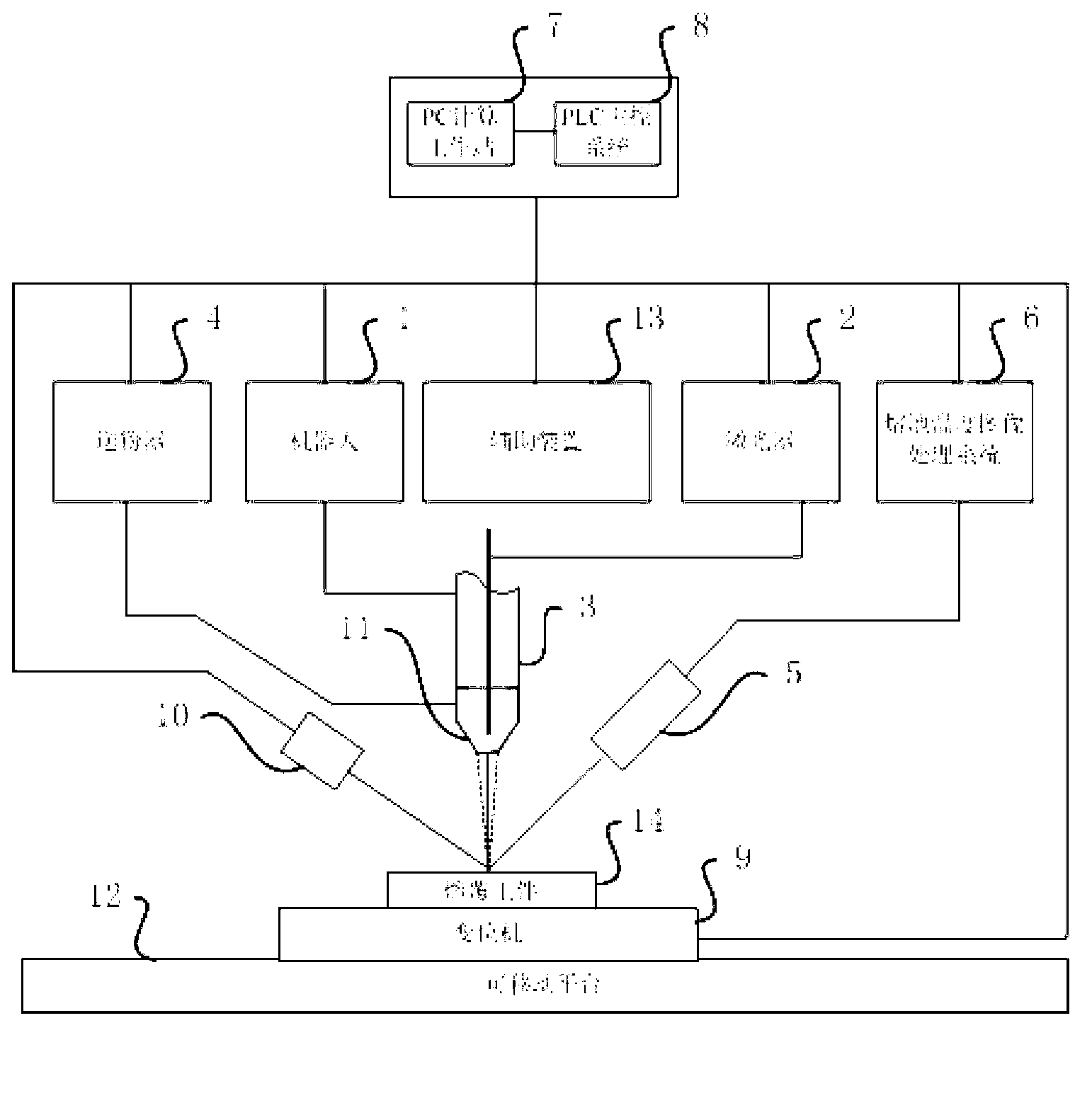

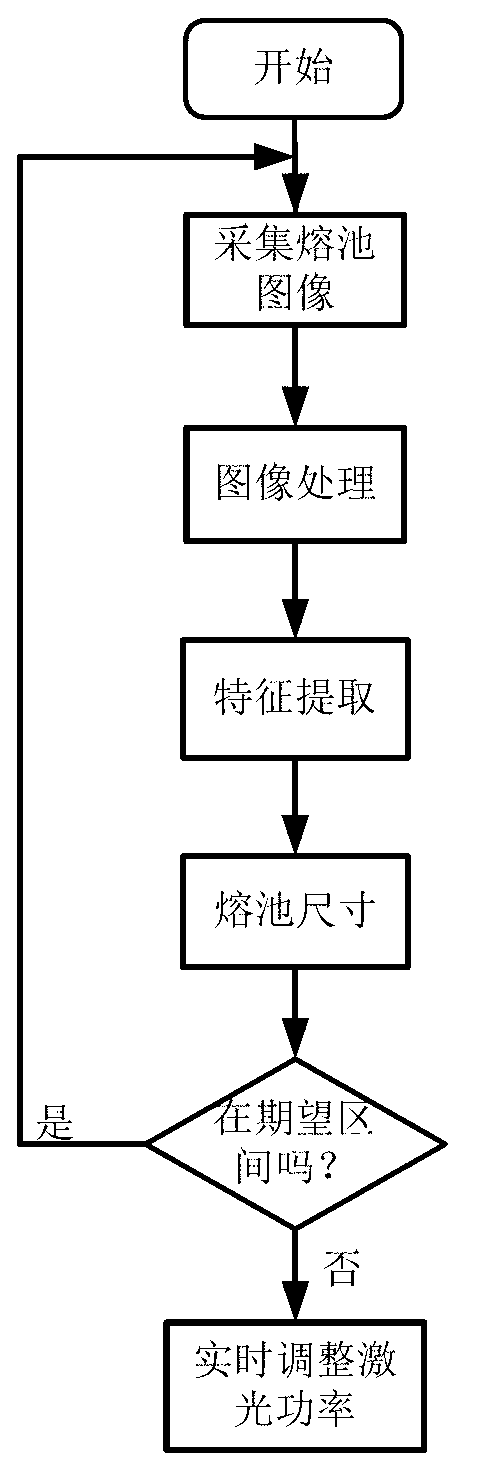

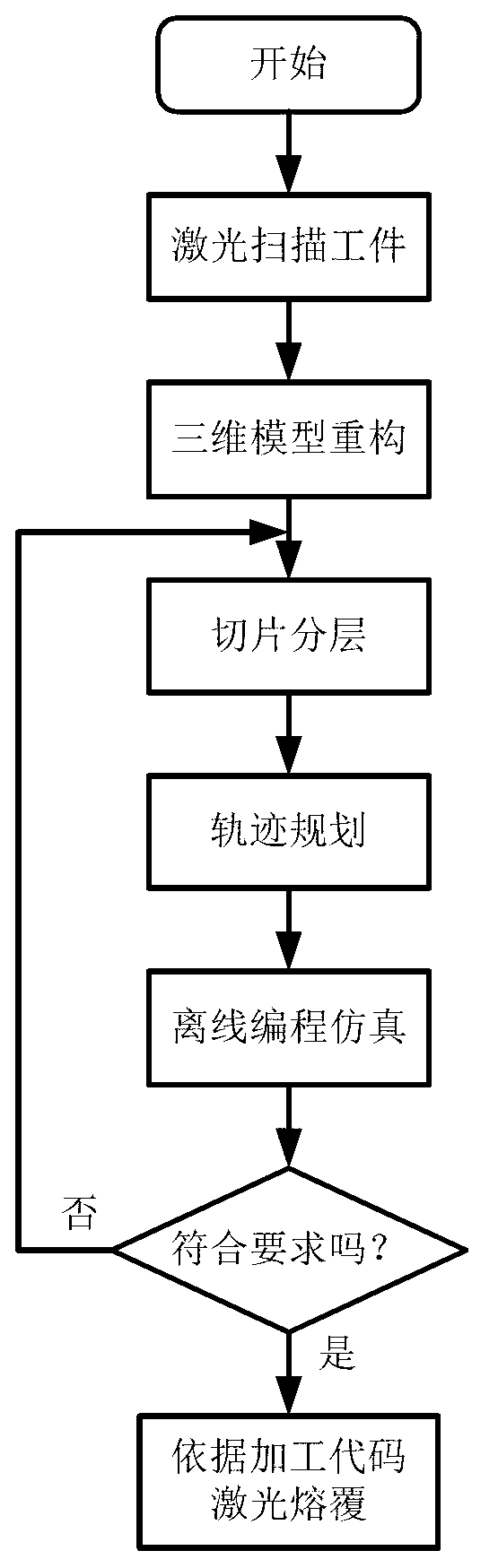

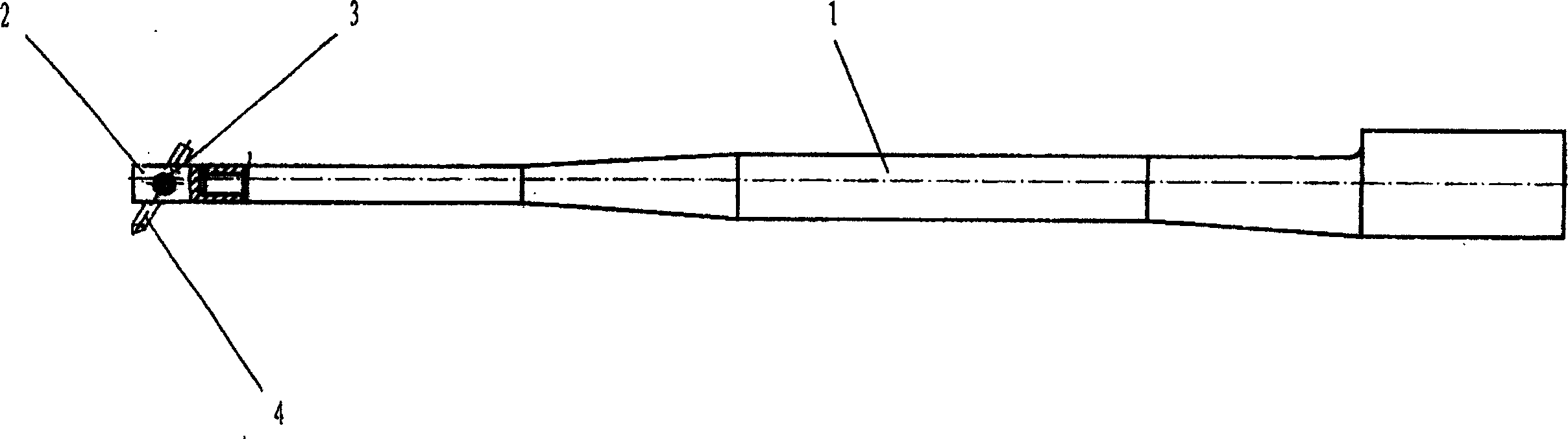

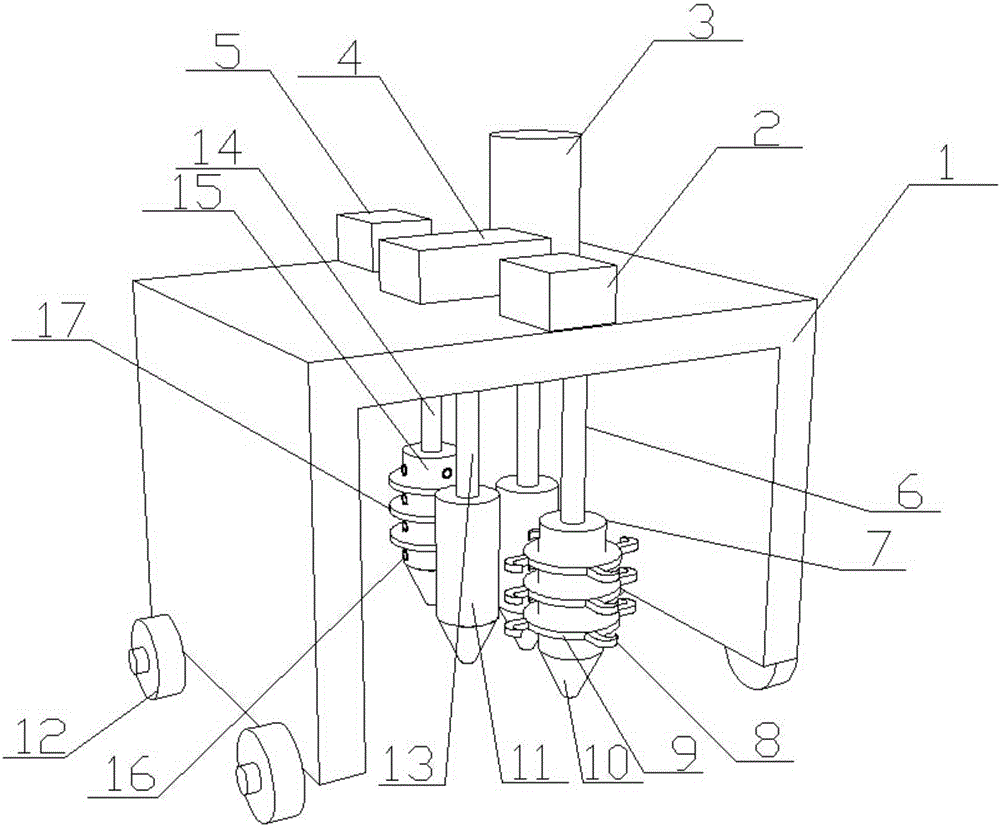

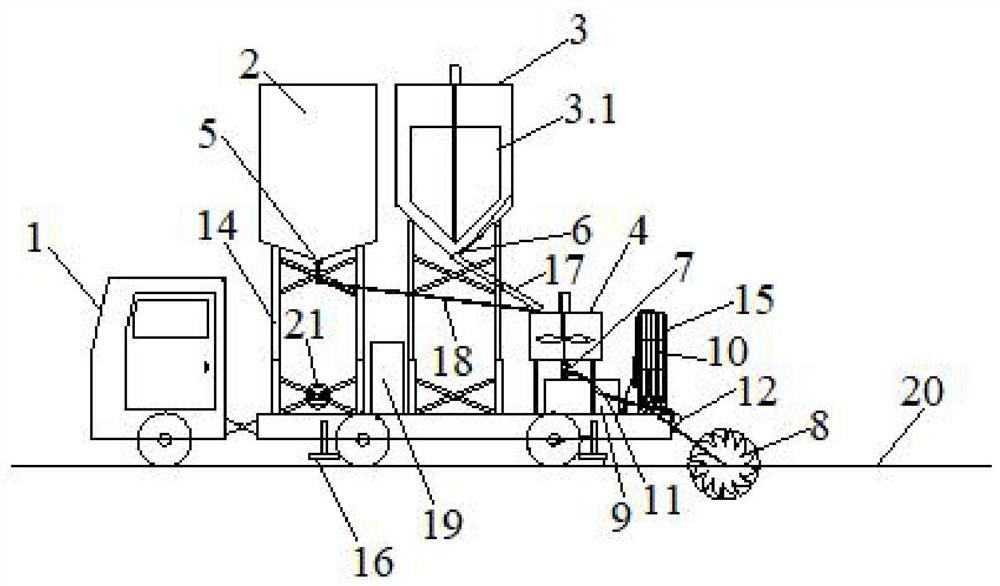

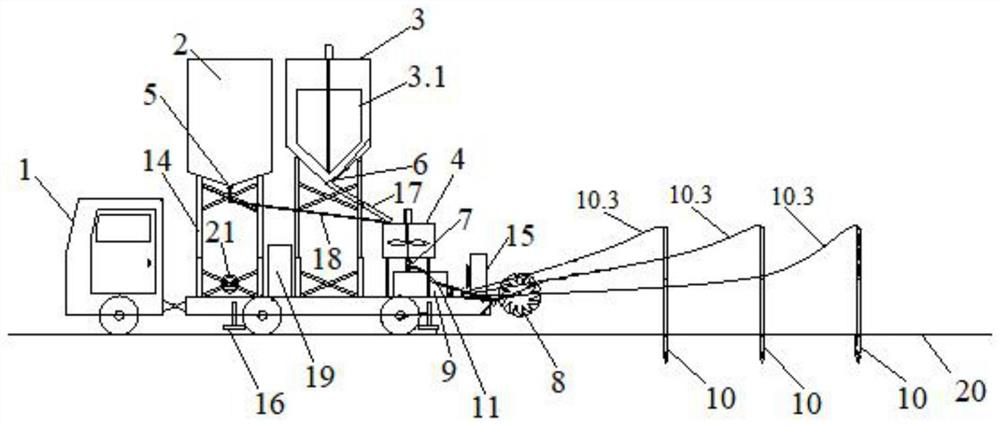

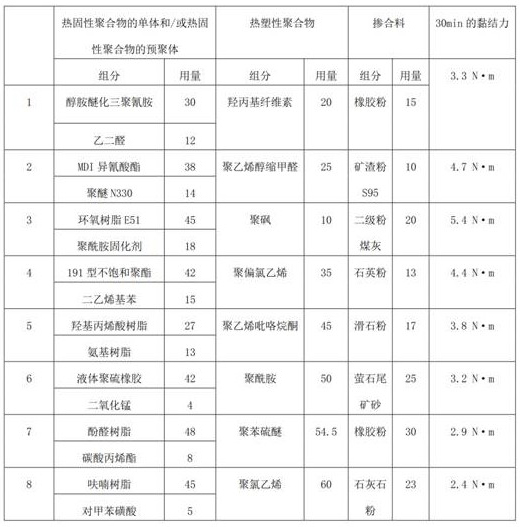

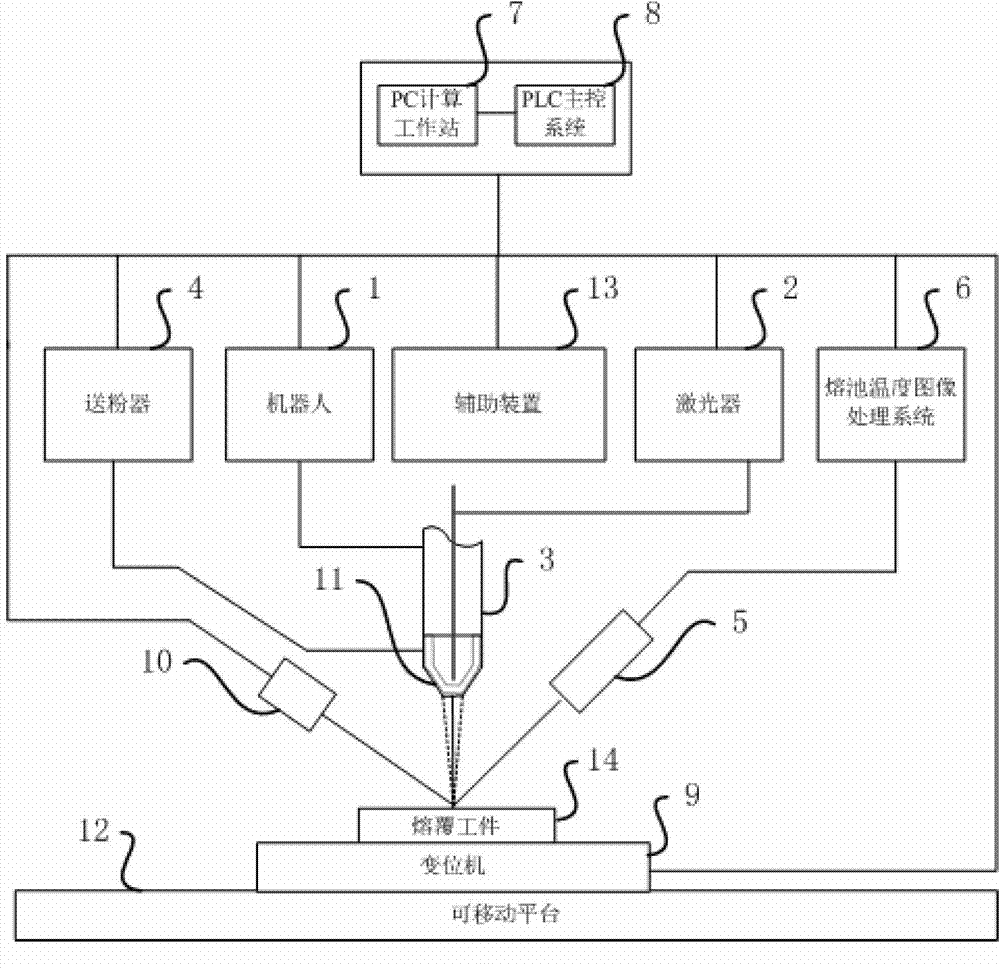

The invention provides a movable laser cladding and repairing system in the field of laser cladding and repairing. The movable laser cladding and repairing system comprises a movable platform, wherein a laser, a robot, a position changing machine, a powder feeder, an image processing system, a control system (comprises a PLC (programmable logic controller) main control system, a PC (personal computer) computing workstation), a video camera, a three-dimensional laser scanning sensor, a laser processing head and a coaxial powder feeding head are fixedly arranged on the movable platform. The movable laser cladding and repairing system takes the robot as a moving body, controls the clad pool size, the temperature and other information by using an image acquiring and processing system, and scans a workpiece to slice, stratify and automatically clad a three-dimensional workpiece model based on the three-dimensional laser sensor; the movable laser cladding and repairing system is convenient and flexible, simplifies a repairing process, achieves precision and self-adaptive control of a cladding process, effectively improves the cladding quality, and facilitates field application of a large component through the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

Method for machining deep hole and its special tool

InactiveCN1781653ARepair process is simpleImprove efficiencyAdhesive processes with surface pretreatmentSoldering apparatusDiameter ratioEngineering

The deep hole machining process includes the following successive steps: drilling hole, expanding, coarse reaming, boring and finish reaming. The wall thickness difference in the whole machined length is controlled in 0.02-0.10. The cutter for deep holes machining is long cutter bar of hard alloy and in the length / diameter ratio of 10-20. The deep hole machining technology of the present invention is advanced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

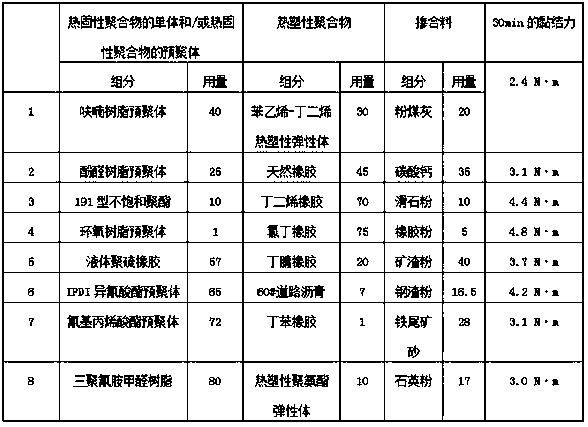

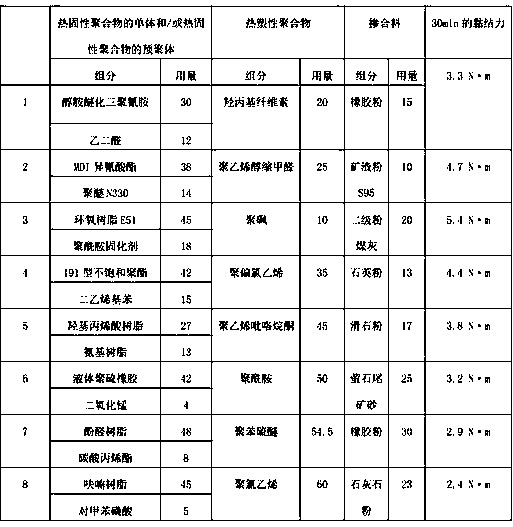

Asphalt pavement repair material

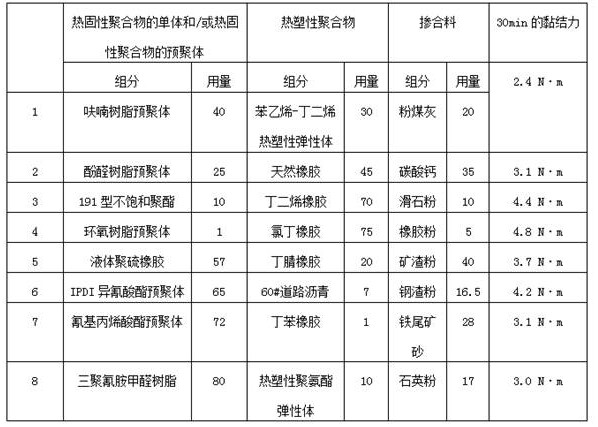

ActiveCN109401519AEasy to fixPromote repairConjugated diene hydrocarbon coatingsNatural rubber coatingsPrepolymerAntioxidant

The invention discloses an asphalt pavement repair material, and belongs to the field of engineering materials. The asphalt pavement repair material is prepared from 20-60 parts of monomers of thermosetting polymers and / or prepolymers of the thermosetting polymers, 2-8 parts of an antioxidant, 1-8 parts of an accelerant, 10-30 parts of an admixture, 5-60 parts of the thermosetting polymers, 10-40parts of an initiator, 10-20 parts of a reinforcing agent, 1-60 parts of a diluent and 10-40 parts of aggregates. The asphalt pavement repair material has the advantages of being high in condensationrate, strength, waterproofness and abrasion performance and capable of repairing pavement and getting the traffic to move again in 30 minutes and making construction easy. According to a pavement repaired with the asphalt pavement repair material, the compressive strength can reach 100 MPa, the wet wheel abrasion value is smaller than 800 g*m<-2>, and the load wheel adhesion sand amount water immersion 1d is smaller than 450 g*m<-2>.

Owner:DALIAN UNIV OF TECH

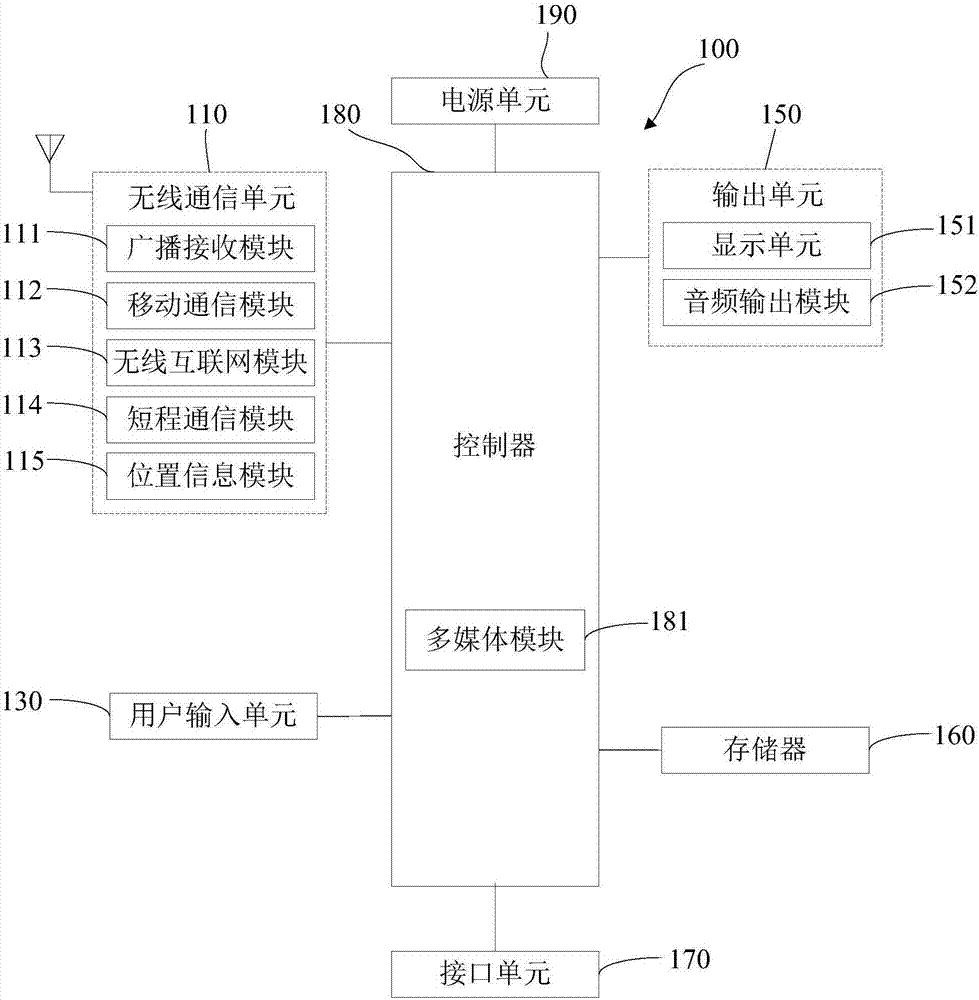

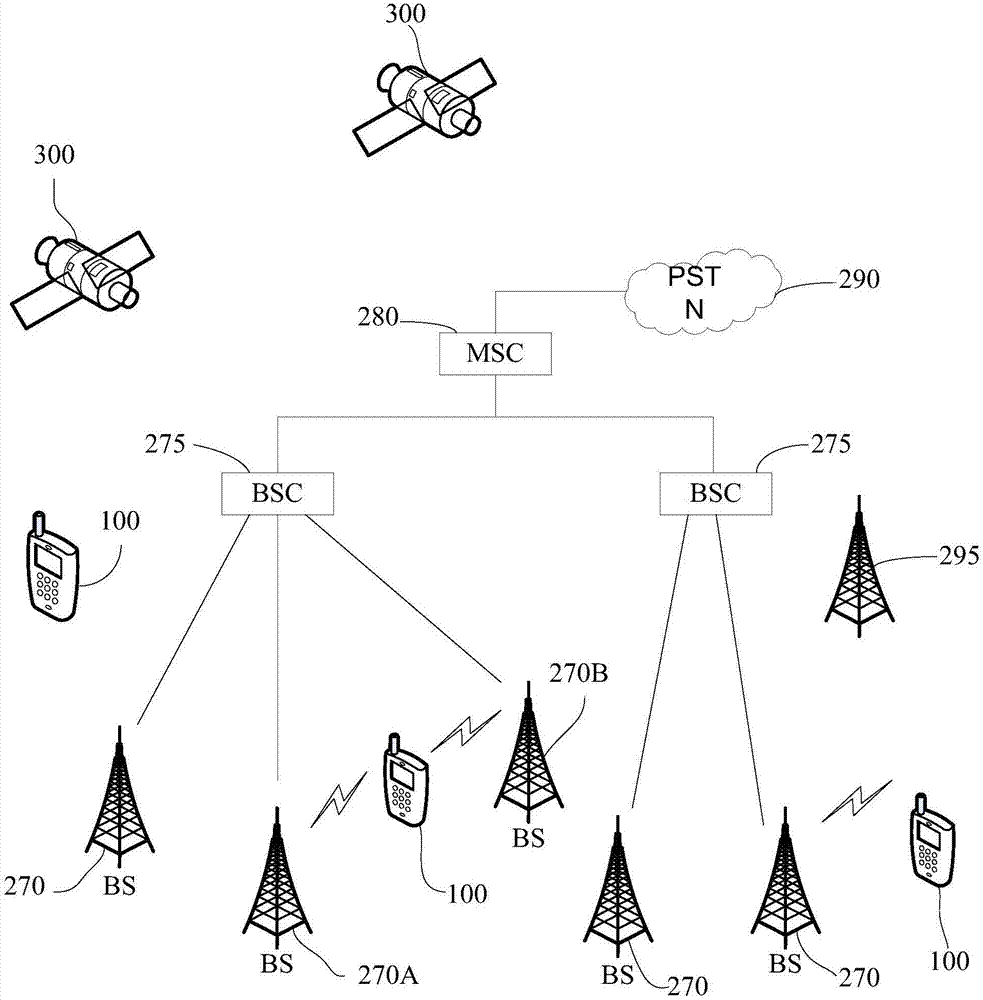

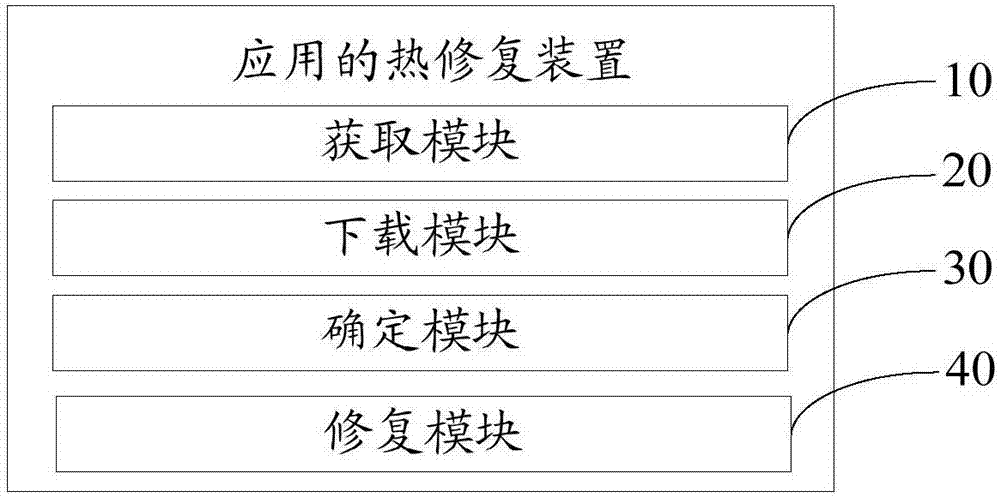

Thermal remediation device and method for applications

InactiveCN106951279ARepair process is simpleLow costSoftware engineeringSubstation equipmentSoftware engineeringVulnerability

The invention discloses a thermal remediation device for applications. The device comprises an acquisition module, a downloading module, a determination module and a remediation module, wherein the acquisition module is used for acquiring current application version information of an application to be remedied and current existing patch version information of the application; the downloading module is used for downloading a to-be-remedied patch pack from a server based on the application version information and the existing patch version information; the determination module is used for determining a to-be-remedied target method according to the downloaded to-be-remedied patch pack and the existing patch version information; and the remediation module is used for intercepting calling of the target method and performing modification processing on the target method based on the to-be-remedied patch pack and a preset remediation framework in the running process of the application to realize remediation of the application. The invention furthermore provides a thermal remediation method for applications. Through the thermal remediation device and method for applications, the problems that in the prior art, remediation cost of application vulnerabilities is high, and the process is excessively complicated are solved.

Owner:NUBIA TECHNOLOGY CO LTD

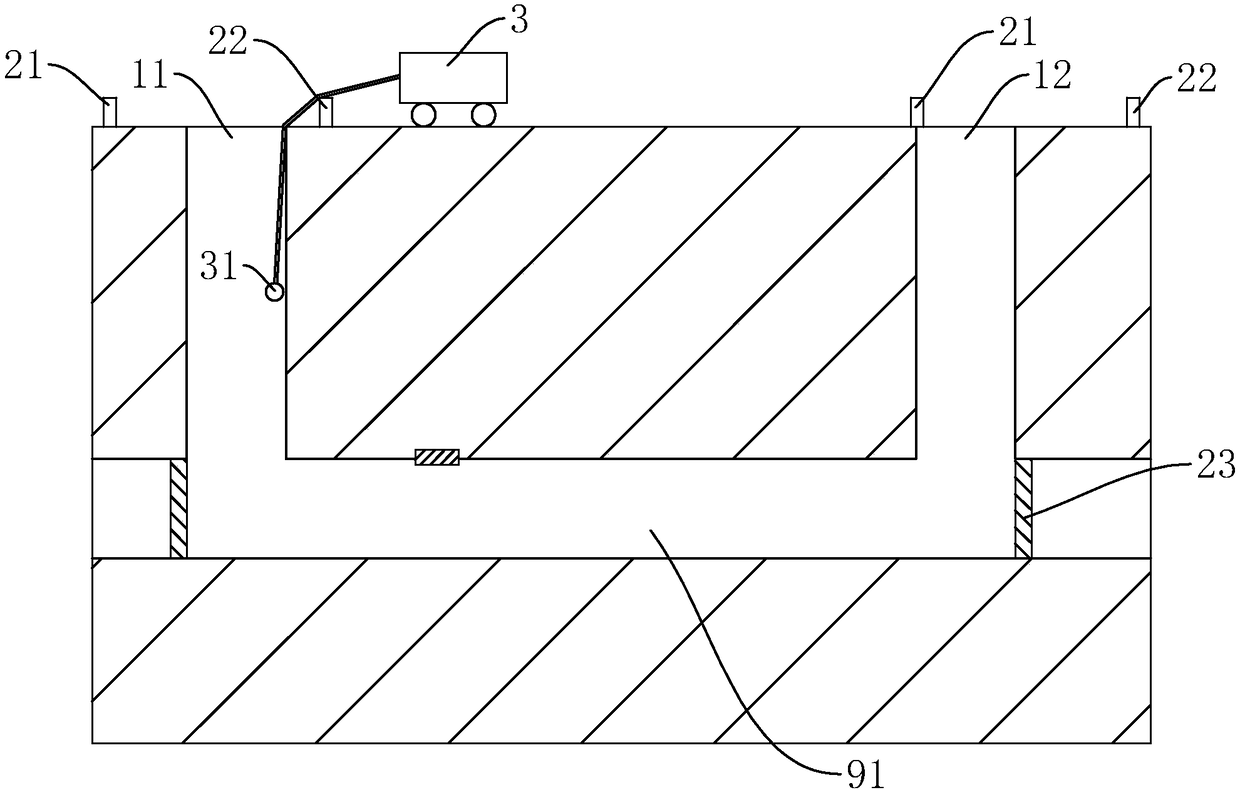

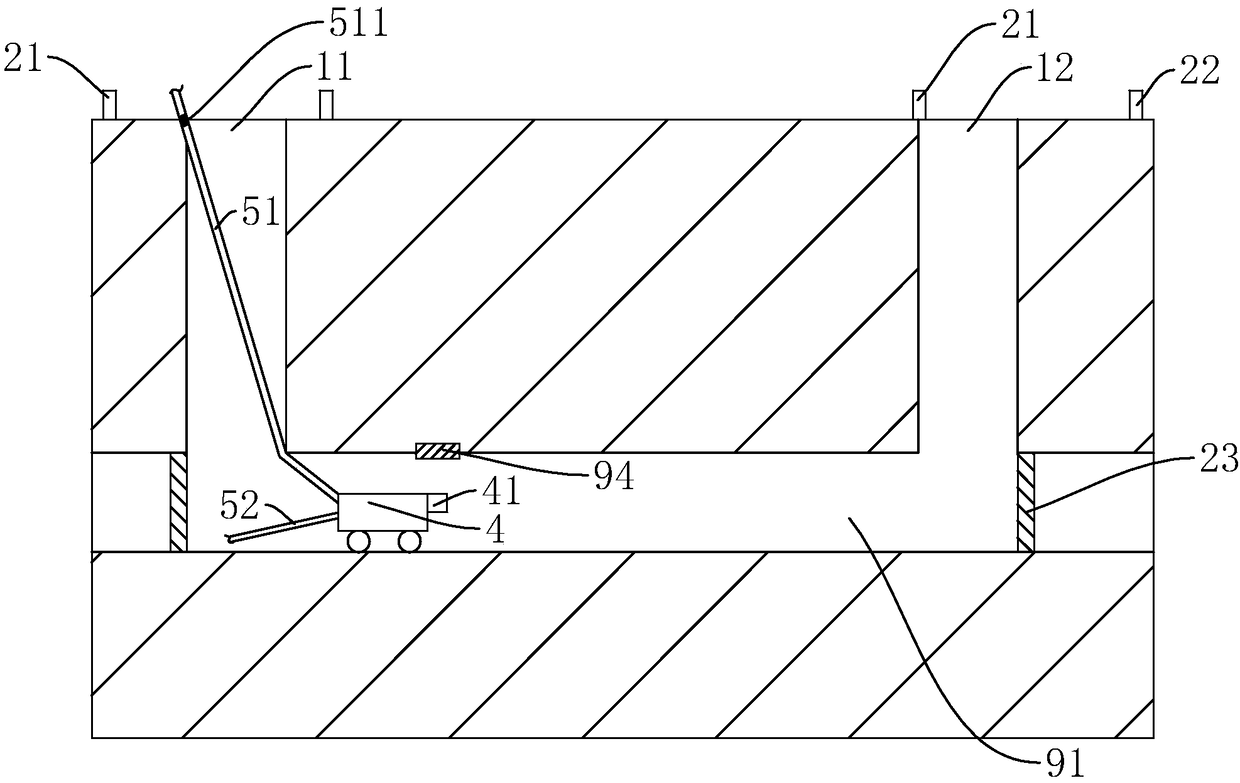

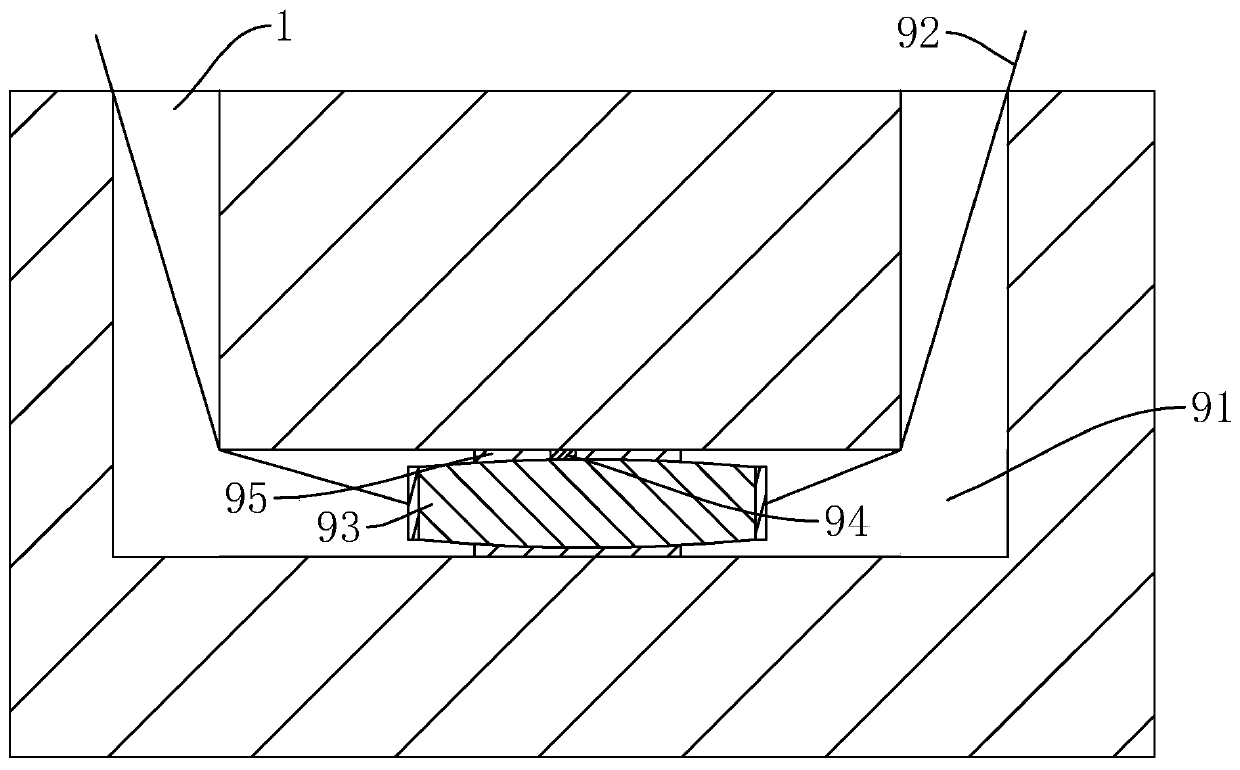

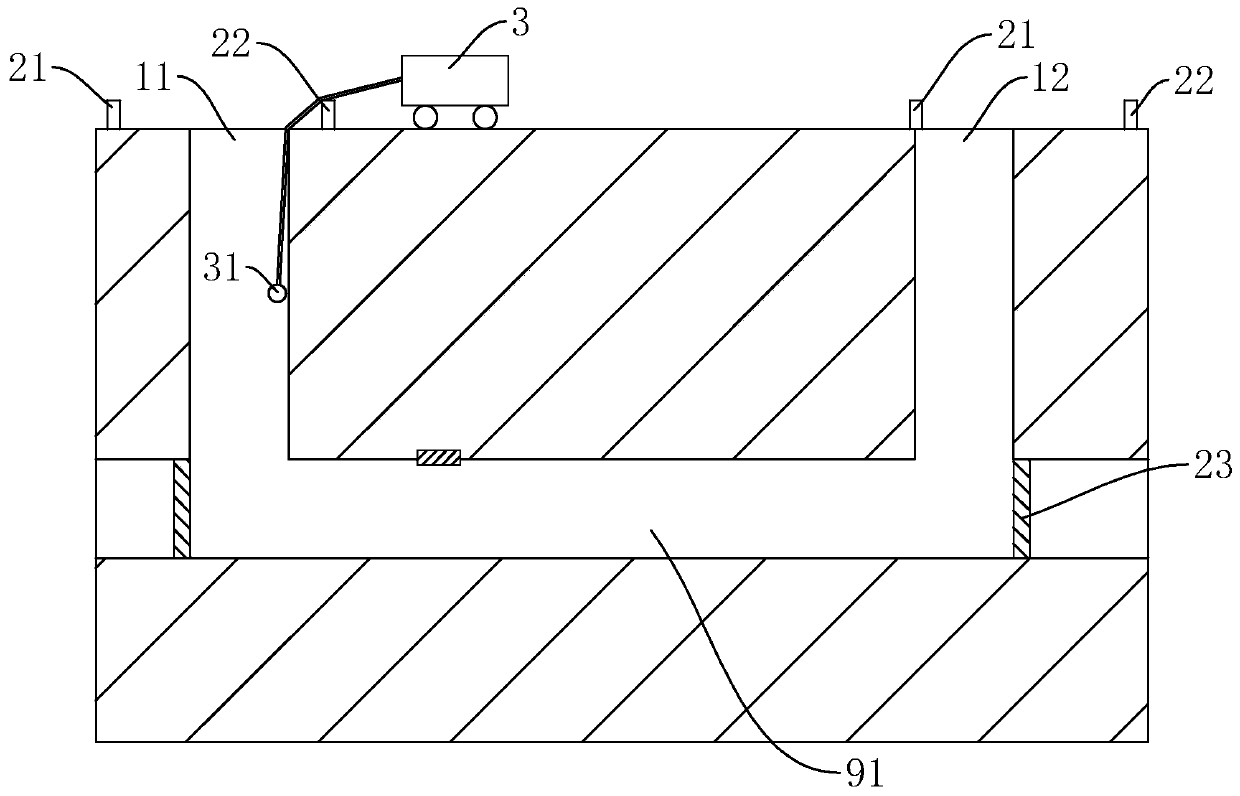

Positioning method of underground pipe non-excavation repair defect points

The invention discloses a positioning method of underground pipe non-excavation repair defect points, and solves the problem of a difficulty how to determine defect points of underground pipes alwaysin the repair process caused by people incapable of entering the pipes to examine the defect points. The positioning method comprises the following steps: a dredging car is cleaned; a connecting ropeis arranged on a remote control car provided with a camera, and the defect points in the pipes are searched through the camera; a first positioning mark is arranged in the position, positioned in an opening of a drainage well, of the connecting rope; a positioning rope is bound on a pipe repair airbag, and is provided with a second positioning mark corresponding to the first positioning mark; thesurface of the pipe repair airbag is coated with a repair material; after the second positioning mark is positioned in the opening of the drainage well, the pipe repair airbag is used for repair; andmultiple defect points can be once determined, and can be gradually repaired, so that the time and the times of the remote control car searching the defect points are saved, the working efficiency isimproved, and the repair flow is simplified.

Owner:浙江景迈环境科技有限公司

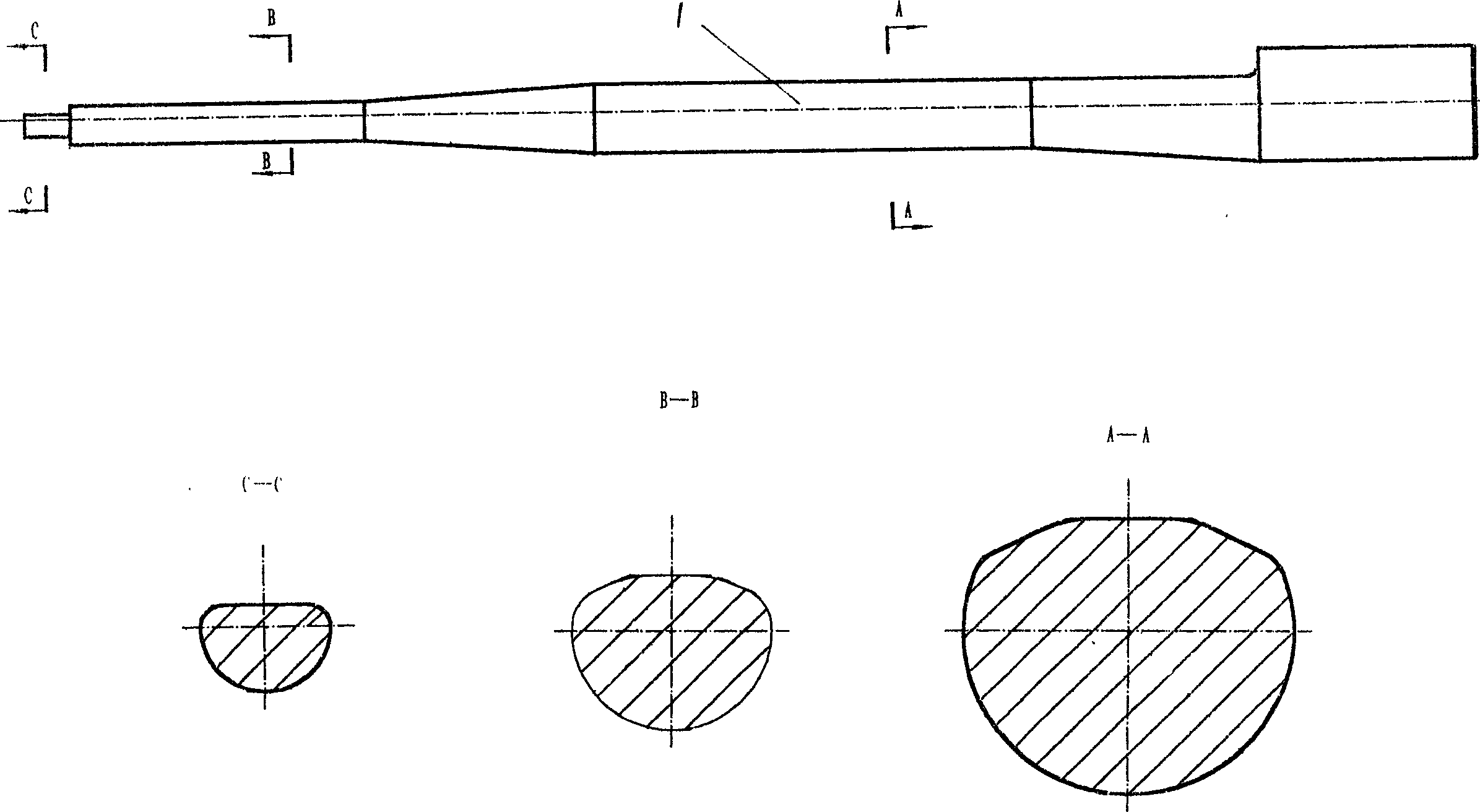

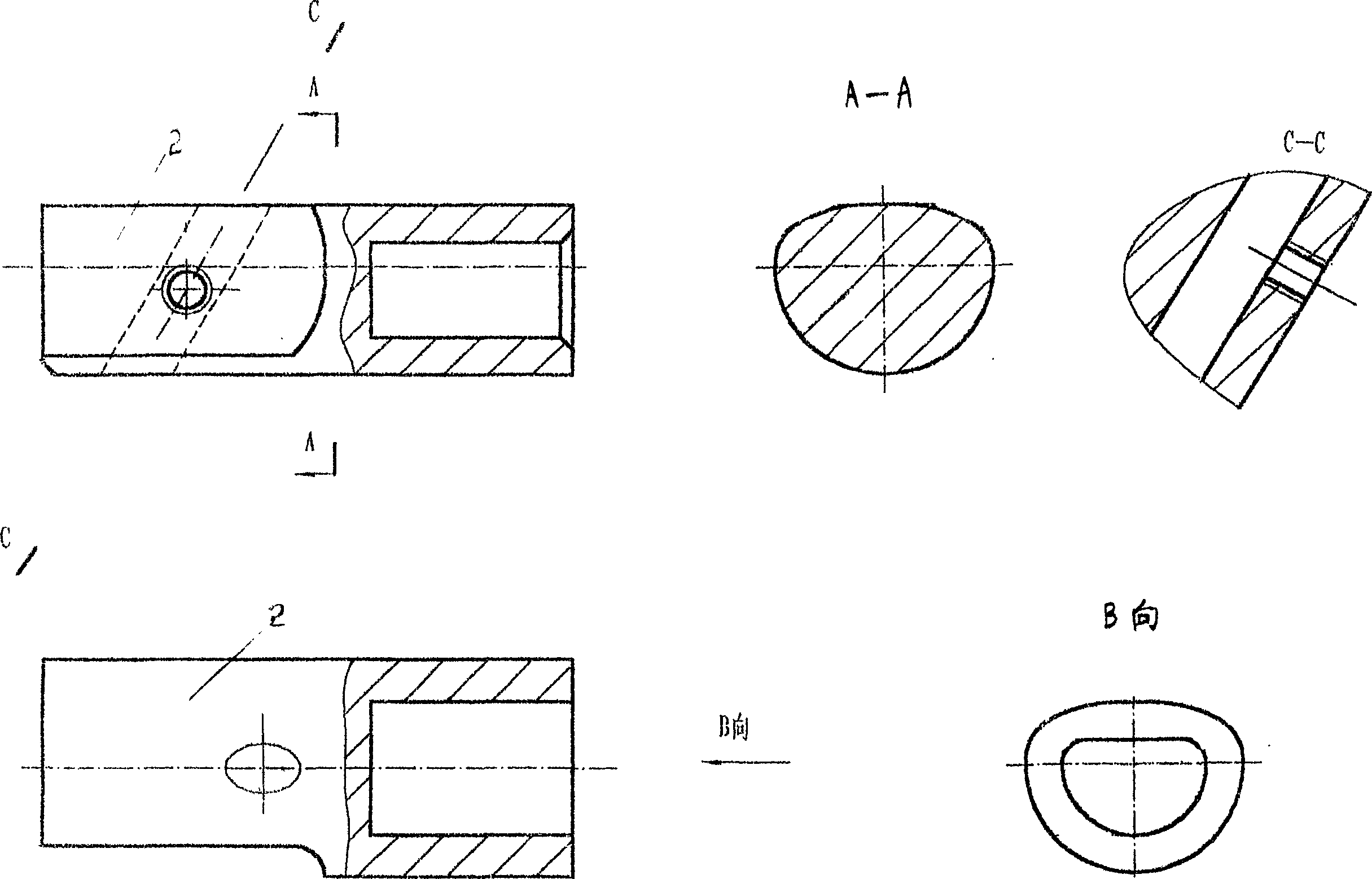

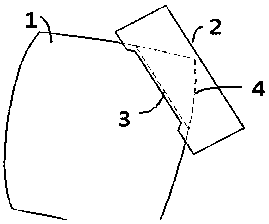

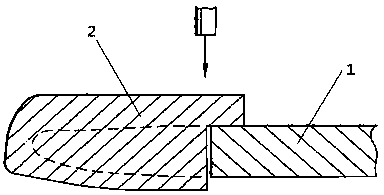

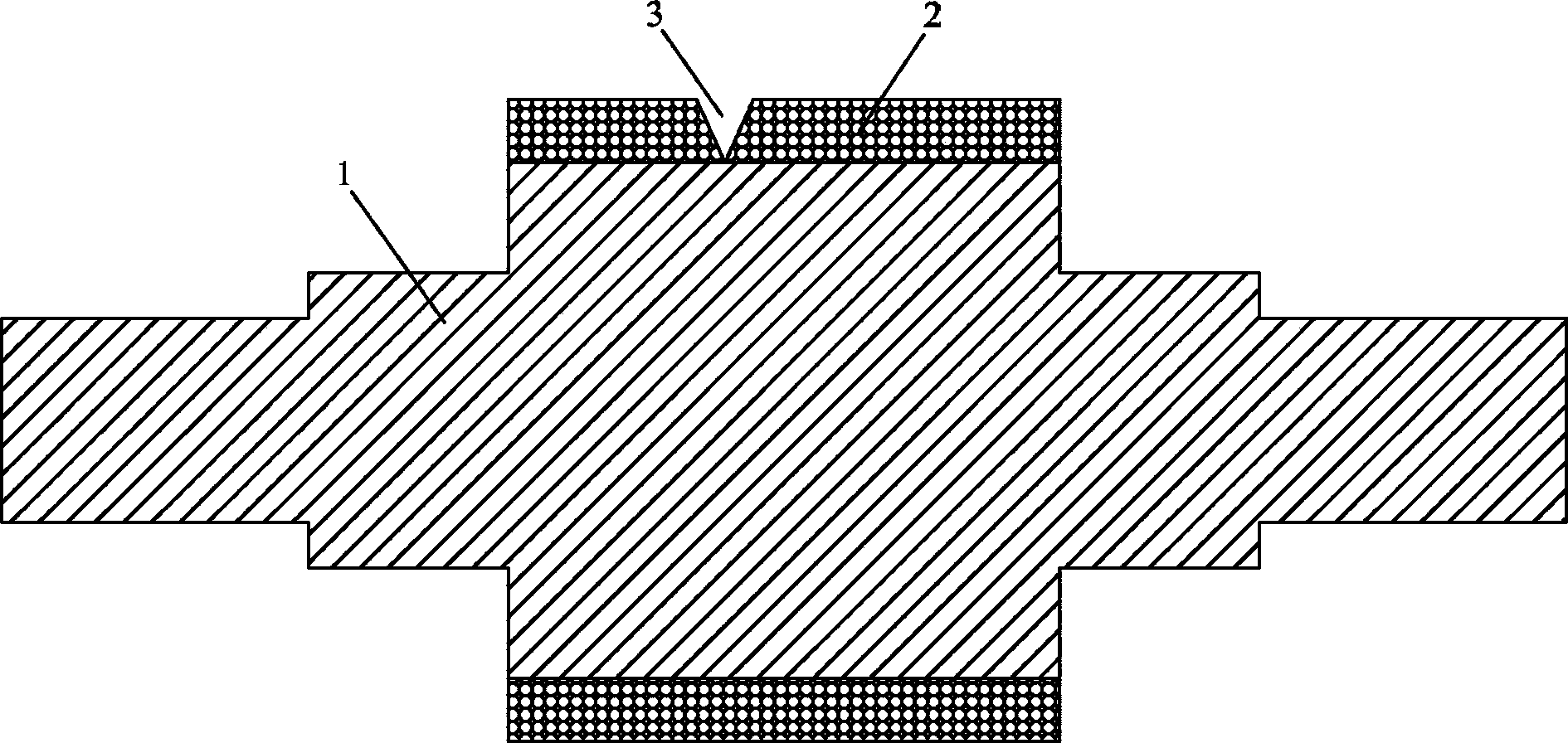

Blade-repairing type repair method of engine blade

The invention relates to a blade-repairing type repair method of an engine blade. The method comprises the steps that a patch is designed according to the cross-section shape of a removed blade, a groove is processed in the patch section, and a welding fixture is designed according to the shape of the patch, and a welding experiment is carried out on a locally simulated blade to obtain the best welding parameters; and the blade to be repaired and the patch are then welded formally. The molded surface of the groove corresponds to the upper and lower surfaces of the blade, and full-cover and half-cover grooves can be used to form an equal-thickness curved seam. The blade-repairing type repair method of the engine blade simplifies the welding process for forming a welded joint and prevents defects and deformation of the front and rear edges, the welded joint form is applicable to other welding methods, such as argon arc welding, plasma welding, laser welding and the like, the repair costcan be greatly reduced, and the welded joint quality and stability are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Loading system

InactiveCN101522512AAvoid getting stuckImprove flexibilityCargo handling apparatusDrilling rodsEngineeringMechanical engineering

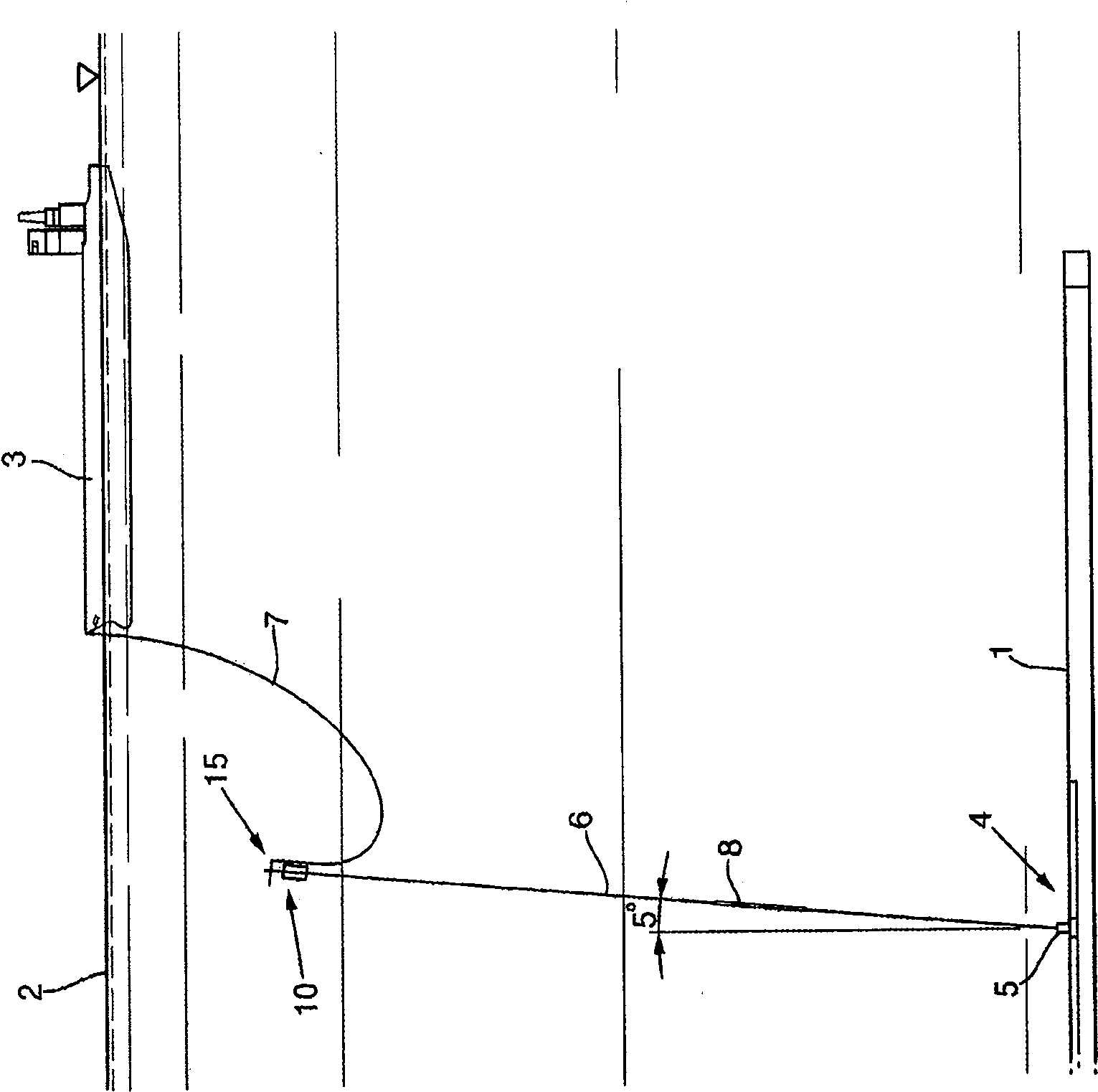

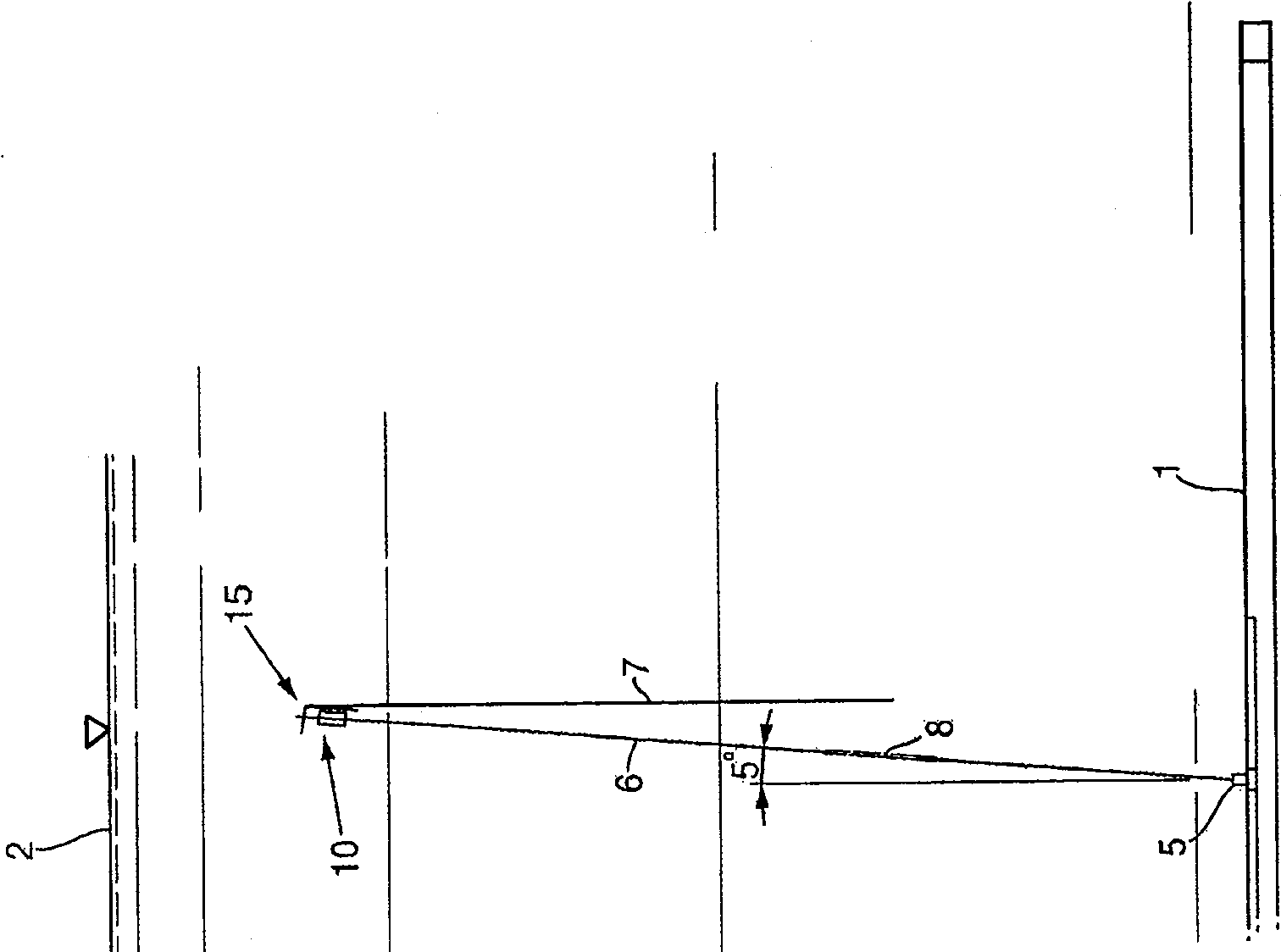

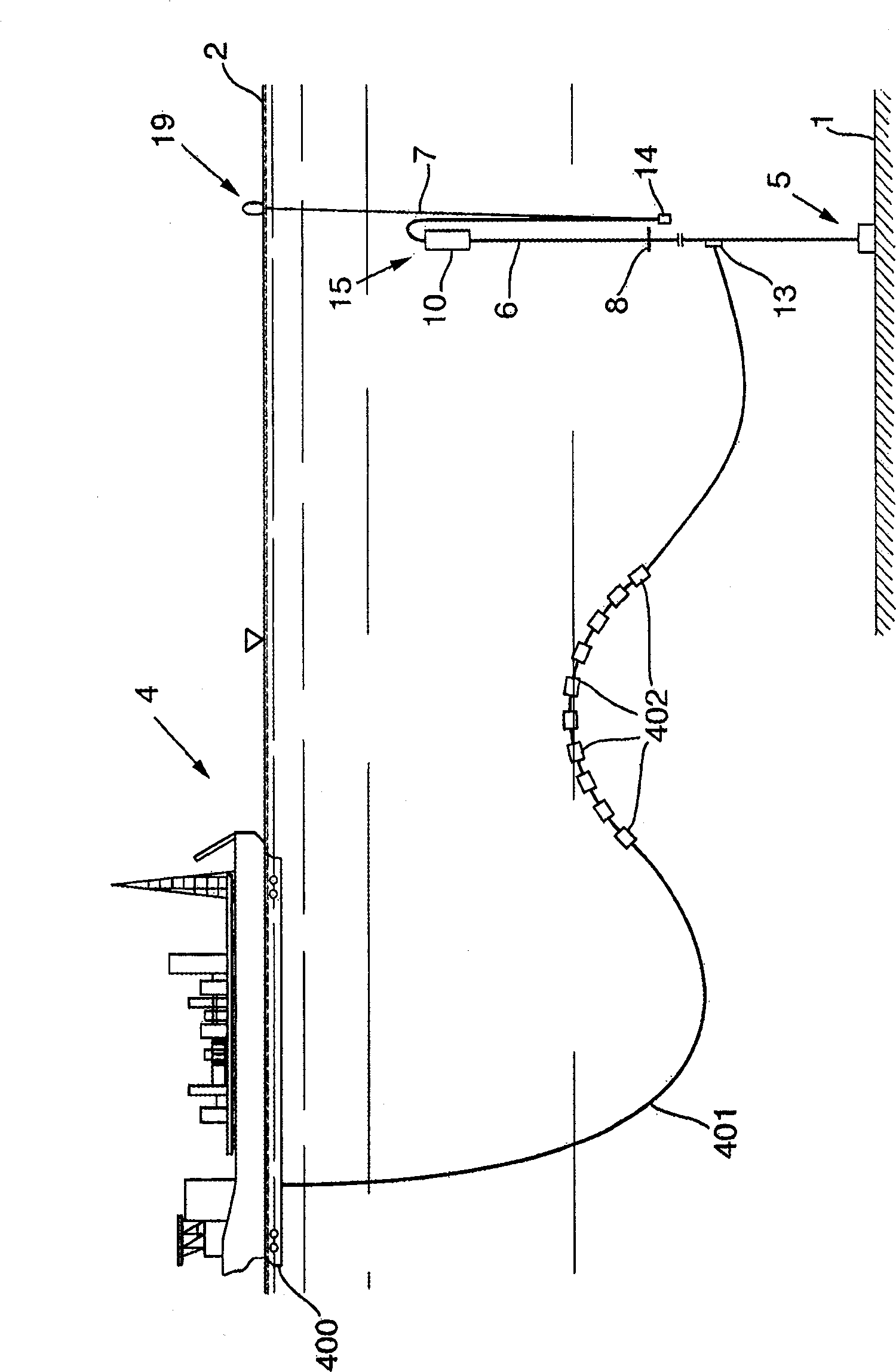

The present invention relates to a loading system for transferring at least one medium between a first installation (4) and a floating vessel (3), comprising an anchoring device (5) which can be fixed relative to a seabed (1), at least one elongated first transfer element (6), which is normally vertically oriented in an installed state, at least one flexible second transfer element (7) arranged in the extension of the first transfer element (6) by a swivel arrangement (15) which is mounted between the first (6) and second transfer element (7). The swivel arrangement (15) is rotatable at least about a longitudinal axis of the first transfer element (6). A free end of the second transfer element (7), in an installed state when the system is not being used, is located freely suspended in the body of water. The invention also relates to a retrieval system and method.

Owner:FRAMO ENG

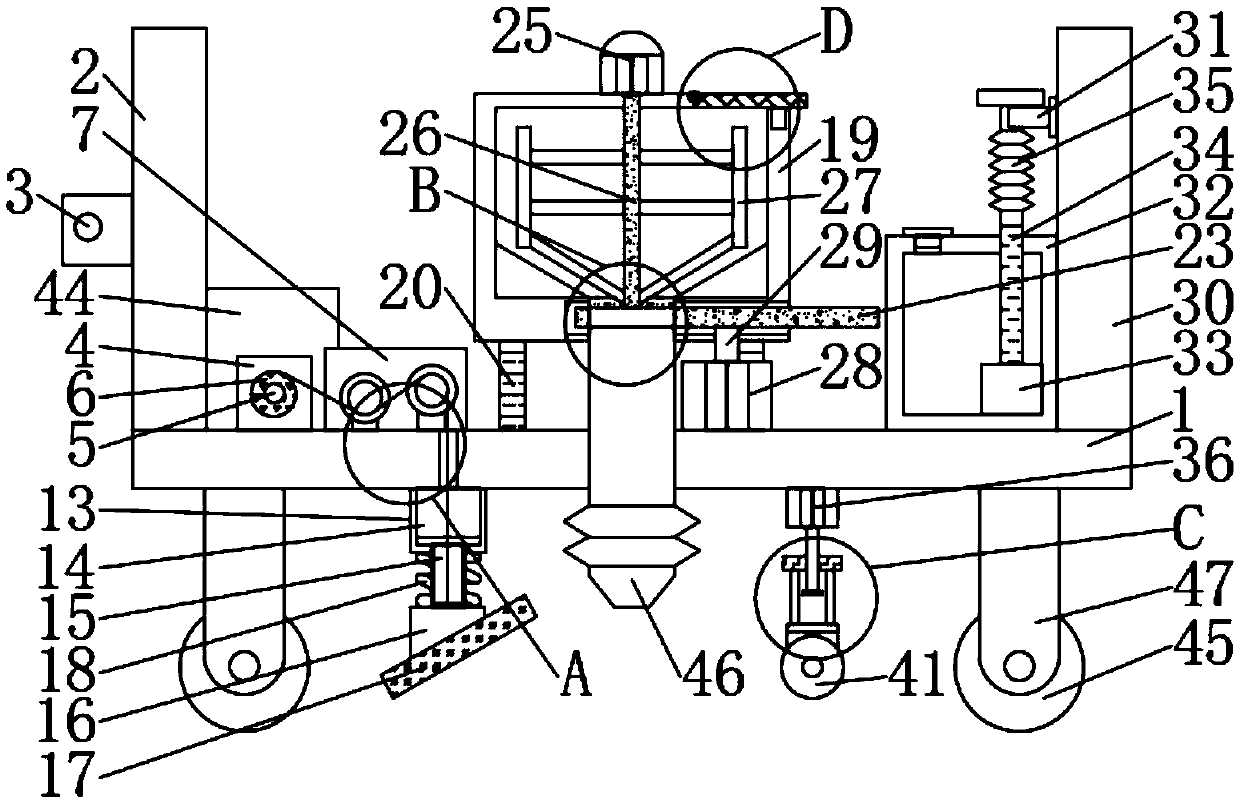

Contaminated soil in-situ remediation equipment

InactiveCN106694543ARepair process is simpleImprove repair efficiencyContaminated soil reclamationGrain treatmentsIn situ remediationPollution soil

Provided is contaminated soil in-situ remediation equipment. The contaminated soil in-situ remediation equipment comprises a traveling rack. The traveling rack is sequentially provided with a rotatable soil loosening bar, rotatable soil breaking bars and a rotatable soil remediation bar. The soil loosening bar, the soil breaking bars and the soil remediation bar are connected with the top of the traveling rack through a first telescopic rod, second telescopic rods and a third telescopic rod. Soil scarifiers are evenly distributed on the outer wall of the soil loosening bar. The two soil breaking bars are distributed side by side and are opposite in rotation direction. A gap allowing soil to pass through is reserved between the soil breaking bars. The soil remediation bar and the third telescopic rod are both of a hollow structure and communicate with each other. Chemical spray holes are formed in the soil remediation bar. The top of the third telescopic rod communicates with a chemical tank arranged on the top of the traveling rack. The contaminated soil in-situ remediation equipment can carry out loosening, breaking and remediation of soil simultaneously, the remediation procedures of contaminated soil are simplified, the remediation efficiency of contaminated soil is greatly improved, and the remediation effect is good.

Owner:弘毅天承知识产权股份有限公司

Fault diagnosis method in vehicle-mounted wireless communication system and device thereof

InactiveCN102130726AAccurately determineSave resourcesTransmission monitoringWireless communicationCommunications systemDiagnosis methods

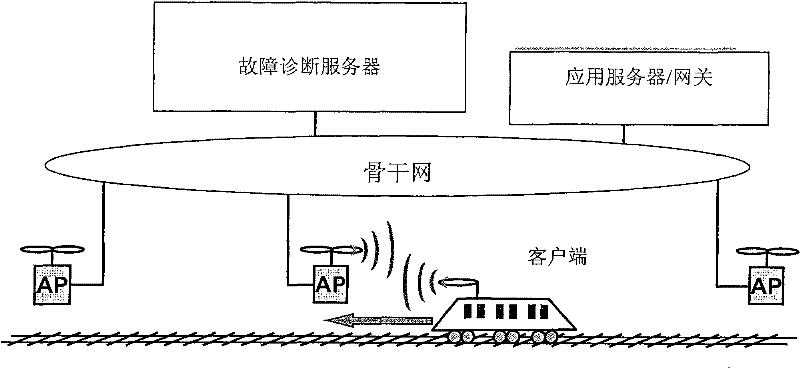

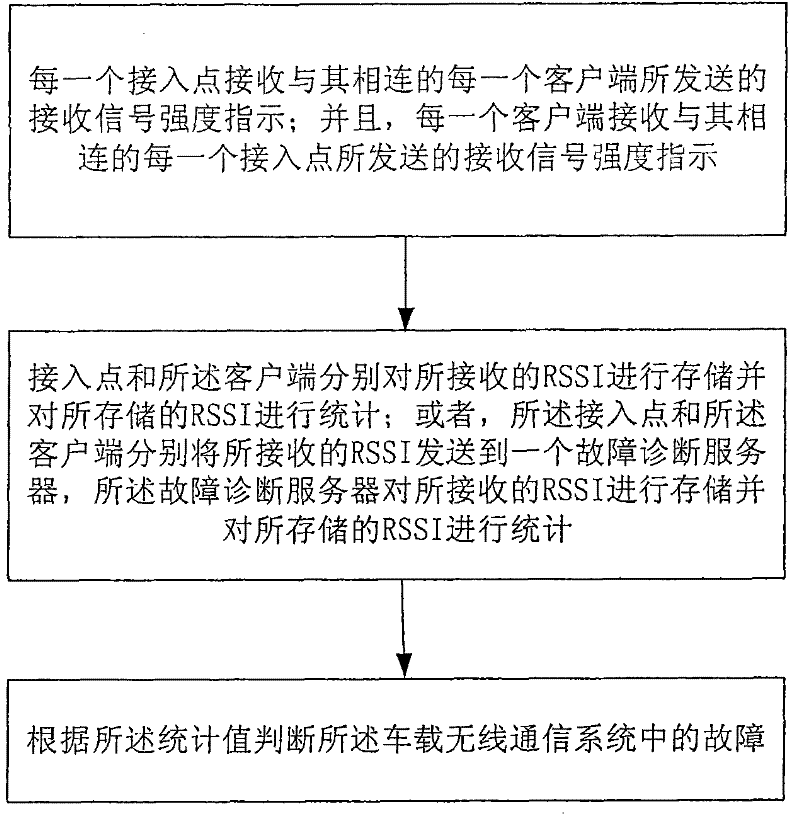

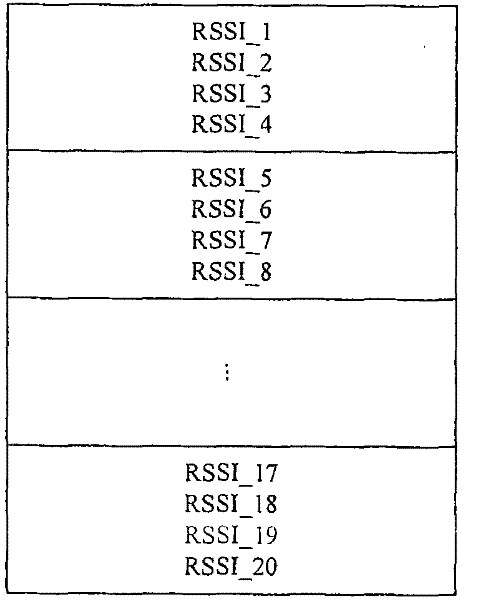

The invention provides a fault diagnosis method in a vehicle-mounted wireless communication system. The system comprises a backbone network, at least one of access points and at least one of client sides, wherein the access points are accessed to the backbone network. The method comprises the steps of: (1) each access point is used for receiving an RSSI (received signal strength indicator) which is sent by each client side connected with each access point; and each client side is used for receiving an RSSI which is sent by each access point which is connected with each client side; (2) the access points and the client sides are used for storing and counting the received RSSIs; or the access points and the client sides are respectively used for sending the received RSSIs to a fault diagnosis server, and the fault diagnosis server is used for storing and counting the received RSSIs; and (3) the fault in the communication system is judged according to the statistic. The method in the invention can more exactly confirm the component which has a fault, and can run when the system normally operates.

Owner:SIEMENS AG

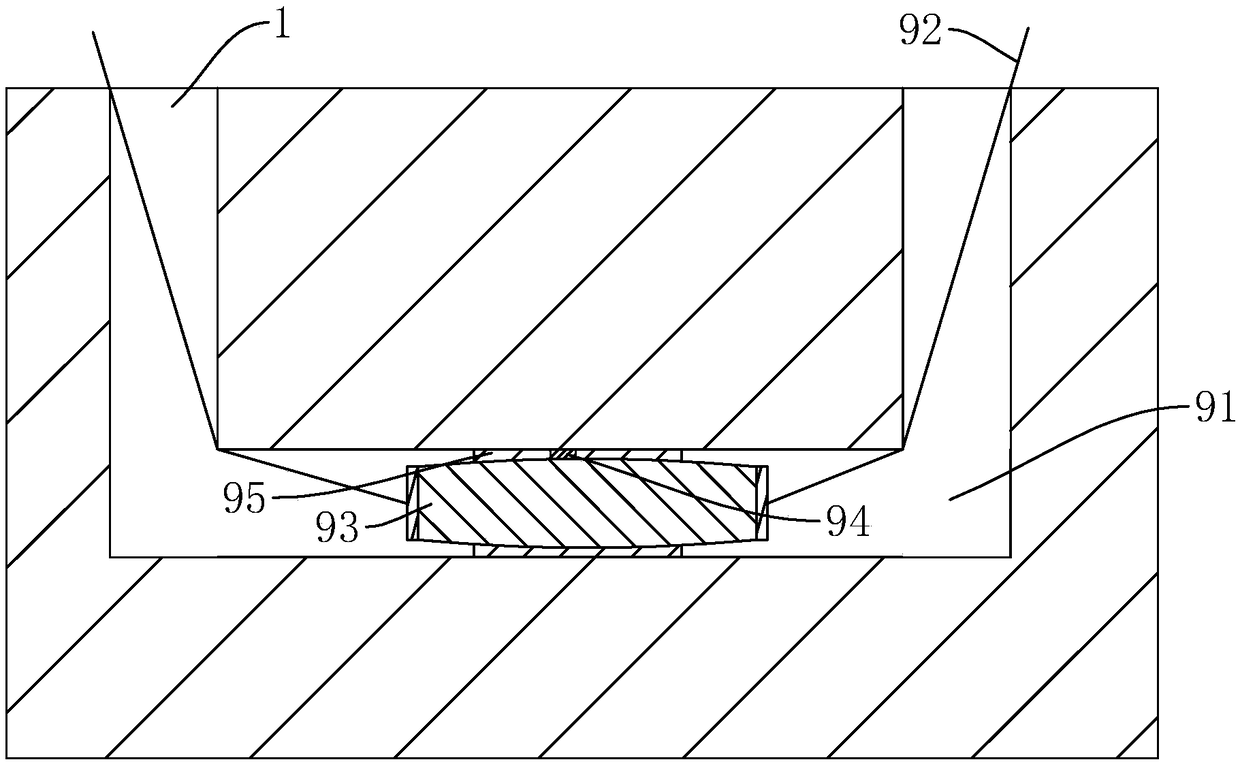

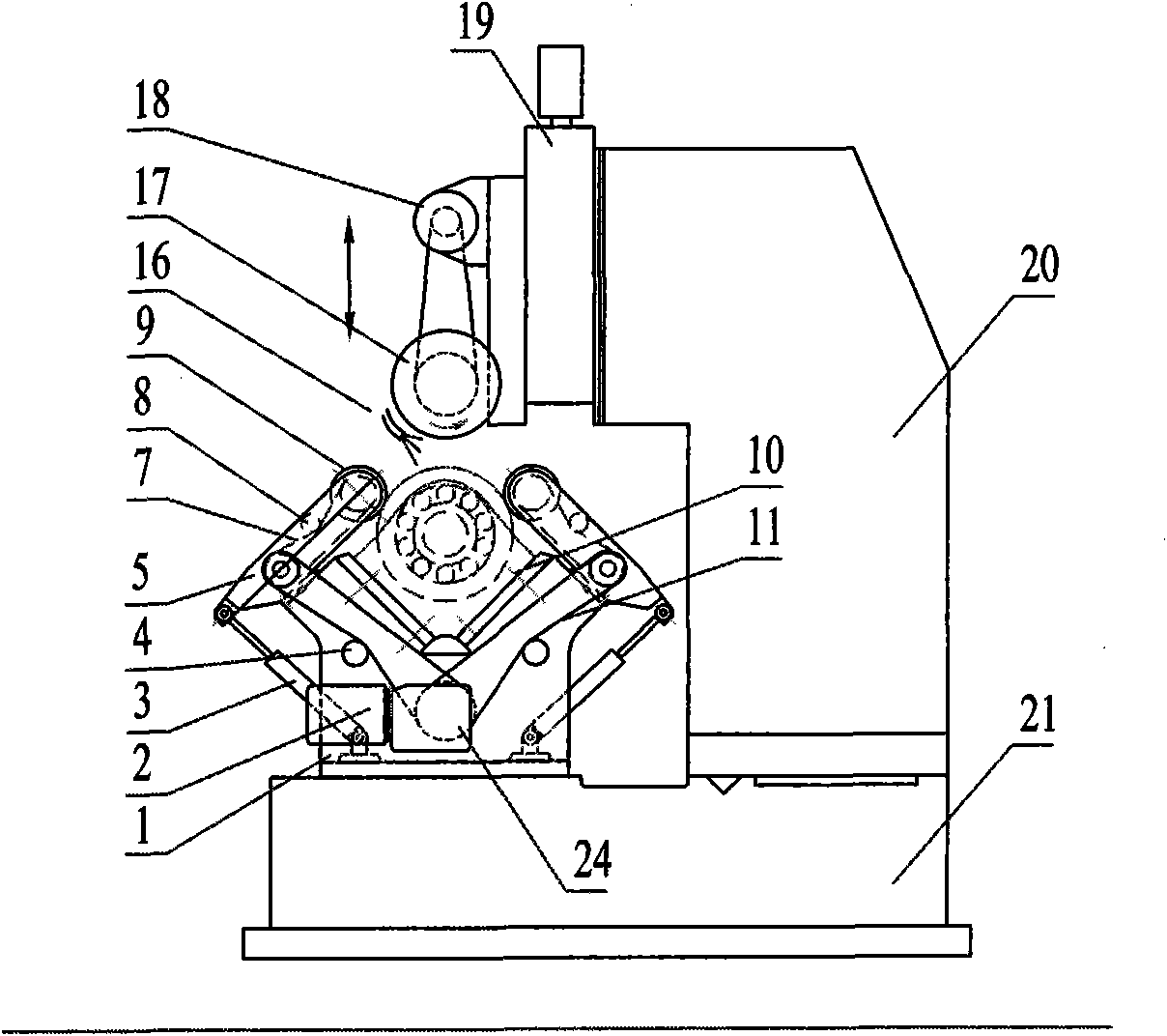

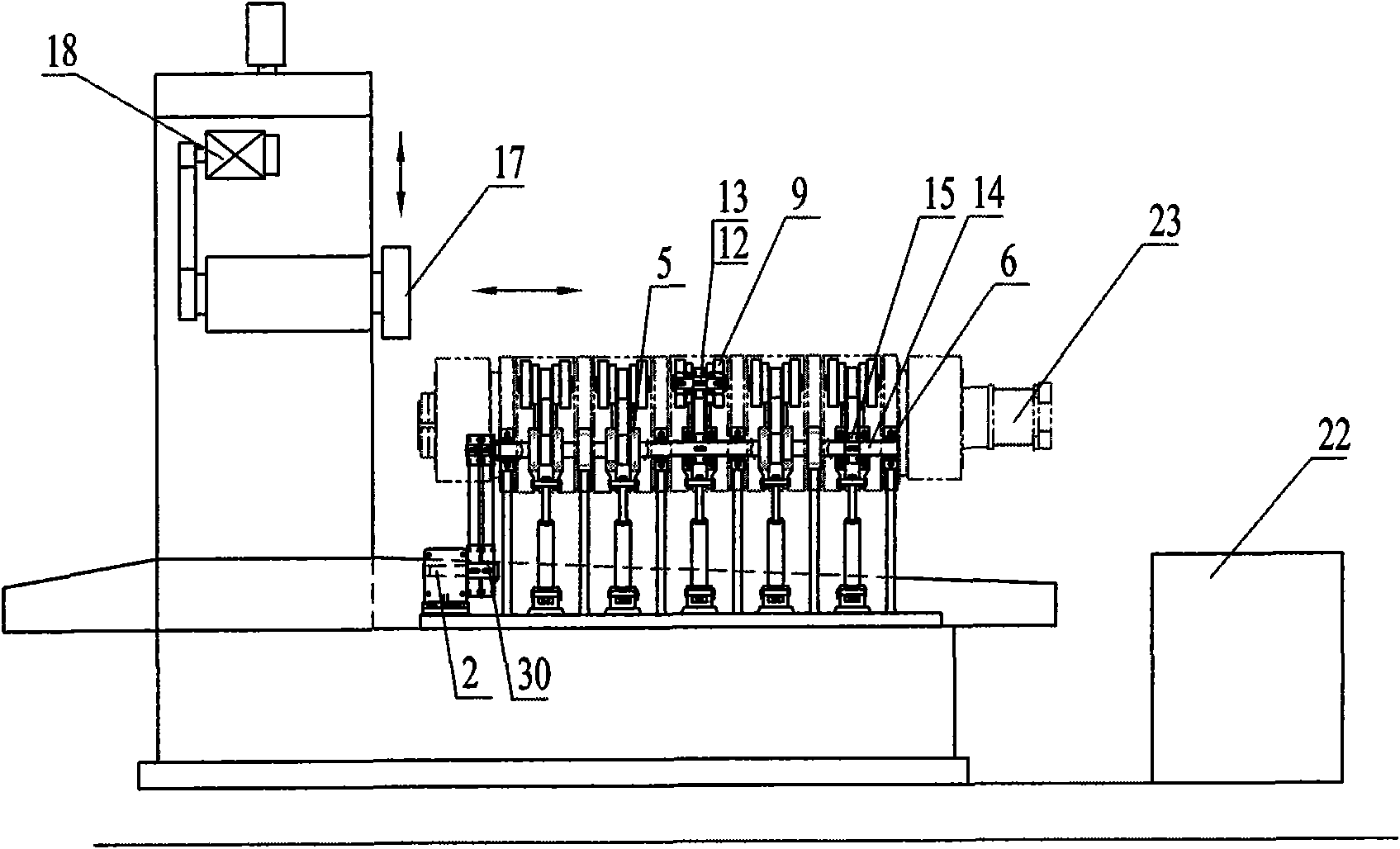

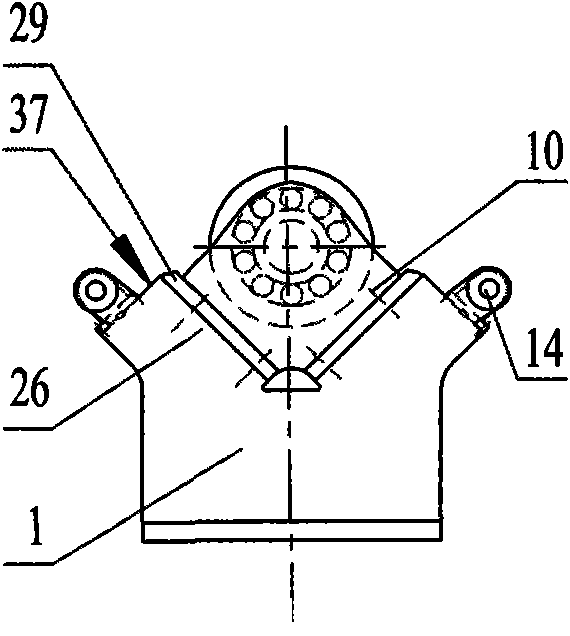

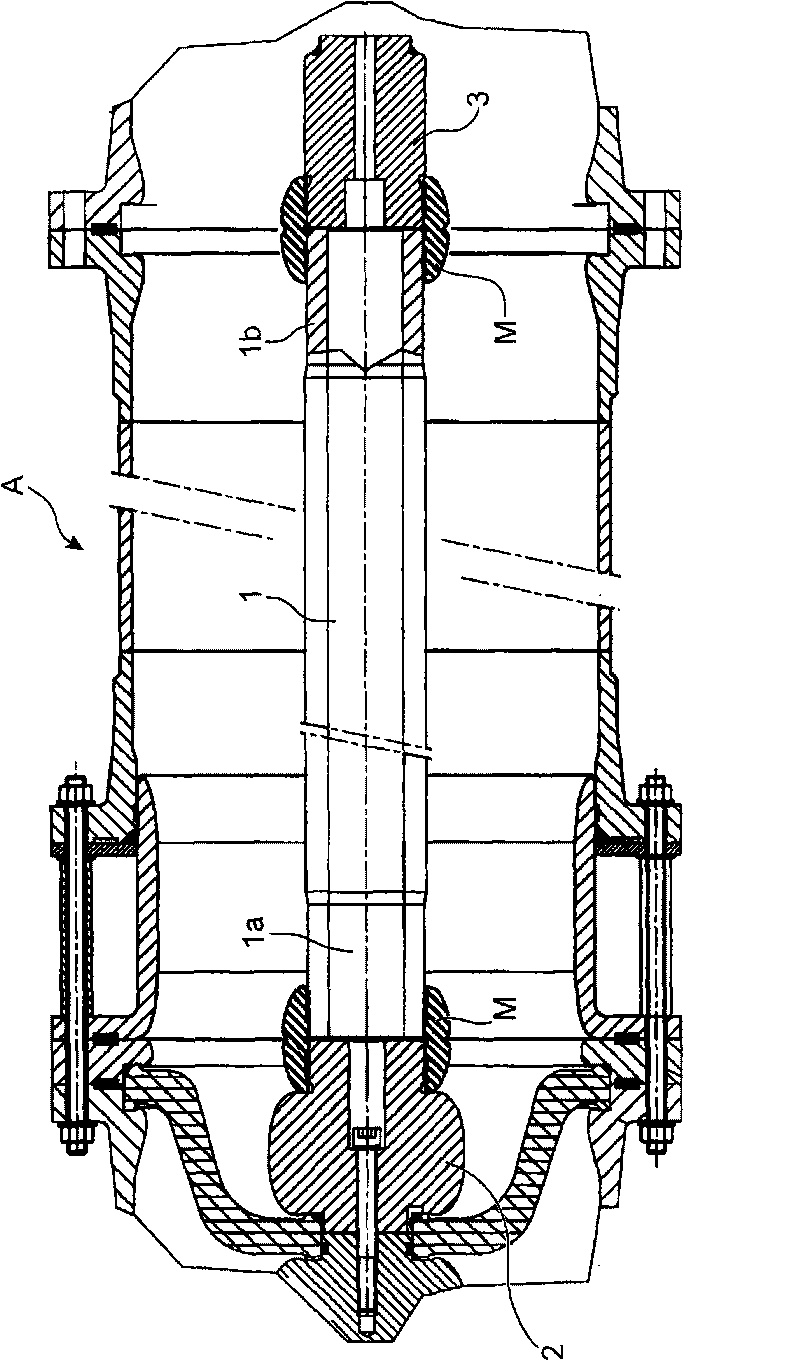

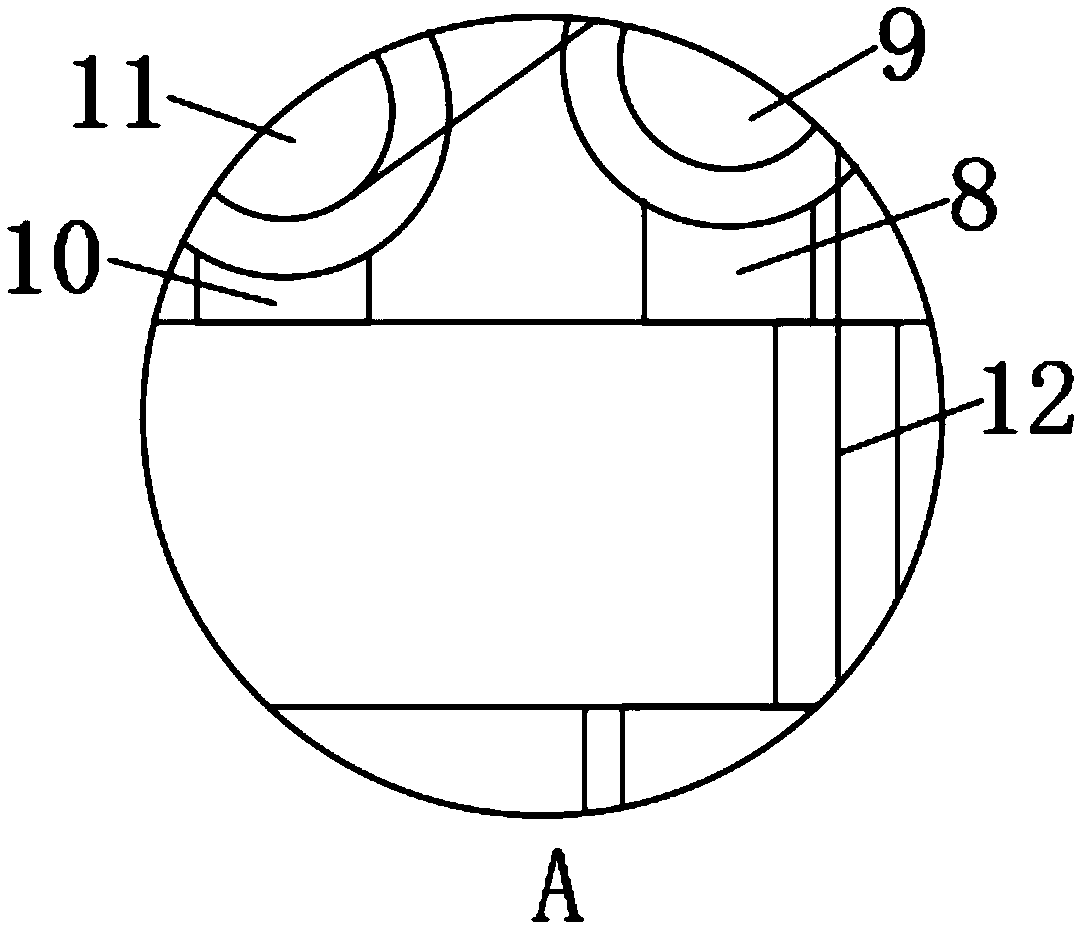

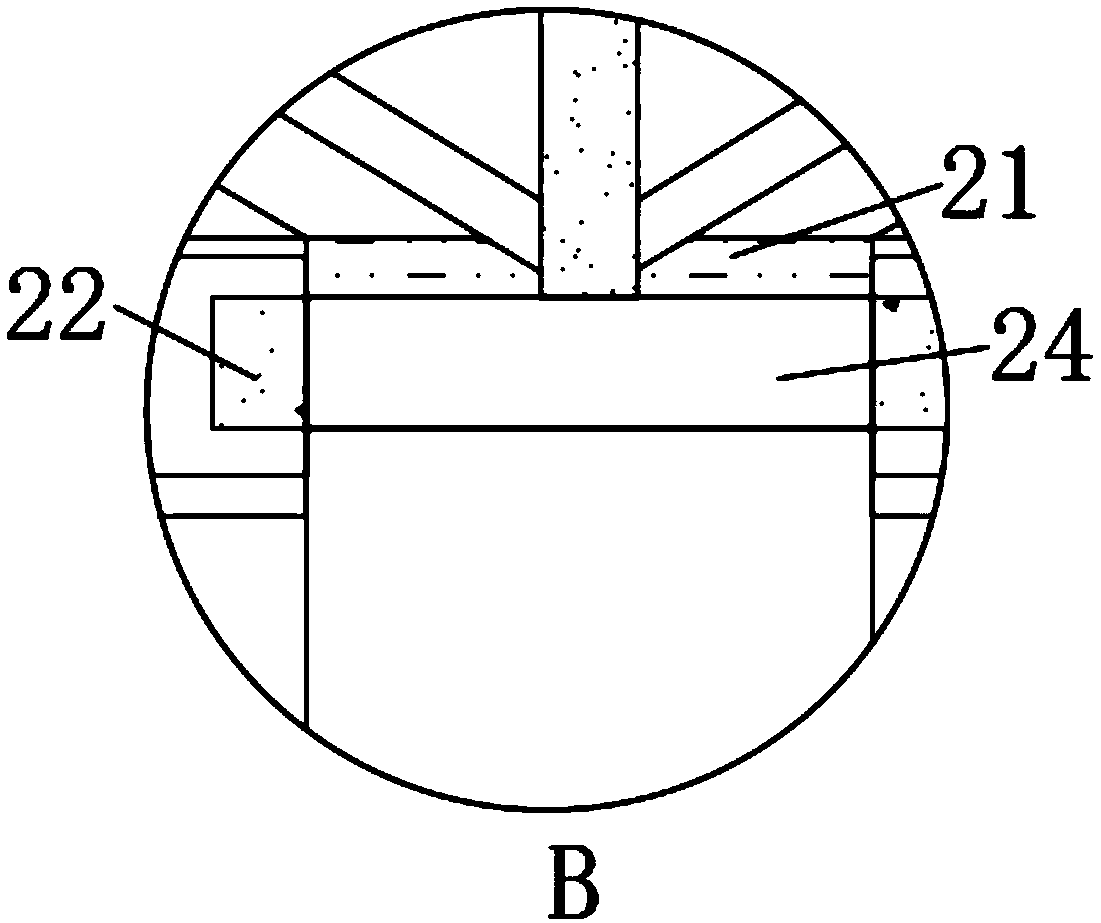

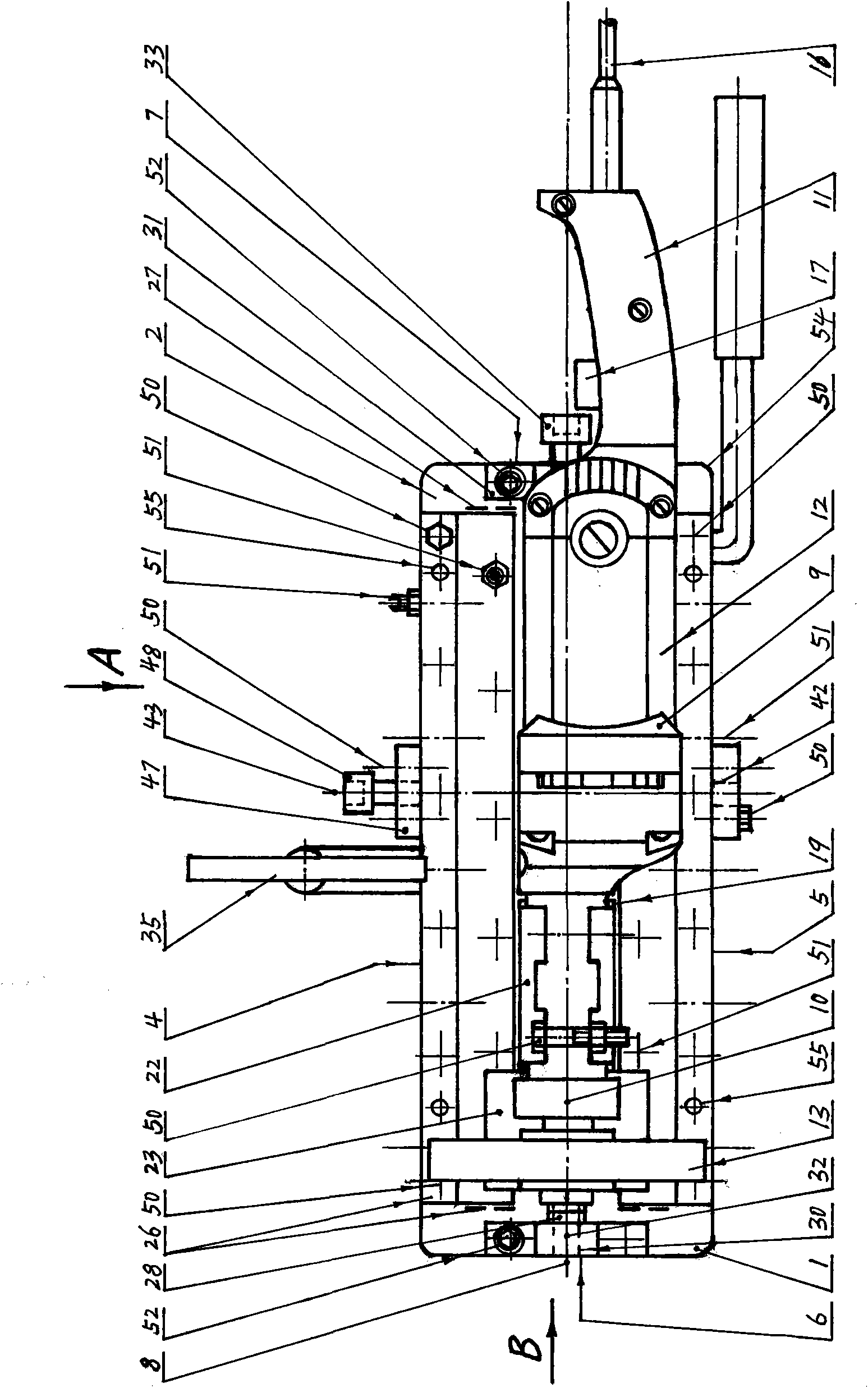

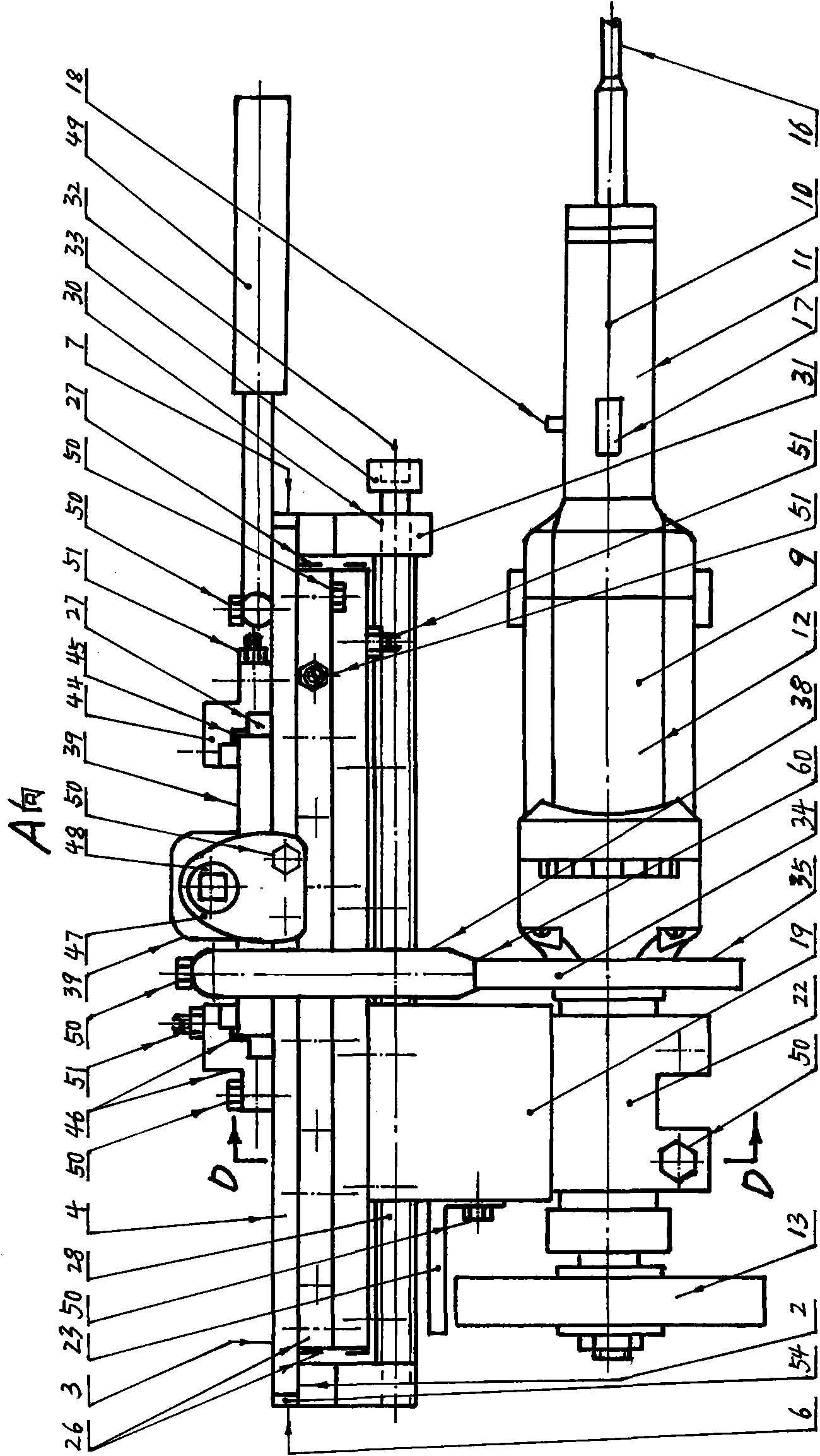

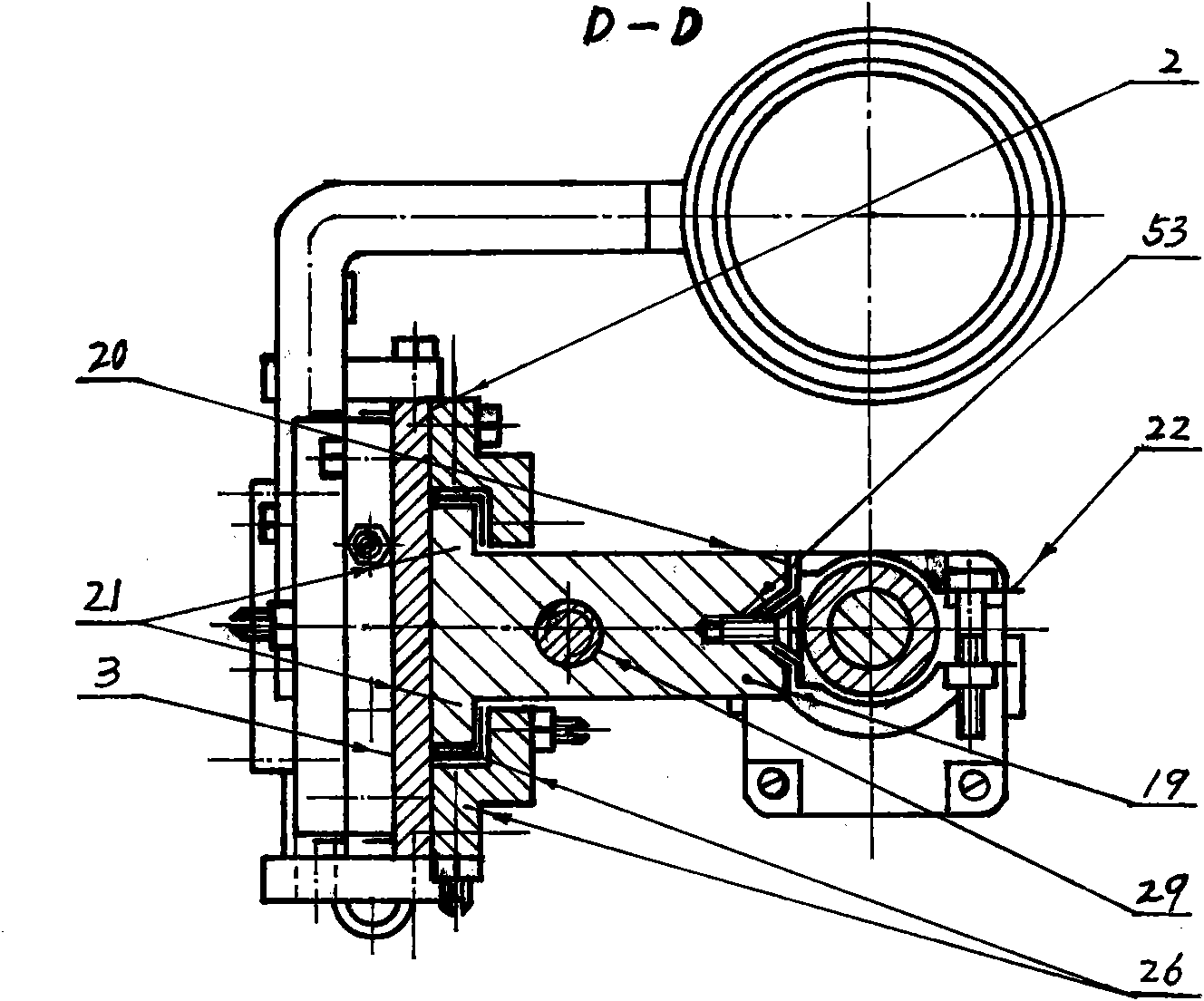

Multi-roller mill backing roller integral gapless repairing method and repairing device thereof

The invention relates to a multi-roller mill backing roller integral repairing method, which includes steps of: selecting, assembling and grinding, wherein bottom surface of a base plate (26) of a backing roller is used as installation standard, the backing roller to be repaired is integrally installed on a grinding processing standard surface of a reconditioning mold. The invention also relates to a multi-roller mill backing roller integral repairing device, which includes a mold arranged on a workbench (21). The mold comprises a fixed base (1) for supporting the backing roller to be repaired, the fixed base is provided with a compaction roller driving device with a power machine and a transmission mechanism and compaction devices which has same number with bearing roller on the backing roller and are arranged at one side or two sides of the backing roller to be repaired, a groove (29) which is adapted with shape of the base plate of the backing roller is arranged at upper end of the fixed base (1), and the groove is in V shape or circular arc shape. The invention can carry out integral gapless grinding for the backing roller to be repaired, realizes integral moulding grinding, and has advantages of simple process, high precision and low cost.

Owner:CERI TECH

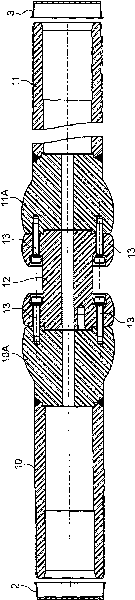

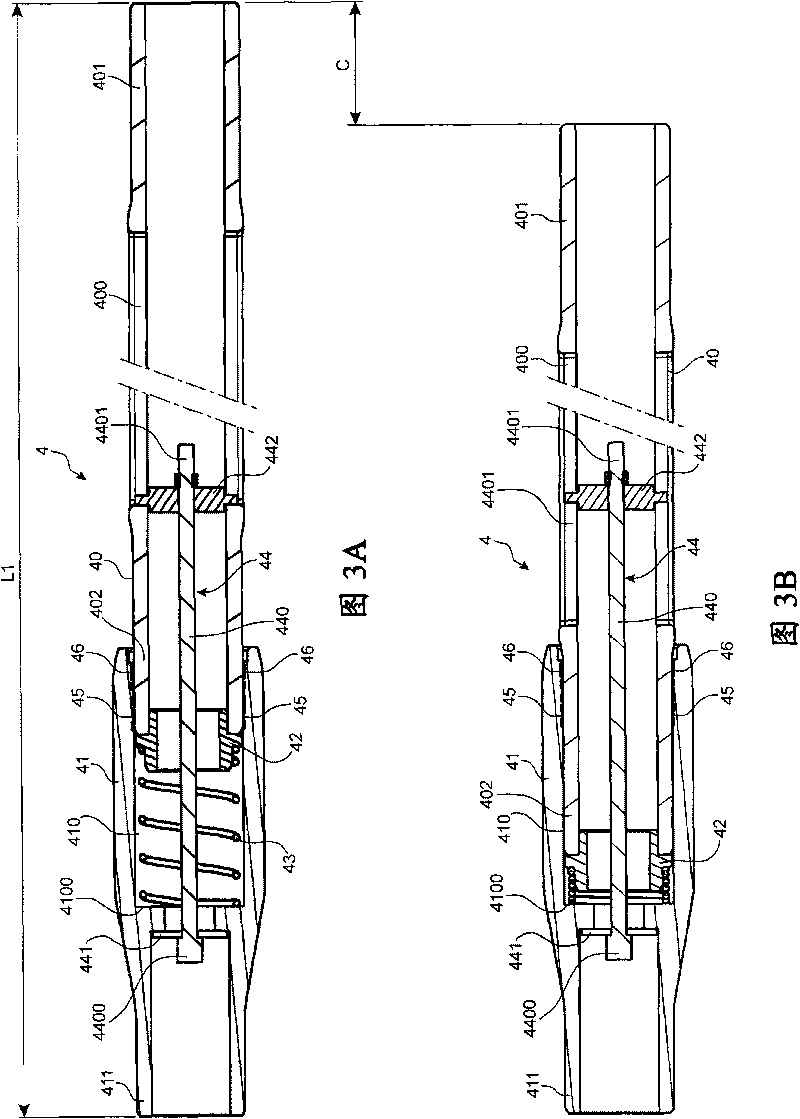

Method for establishing an electrical connection between two contact blocks, associated connection device and high- or medium-voltage device

InactiveCN101728094AEasy to assembleGuaranteed lengthBus-bar installationCouplings bases/casesElectricityElectrical connection

The present invention relates to a novel electrical connecting device which is provided with cylindrical dents (20, 30) and is used between two contact blocks (2, 3). According to the invention, a conductive extension assembly (4) is adopted. One end of the conductive extension assembly is firstly inserted into one contact block (2) and then retracts so the other end (40, 410) can be inserted into the other contact block (3). The electrical connecting device of the invention facilitates the assembling and detaching of the electrical connection between two components of high-voltage or medium-voltage gas insulation switches (GIS).

Owner:AREVA T&D

Method for Locating Defect Points in Trenchless Repair of Underground Pipelines

The invention discloses a positioning method of underground pipe non-excavation repair defect points, and solves the problem of a difficulty how to determine defect points of underground pipes alwaysin the repair process caused by people incapable of entering the pipes to examine the defect points. The positioning method comprises the following steps: a dredging car is cleaned; a connecting ropeis arranged on a remote control car provided with a camera, and the defect points in the pipes are searched through the camera; a first positioning mark is arranged in the position, positioned in an opening of a drainage well, of the connecting rope; a positioning rope is bound on a pipe repair airbag, and is provided with a second positioning mark corresponding to the first positioning mark; thesurface of the pipe repair airbag is coated with a repair material; after the second positioning mark is positioned in the opening of the drainage well, the pipe repair airbag is used for repair; andmultiple defect points can be once determined, and can be gradually repaired, so that the time and the times of the remote control car searching the defect points are saved, the working efficiency isimproved, and the repair flow is simplified.

Owner:浙江景迈环境科技有限公司

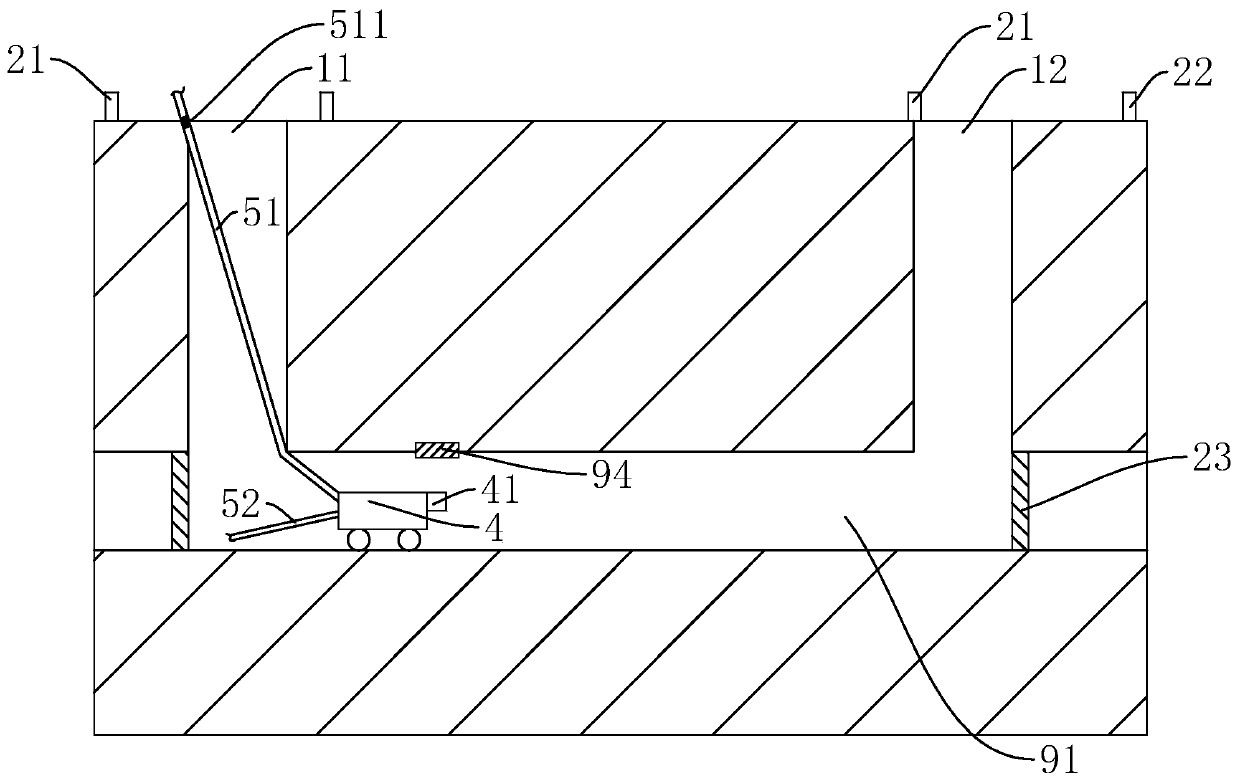

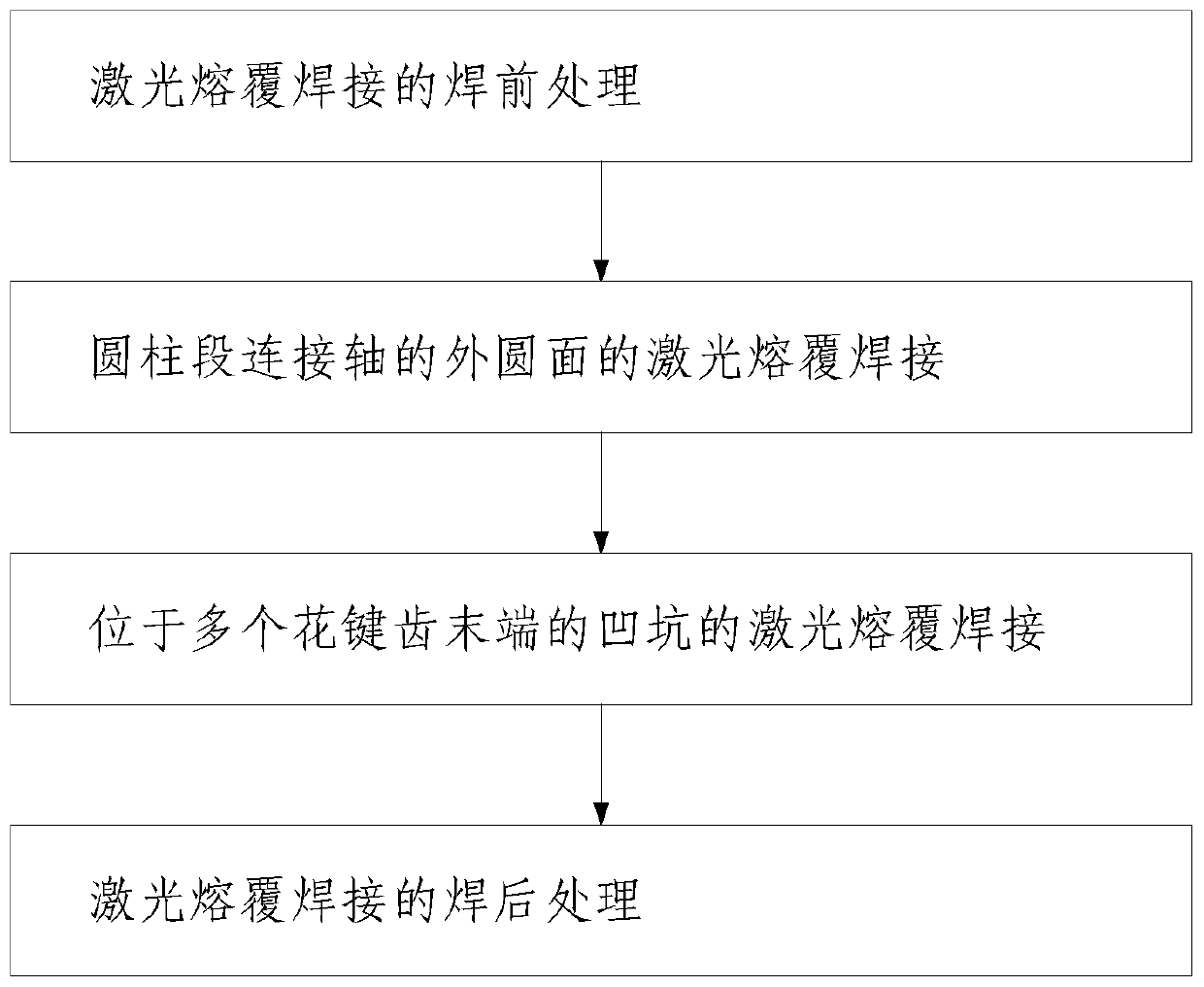

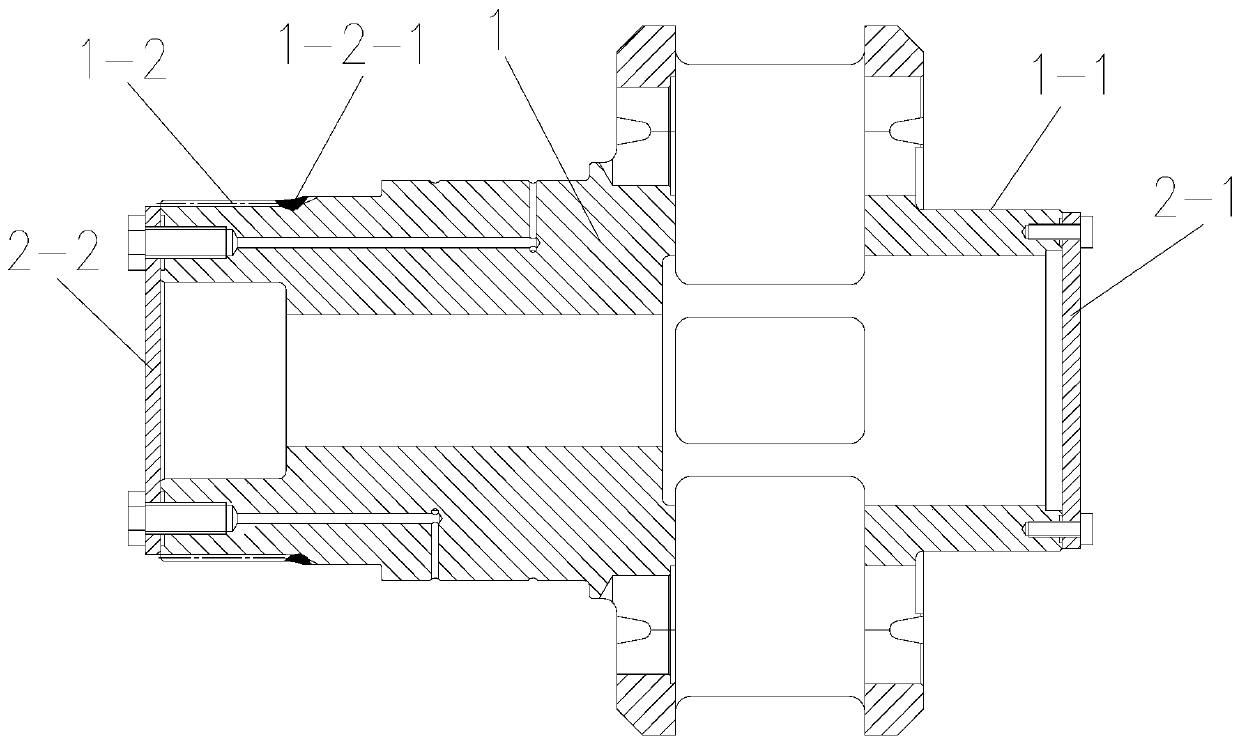

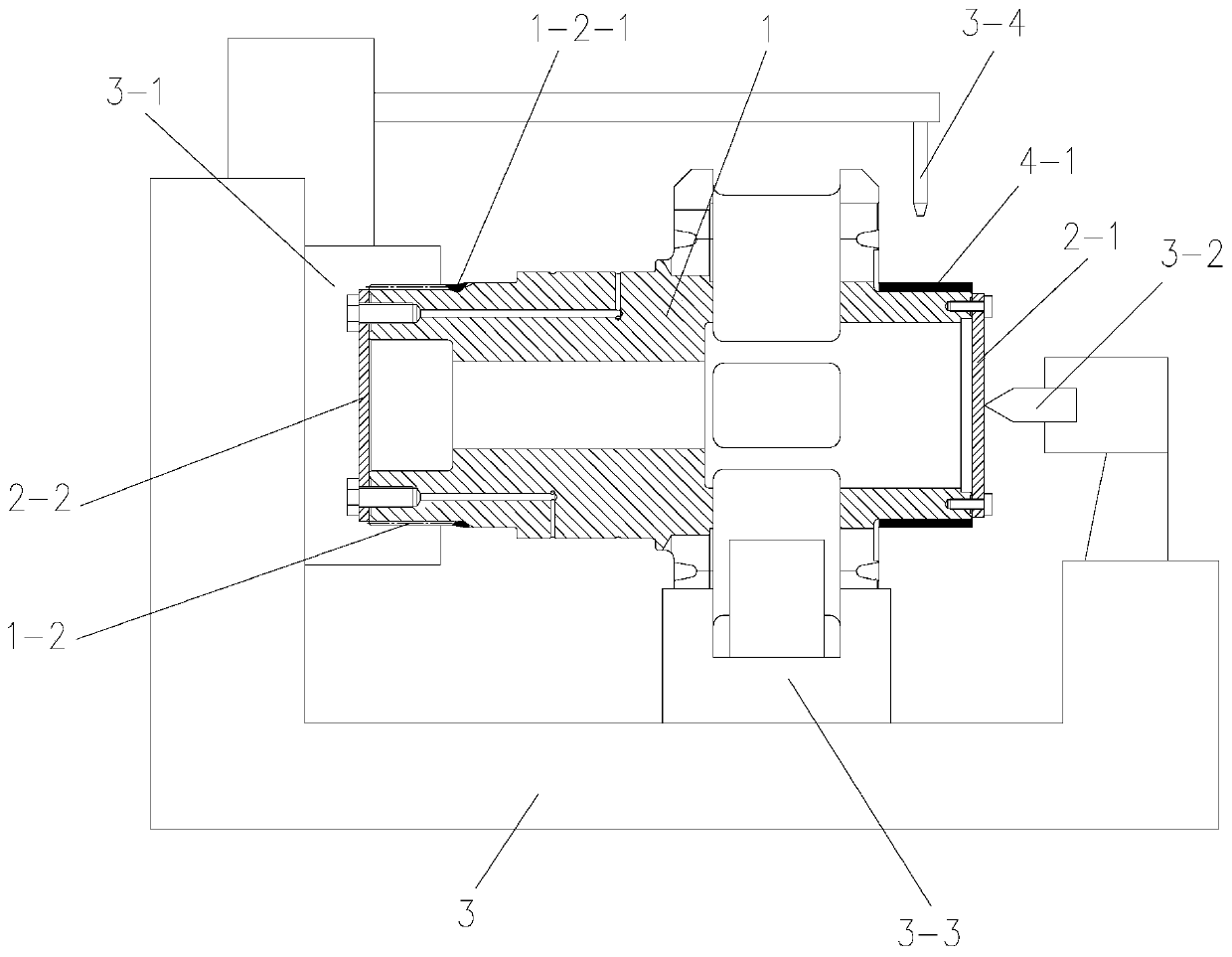

Repair method of coal cutter planet carrier based on laser cladding welding

InactiveCN110453218AMeet the precision requirementsPrevent thermal deformationMetallic material coating processesLaser beam welding apparatusFatigue damageEngineering

The invention discloses a repair method of a coal cutter planet carrier based on laser cladding welding. The method comprises the steps of firstly, pre-welding treatment of laser cladding welding, secondly, laser cladding welding of the outer circle face of a cylinder segment connecting shaft, thirdly, laser cladding welding of concave pits located at the tail ends of multiple spline teeth and fourthly, post-welding treatment of laser cladding welding. The process of the repair method is simple, in the process of repairing the planet carrier through laser cladding welding, the planet carrier can be prevented from generating heat deformation and heat fatigue damage, and meanwhile the bonding strength of a cladding layer and a matrix material is high; and secondary damage can be prevented from being generated to an outer spline of the planet carrier, the repair precision is high, the repair cost is low, and application and popularization are convenient.

Owner:XIAN COAL MINING MACHINERY

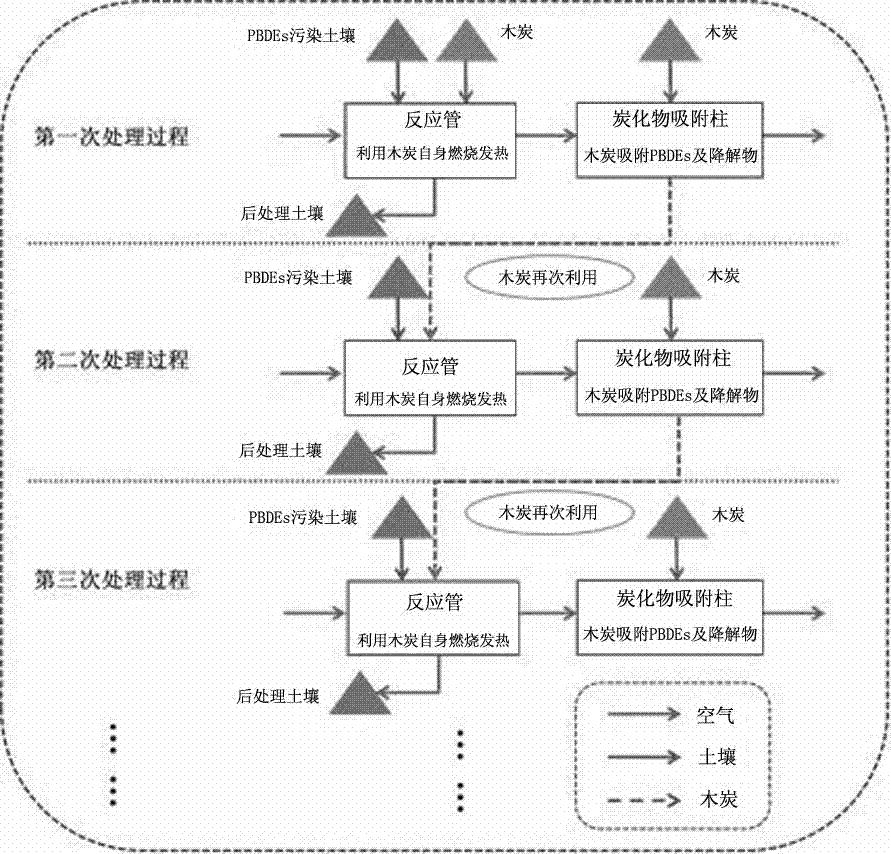

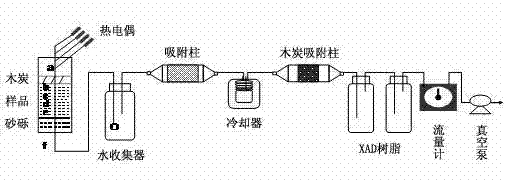

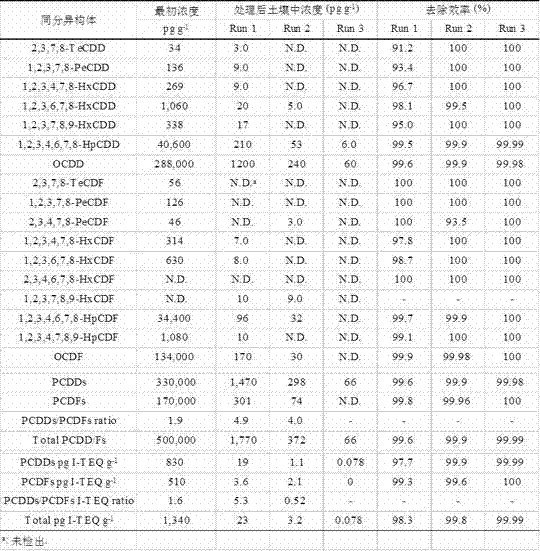

Novel thermal desorption restoring system and novel thermal desorption restoring method for treating POPs (persistent organic pollutants) polluted soil

InactiveCN104741372ALow priceSave energyDispersed particle separationContaminated soil reclamationEdaphicThermal desorption

The invention provides a novel thermal desorption restoring method for treating POPs (persistent organic pollutants) polluted soil. The charcoal which is low in price is used for substituting active carbon to be used as a tail gas adsorption agent, the charcoal is mixed with the polluted soil to be used as a combustion heat source for supplying heat for the thermal desorption treatment on the soil, no additional external heat is needed except for the ignition of a carbide in the thermal desorption process, and the ignited soil can be spontaneously restored. In addition, in order to avoid the generation of secondary pollutants, a continuous restoring model is established, so that the adsorbed charcoal can be remixed with the polluted soil to be used as a combustion heat source for the next thermal desorption reaction so as to be recycled, and finally, a purpose for effectively, economically and environmentally restoring the POPs polluted soil can be realized. Each sample after the heat treatment is extracted by utilizing an acceleration solvent extraction method, then the sample is acidified by virtue of sulfuric acid and purified by a multilayer chromatographic column, and finally, the restoration treatment effect is verified by utilizing an analysis test means such as GC-MS (Gas Chromatography-Mass Spectrometer) combination.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

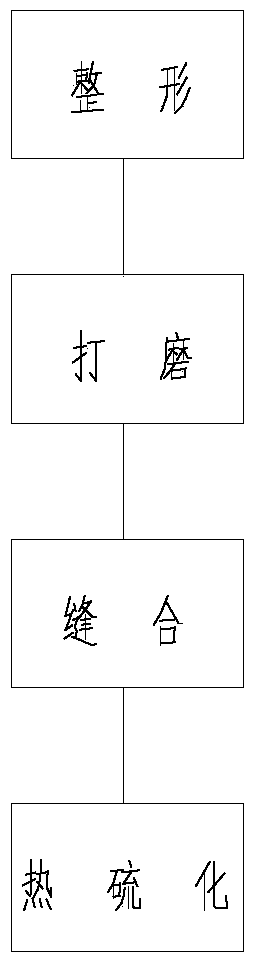

Method for repairing mechanical damage of radial tire

The invention provides a method for repairing mechanical damage of a radial tire, relates to the technical field of tire repair, and aims to solve the problems that a patch is easy to flake off, which causes second damage to the broken part, multiple repair steps and long repair time in the conventional repair technology. The method comprises the following steps: 1) shaping treatment is performed on the broken part so as to from a rectangular digging opening; 2) polishing treatment is performed on the broken part so as to enable the new rubber of a tire to be exposed completely, meanwhile, the line layer structure of the tire is not exposed; 3) stitching treatment is performed on the broken part, stitching is started from one corner of the digging opening, and threads are arranged in a cross manner up and down within a polishing range, and vertically arranged in the direction from the inner side of the tire to the outer side of the tire; 4) rubber hot vulcanization treatment is performed, a vulcanizing agent and raw rubber repaired newly are adopted for performing extrusion heat vulcanization treatment in a vulcanizing machine. According to the invention, the reinforcement of the interior of the broken part and rubber hot vulcanization treatment are combined, and reinforcement and vulcanization treatment are completed at one step, so that a patch inside the repaired tire is solid and firm, and is less susceptible to flaking, the repair process is simplified greatly, the repair efficiency is high, and the using effect is excellent.

Owner:SHIJIAZHUANG DENAIFU TECH

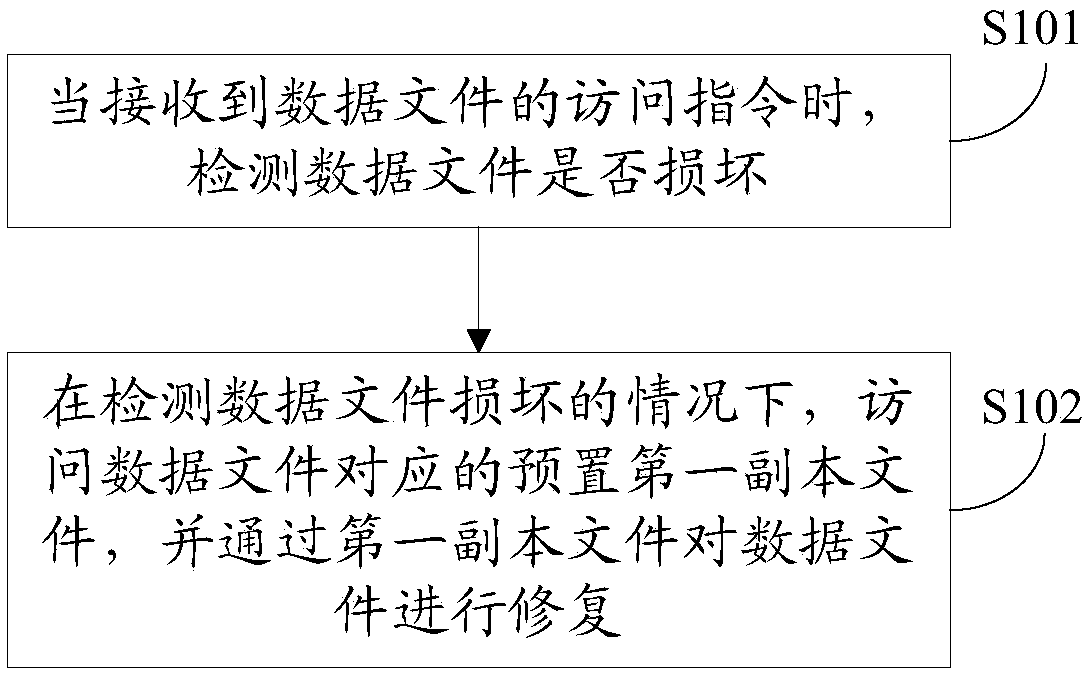

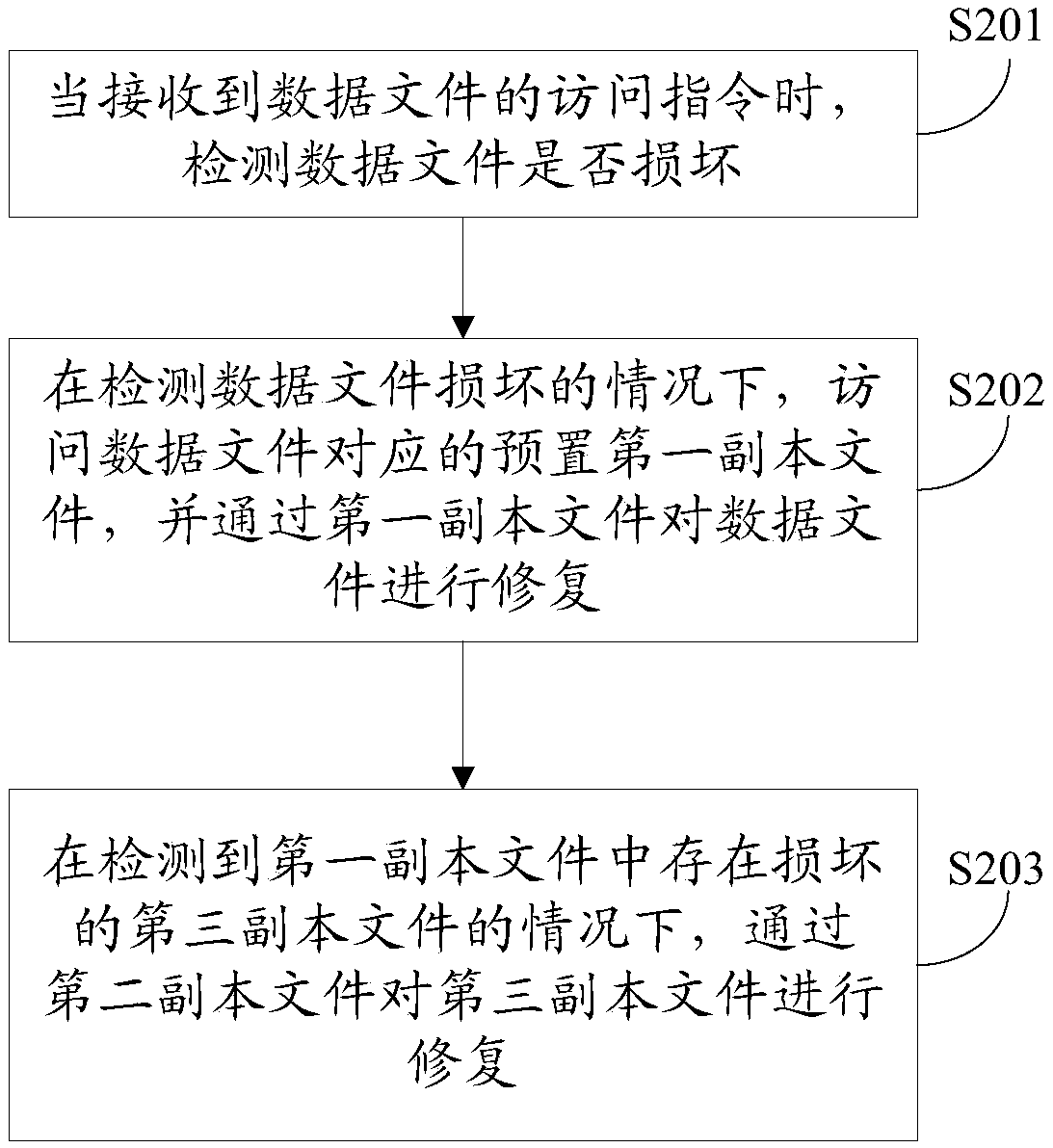

Data file repair method and device and computer-readable storage medium

ActiveCN109426586ARepair process is simpleImprove stabilityRedundant operation error correctionData fileSoftware

The invention provides a method for repairing a data file, which comprises the following steps of detecting whether the data file is damaged or not when an access instruction of the data file is received; in the case of detecting corruption of the data file, accessing a first copy file corresponding to the data file, and repairing the data file through the first copy file. The invention also discloses a data file repairing device and a computer readable storage medium. By implementing the scheme, the damaged data files can be repaired automatically in real time, the repair flow of the data files is simplified, the stability and security of the file system storing the data files are improved, and the security and reliability of accessing the data files by the application layer software areimproved.

Owner:ZTE CORP

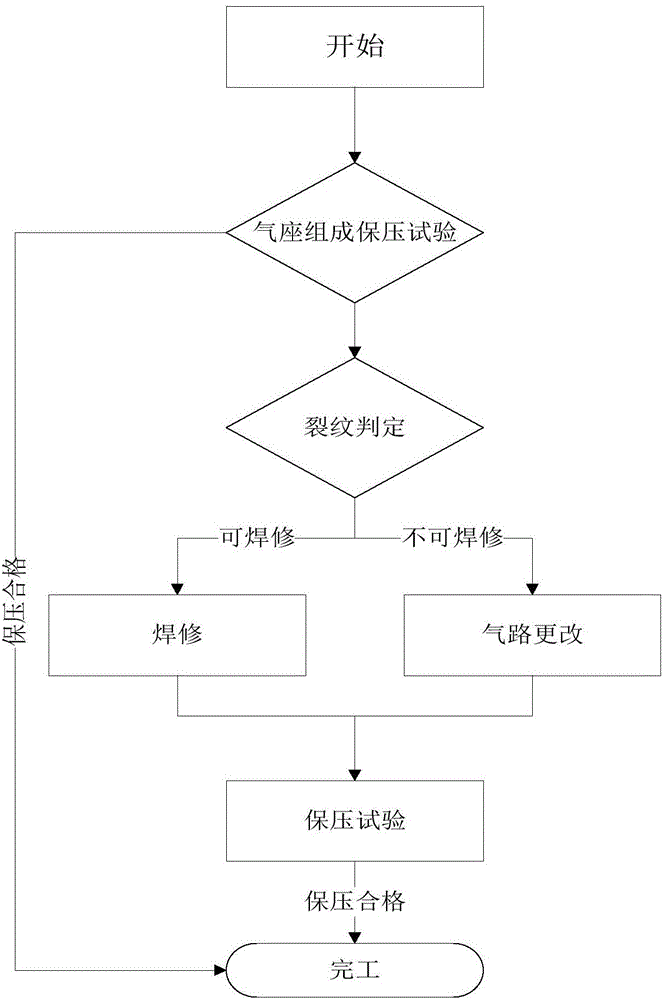

Sleeper beam welded gas pipe repair technology

InactiveCN106270925AFlatness is not affectedRepair process is simpleArc welding apparatusAir springEngineering

The invention relates to a sleeper beam welded gas pipe repair technology. The sleeper beam welded gas pipe repair technology comprises the steps that a gas base composition pressure maintaining test is conducted at first, if a gas pipe is qualified, repairing does not need to be carried out, and if the gas pipe is not qualified, Dg20 gas pipe crack judgment is conducted; if it is judged that a crack can be subjected to welding repairing, the Dg20 gas pipe is subjected to welding repairing, if it is judged that the crack cannot be subjected to welding repairing, an original pipeline is cut off along the inner side of a leakage point position of the Dg20 gas pipe, and an opening of the Dg20 gas pipe is blocked; and a t-branch pipe is additionally arranged on a gas base Dg50 gas pipe, a Dg20 gas pipe is additionally arranged nearby a gas base pipeline and is connected with the t-branch pipe, an original air supply pipeline is adjusted to supply air to the new Dg20 pipeline instead of supplying air to the original Dg20 pipeline. By means of the sleeper beam welded gas pipe repair technology, a sleeper beam welded gas pipe can be repaired, the repair process is simple and easy to operate, the repair speed is high, and the repair cost is low; and a sleeper beam does not need to be disassembled in the repair process, and the flatness of air spring installation bases on the two sides is not influenced.

Owner:CRRC NANJING PUZHEN CO LTD

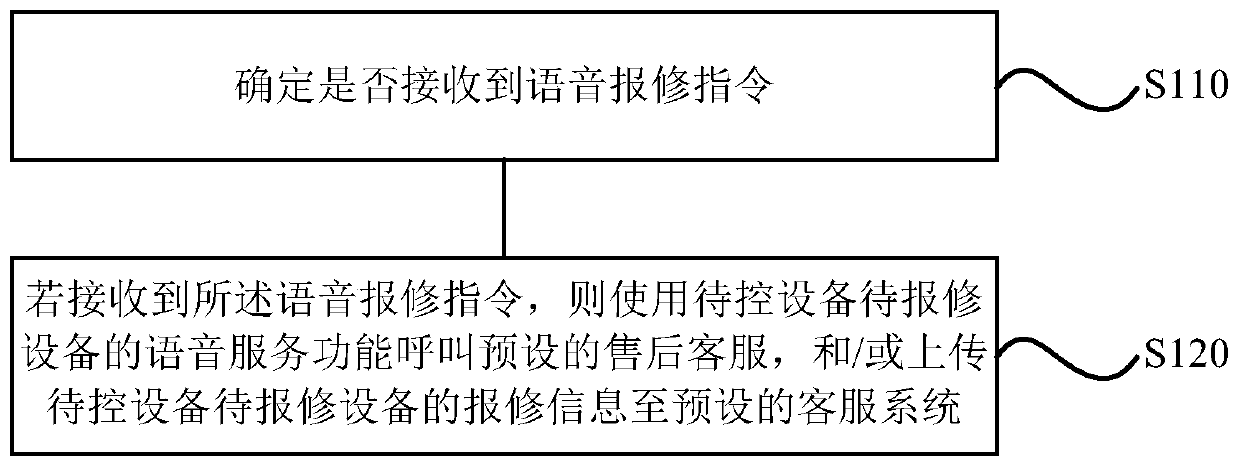

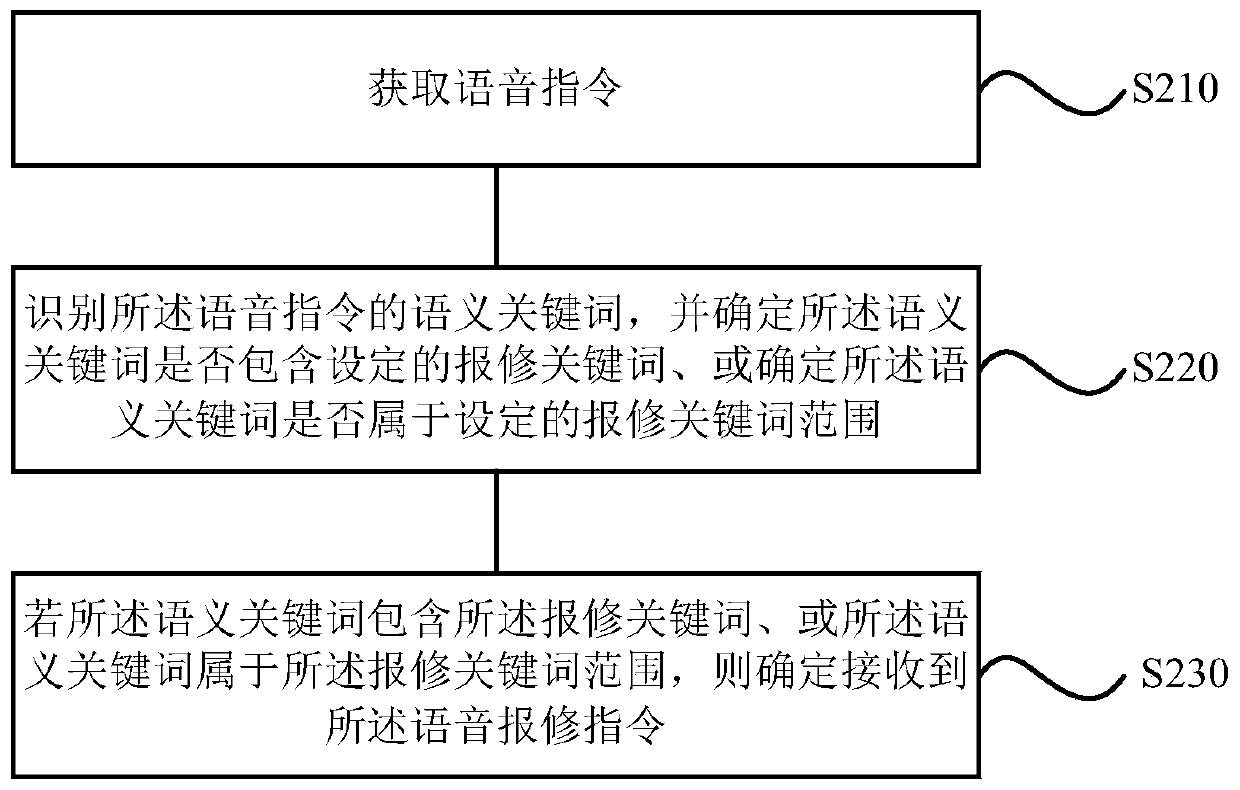

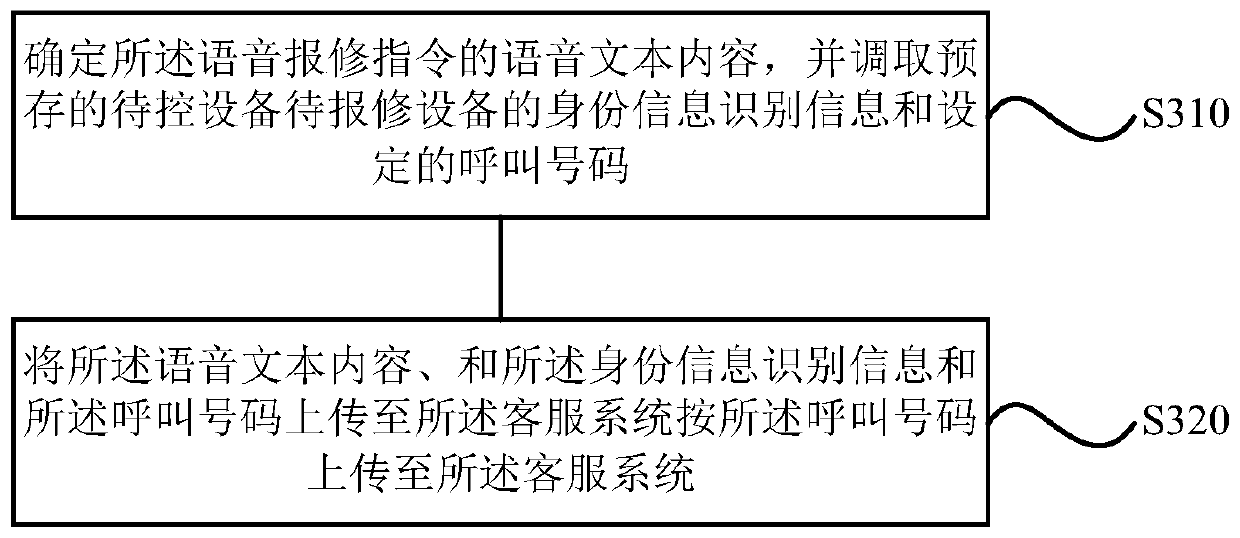

Voice repair method and device, storage medium and air conditioner

ActiveCN111354355AEasy to troubleshootSimplify repair operationsSpecial service for subscribersSpeech recognitionEngineeringSpeech sound

The invention discloses a voice repair method and device, a storage medium and an air conditioner. The method comprises the steps of determining whether a voice repair instruction is received or not;and if the voice repair instruction is received, calling a preset after-sales customer service by using a voice service function of to-be-repaired equipment, and / or uploading repair information of theto-be-repaired equipment to a preset customer service system. According to the scheme provided by the invention, the problem that the repair process is complicated in a mode of contacting the customer service and informing the customer service of the information needing to be repaired when a household appliance has a fault and needs to be repaired can be solved, and the effect of simplifying therepair process is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

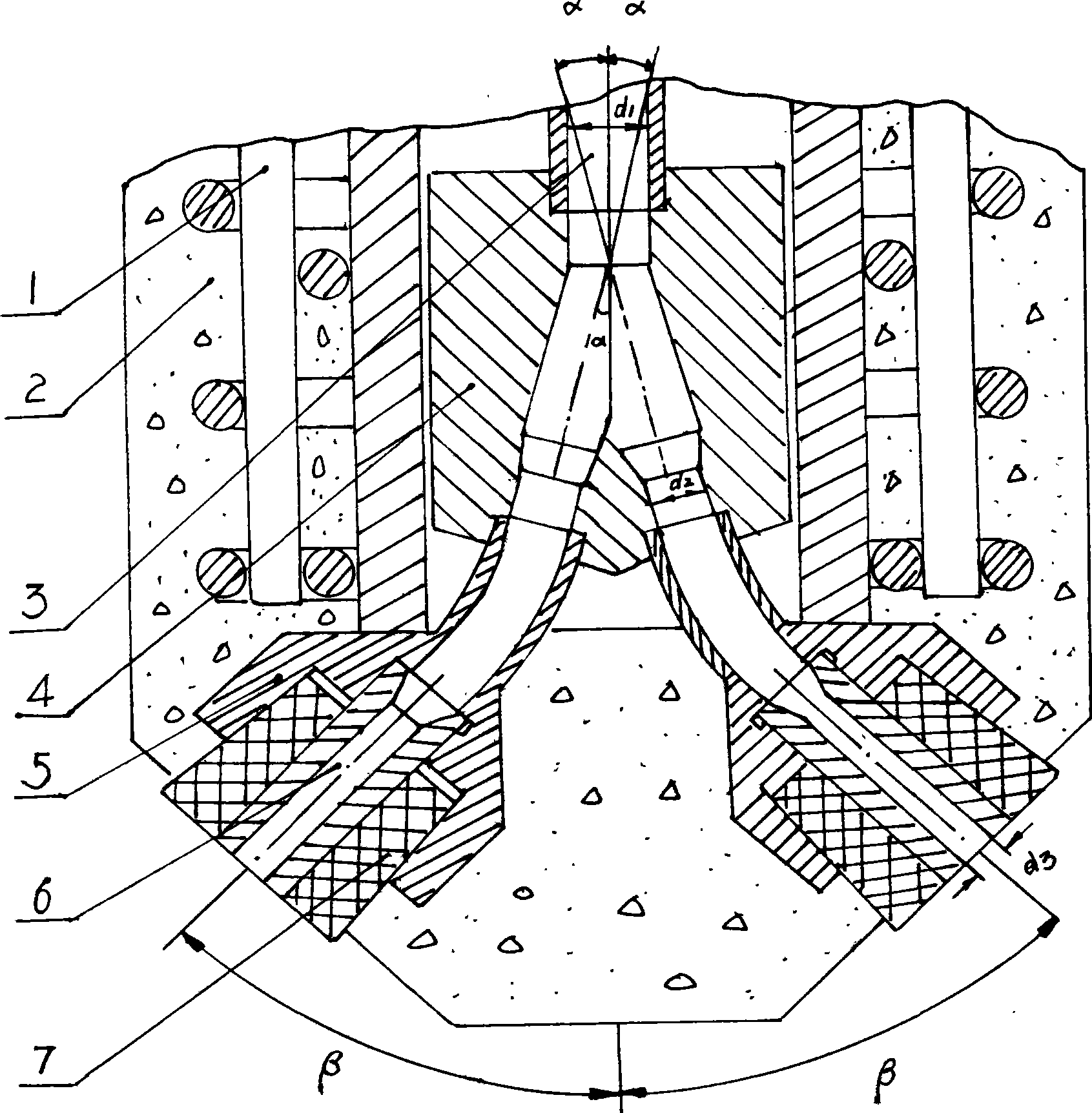

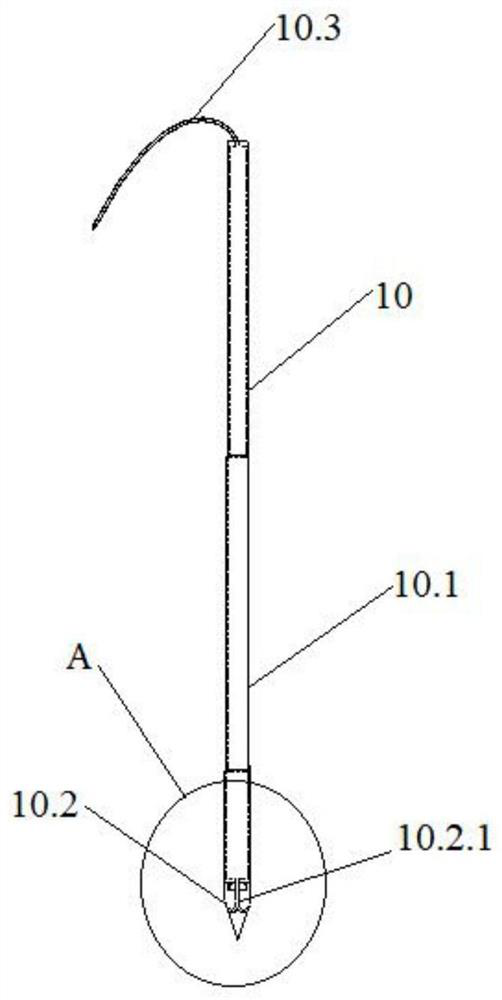

Reverse V-shaped granule magnesium molten iron desulfuring spray gun

The invention belongs to the field of ferrous metallurgy, namely the field of external desulphurization treatment to molten iron in a ladle, and particularly relates to an inverse V shaped granular magnesium molten iron desulphurization spray gun. The spray gun comprises a gun body; the gun body comprises a frame (1) matched with a refractory material (2), a passage arranged in the gun body (3), a material flow distributor (4), and a bent pipe (5); a feeding port of the material flow distributor (4) is matched and connected with a discharge port of the passage (3); the discharge port of the material flow distributor (4) is matched and connected with the feeding port of the bent pipe (5); one end of the bent pipe (5) is provided with a nozzle (6); the outside of the nozzle (6) is provided with a refractory bushing (7); the discharge port of the material flow distributor (4) is detachably matched and connected with the feeding port of the bent pipe (5); and the end of the bent pipe (5) is detachably matched and connected with the nozzle (6). The spray gun has high feeding strength and short processing period, can effectively ensure the reliability of pneumatic conveying of a magnesium material, and guarantee the process requirement.

Owner:YINGKOU DSMK TECH DEV

Municipal ground repairing device

InactiveCN109629385ARepair process is simpleImprove work efficiencyRoads maintainenceEngineeringMaterial storage

The invention discloses a municipal ground repairing device. The municipal ground repairing device comprises a base, a first vertical plate is welded to one side of the upper end of the base, a pushing handle is welded to the middle of the first vertical plate, a protection shell is welded to one side of the upper end of the base, a second support plate is welded to the portion, at one side in theprotection shell, on the base, a second pulley is movably connected to the upper end of the second support plate, a first support plate is welded to the portion, at the other side in the protection shell, on the base, and a first pulley is movably connected to the upper end of the first support plate; a first motor is welded to one side of the upper end of the base and located between the first vertical plate and the protection shell. When the municipal ground repairing device works, a worker can repair a road by using the device, the repairing process is relatively simple, the time and laborare saved, and the working efficiency of the worker is improved; the base is provided with a material storage tank and a water tank, the material storage tank is internally provided with a second transmission shaft with stirring blades, and the worker conveniently mixes and stirs a raw material for repairing the road surface.

Owner:张子棋

General suspended automobile drive axle balance shaft on-vehicle repair machine

InactiveCN102049718ARepair process is simpleStandard operating proceduresGrinding machinesBalance shaftAutomotive engineering

The invention discloses a general suspended automobile drive axle balance shaft on-vehicle repair machine capable of quickly repairing an abraded automobile drive axle balance shaft on vehicle. A cuboid plate is used as a main framework on the main machine, a main grinder and a longitudinal main grinder operating device are arranged on the surface a of the main framework, and a suspended steering arm, a transverse main grinder operating device and a main machine steering handle are arranged on the surface b of the main framework; and the repair machine is provided with a plurality of accessories matched with the main machine. When the automobile drive axle balance shaft is repaired, only a balance shaft plate spring seat needs to be detached from the working section shaft diameter of the automobile drive axle balance shaft, the abraded part on the working section shaft diameter of the balance shaft is electrically welded for replenishing, then the main machine of the repair machine is arranged on the fixed shaft section of the balance shaft, and the repair machine is operated so that the main grinder on the main machine polishes and repairs the working section shaft diameter of the balance shaft.

Owner:田野

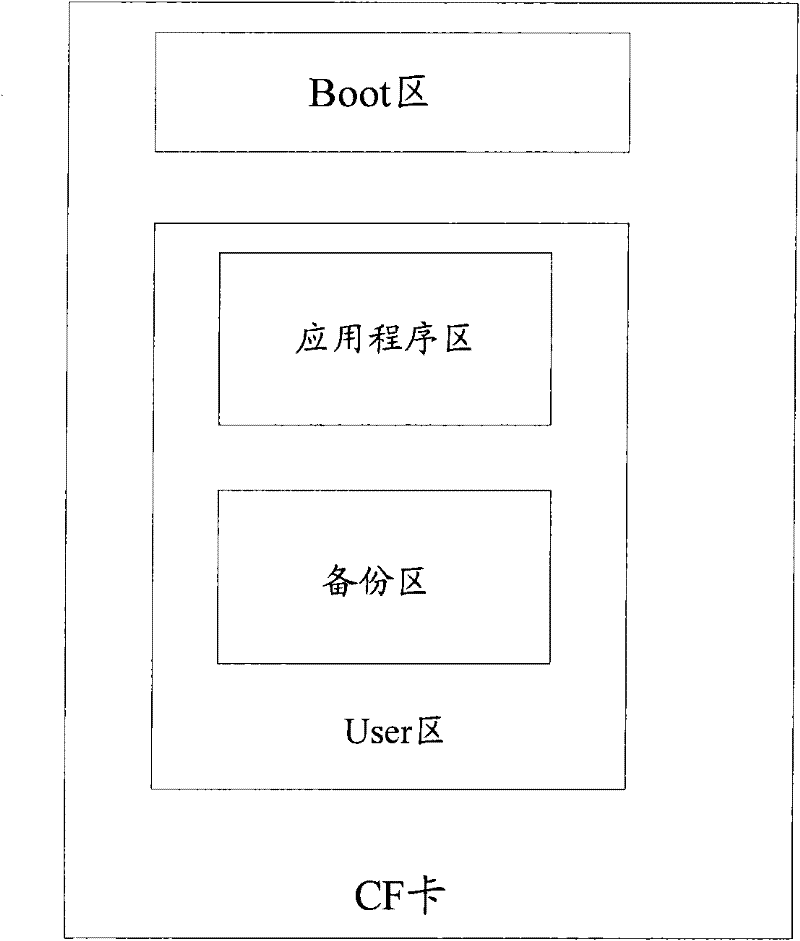

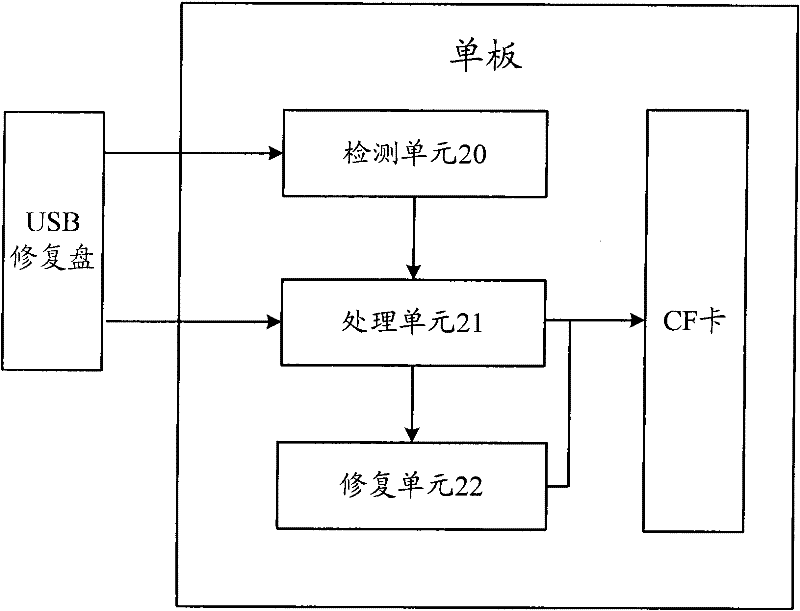

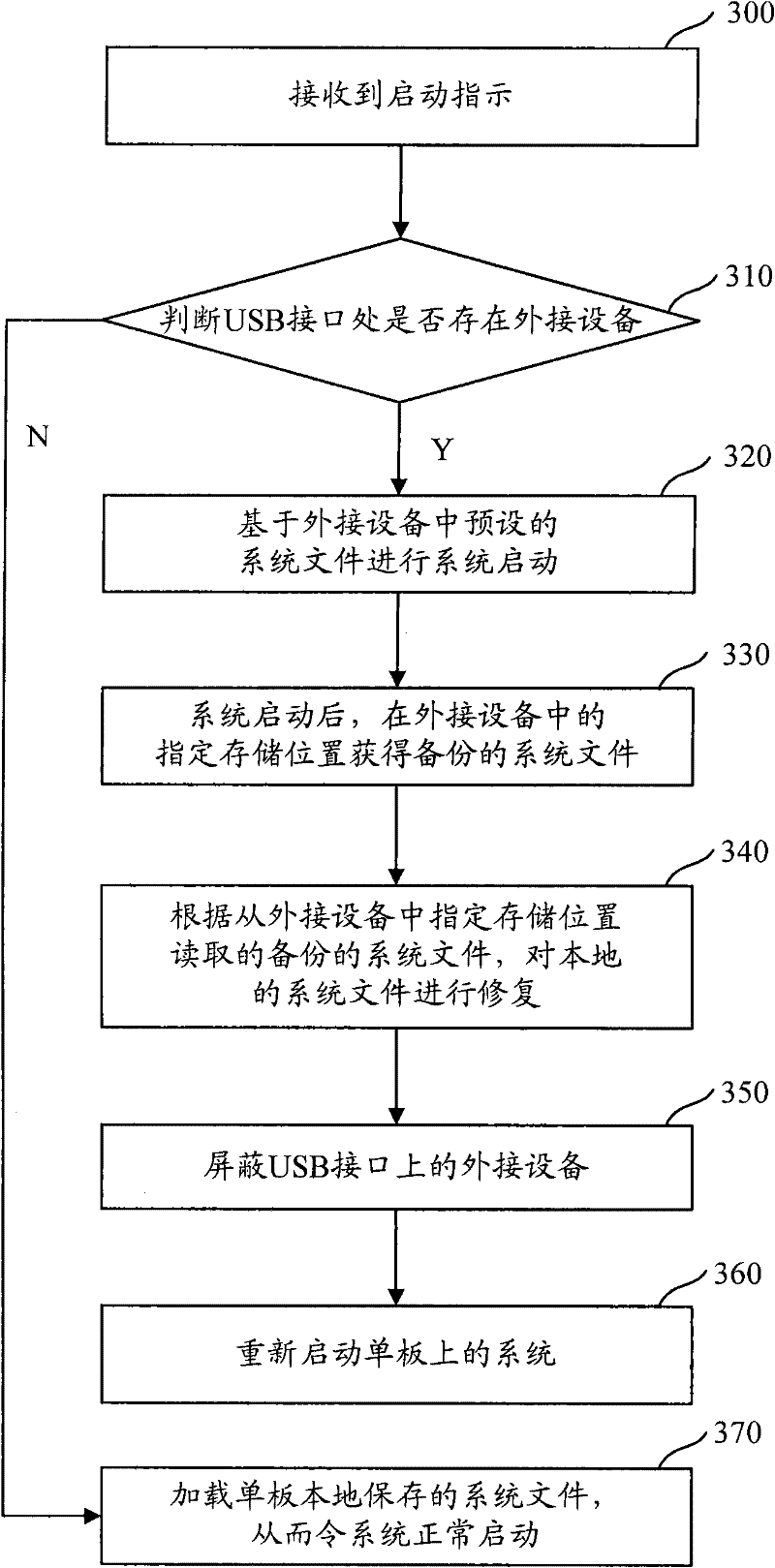

Method and device for repairing system file based on X86 architecture

ActiveCN102456047AReduce the difficulty of implementationSimplify the repair processRedundant operation error correctionSpecial data processing applicationsX86Web environment

The invention relates to the computer field, in particular to a method and a device for repairing a system file based on X86 architecture, aiming to simplify the repair flow of the system file and simultaneously ensuring the system performance. The method comprises the following steps of: detecting whether a USB (Universal Serial Bus) interface is connected with a peripheral device upon receiving a startup instruction; if determining that the USB interface is connected with the peripheral device, reading a system file from a specified storage position in the peripheral device; and repairing a locally stored system file by employing the read system file. In this way, while repairing the system file on a single plate, the modification of Bios source code on the single plate is not involved and a network environment is not needed to be built; therefore, the implementation difficulty of the repair flow can be effectively reduced and the repair flow is simplified; and simultaneously, power interruption for the single plate is avoided; therefore, the influence on the neighboring environment is minimized; as a result, the system performance is effectively ensured.

Owner:DATANG MOBILE COMM EQUIP CO LTD

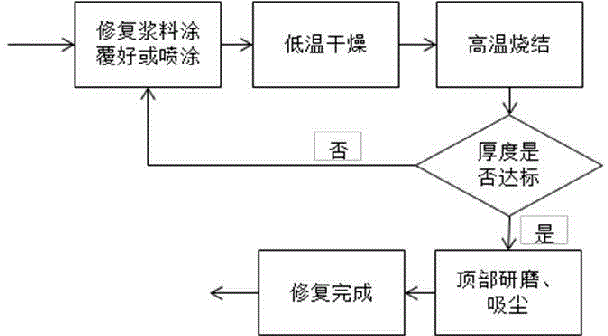

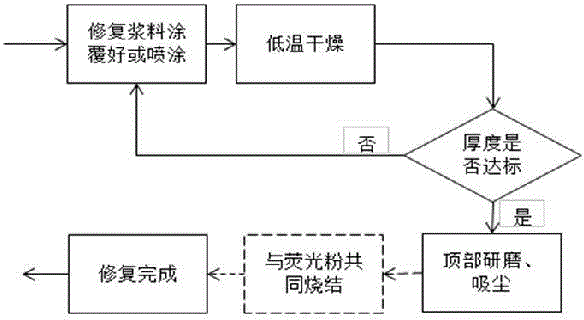

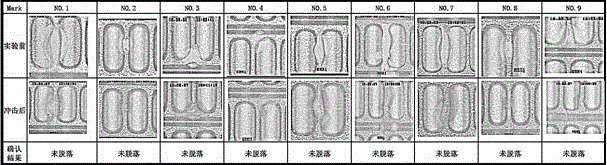

A plasma display barrier repairing slurry and a repairing method thereof

InactiveCN103606502ALow melting pointStrong adhesionElectronic waste recyclingDefective tube/lamp repair/regenerationPlasticizerRepair material

The invention relates to barrier manufacturing materials and processing techniques for barriers in plasma displays, and especially relates to a plasma display barrier repairing slurry and a repairing method thereof. The plasma display barrier repairing slurry and the repairing method thereof are characterized in that: the repairing slurry comprises 70-92% by mass percentage of a glass powder system and 8-30% by mass percentage of an organic system, wherein the components in the glass powder system and the mass percentage of the components are: 60-70% of Bi[2]O[3], 5-20% of AL[2]0[3], 3-10% of ZnO, 2-10% of B[2]O[3] and 1-5% of SiO[2]; the content of each component satisfies one hundred percent; a mass percentage of the components in the organic system are that: 70-94.5% of a solvent, 4-15% of polymers, 1%-15% of plasticizer and 0.5-8% of additive. The plasma display barrier repairing slurry of the invention is low in melting point. Repairing points are strong in adhesive forces. The plasma display barrier repairing slurry will not easily fall off. The repairing method is simple to operate and the repairing rate is high. Manufacturing of plasma barriers is carried out through utilizing the repairing slurry and the repairing method of the invention, traditional plasma display barrier repairing slurry and repairing methods are replaced. Plasma displays and plasma televisions with a simpler process, a higher processing efficiency, and a better mass production performance and a lower cost are manufactured.

Owner:SICHUAN COC DISPLAY DEVICES

Vehicle-mounted multimedia equipment with diagnosis function and diagnosis method

PendingCN113960988ASimplify the diagnostic processSimplify the exclusion processProgramme controlElectric testing/monitoringData connectionIn vehicle

Vehicle-mounted multimedia equipment with a diagnosis function comprises a data storage and processor and a man-machine interaction device, is in data connection with a vehicle bus, is provided with fault diagnosis software, and allows a user to perform off-line fault diagnosis and repair through the control of the man-machine interaction device. The equipment does not depend on external fault diagnosis equipment and remote data communication, is low in use cost and wide in application range, and improves the vehicle use experience. The invention further provides an automobile fault diagnosis method.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

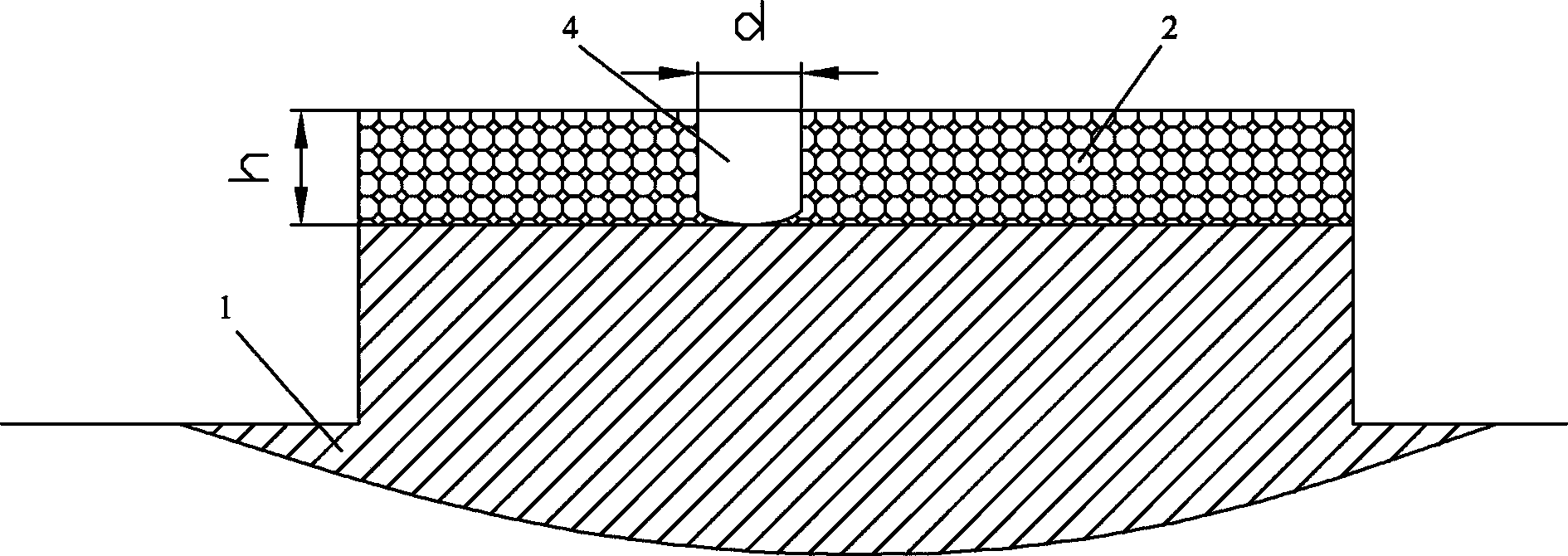

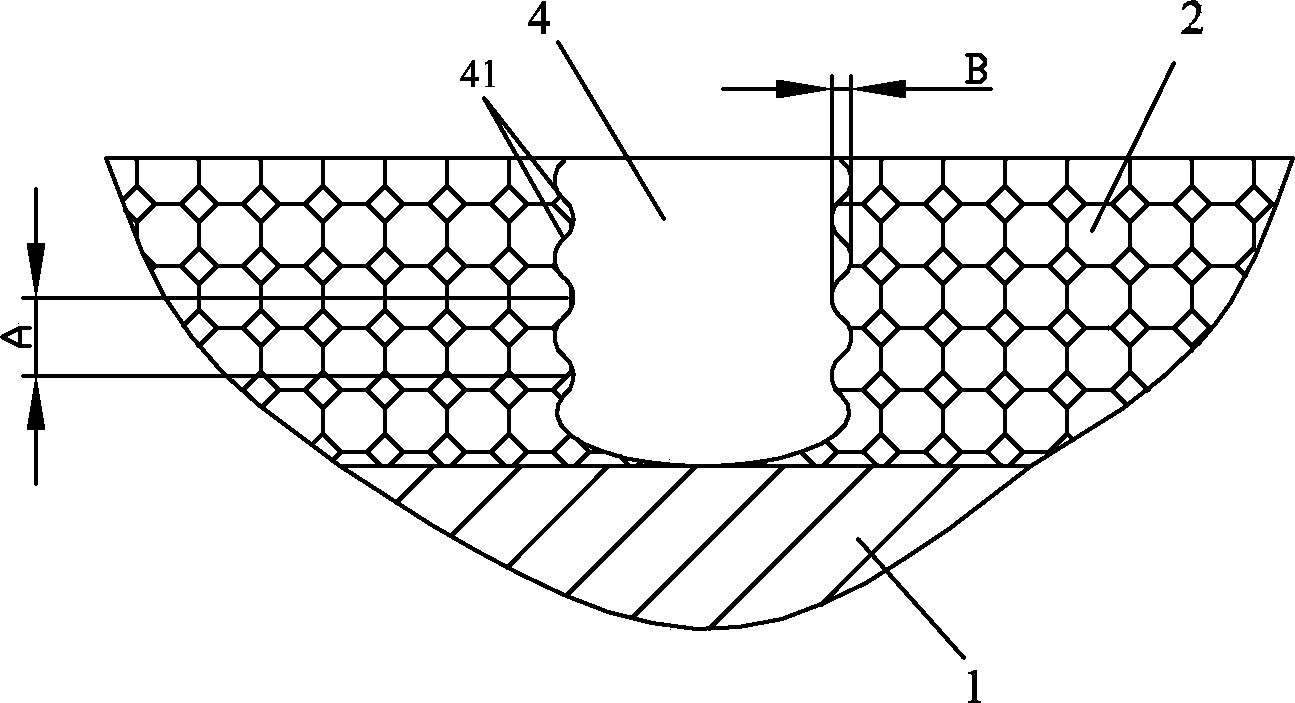

Crystallization roller surface taper hole defect online recovery method

ActiveCN104178761AHigh bonding strengthImprove thermal fatigue strengthPressure inorganic powder coatingRecovery methodSurface recovery

A crystallization roller surface taper hole defect online recovery method comprises the following steps: processing a crystallization roller surface taper hole defect inner wall to form a cylindrical flat-bottom hole inner wall, and processing the inner wall to have equidistantly distributed wave texture structures; carrying out smoothing and frosting treatment on the wave texture structure by using a high pressure gas and ceramic particles; and bumping the bottom and the inner wall of the cylindrical flat-bottom holes by using metal particles having a same recovery layer with the surface of the above crystallization roller in order to realize online rapid recovery. The whole recovery process basically has no thermal influences on the crystallization roller, and the microstructure of a taper hole defect recovery area is consistent to that of the crystallization roller surface recovery layer, so the generation of extra stress is effectively avoided, the bonding strength of the taper hole defect recovery area and the crystallization roller surface recovery layer is improved by above 30%, and the thermal fatigue strength is improved by above 25%; and the method has the advantages of online implementation in the whole process, simple technology, realization of the zero removal of the crystallization roller surface recovery layer, increase of the crystallization roller surface recovery rate by above 30%, great shortening of the recovery cycle, and recovery cost reduction.

Owner:BAOSHAN IRON & STEEL CO LTD

Surface scratch repair process of glass light guide plate

InactiveCN107030553AAffect the quality of light guideReduce manufacturing costPlane surface grinding machinesEpoxyColloidal silica

The invention provides a surface scratch repair process of a glass light guide plate. The process comprises the following steps: (1) cleaning: a light guide plate with a light outlet surface scratched in the machining process is cleaned; (2) checking and positioning: the scratched place on the light outlet surface of the light guide plate is accurately positioned through detection setting, and is marked; (3) repair: a repair mixture is splashed at the scratched part; the scratched part is polished by a grinding wheel; the repair mixture is formed by mixing polishing powder, epoxy resin powder and inorganic silica gel; and the mixing ratio of the polishing powder, the epoxy resin powder and the inorganic silica gel is 7: 1: 2; and (4) the light guide plate is cleaned again after the step (3), and is dried to obtain a finished product. The process has the following beneficial effects: the process modifies the scratched surface of the glass light guide plate, guarantees no influence on the light guide quality of the light guide plate due to scratching, protects the environment, is simple in repair flow, saves the production cost for enterprises, and reduces the loss.

Owner:DONGGUAN YINTAIFENG OPTICAL TECH CO LTD

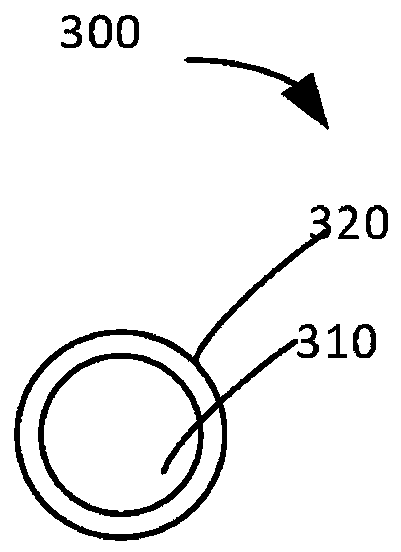

An integrated device for soil in situ remediation

ActiveCN113020240BGood restorativeAvoid wastingContaminated soil reclamationSoil scienceIn situ remediation

The invention provides an integrated device for soil in-situ restoration, which includes a moving mechanism, a shallow soil restoration unit, a deep soil restoration unit, and a liquid medicament silo, a solid medicament powder silo, and a medicament mixing unit arranged on the moving mechanism. Mechanism and power control assembly; the liquid medicament silo communicates with the medicament mixing mechanism, and the solid medicament powder silo communicates with the medicament mixing mechanism; the shallow soil remediation unit includes a soil turning component and a medicament splitting spray assembly; the deep soil remediation The unit includes a booster pump and a plurality of spin medicament injection needles, the spin medicament injection needles include a spin spray head, and the spin spray head includes an even number of nozzles, for the projection of any two opposing nozzles on a vertical plane It is W-shaped, and the projection on the horizontal plane is S-shaped. The invention can realize integrated restoration of shallow soil and deep soil and improves restoration efficiency.

Owner:中铝环保生态技术(湖南)有限公司

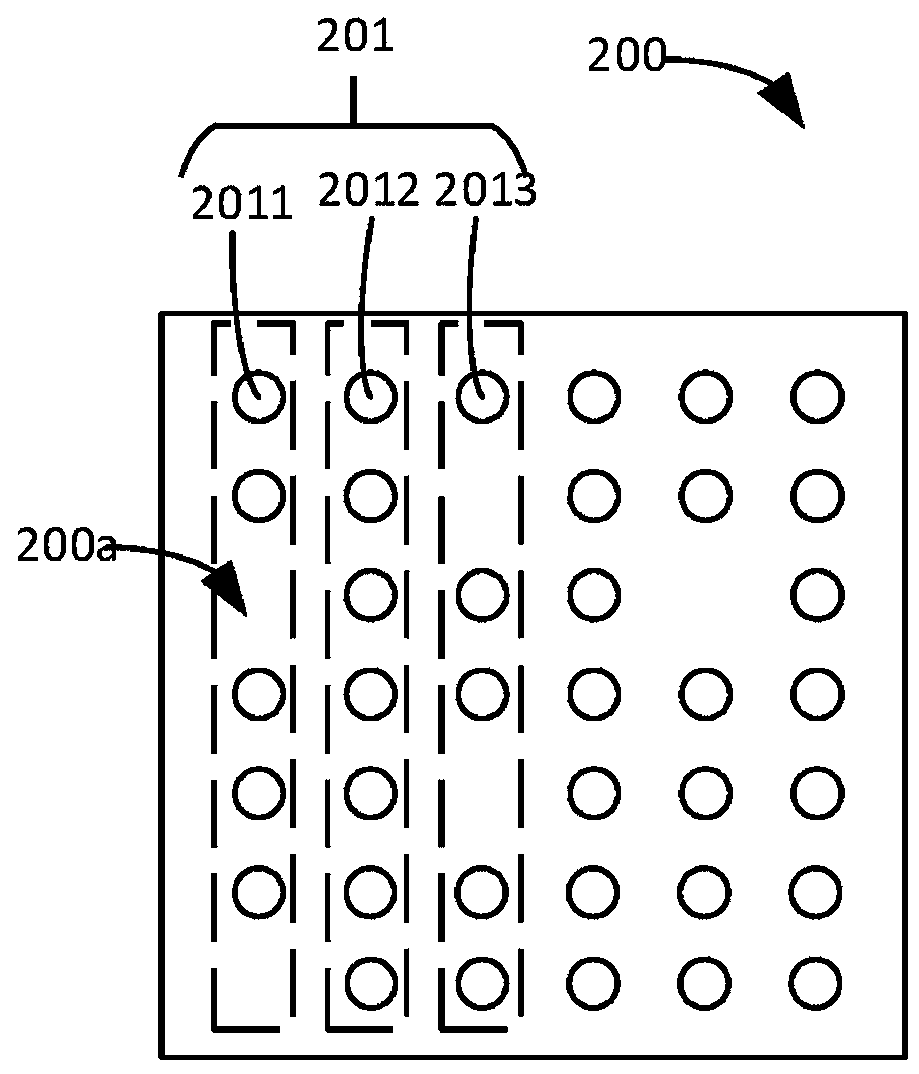

Repairing device of display panel

InactiveCN111162022ARepair process is simpleSave man hoursSemiconductor/solid-state device testing/measurementSolid-state devicesComputer hardwareEmbedded system

The invention provides a repairing device of a display panel, and the device comprises a defect sensor which is used for carrying out the defect inspection of the display panel, and obtaining defect information; a chip picking and placing part which is used for picking up, storing and releasing the light-emitting chips, wherein the chip taking and placing part comprises a chip accommodating cavityand a controller, the chip accommodating cavity is used for storing the light-emitting chips, and the controller is used for picking up and releasing the chips; a chip moving part which is connectedwith the chip taking and placing part and is used for moving the chip taking and placing part to the position of the defect according to the defect information; and a chip binding part which is used for binding the light-emitting chip on the display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

A kind of asphalt pavement repair material

ActiveCN109401519BEasy to fixPromote repairConjugated diene hydrocarbon coatingsNatural rubber coatingsWater immersionRoad surface

An asphalt pavement repair material, which belongs to the field of engineering materials, the asphalt pavement repair material comprises 20-60 parts of a thermosetting polymer monomer and / or a thermosetting polymer prepolymer, 2-8 parts of an antioxidant, an accelerator 1-8 parts, admixture 10-30 parts, thermoplastic polymer 5-60 parts, initiator 10-40 parts, reinforcing agent 10-20 parts, diluent 1-60 parts, aggregate 10-40 parts. The asphalt pavement repairing material provided by the invention has the advantages of fast setting speed, repairing the pavement and restoring traffic within 30 minutes, high strength, high water density, wear resistance, simple construction and the like. The compressive strength of the pavement repaired by the asphalt pavement repair material can reach 100MPa, and the wet wheel wear value is less than 800 g m ‑2 , the amount of adhering sand to the loaded wheel is less than 450 g m in 1d of water immersion ‑2 .

Owner:DALIAN UNIV OF TECH

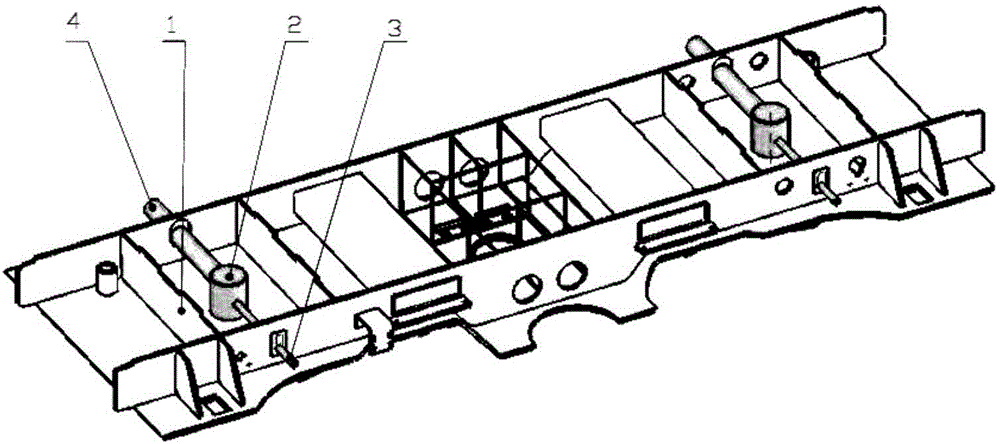

Movable laser cladding and repairing system

ActiveCN103074625BAchieve fixEasy to carryMetallic material coating processesLaser scanningLaser sensor

The invention provides a movable laser cladding and repairing system in the field of laser cladding and repairing. The movable laser cladding and repairing system comprises a movable platform, wherein a laser, a robot, a position changing machine, a powder feeder, an image processing system, a control system (comprises a PLC (programmable logic controller) main control system, a PC (personal computer) computing workstation), a video camera, a three-dimensional laser scanning sensor, a laser processing head and a coaxial powder feeding head are fixedly arranged on the movable platform. The movable laser cladding and repairing system takes the robot as a moving body, controls the clad pool size, the temperature and other information by using an image acquiring and processing system, and scans a workpiece to slice, stratify and automatically clad a three-dimensional workpiece model based on the three-dimensional laser sensor; the movable laser cladding and repairing system is convenient and flexible, simplifies a repairing process, achieves precision and self-adaptive control of a cladding process, effectively improves the cladding quality, and facilitates field application of a large component through the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com