Method for machining deep hole and its special tool

A processing method and a technology for processing cutting tools, which are applied in the field of mechanical processing, can solve the problems of not being able to meet the structural requirements of hollow shafts, processing rigidity, and unsatisfactory effects, and achieve the effects of improving efficiency, simplifying the repair process, and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

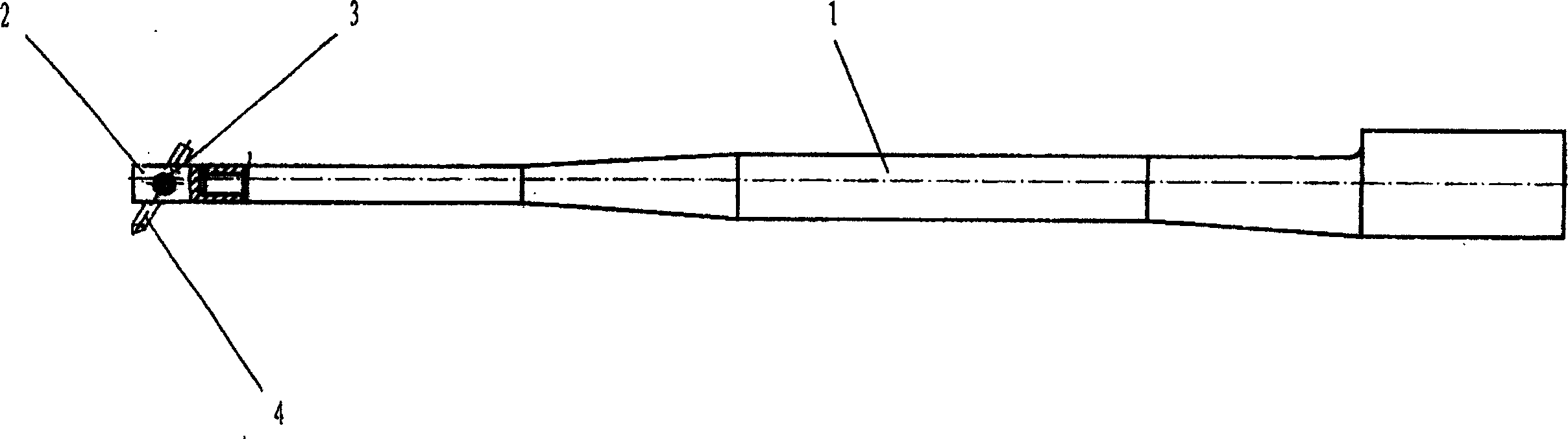

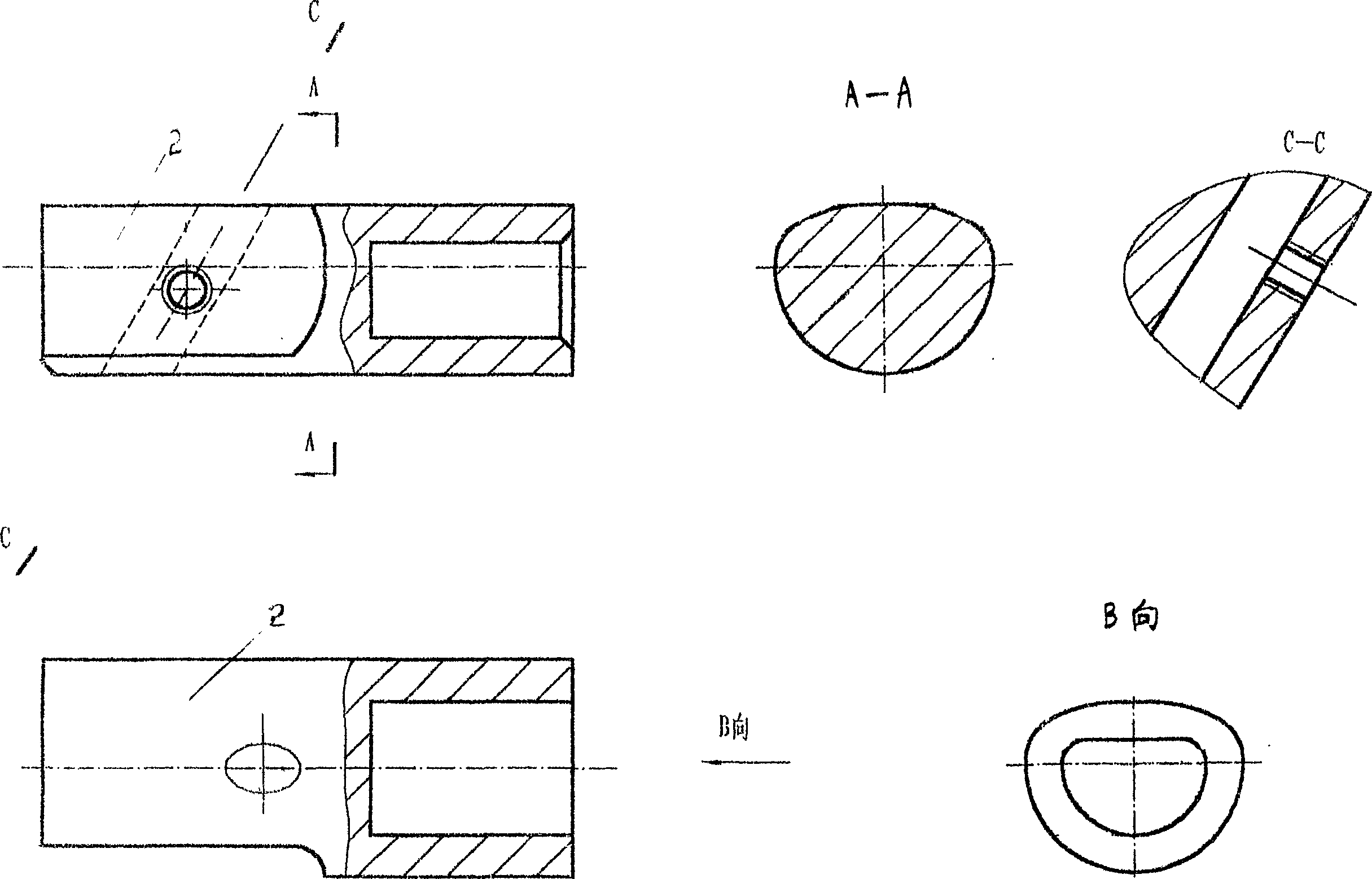

[0055] Embodiment 1 Carbide Long Tool Arbor Deep Hole Boring Test Application 1

[0056] Test application conditions:

[0057] 1. The processing equipment is KDM-18 deep hole boring machine;

[0058] 2. The tooling used is: hard alloy long knife rod, the tool material for structural steel processing is YT15 turning tool, and the template for profiling (as attached Figure 9 shown) etc.

[0059] In this simulation test, we can find that: after the tool is inserted, the amount of tool clearance of the carbide long tool bar, the springback of the tool bar during processing, and the tremor feeling near the root are all significantly better than those of the traditional structure. Steel blade. See attached table 1 for the data collected during the application process.

Embodiment 2

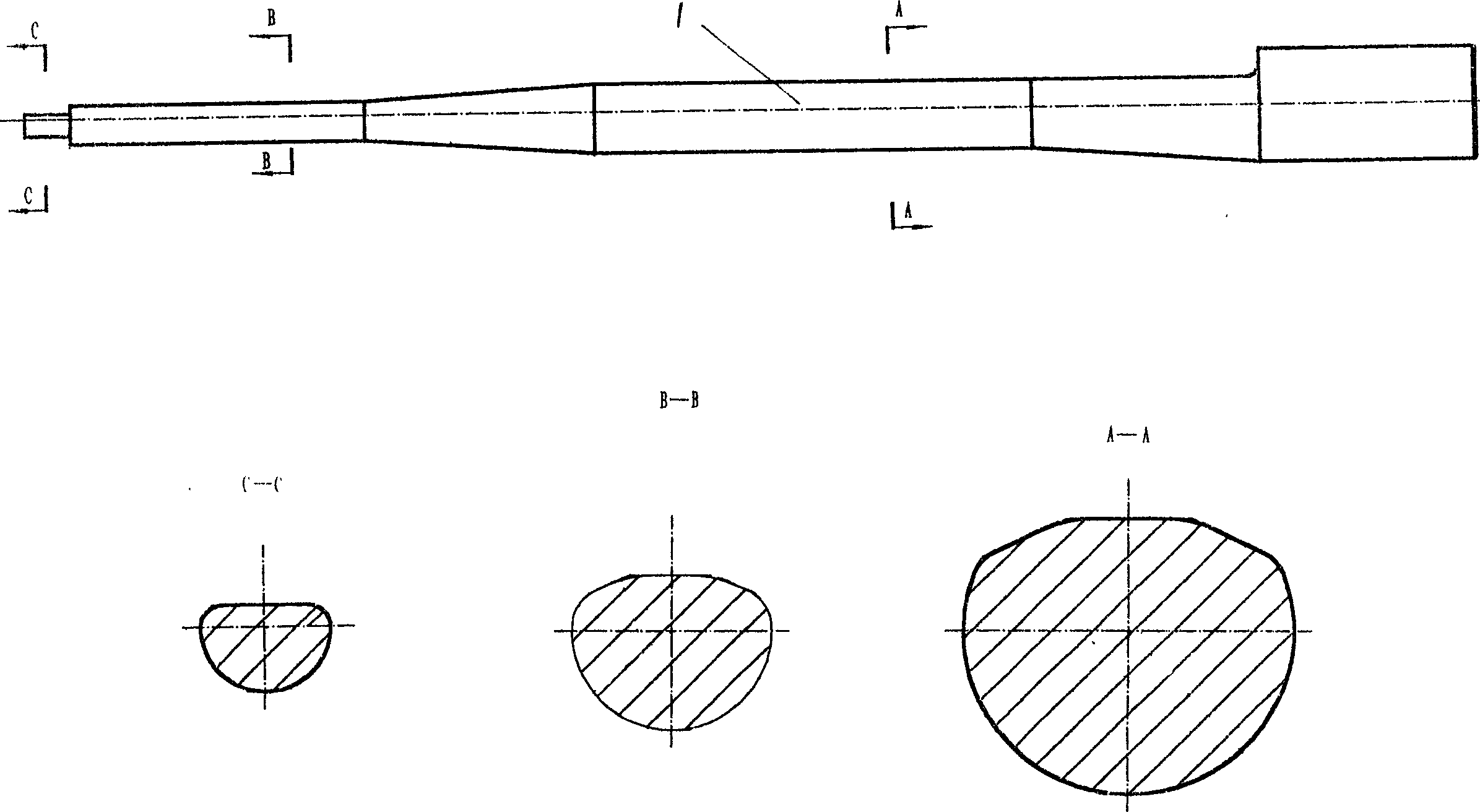

[0060] Embodiment 2 The application of deep hole processing of a certain hollow shaft (referring to the attached Figure 8 )

[0061] Application conditions:

[0062] 1. The equipment is DDM-18 deep hole boring machine;

[0063] 2. Tooling used: Carbide long tool rod, tool material is YG8 turning tool, and template for profiling (as attached Figure 9 shown).

[0064] In this embodiment, we use cemented carbide tool holders to attach Figure 8 The shown hollow shaft is subjected to deep hole machining, and the machining result is similar to that of the hollow shaft in Example 1. Schedule 2 shows the process attached Figure 8 The hollow shafts shown are the application parameters and machining results. Among them: the cutting test parameters are consistent with the parameters of serial numbers 2, 3, 4, 5, and 6 in the attached table 1, and the effect is very satisfactory.

[0065] Application conclusion: the carbide tool holder is used to attach the Figure 8 The shown...

Embodiment 3

[0066] Embodiment 3 The application of deep hole machining of a certain hollow shaft (referring to the attached Figure 8 )

[0067] Application conditions:

[0068] 1. The equipment is DDM-18 deep hole boring machine;

[0069] 2. Tooling used: Carbide tool holder, turning tool with tool material YT15, template for profiling (as attached Figure 9 shown).

[0070] In this test project, we use carbide long tool holder to attach Figure 8 The hollow shaft shown is processed for deep holes, and the processing result is similar to that of the first type of hollow test shaft. The cutting test parameters are consistent with the parameters of serial numbers 2, 3, 4, 5, and 6 in Attached Table 1, and the effect is very ideal.

[0071] Schedule 1

[0072] serial number

[0073] Preface

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com